Efficient and energy-saving electric boiler

A high-efficiency energy-saving, electric boiler technology, applied in fluid heaters, steam generation methods, steam generation, etc., can solve problems such as dead burning, boiler dry burning, difficult control of boiler temperature and steam pressure, etc., and achieve high heating efficiency and high heating efficiency. uniform area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

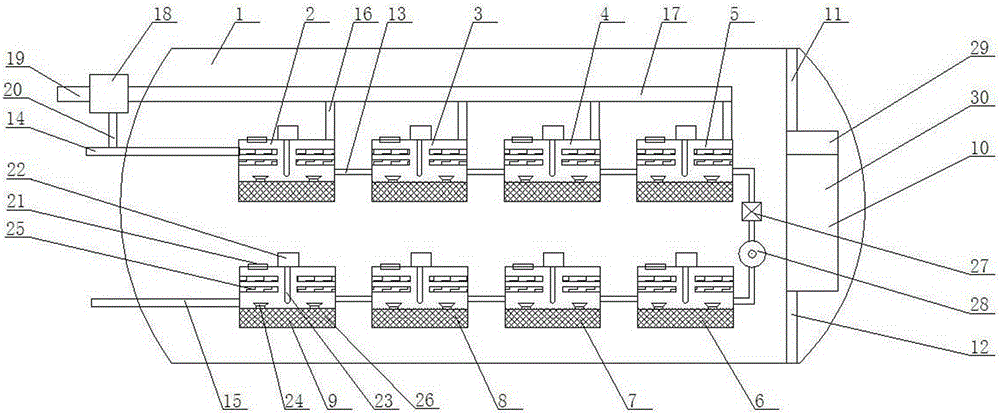

[0017] Such as figure 1 As shown, a high-efficiency and energy-saving electric boiler includes a furnace body 1, a first heating box 2, a second heating box 3, a third heating box 4, a fourth heating box 5, a fifth heating box 6, and a sixth heating box 7 , the seventh heating box 8, the eighth heating box 9, the control box 10, the first heating box 2, the second heating box 3, the third heating box 4, and the fourth heating box 5 are arranged side by side inside the furnace body 1 At the upper end, the fifth heating box 6, the sixth heating box 7, the seventh heating box 8, and the eighth heating box 9 are arranged side by side at the inner lower end of the furnace body 1, and the control box 10 passes through the upper fixing frame 11, the lower The fixed frame 12 is arranged at the right end inside the furnace body 1, the first heating box 2, the second heating box 3, the third heating box 4, the fourth heating box 5, the fifth heating box 6, the sixth heating box 7, T...

Embodiment 2

[0019] Such as figure 1 As shown, the first heating box 2, the second heating box 3, the third heating box 4, the fourth heating box 5, the fifth heating box 6, the sixth heating box 7, the seventh heating box 8, the eighth heating box Temperature detector 21, warning device 22, water level detection device 23, two water flow vortexers 24, many heating rods 25 are all installed inside heating box 9, and heater 26 is all installed at the bottom.

Embodiment 3

[0021] Such as figure 1 As shown, a water stop valve 27 and a miniature water pump 28 are set on the water conduits of the fourth heating box 5 and the fifth heating box 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com