Heating tatami

A technology of tatami and heating layer, applied in the field of heating tatami, can solve the problems of poor comfort, hard tatami, poor elasticity of core material, etc., and achieve the effects of good elasticity, soft and comfortable touch, and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

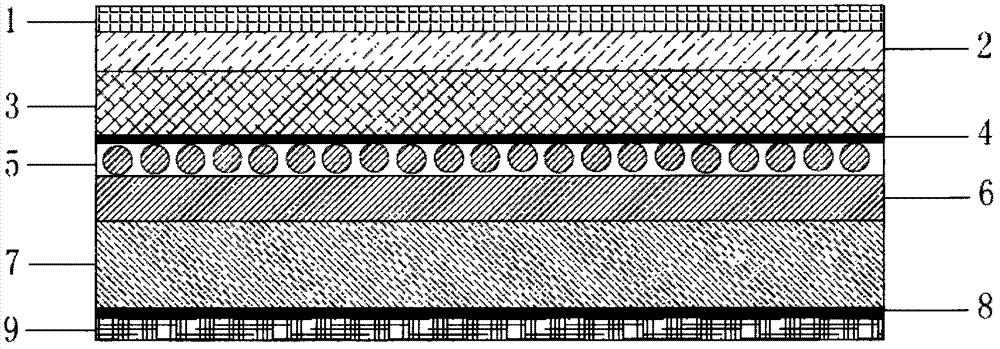

[0022] Embodiment 1 refers to figure 1 , the heating tatami mat includes a mat surface 1, a non-woven cotton layer 2, a non-woven board 3, a second waterproof layer 4, a carbon fiber heating layer 5, a core material, a first waterproof layer 8 and an anti-slip layer 9 arranged in sequence from top to bottom , the carbon fiber heating layer is electrically connected to a power source.

[0023] Wherein, the core material includes a third waterproof layer 6 and a plant fiber board 7 sequentially arranged from top to bottom.

[0024] Both the first waterproof layer and the second waterproof layer adopt a PET waterproof film with a thickness of 0.3mm, and the third waterproof layer preferably adopts a PET plate with a thickness of 7mm. Through the design of the three waterproof layers, the heated tatami mat has better moisture-proof performance and is safer to use.

[0025] The anti-slip layer adopts plastic drop anti-slip cloth.

[0026] The carbon fiber heating layer adopts a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com