Flexible induction heating power supply and its control method for fan bearing disassembly

An induction heating power supply and flexible technology, applied in induction heating control, induction heating, induction current source and other directions, can solve the problems of single type of heating object and uncontrollable temperature distribution of heating object, improve power efficiency and avoid surface damage of workpiece , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention are described below with reference to the drawings.

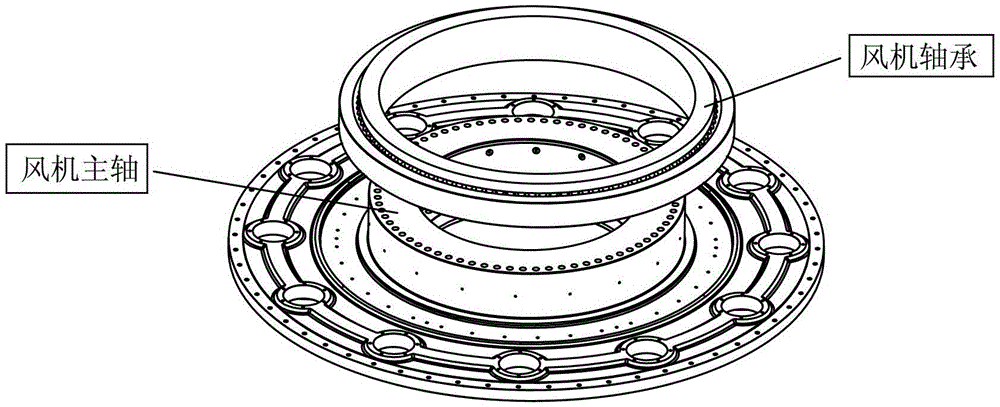

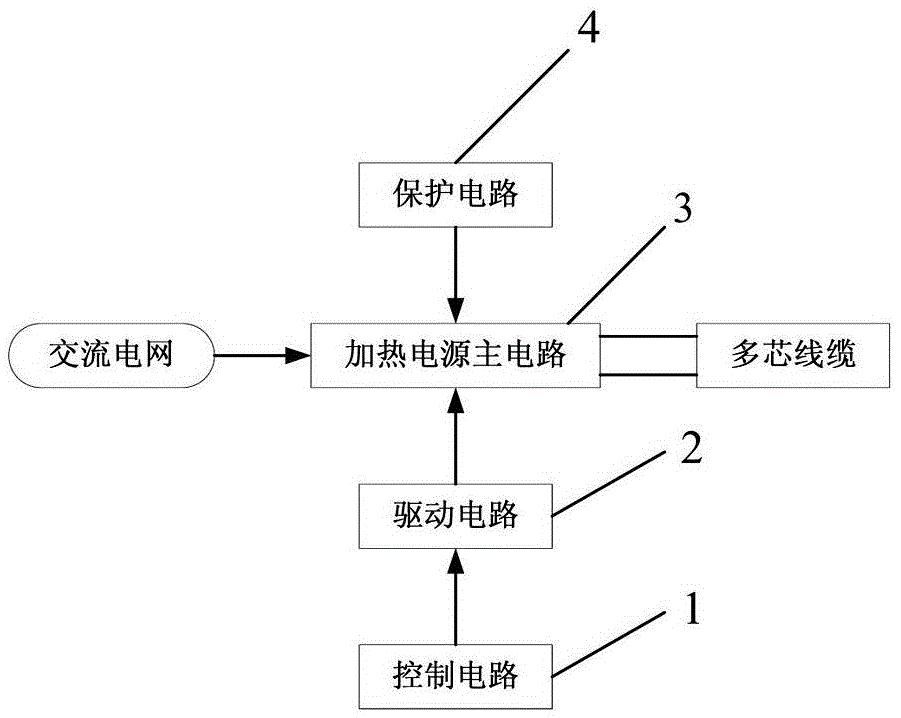

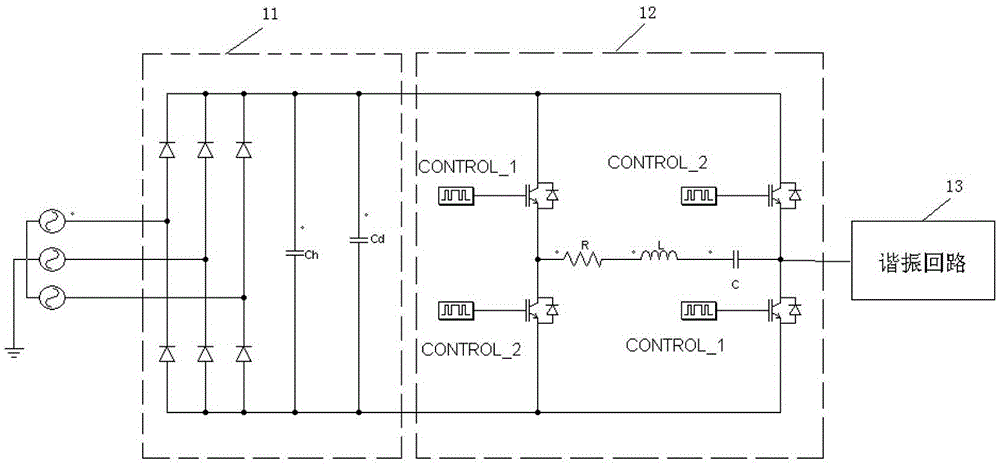

[0054] In the present invention, the induction coil of the fixed structure is replaced by a multi-core cable winding workpiece (such as a fan bearing), and the real-time tracking of the output frequency of the induction heating power supply to the load resonance frequency is realized based on the software phase-locked loop (SPLL). The closed-loop fuzzy proportional-integral (PI) control of the power supply is realized by using the phase-shift pulse width modulation (PWM) strategy, and the temperature control of the heated workpiece is realized based on the programmable logic controller (PLC) and temperature sensor in the power supply, so as to achieve heating The object's temperature is evenly distributed and the temperature rise rate is controllable for the purpose.

[0055] figure 2 It is a block diagram showing a flexible induction heating power supply for fan bearing dismoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com