Anaerobic dry fermentation device and method of pre-aeration temperature-rising sequencing batch type

A fermentation device and anaerobic drying technology, which is applied in the field of pre-aeration and temperature-sequencing batch anaerobic dry fermentation devices, can solve the problems of incomplete reaction of reactants, high fiber content of agricultural waste, unstable fermentation, etc. Reaction efficiency and biogas yield, beneficial heat transfer, and the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

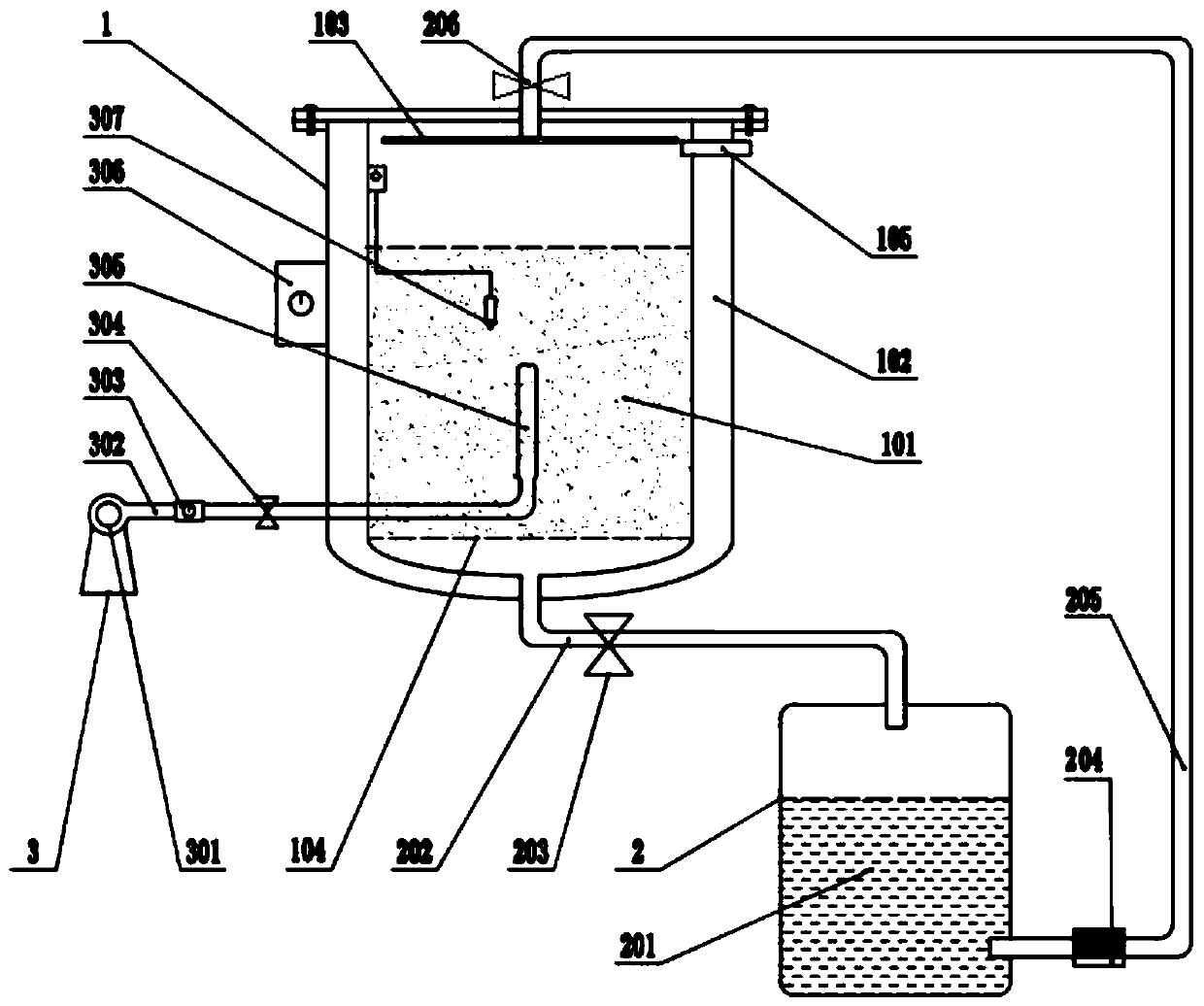

[0026] Such as figure 1 As shown: this embodiment provides a pre-aeration temperature-raising sequence batch type anaerobic dry fermentation device, including anaerobic dry fermentation reactor 1 and aeration mechanism 3, and the detachable cover on anaerobic dry fermentation reactor 1 is covered with Sealing cover, the anaerobic dry fermentation reactor 1 is provided with a material reaction area 101, the material reaction area 101 is used to place the reaction materials, the upper end of the anaerobic dry fermentation reactor 1 is provided with an air outlet 105, and the lower end is provided with a liquid outlet, specifically of, such as figure 1 As shown, the air outlet 105 is provided in the upper right corner of the anaerobic dry fermentation reactor 1, and the air outlet 105 is used to collect biogas. In order to record the amount of biogas produced, the liquid outlet hole is set at the center of the bottom of the anaerobic dry fermentation reactor 1, and a filtrate ad...

Embodiment 2

[0031] This embodiment provides a pre-aeration and temperature-raising sequential batch anaerobic dry fermentation method, which uses the pre-aeration and temperature-raising sequential batch anaerobic dry fermentation device in the above technical scheme, and includes a pre-heating aerobic fermentation step and anaerobic fermentation. Dry fermentation steps:

[0032] S1: pre-heating aerobic fermentation step: select the reaction material with a solid content rate of 25% to 45%, preferably 35%. In this step, the reaction material is mixed and fermented according to a certain dry matter ratio. If the raw material is mixed corn stalks and cow dung, the ratio of reaction materials is preferably 6:4 (corn stalk: cow dung), the aeration mechanism 3 is first opened to feed air into the anaerobic dry fermentation reactor 1 during operation, and the aeration frequency is 0.5-1.5m 3 / (m 3 d -1 ), preferably 1m 3 / (m 3 d -1 ), when the temperature rises to 35-40°C, preferably 35°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com