Patents

Literature

38results about How to "Achieve self-heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

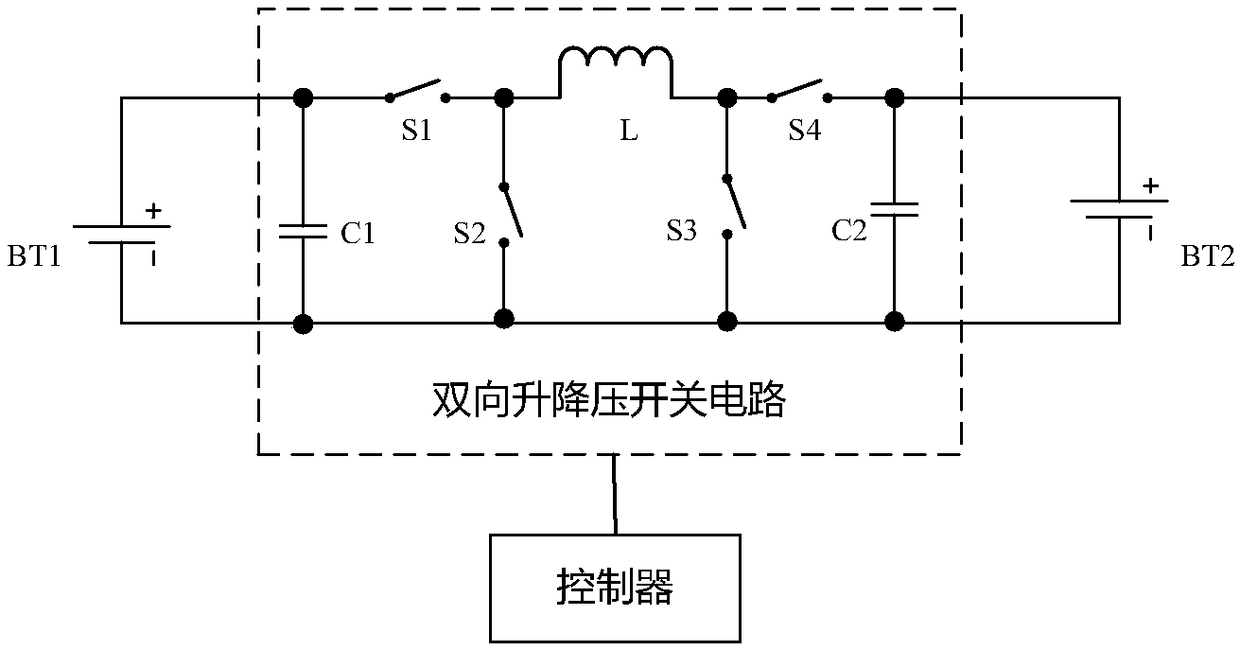

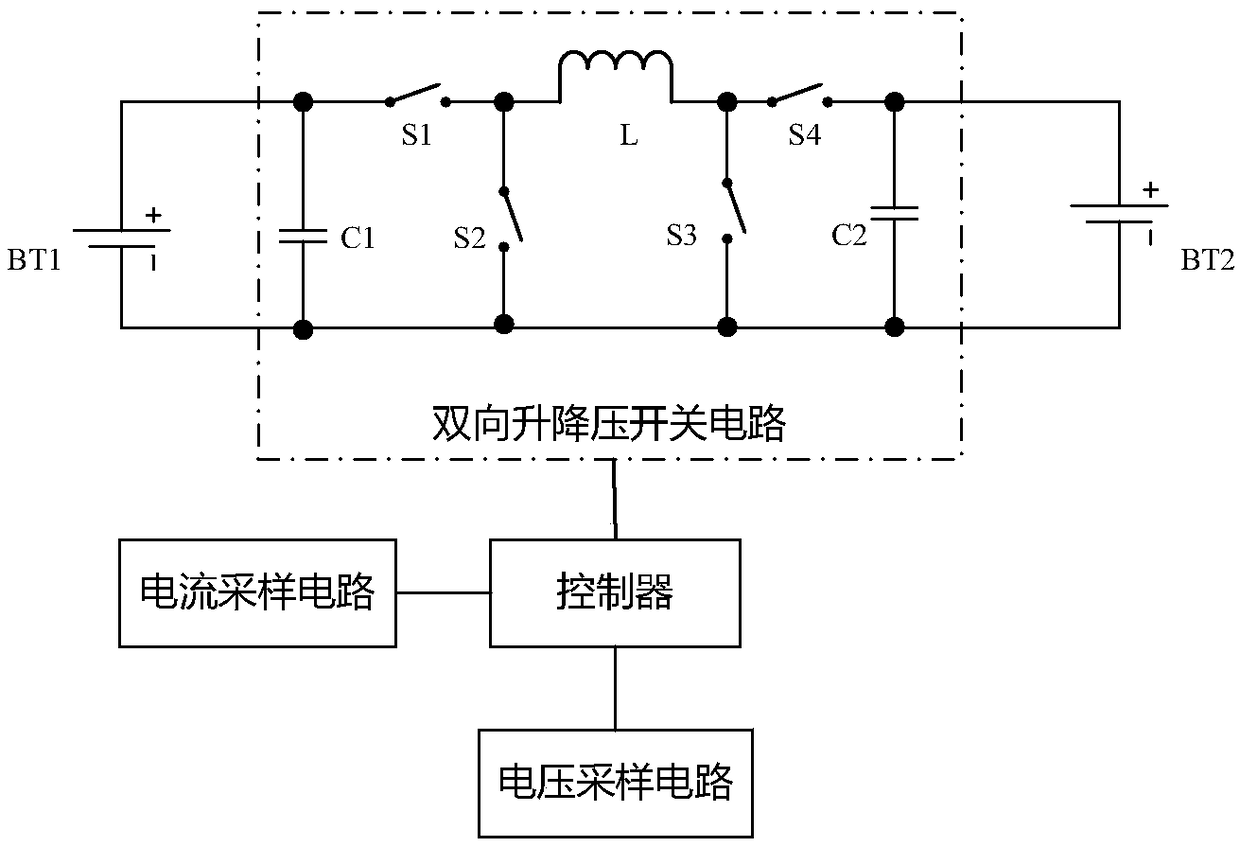

Battery pack circuit and battery pack heating method

PendingCN109301366AIncrease temperatureAchieve self-heatingSecondary cells charging/dischargingElectricityInput/output

The invention discloses a battery pack circuit and a battery pack heating method. The circuit comprises a battery pack, a bidirectional buck-boost switch circuit, and a controller, wherein the batterypack comprises at least two battery units; the bidirectional buck-boost switch circuit is electrically connected between any two battery units through a first input / output end and a second input / output end which are mutually input and output ends; and the controller is electrically connected with the bidirectional buck-boost switch circuit, and is used for controlling the voltage conversion of the bidirectional buck-boost switch circuit is enabled or not according to the temperature of the battery pack, controlling whether the current voltage conversion of the bidirectional buck-boost switchcircuit is a boost voltage conversion or a buck voltage conversion, and controlling the input and output directions of the voltage conversion. When the temperature of the battery pack is lower than apredetermined low-temperature threshold, the technical scheme can utilize mutual charging and discharging of each battery unit in the battery pack to heat the batteries, so that the temperature of thebattery pack is increased.

Owner:深圳市格瑞普智能电子有限公司

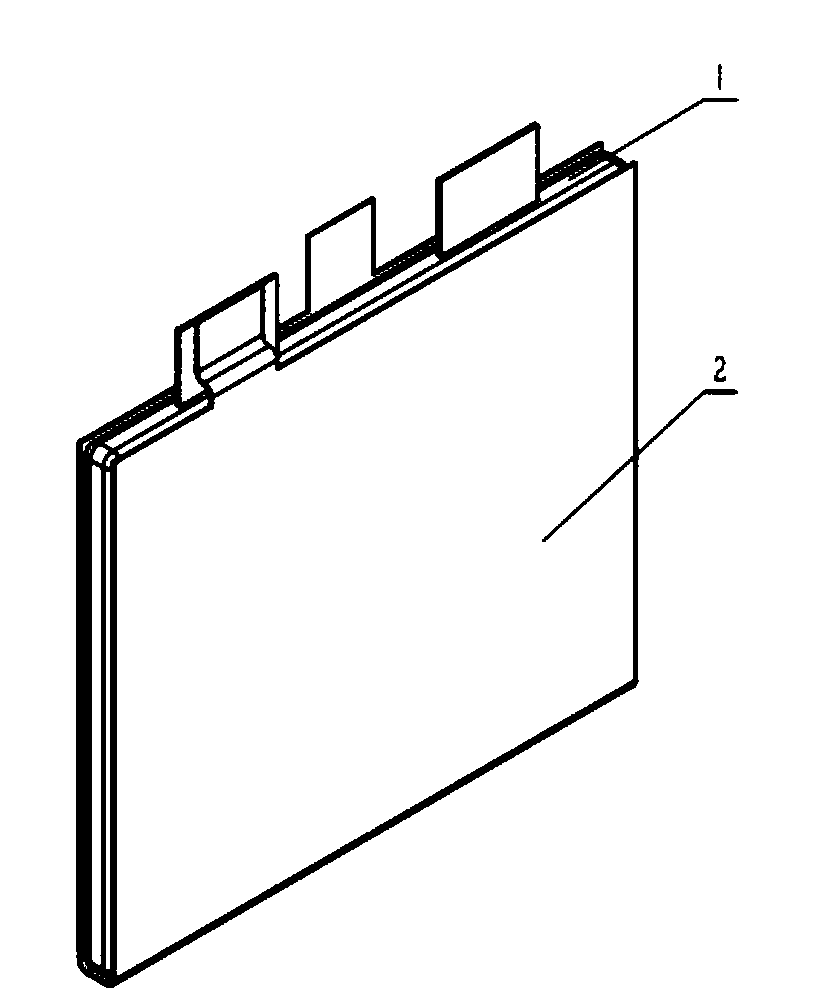

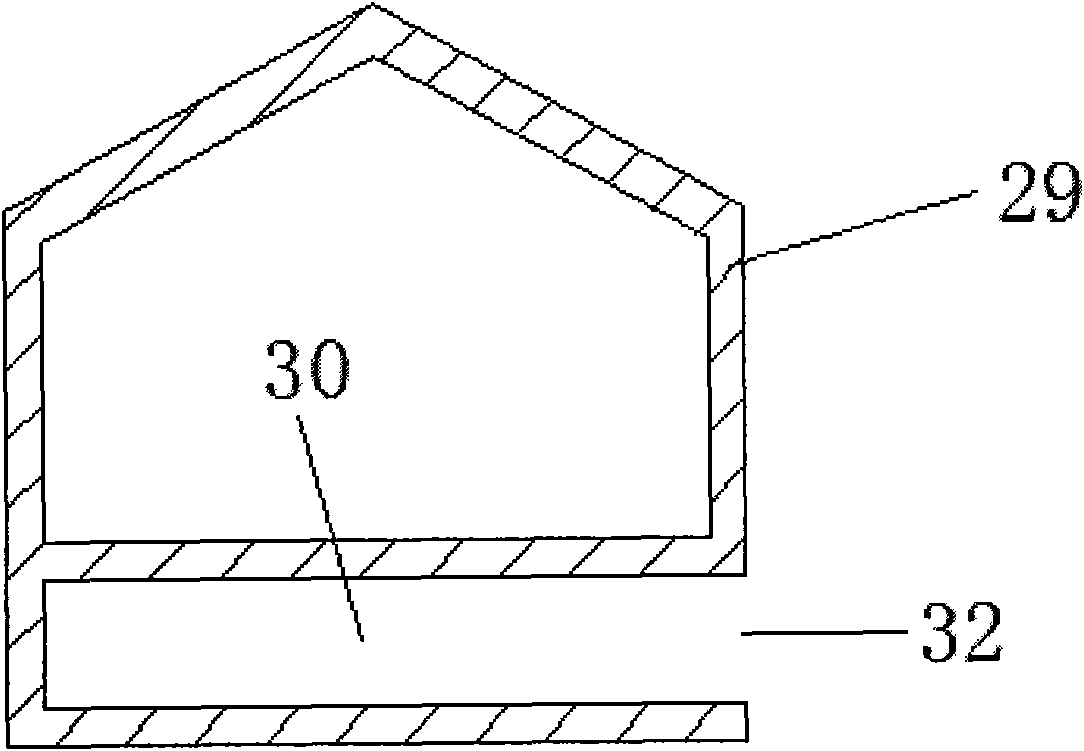

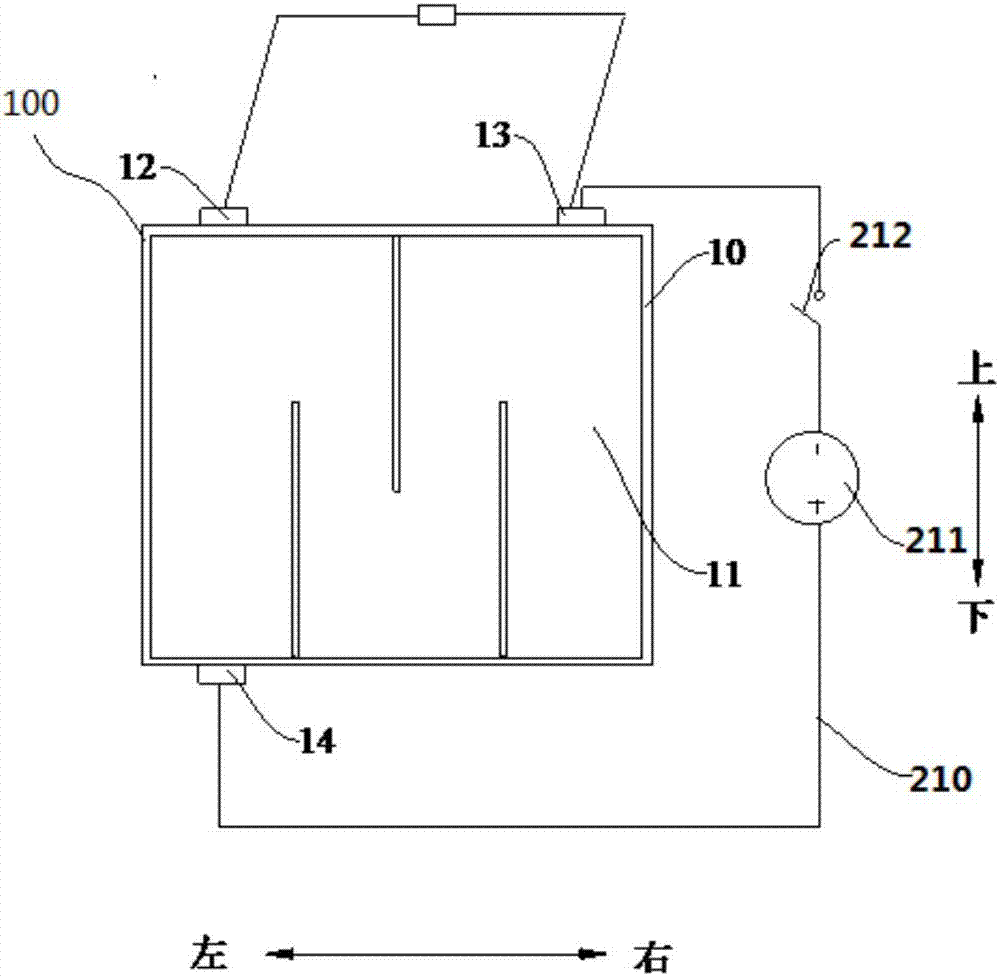

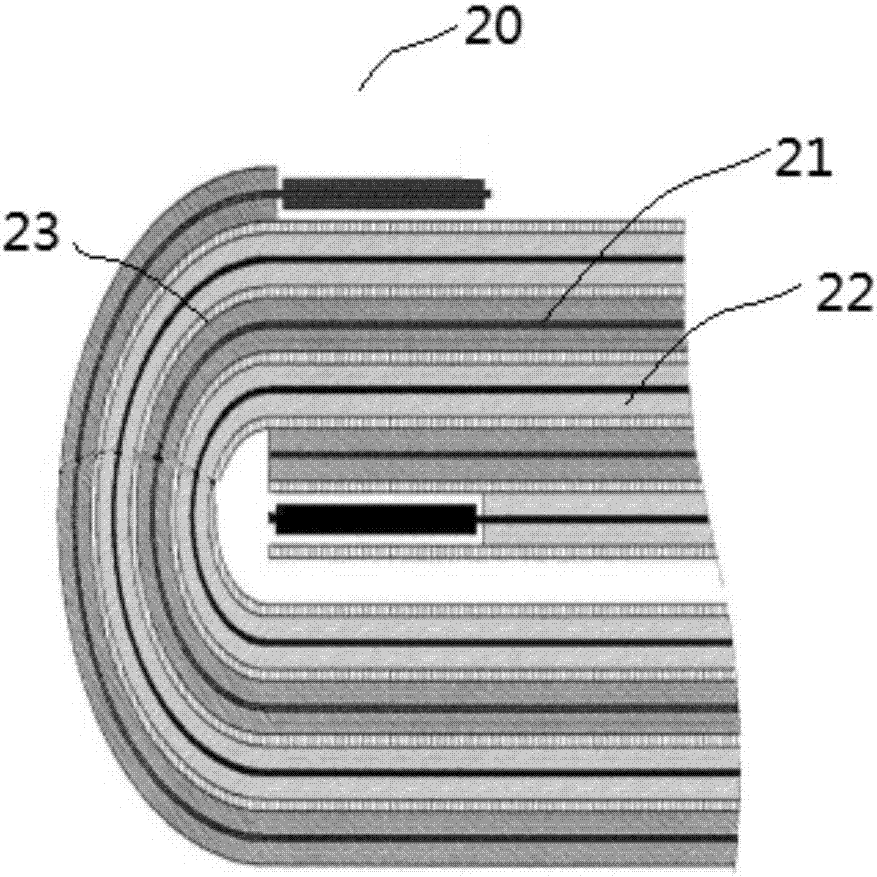

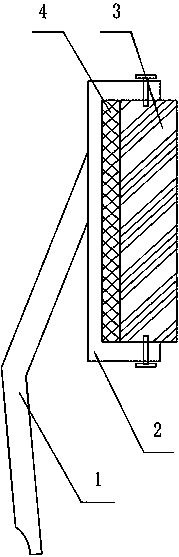

Battery self-heating and heat preserving device

ActiveCN110299580AFix Heating ProblemsEfficient self-preheating and heat preservationSecondary cellsPower batteryJoule

The invention discloses a battery self-heating and heat preserving device. The battery self-heating and heat preserving device comprises a power battery monomer, a heating diaphragm, an aerogel shell,a temperature sensor and a switching circuit. The outer surface of the power battery monomer is coated with the heating diaphragm. The outer surface of the heating diaphragm is coated with the aerogel shell. The temperature sensor is arranged on the power battery monomer, and the temperature sensor is arranged between the power battery monomer and the heating diaphragm. The temperature sensor andthe switching circuit are connected by a signal line. Every two of the power battery monomer, the heating diaphragm and the switching circuit are connected with each other. The switching circuit is used to connect the power battery monomer and the heating diaphragm to form a heating hoop. The heating diaphragm is used to generate heat by the Joule heat effect and heat the power battery monomer bythe heat conduction effect. By adopting the battery self-heating and heat preserving device provided by the invention, batteries can be efficiently self-preheated and kept warm under low temperatureconditions, and the charging and discharging performance of batteries can be enhanced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Milk maker

InactiveCN101589913ARealize the stirring functionAchieve self-heatingBeverage vesselsDrive motorEngineering

The invention discloses a milk maker, which comprises a support cylinder, a base for placing a milk making bottle, and a water barrel, wherein the inside of the support cylinder is provided with a driving motor, the support cylinder is provided with a powdered milk barrel, a rotating shaft is inserted into the bottom surface of the powdered milk barrel, and the rotating shaft is linked with an output shaft of the driving motor; the inside of the powdered milk barrel is provided with a link mechanism, the link mechanism is connected with a powder pushing block, and the powder pushing block can travel to the outer wall, which is provided with a powder falling cavity, of the powdered milk barrel; the milk making bottle is arranged below the powder falling cavity, a stirring shaft is inserted into the bottom surface of the milk making bottle and is provided with stirring blades, and the stirring blades are positioned in the milk making bottle; the inside of the base is provided with a mechanism for driving the rotation of the stirring shaft; and the inside of the water barrel is provided with a water pump, the water pump is connected with a water outlet pipe, and a tail-end water outlet of the water outlet pipe aligns with a bottle mouth of the milk making bottle. The milk maker realizes the integrated automation of automatic and quantificational powdered milk taking, water feeding and automatic stirring.

Owner:王光力

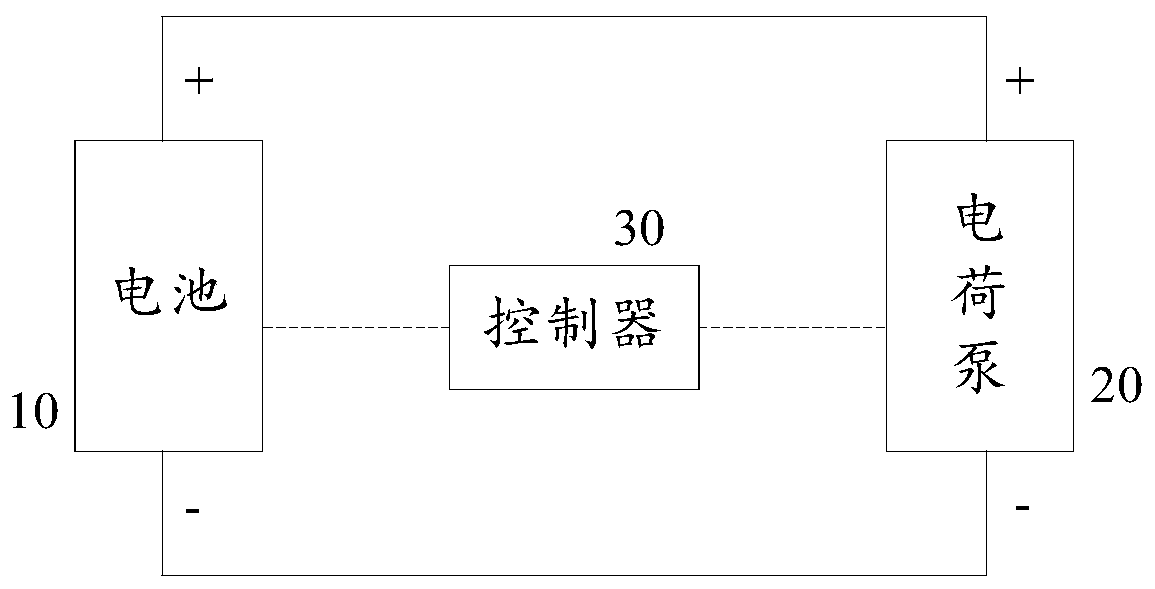

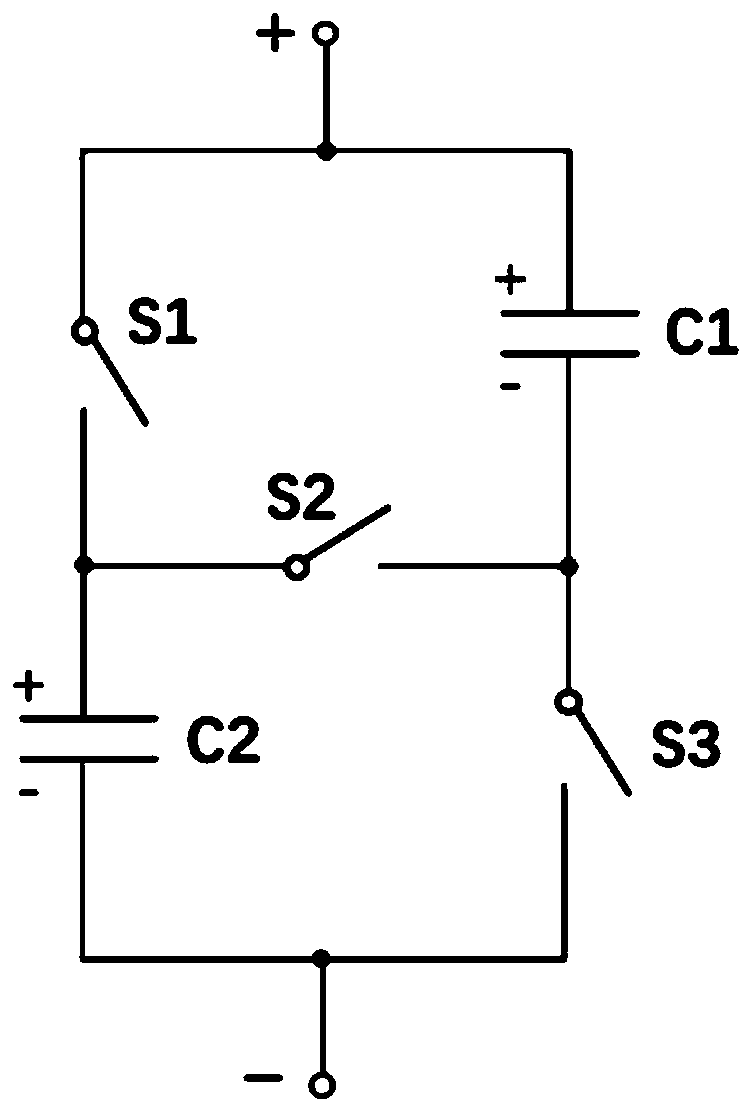

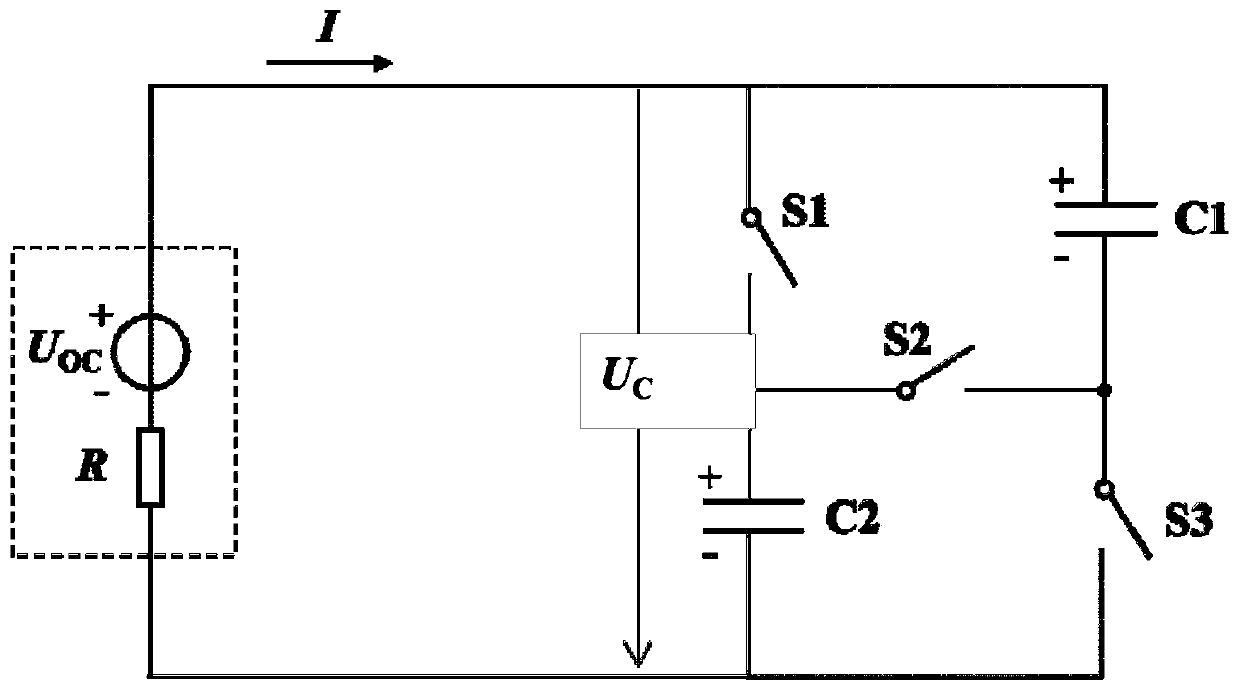

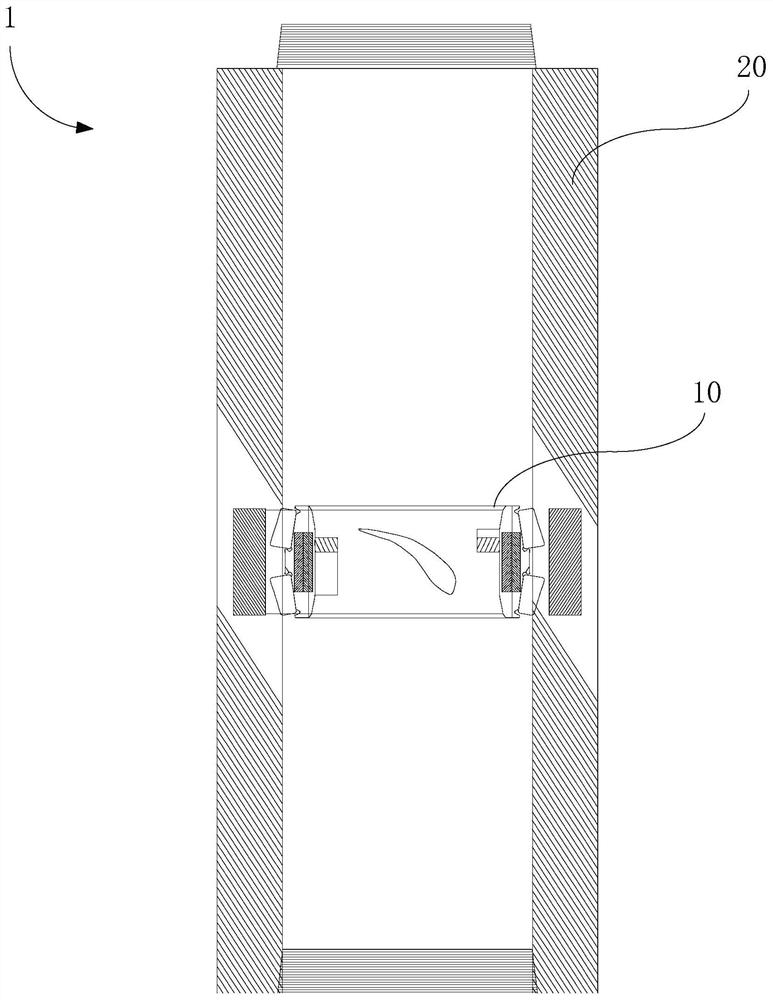

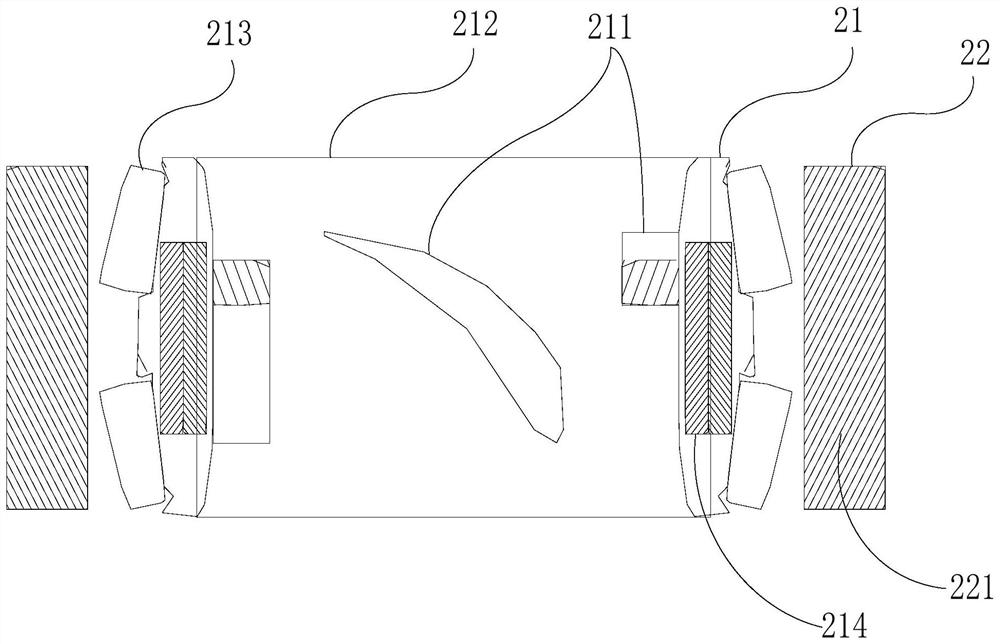

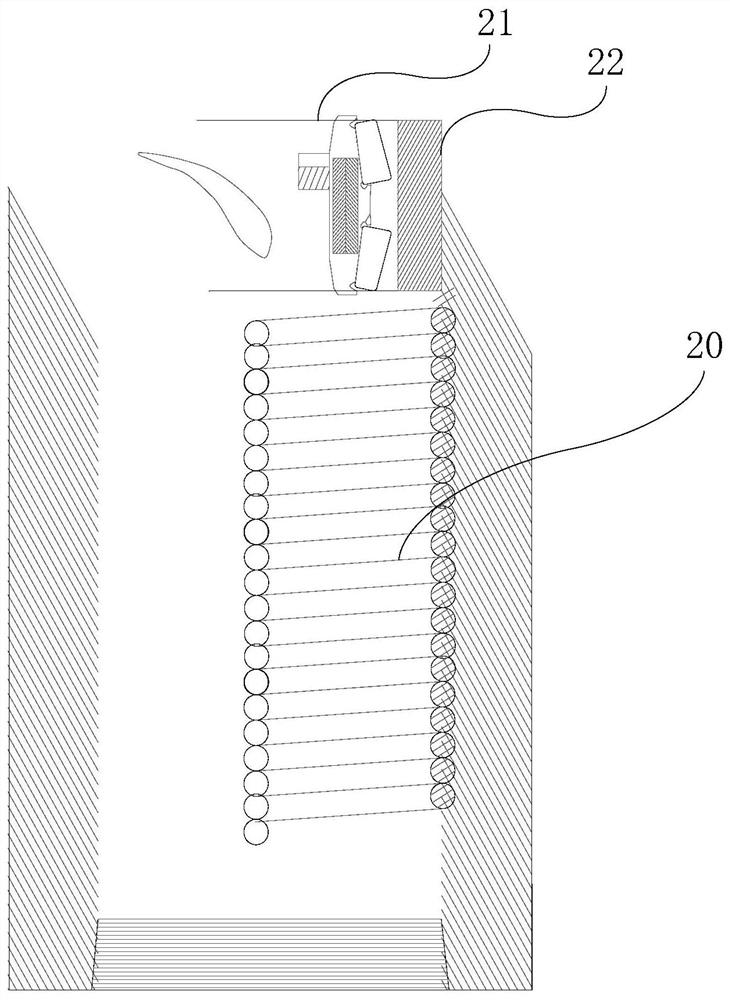

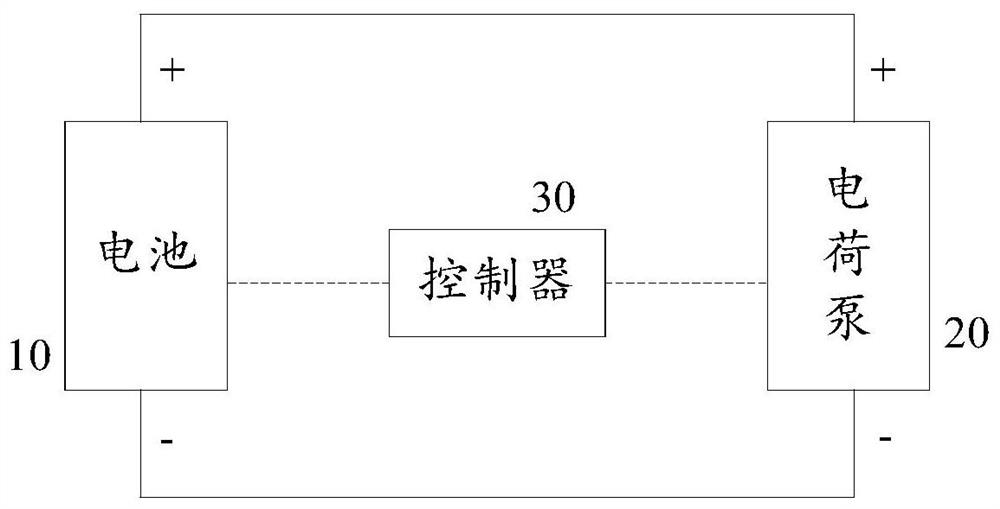

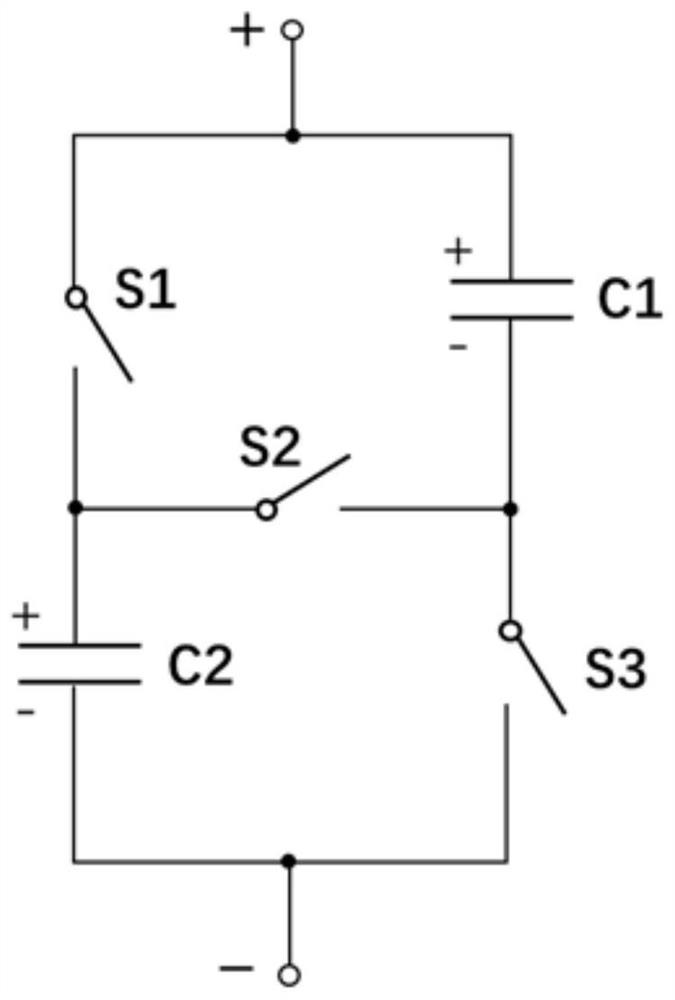

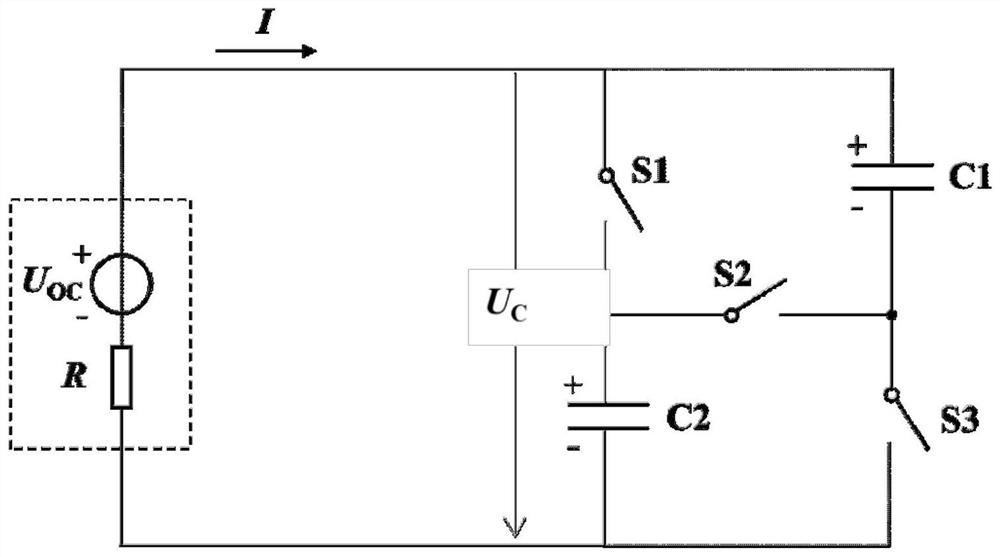

Battery self-heating method and device

ActiveCN110336099AEasy to useAchieve self-heatingCell temperature controlAutomatic controlElectrical battery

The invention discloses a battery self-heating method and device. The device comprises a battery, a charge pump and a controller. The charge pump can be controlled to be charged or discharged. The controller, when the operating status information of the battery indicates that the battery is required to be self-heated, instructs the charge pump to be alternately charged and discharged in order to alternately discharge and charge the battery to generate heat to achieve self-heating. The battery self-heating method and device disclosed in the embodiment of the present invention can automaticallyinstruct the charge pump to be alternately charged and discharged in the event of excessively low battery temperature, so that the battery is correspondingly discharged and charged. Since the batteryhas internal resistance, the charging and discharging processes can cause the battery to generate heat and to achieve a self-heating effect. The battery self-heating method does not need external source-containing equipment, can be self-heated anytime anywhere as needed, and greatly facilitates the use.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

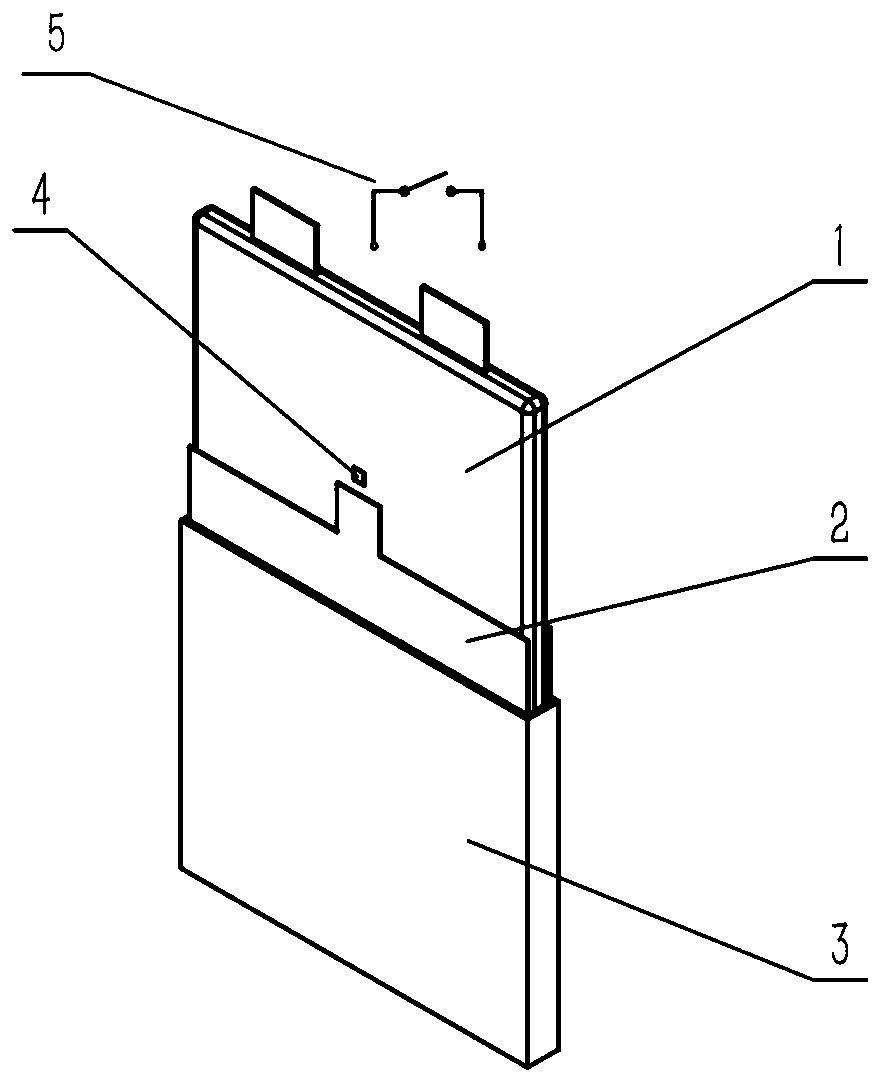

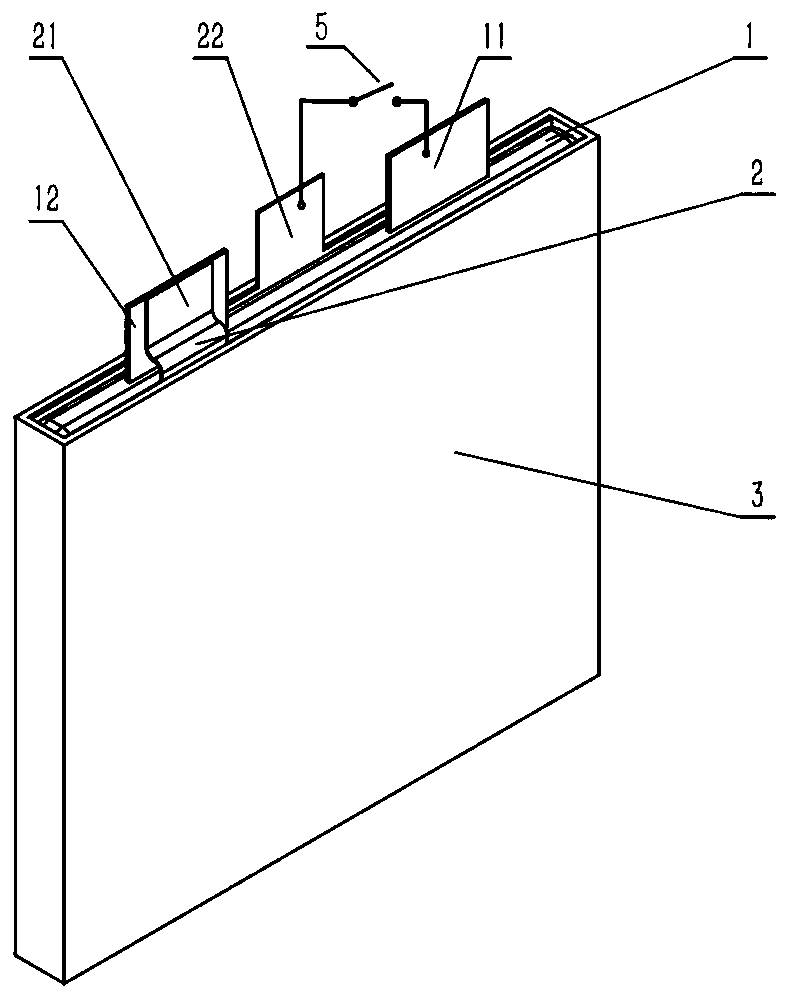

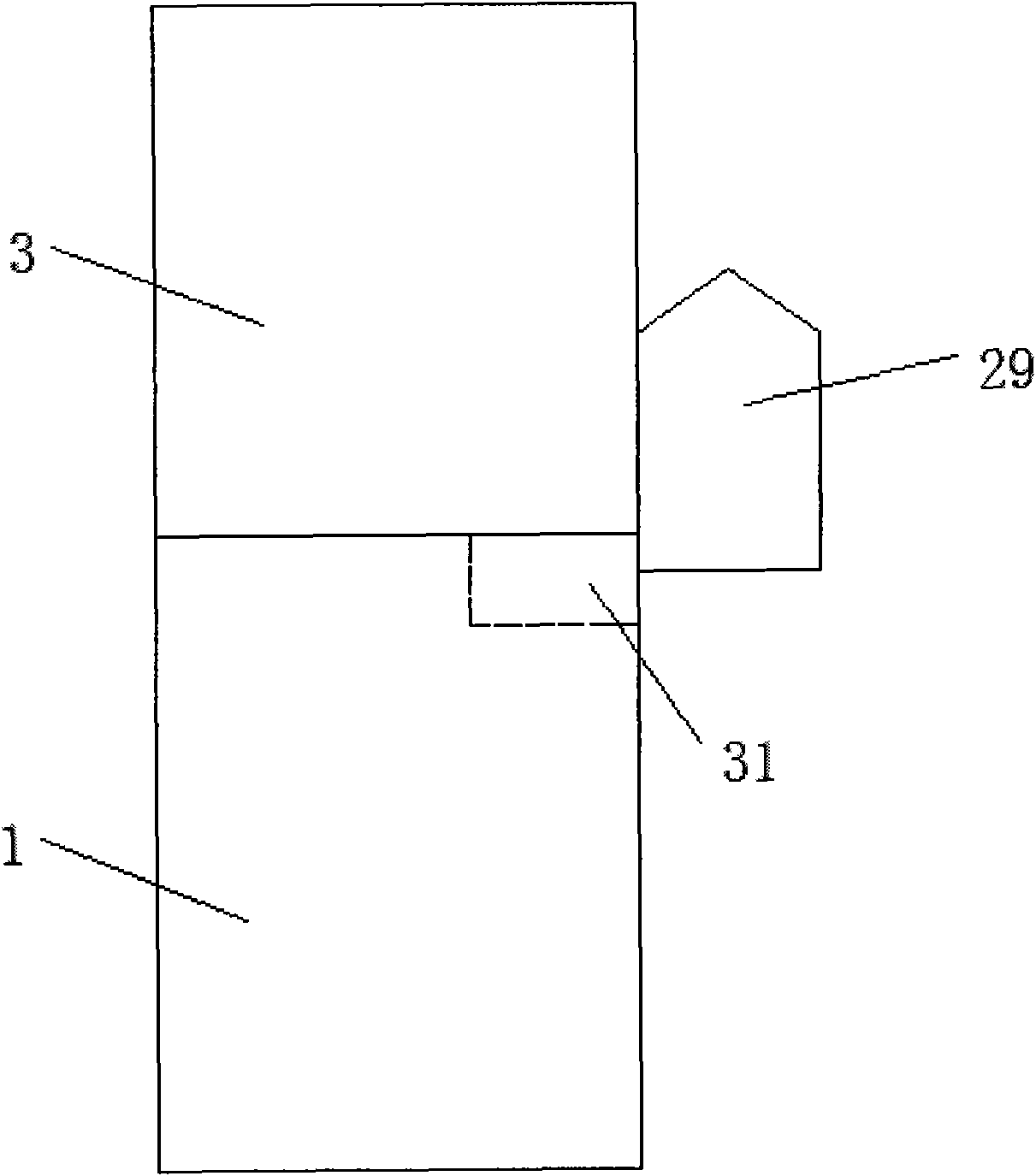

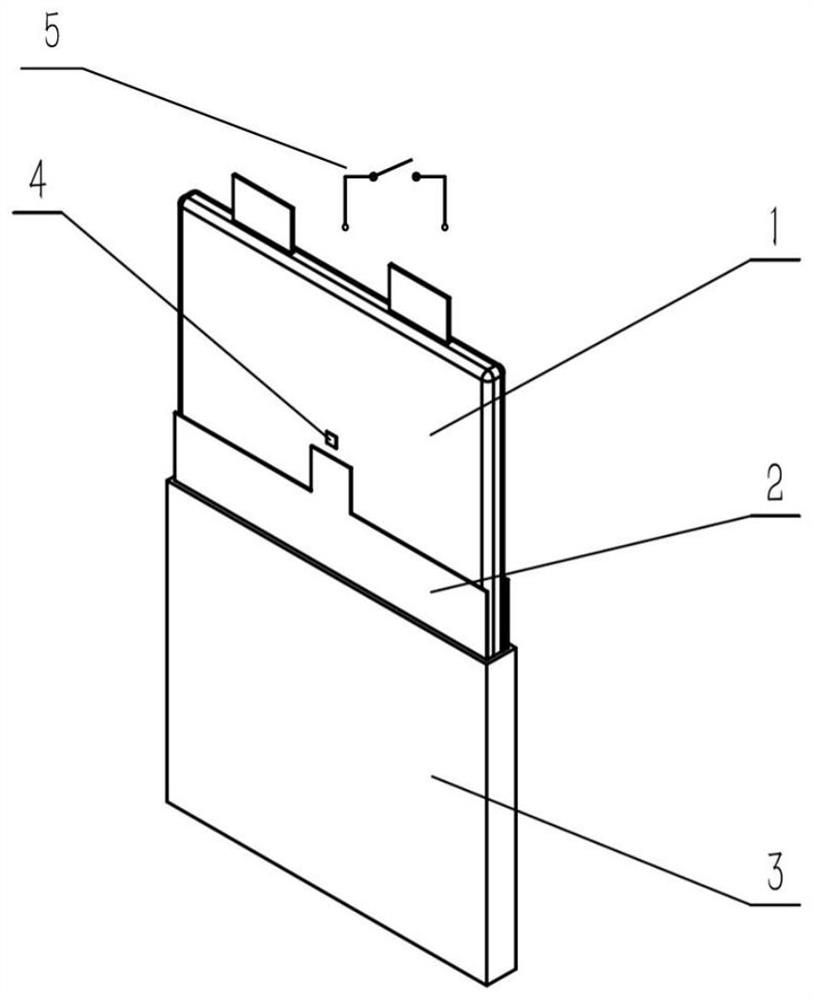

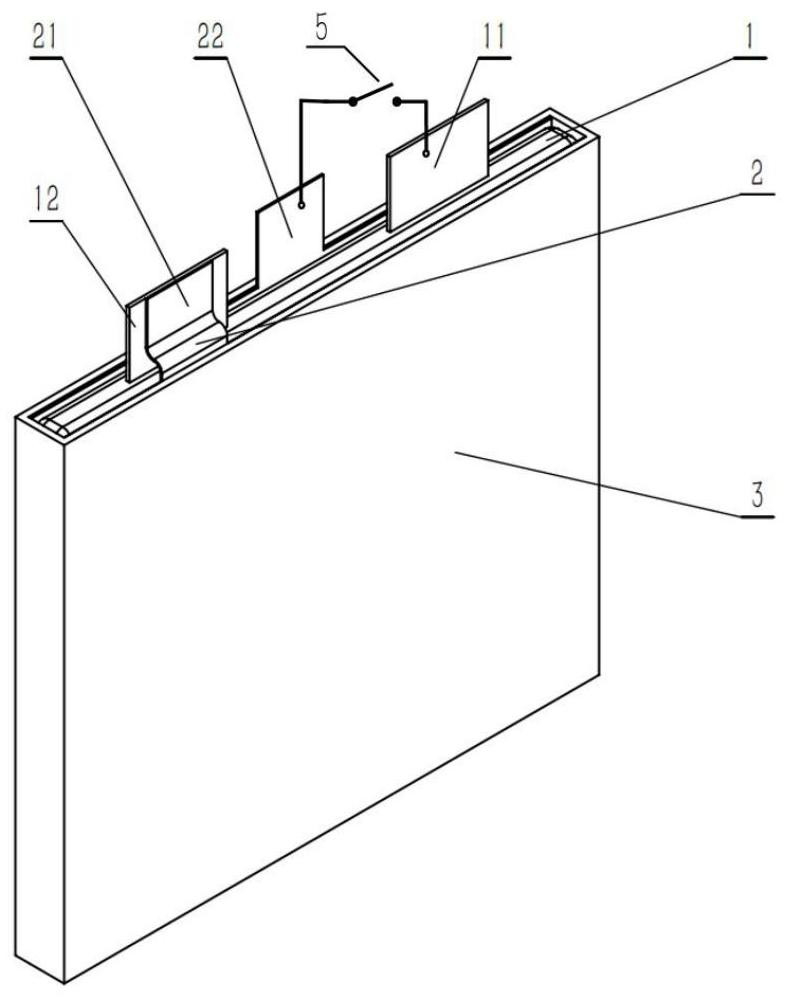

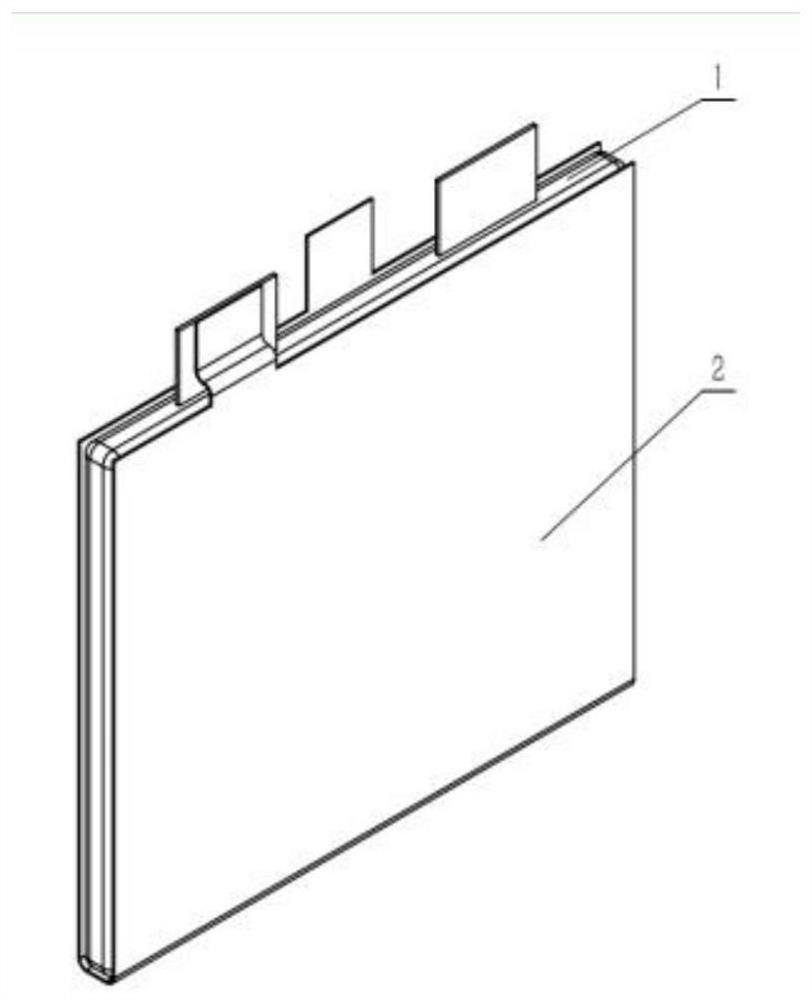

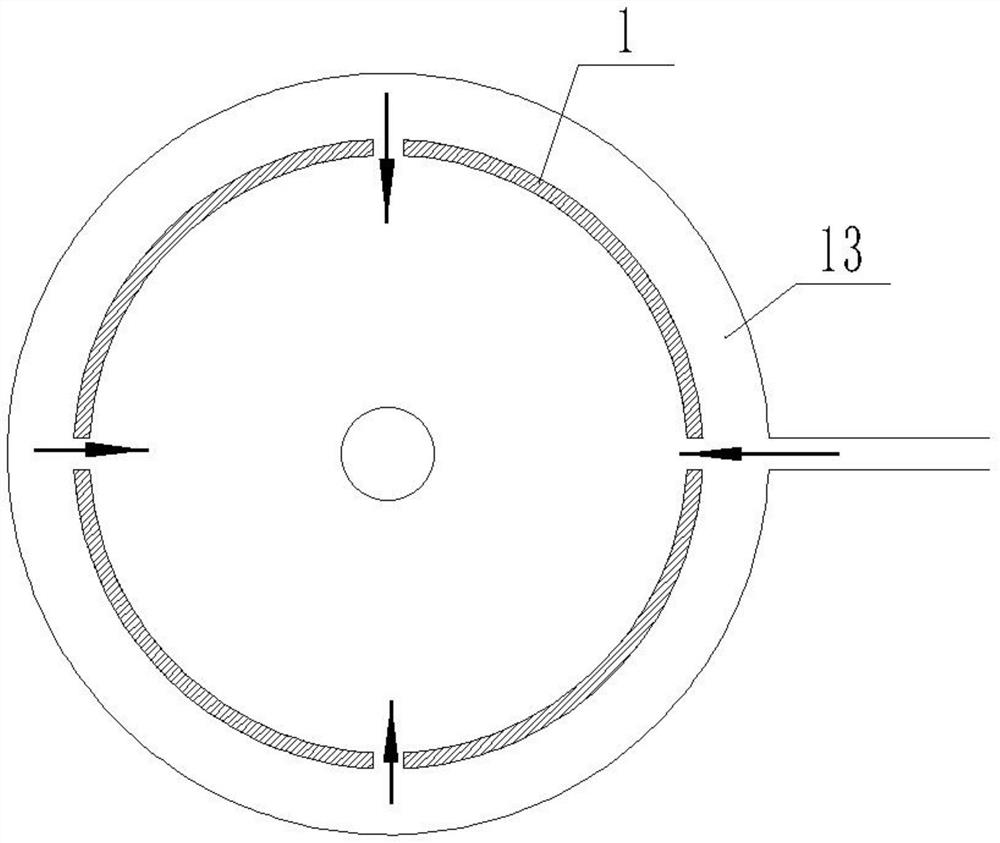

Single battery, battery pack and vehicle equipped with battery pack

InactiveCN106960990AAvoid damageExtended service lifeCell temperature controlBatteriesElectrical connectionBattery pack

The invention discloses a single battery, a battery pack and a vehicle equipped with the battery pack. The single battery comprises a shell, electrodes and a cell, wherein the electrodes include a positive electrode and a negative electrode arranged on the shell; at least one of the positive electrode and the negative electrode comprises two polar columns; the polar columns are both applicable to electrical connection; the cell is arranged in the shell, and the cell comprises a positive electrode plate, a negative electrode plate and a diaphragm; the positive electrode plate is electrically connected with the positive electrode; and the negative electrode plate is electrically connected with the negative electrode. According to the single battery disclosed in the embodiments, at least one of the positive electrode and the negative electrode is provided with two polar columns; the polar columns are electrically connected with an external power supply to enable the positive electrode plate or the negative electrode plate to form a short circuit, so that automatic heating to the interior of the cell can be realized under a condition of slightly modifying the manufacturing process of the single battery.

Owner:BEIJING ELECTRIC VEHICLE

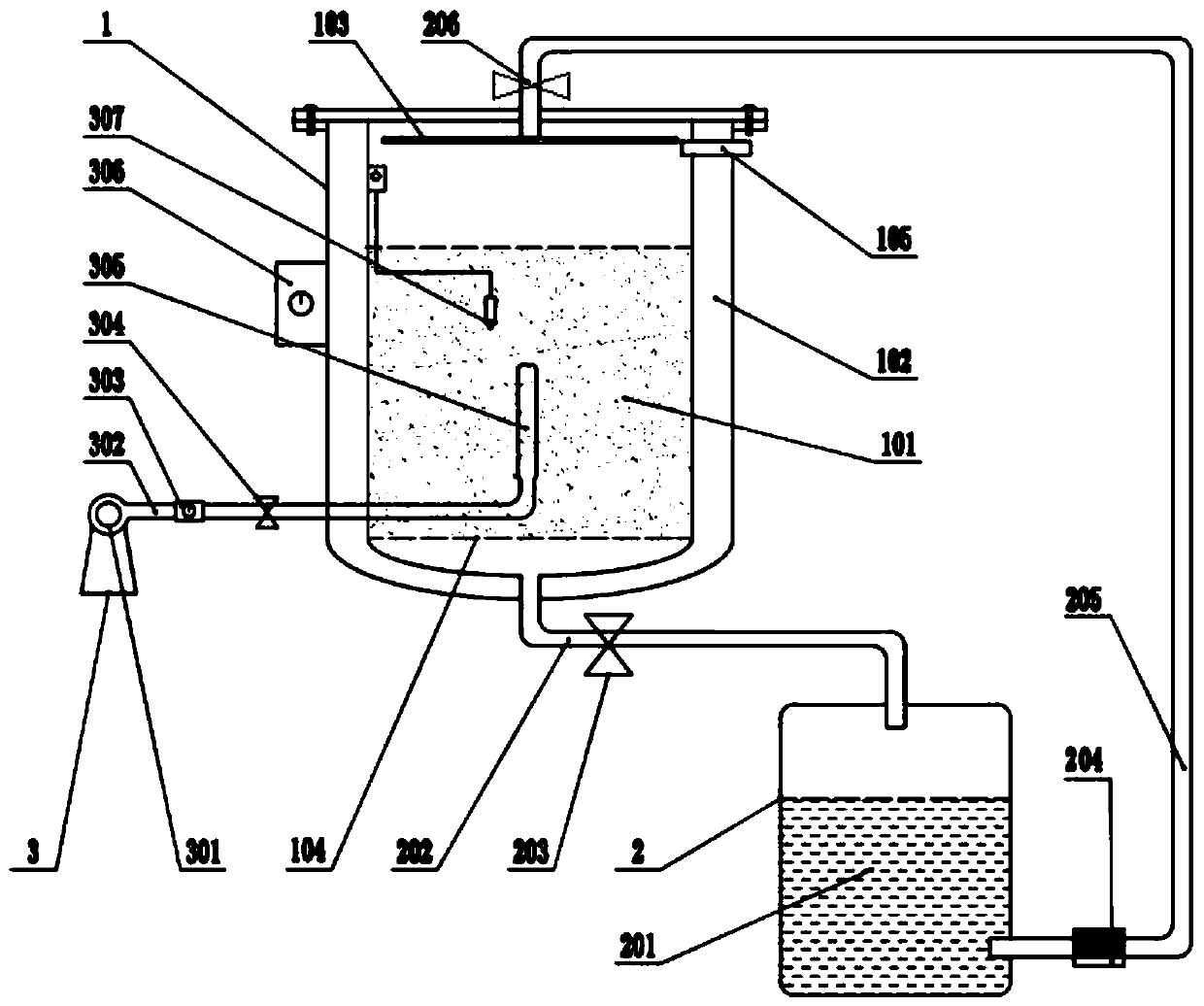

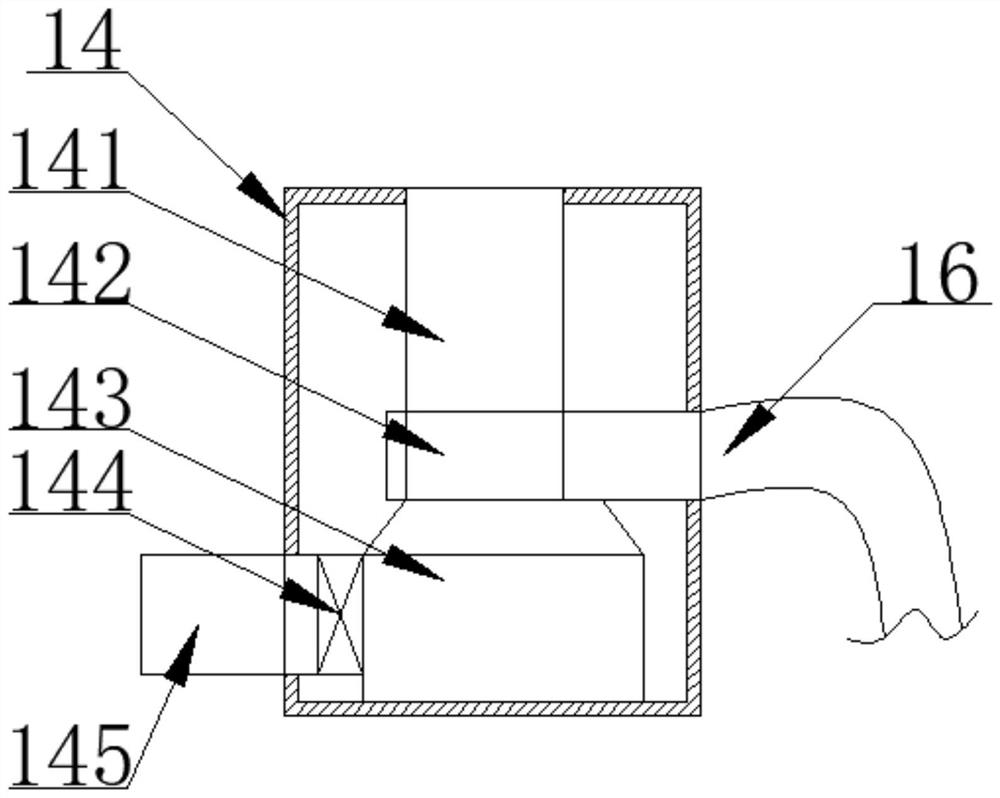

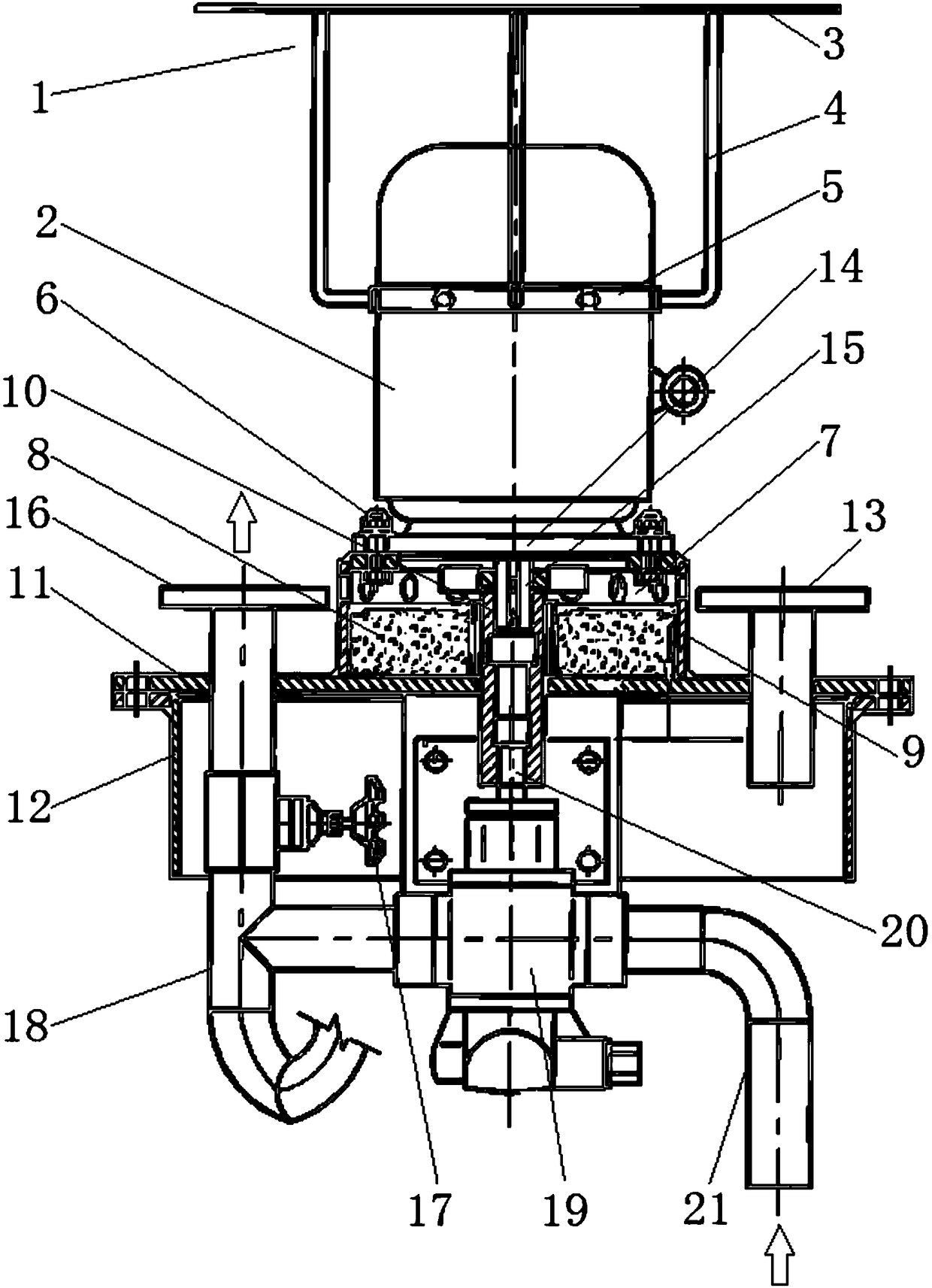

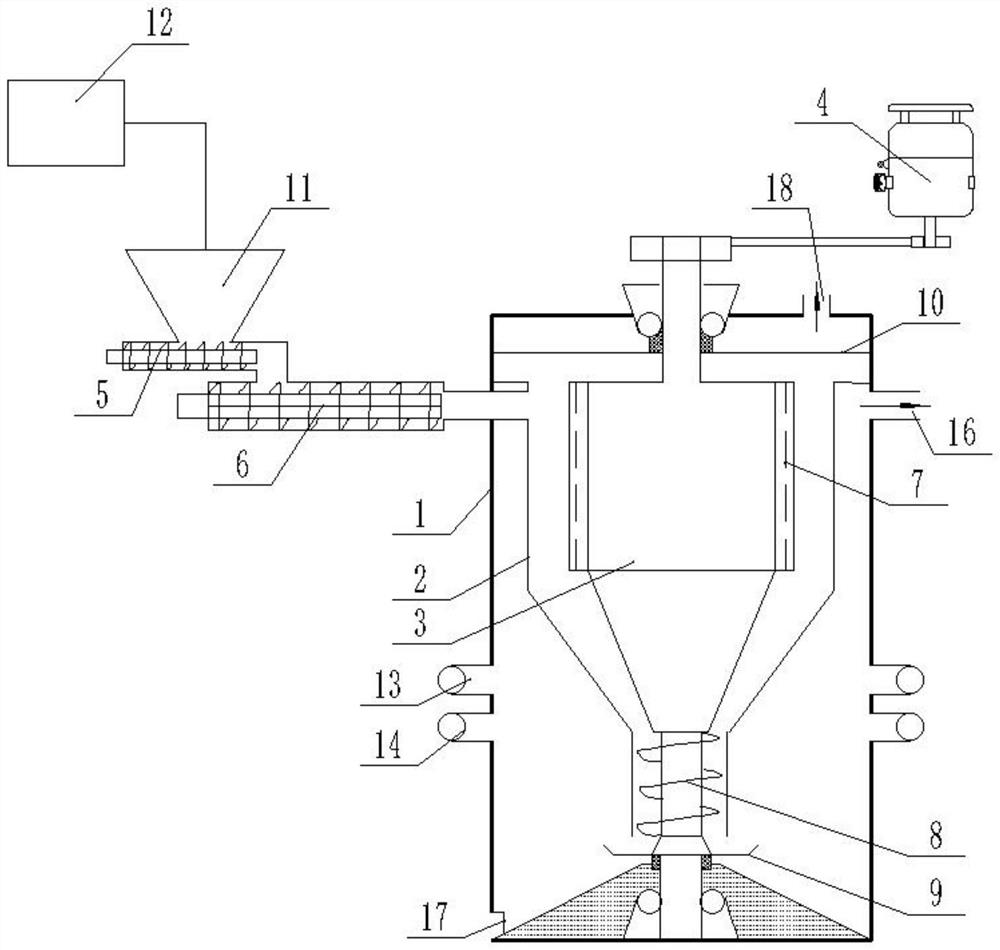

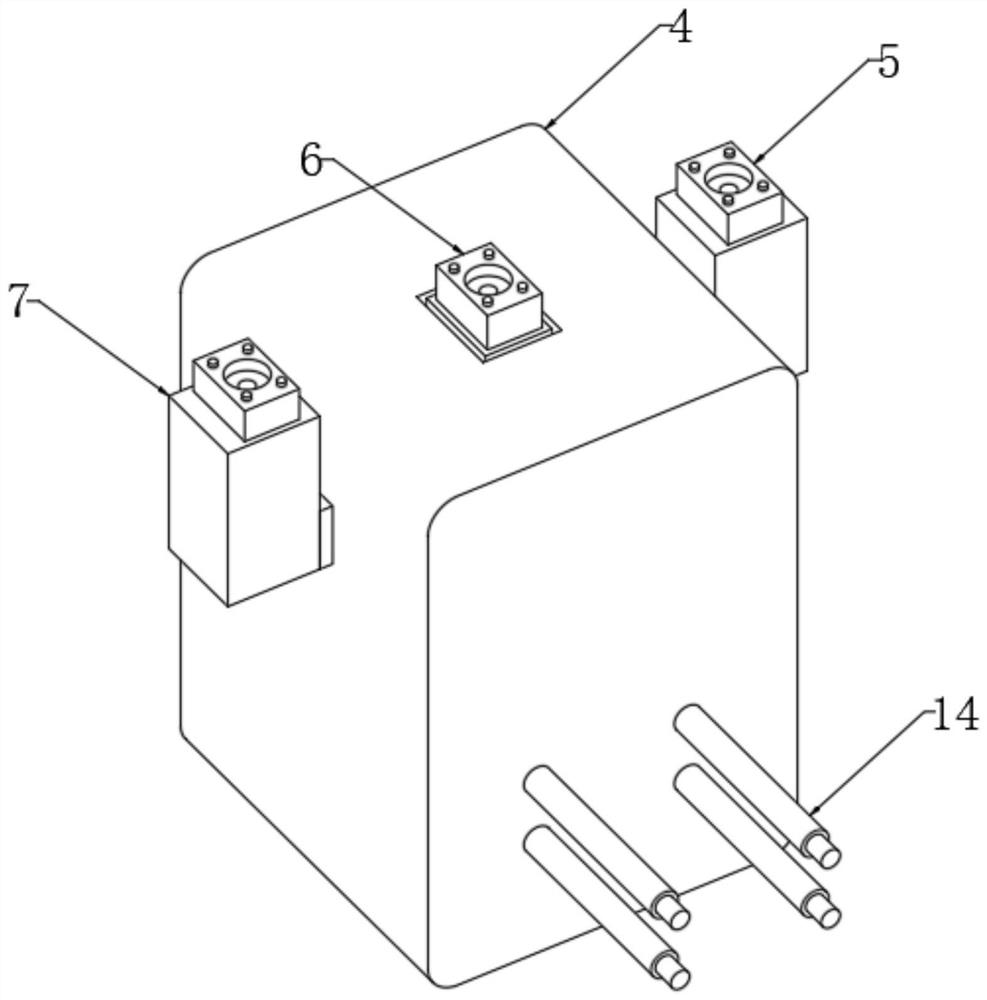

Anaerobic dry fermentation device and method of pre-aeration temperature-rising sequencing batch type

PendingCN110468045AUniform heating areaImprove reaction efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsChemistrySelf heating

The invention discloses an anaerobic dry fermentation device of pre-aeration temperature-rising sequencing batch type. The fermentation device comprises an anaerobic dry fermentation reactor and an aeration mechanism. The anaerobic dry fermentation reactor is detachably covered with a sealing cover, a material reaction zone is arranged in the anaerobic dry fermentation reactor, the material reaction zone is used for placing reaction materials, the upper end of the anaerobic dry fermentation reactor is provided with an air outlet hole, and the lower end of the anaerobic dry fermentation reactoris provided with a liquid outlet hole; the aeration mechanism comprises a fan, an air inlet pipe and an aeration pipe, one end of the air inlet pipe is communicated with the fan, the other end of theair inlet pipe is communicated with the aeration pipe through the air inlet hole of the anaerobic dry fermentation reactor, and the aeration pipe is located inside the material reaction zone; and theupper part inside the anaerobic dry fermentation reactor is provided with a spray head, liquid can be sprayed from the spray head to the material reaction zone, so as to realize self-heating of the reaction materials, ensure the temperature requirements of the materials for anaerobic fermentation, and improve the reaction efficiency and output rate.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Self-heating mask

InactiveCN105411043AAchieve self-heatingReduce usageTherapeutic coolingTherapeutic heatingPatient needRespirator

The invention provides a self-heating mask. The self-heating mask comprises an inner mask surface, an outer mask surface, ear hanging parts, a mouth curtain, snap button minor buttons, snap button main buttons, a breathing opening, a heating piece, a solid aluminum sheet and massaging beads. The self-heating mask can achieve automatic heat emission, and therefore the requirement for self-heating is met on the occasion where a rhinitis patient needs to be kept warm. The self-heating mask has the advantages of being free of power, capable of keeping people warm, filtering out dust and killing bacteria, convenient to use, safe, reliable, light, thin, washable and good in breathability; furthermore, the self-heating mask solves problems existing in the prior art and plays a positive assisting role in treating the rhinitis patient.

Owner:张锐

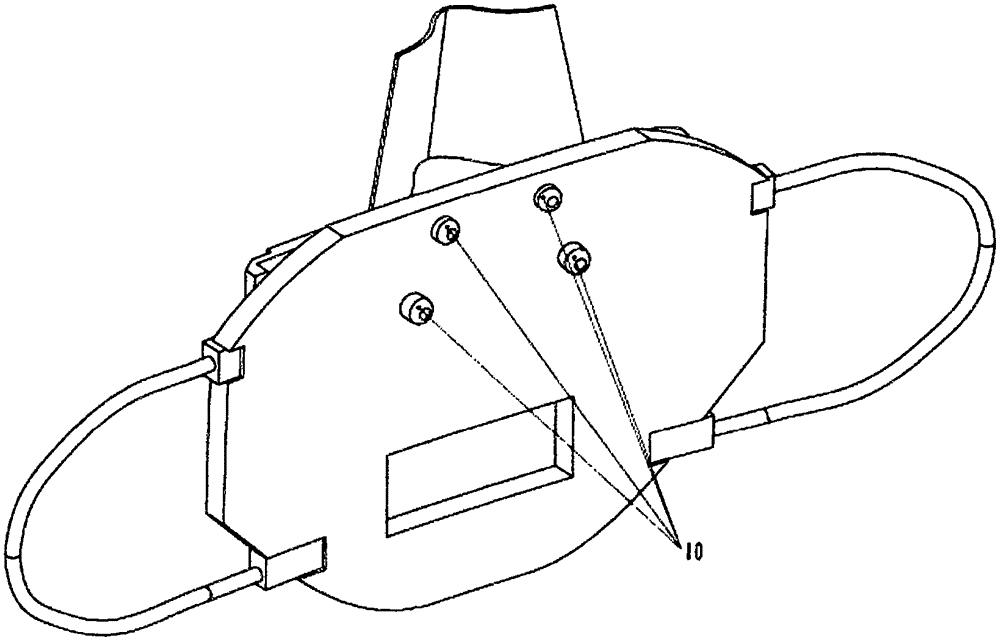

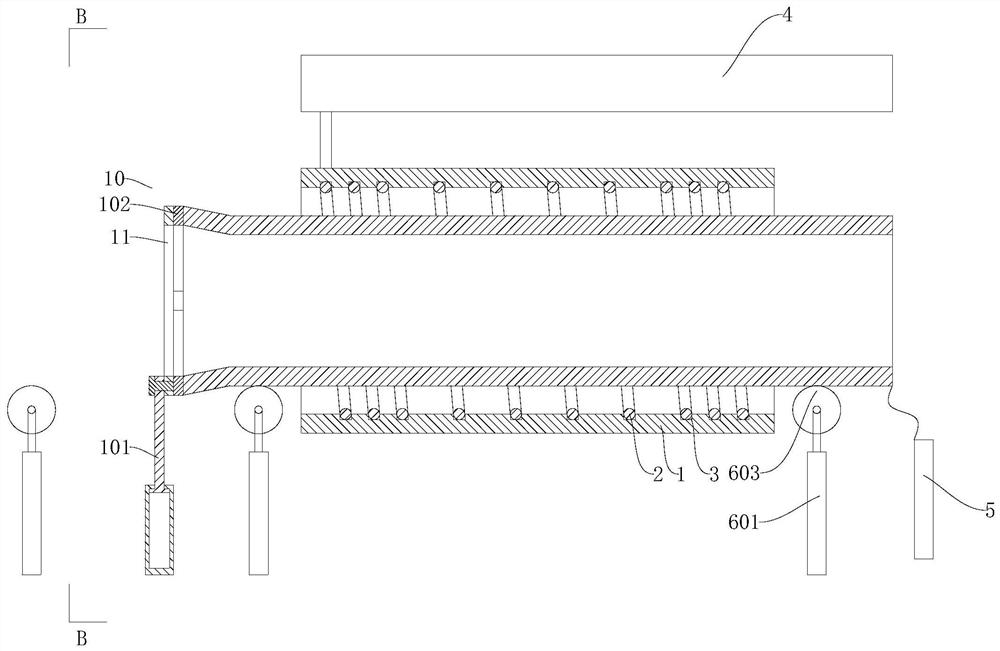

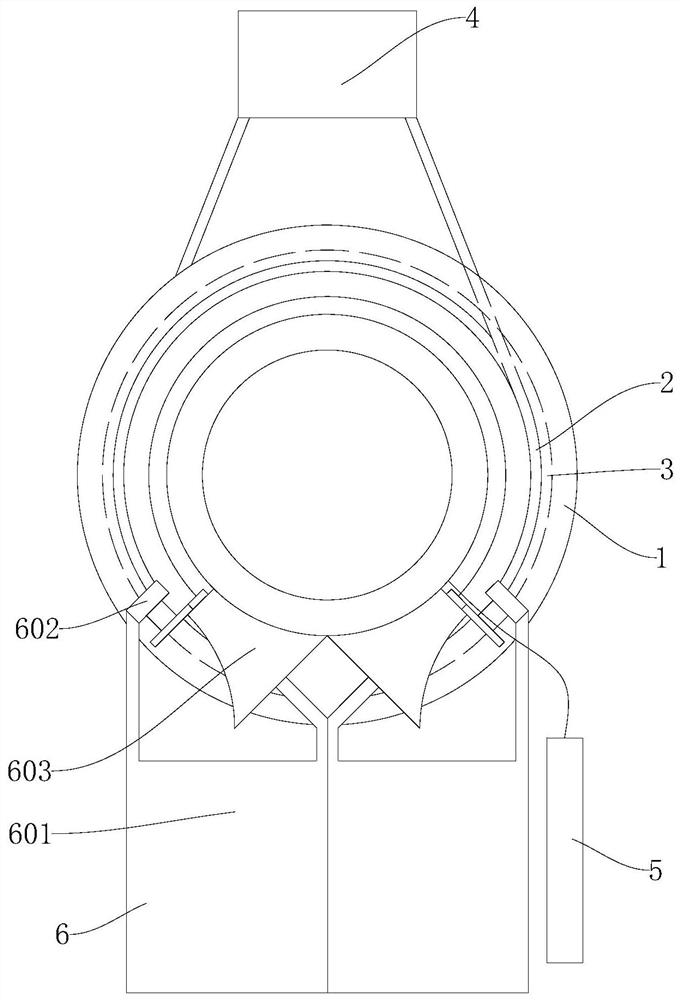

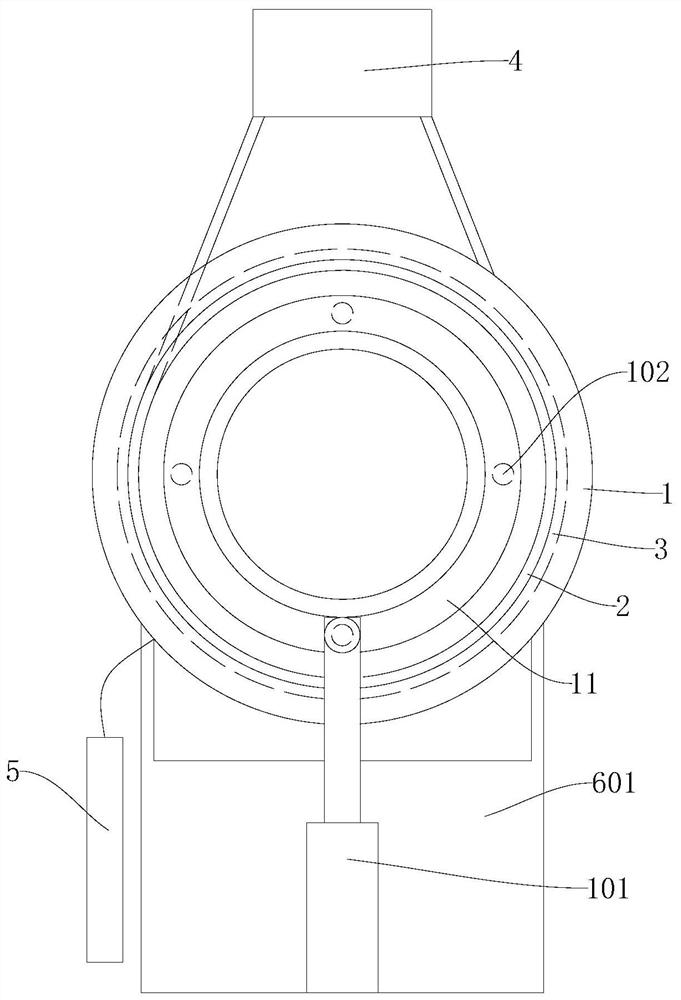

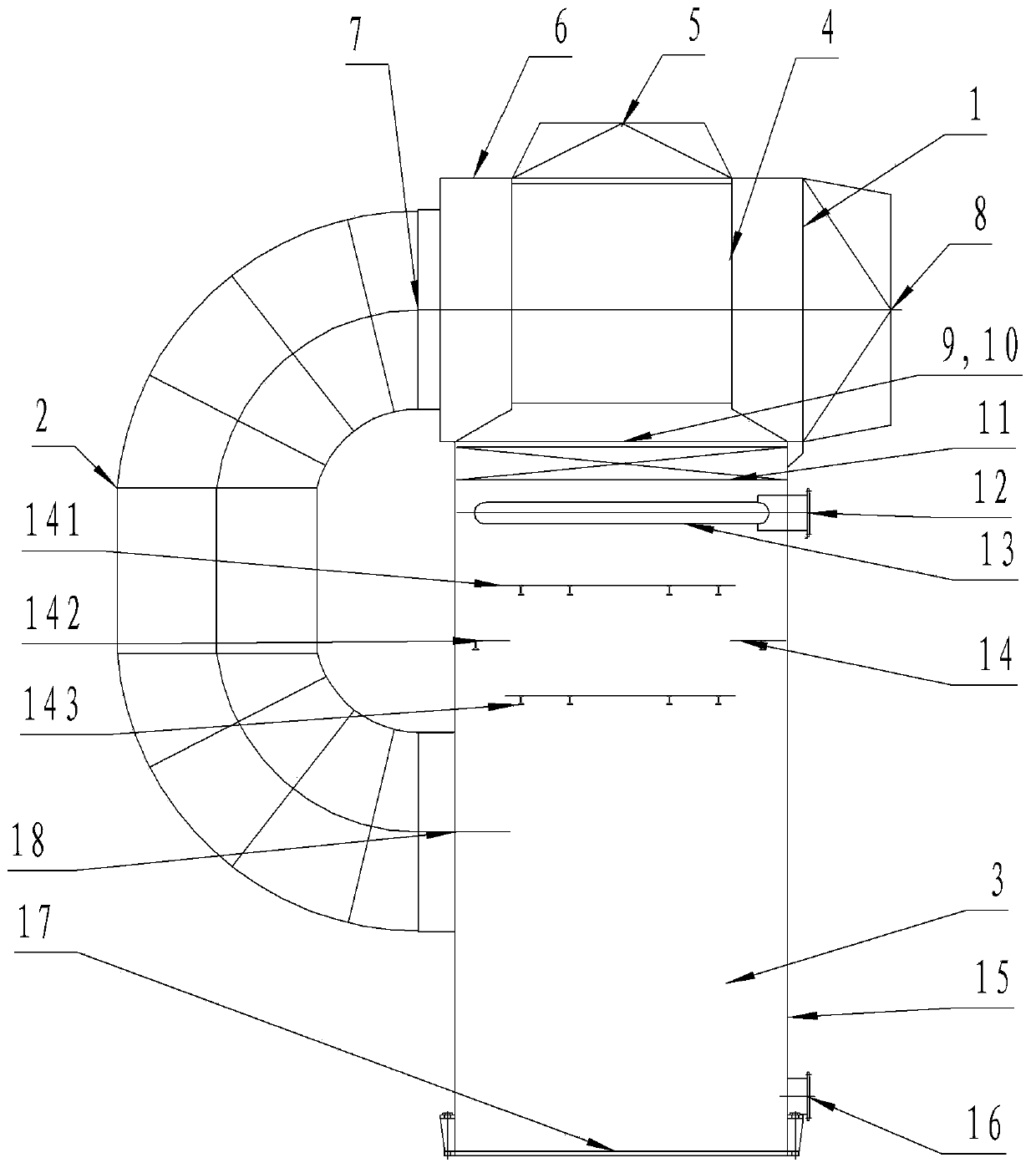

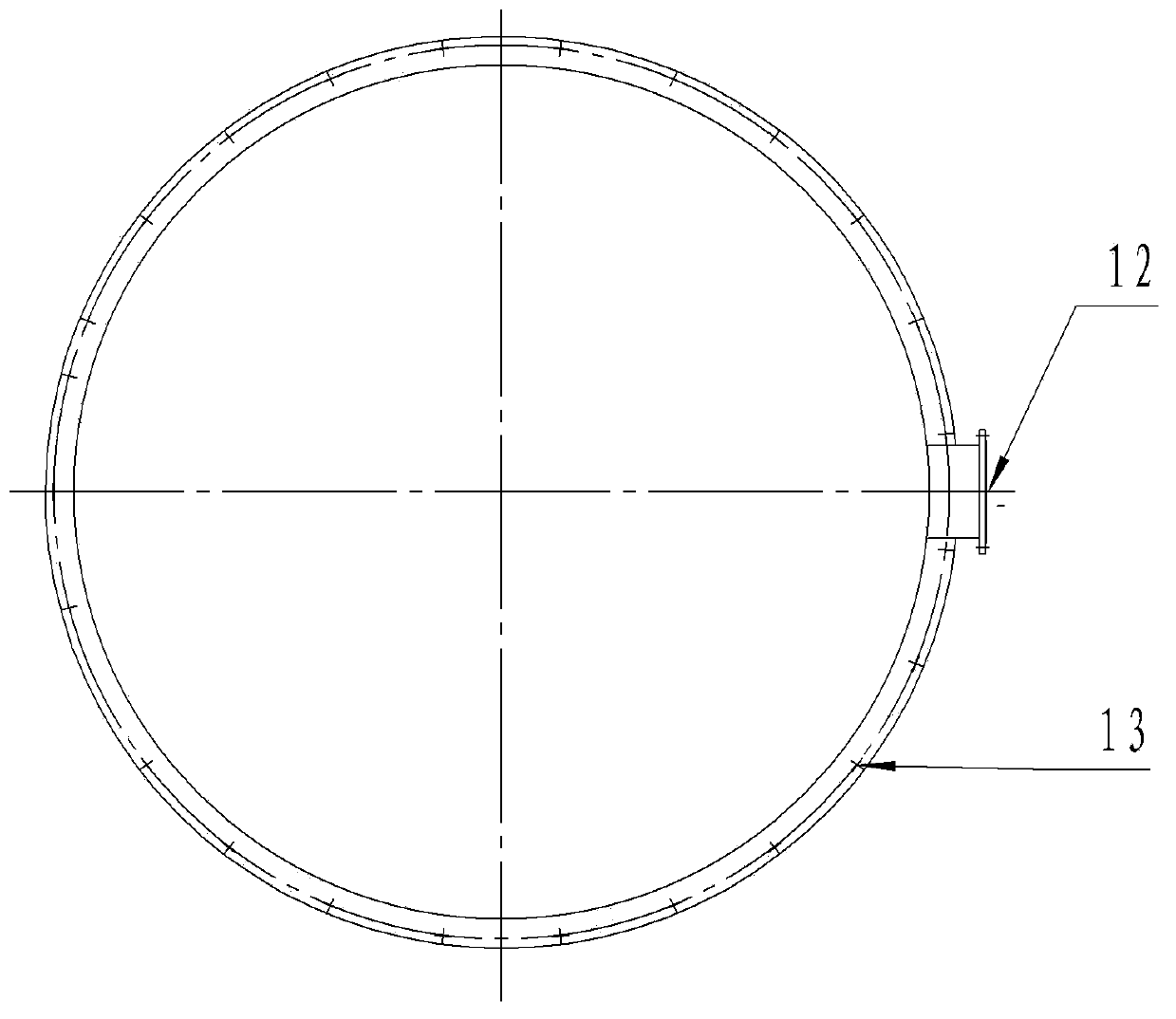

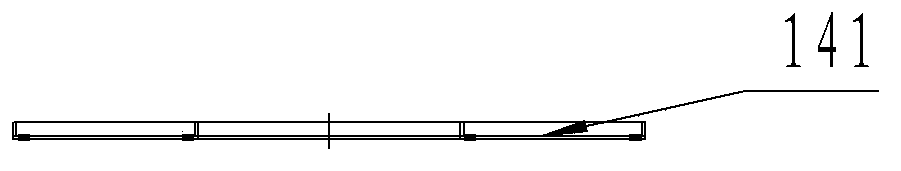

Nodular cast iron pipe preheating equipment

PendingCN111974650ASmall footprintImprove heating efficiencyPretreated surfacesCoatingsHeating efficiencyCast iron pipe

The invention provides nodular cast iron pipe preheating equipment, and belongs to the technical field of nodular cast iron pipes. The equipment comprises a transportation assembly, a sleeve and an induction coil. The transportation assembly is used for bearing the cast iron pipes and moving the cast iron pipes along with the axial direction of the cast iron pipes. The sleeve is used for forming achannel through which the cast iron pipes pass. The induction coil is fixedly arranged on the inner wall of the sleeve and is used for generating eddy currents in the cast iron pipes under the condition of electrification so as to heat the cast iron pipes. According to the nodular cast iron pipe preheating equipment, the cast iron pipes do not need to be heated by a large gas heating furnace, sothat the occupied space is saved; the heating efficiency of the cast iron pipes is improved, and uniform heating for the cast iron pipes can be ensured; an electromagnetic coil replaces gas to avoid hidden dangers of gas leakage and the like, heating for the cast iron pipes is controlled by controlling the induction coil to be power on or off, convenience and safety are higher, and energy waste isreduced.

Owner:XINXING DUCTILE IRON PIPES CO LTD

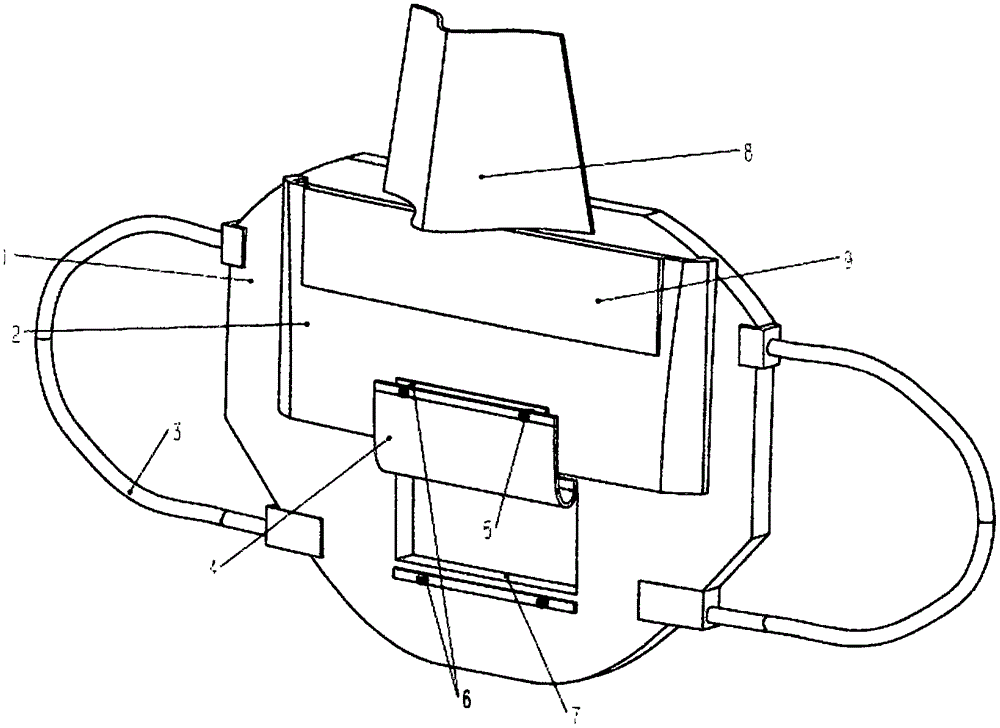

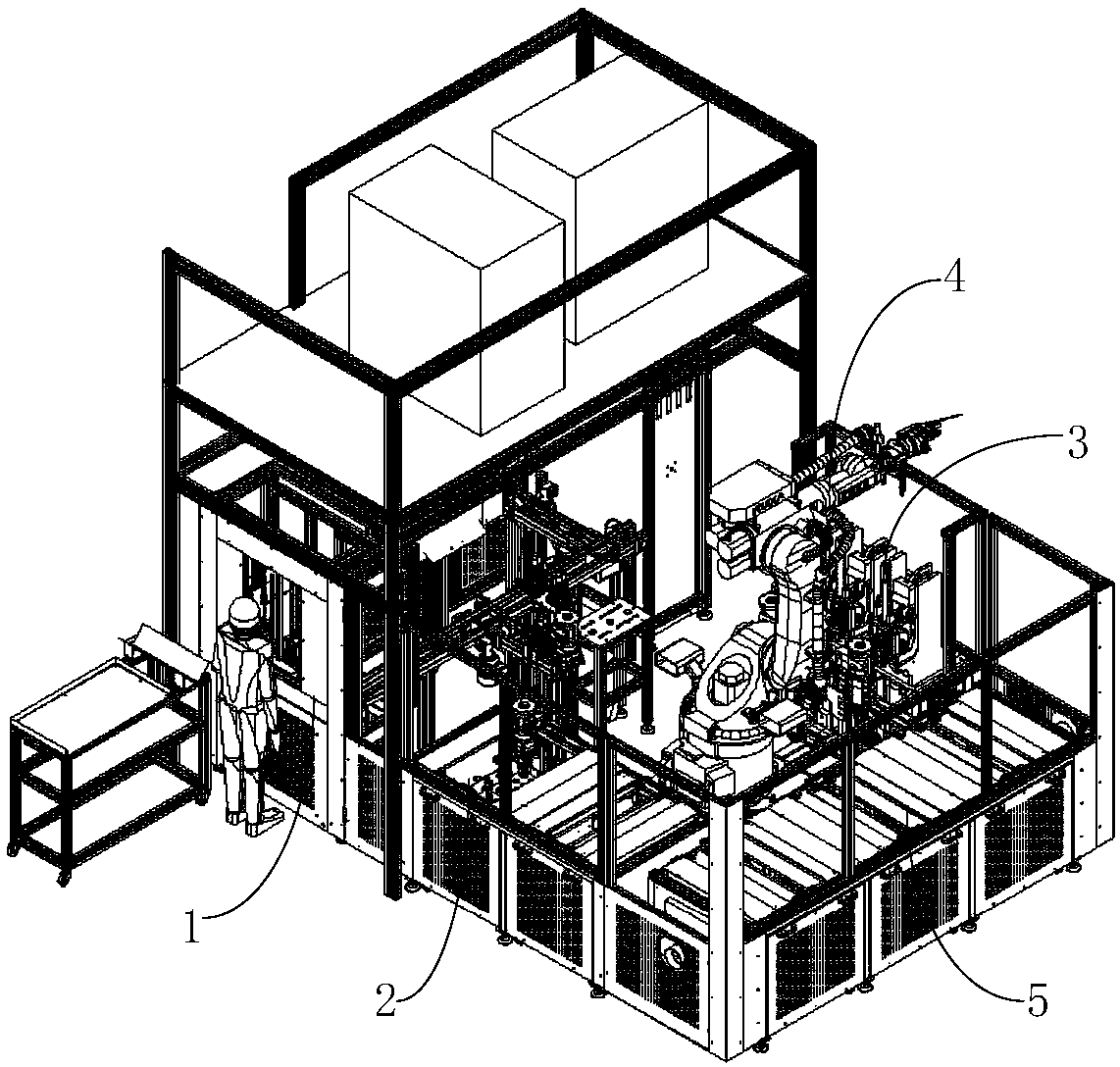

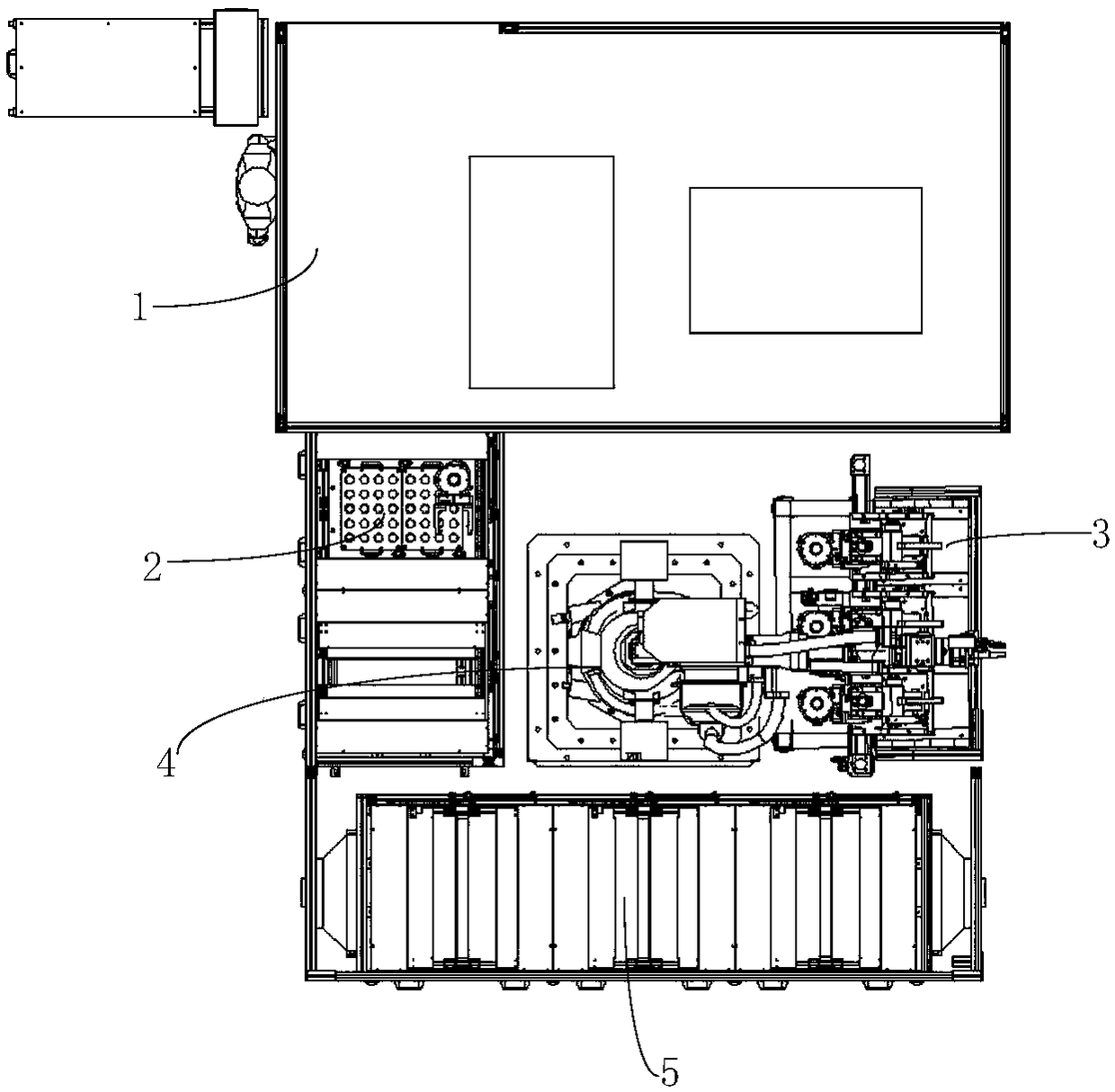

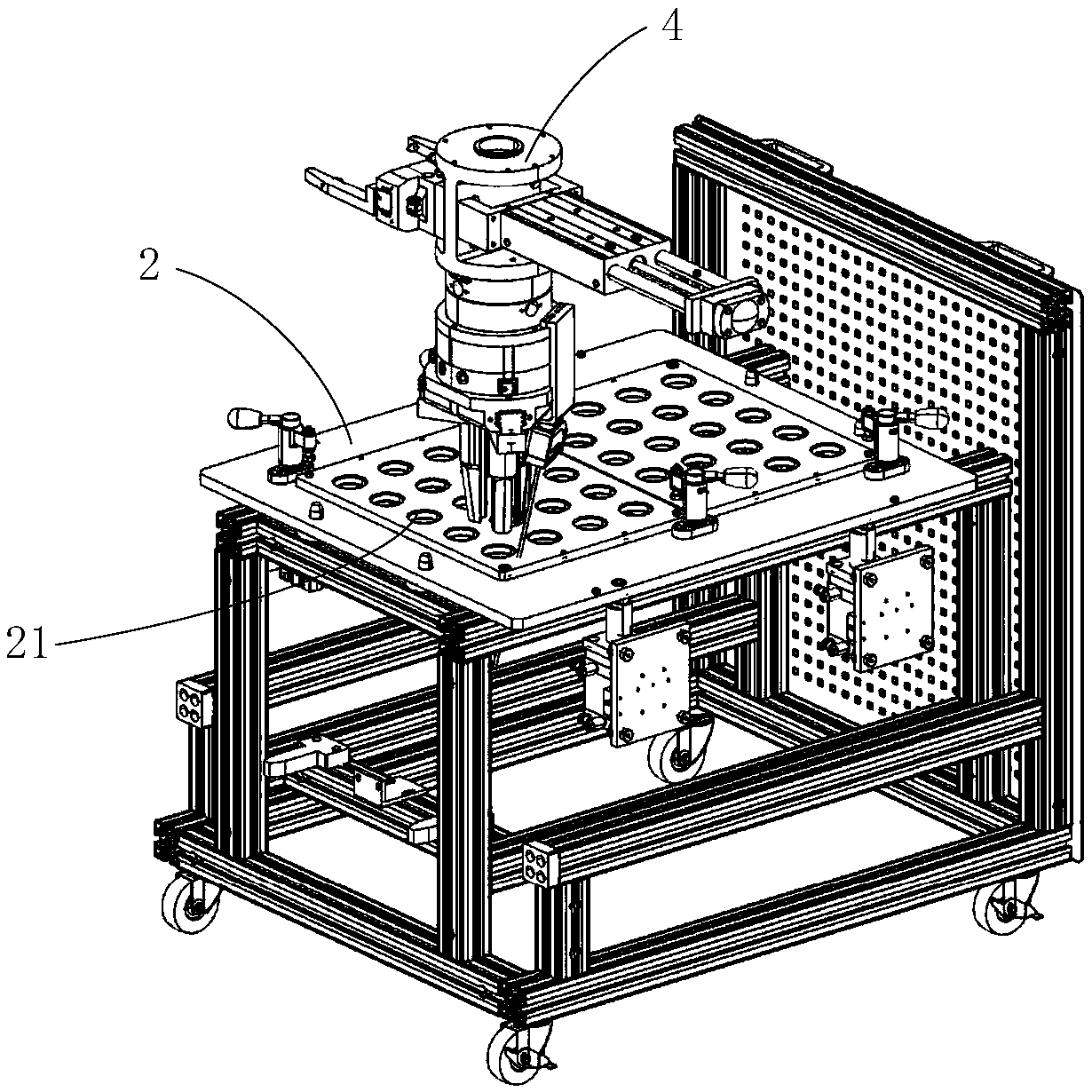

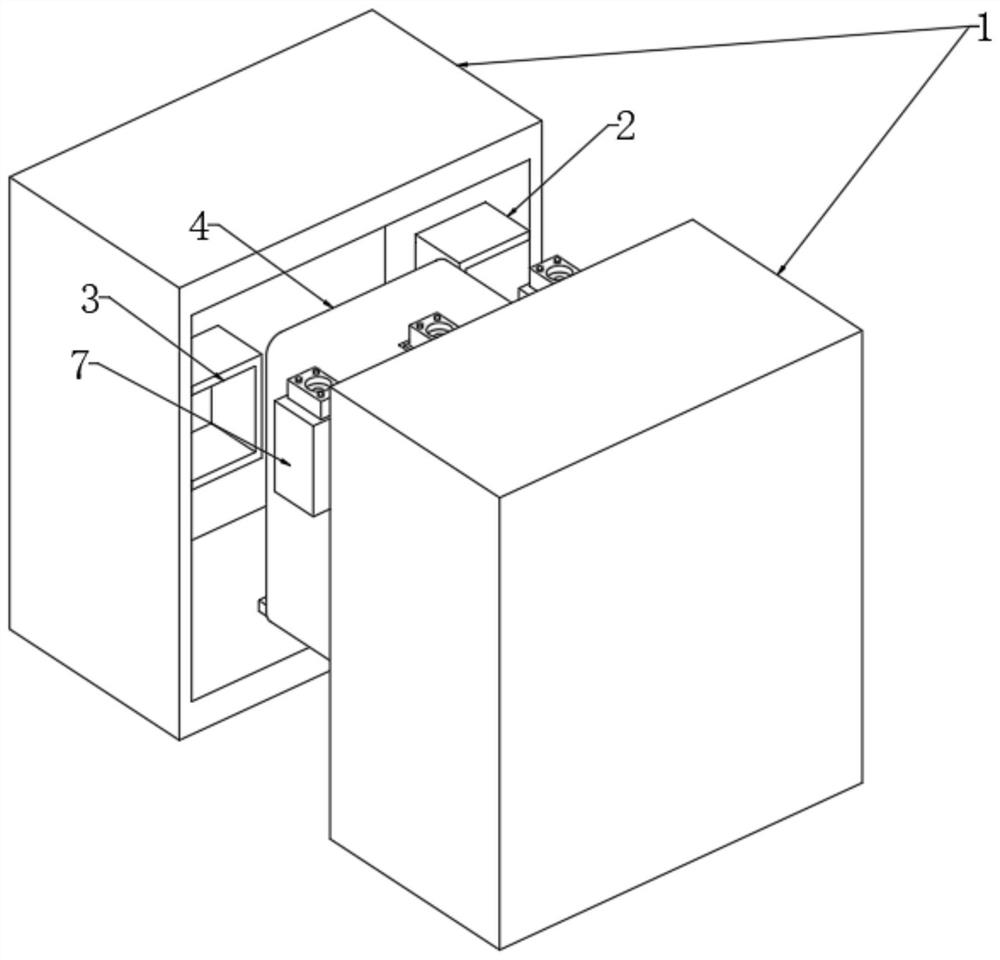

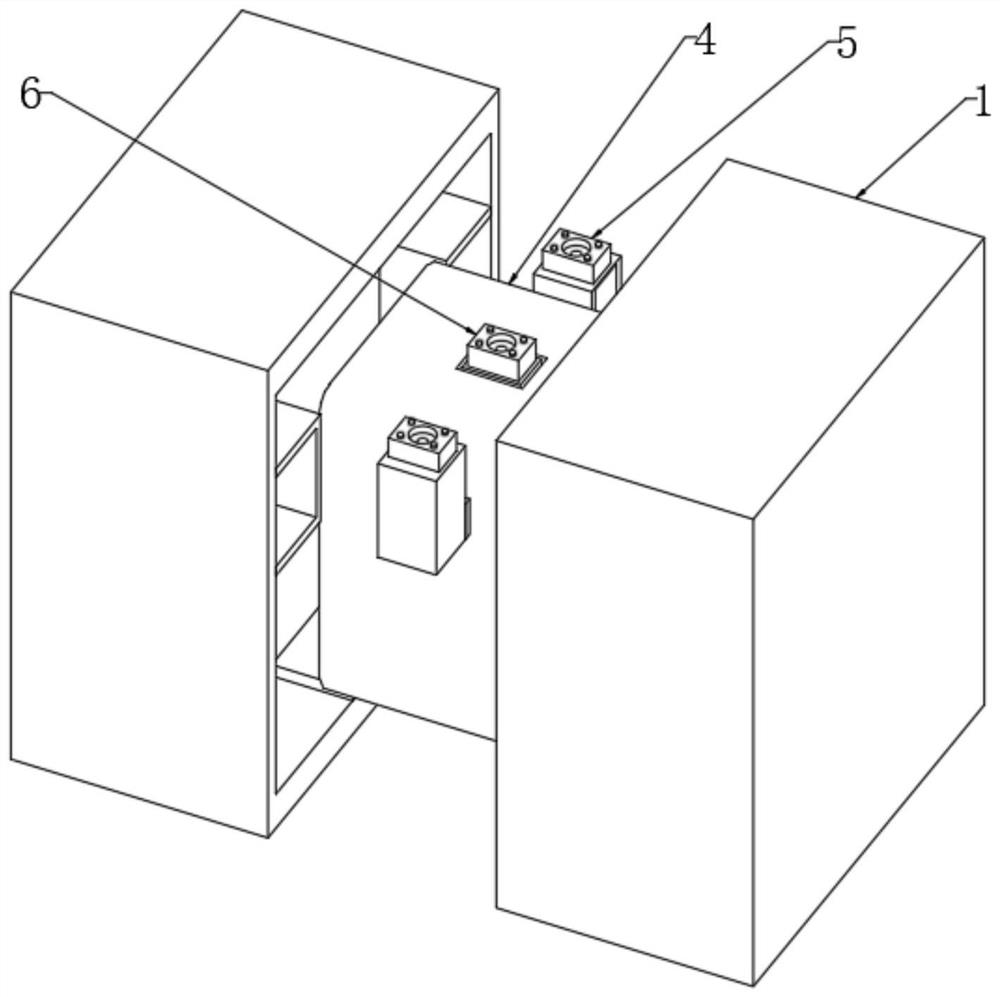

An assembly device and an assembly method of a rotor shaft of a motor

PendingCN109245458AAchieve self-heatingFast heatingManufacturing stator/rotor bodiesManipulatorEngineering

The invention provides an assembly apparatus and an assembly method of a rotor shaft of a motor. the assembly apparatus for motor rotor shafts includes manipulators, silicon steel sheet loading stations, a heating assembly station, and rotor shaft loading stations; a load station of silicon steel sheet comprises a manual assembly station, a pressing device and a jig cooling station. that heatingassembly station comprises a heating device, a heating rod is arranged on the heating device, the heat rod comprises at least one helical conductive member, and at least one metal rod is arranged in each helical conductive member. the electric motor rotor shaft assembly device of the invention combines the heating rod and the silicon steel sheet to form eddy current, and realizes the self-heatingof the silicon steel sheet by utilizing the eddy current induction principle. The heating mode not only has extremely fast heating speed, but also the heating rod itself does not heat, thus improvingthe safety of the operation of the device.

Owner:宁波均普智能制造股份有限公司

Water removal system of one-armed three-dimensional measurement marking instrument

InactiveCN105857255AEasy to operate and controlAchieve self-heatingTransparent/reflecting heating arrangementsVehicle cleaningWindscreen wiperHeating film

The invention discloses a water removal system of a one-armed three-dimensional measurement marking instrument. The water removal system of the one-armed three-dimensional measurement marking instrument comprises a swing arm, a support connected to one end of the swing arm, and a rubber scraping blade arranged on the surface of the support, wherein an electrothermal film is arranged between the support and the rubber scraping blade; a power interface of the electrothermal film is connected with an automotive power supply system; a power switch of the electrothermal film is arranged inside an automobile. The invention aims to provide the water removal system of the one-armed three-dimensional measurement marking instrument so as to solve the problem that a windscreen wiper is not convenient to use after being frozen in winter in the prior art, and achieve the aim that the windscreen wiper can heat automatically to de-ice.

Owner:API ZC PRECISION INSTUMENT CO LTD

Drying air duct system of drying equipment

InactiveCN113007985AAvoid lostIncrease profitDrying gas arrangementsDrying chambers/containersCold airInsulation layer

The invention discloses a drying air duct system of drying equipment, and particularly relates to the field of the drying equipment. The drying air duct system comprises a drying chamber, a desiccation chamber and an evaporator chamber, wherein a drying chamber air inlet and a drying chamber air outlet are formed in one side of the drying chamber; a transmission box and a motor box are mounted on one side of the drying chamber; the inner wall of the drying chamber is lined with a thermal insulation layer; drying nets are mounted inside the drying chamber; an indoor unit and a dehumidifier are mounted inside the desiccation chamber; an air exhaust opening is formed in the top end of the desiccation chamber; and an outdoor unit and a fresh air duct are mounted inside the evaporator chamber. The drying air duct system of the drying equipment has the advantages of improving the heat exchange efficiency by virtue of a plate heat exchanger, reducing the temperature of high-temperature humid air by virtue of cooled external cold air, condensing the high-temperature humid air to recover moisture and increasing the temperature of the cold air at the same time to obtain dry cold air, eliminating the need for an additional cooling system for cooling the high-temperature humid air and the need for an additional heat source for heating the cold air, realizing self-heating, fully realizing comprehensive utilization of energy, and achieving the purposes of environmental protection and energy conservation.

Owner:常州市茂宏干燥设备有限公司

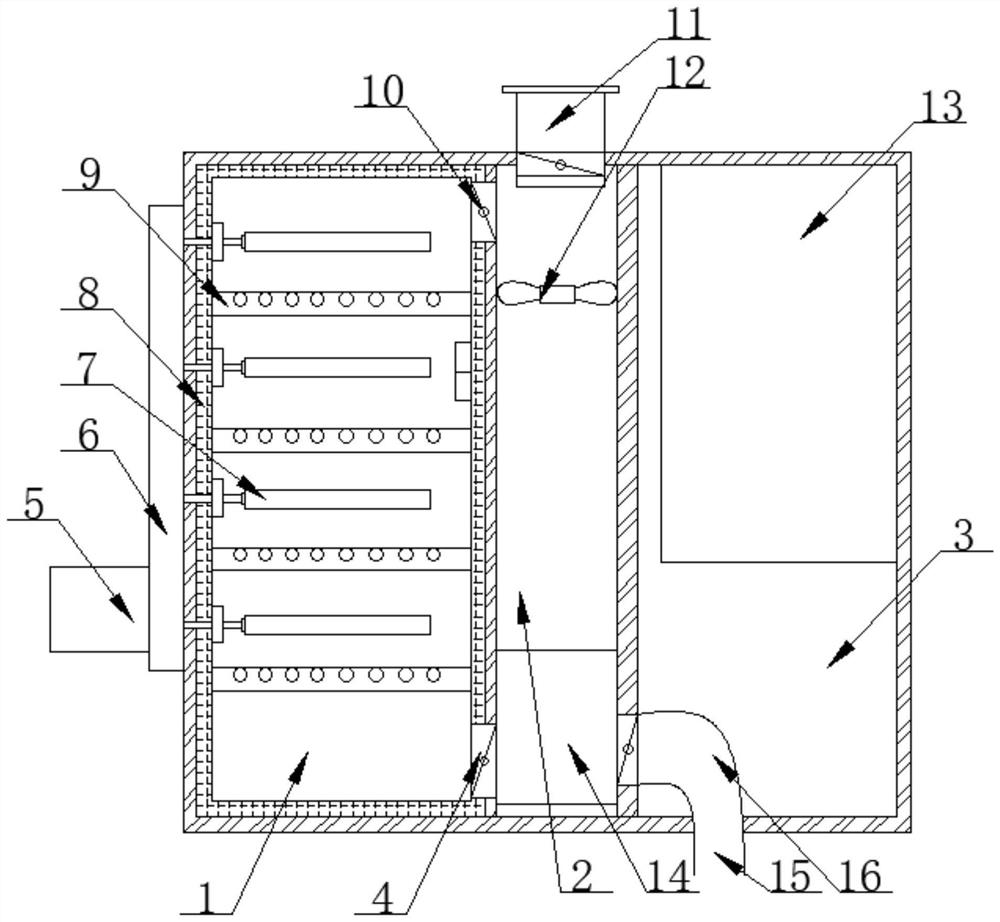

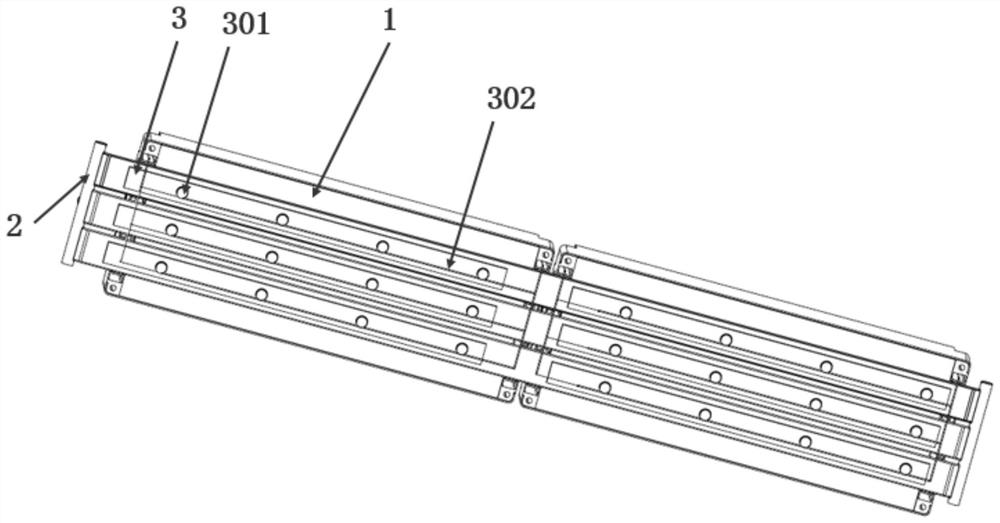

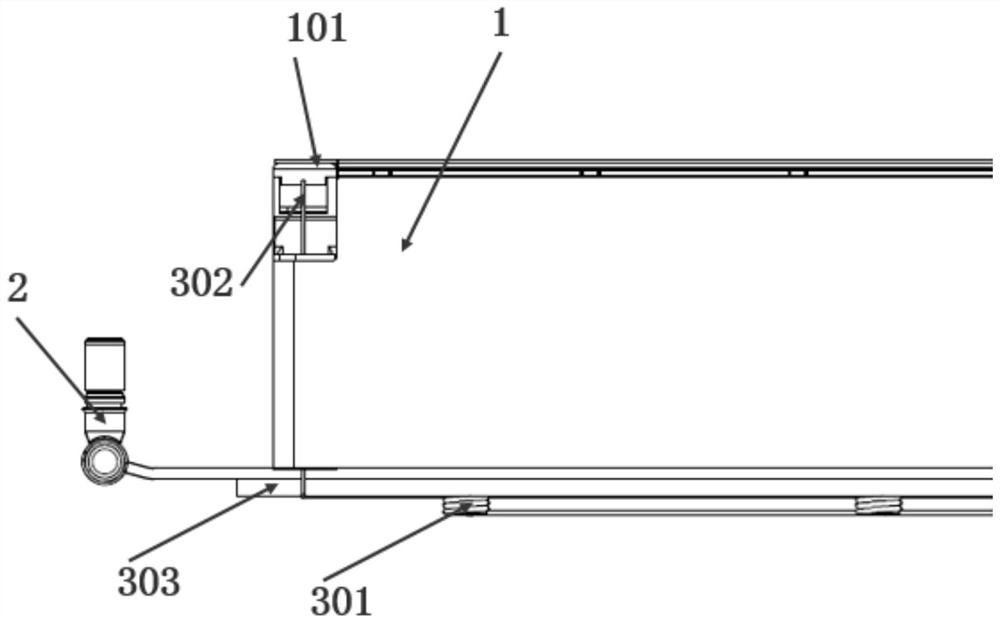

Self-heating battery thermal management control device, battery assembly, electric vehicle and method

PendingCN114335816AAchieve self-heatingImprove thermal management efficiencySecondary cellsPower batteryHeat management

The invention relates to a self-heating battery thermal management control device, a battery assembly, an electric vehicle and a method. Comprising a battery module, a cooling system, a self-heating system and a heat conduction structure, the cooling system is arranged at the lower end of the battery module; the self-heating system is fixed at the lower end of the cooling system and connected with positive and negative electrodes of the battery module to form a loop; a heat conduction structure is arranged between the battery module and the cooling system. IGBT switches in the positive and negative electrodes of the switch control high-frequency on-off with the self-heating high-voltage wiring harness through a battery BMS: after high-frequency on-off is formed, electric field high-frequency change exists in the self-heating high-voltage wiring harness, and a large amount of heat is generated by induction current generated in the heater due to an electromagnetic induction phenomenon through spiral lines around the heater; therefore, the heating function of the heating fixing plate can be achieved, and the heating fixing plate can heat cooling liquid in the cooling system. According to the invention, efficient cooling of the power battery and automatic heating of the battery pack can be realized, and the overall thermal management efficiency of the power battery is improved.

Owner:CHINA FIRST AUTOMOBILE

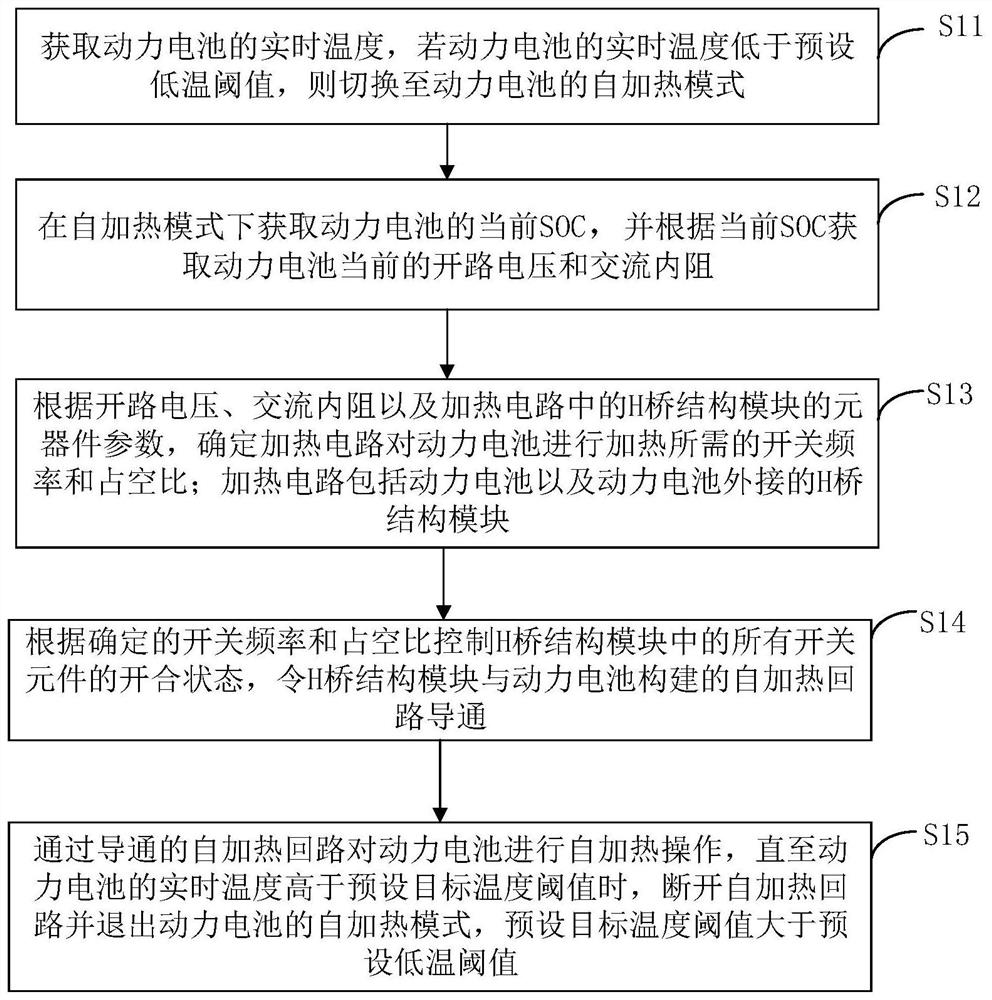

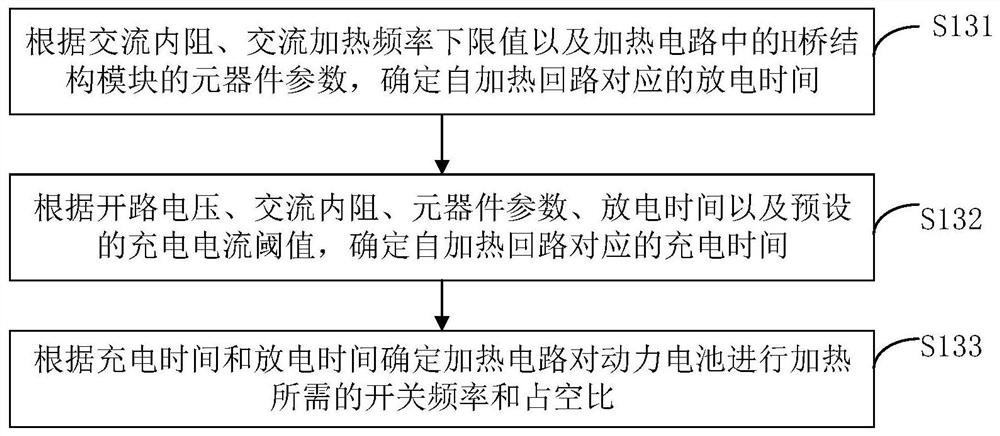

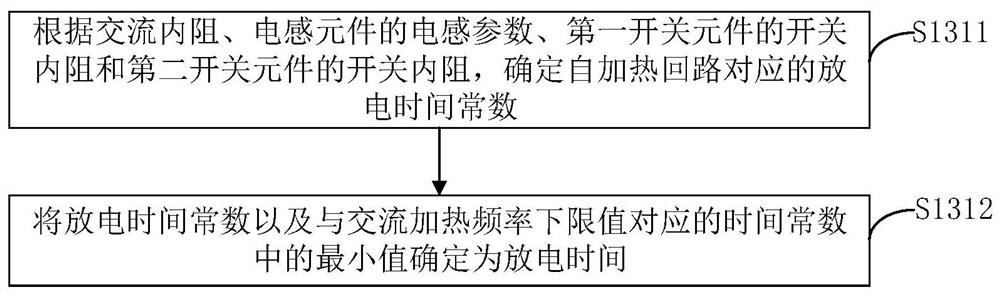

Power battery self-heating control method and system and automobile

PendingCN113904026AAchieve heatingAchieve self-heatingSecondary cellsVehicular energy storageAutomotive engineeringPower battery

The invention discloses a power battery self-heating control method and system and an automobile. The method comprises the steps: when the real-time temperature of the power battery is lower than a preset low-temperature threshold value, switching to a self-heating mode of the power battery; after the current open-circuit voltage and the alternating-current internal resistance of the power battery are obtained according to the current SOC, determining the switching frequency and the duty ratio needed by the heating circuit for heating the power battery; controlling the opening and closing states of all switching elements in the H-bridge structure module according to the determined switching frequency and duty ratio, so that a self-heating loop between the H-bridge structure module and the power battery is conducted; carrying out self-heating operation on the power battery through the conducted self-heating loop until the real-time temperature of the power battery is higher than a preset target temperature threshold value, disconnecting the self-heating loop and quitting the self-heating mode of the power battery. According to the invention, the power battery is heated through the periodic current which is generated by the self-heating loop and can be continuously kept at a relatively high level, so that the heating efficiency is improved.

Owner:BYD CO LTD

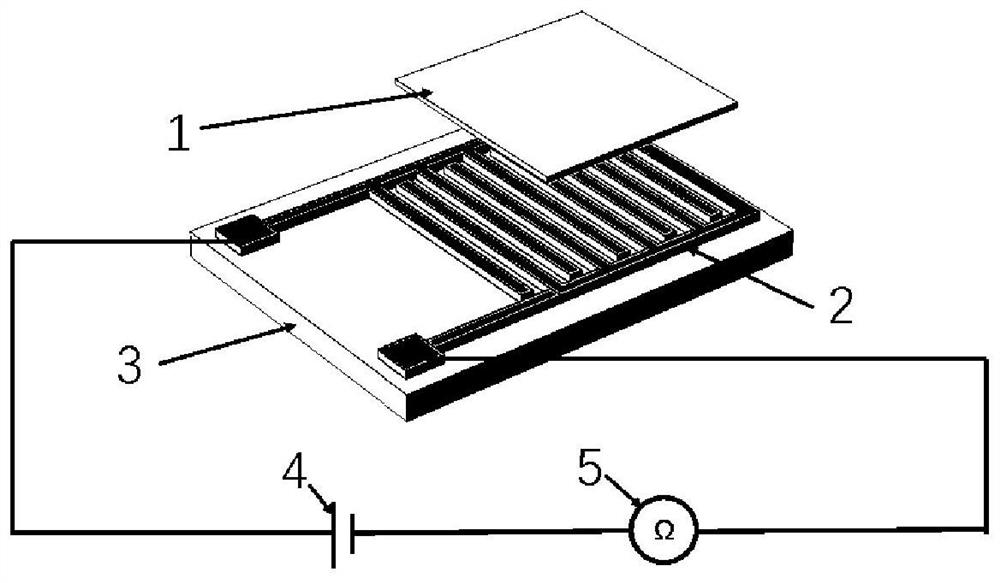

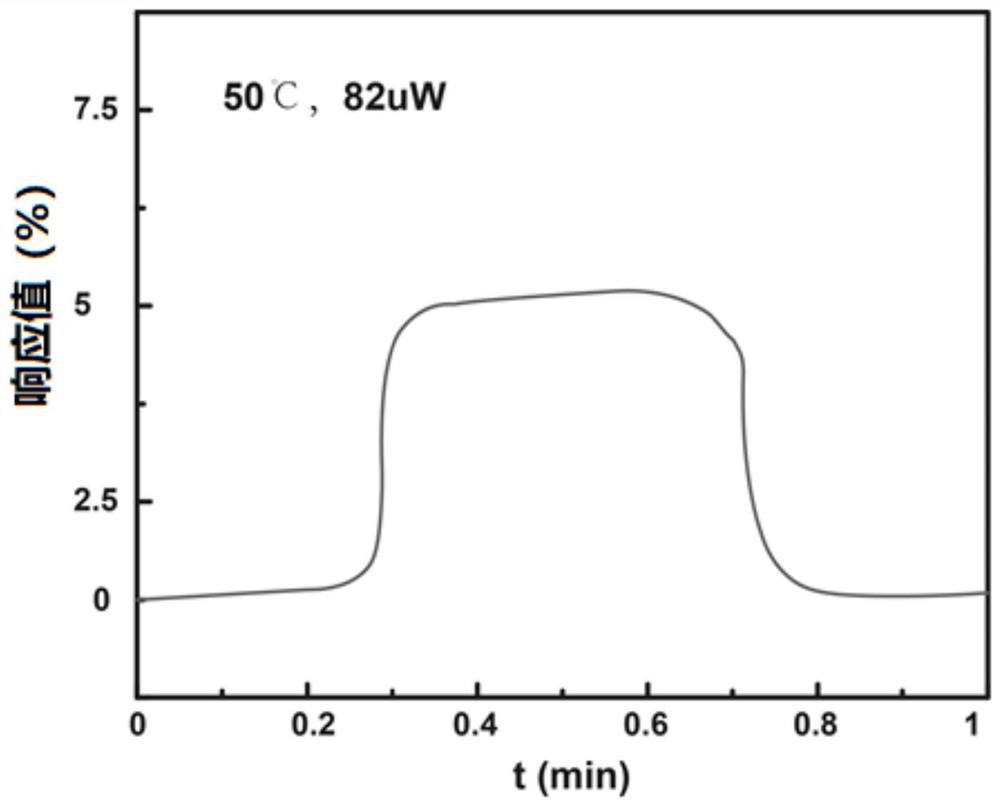

Self-heating gas sensor, gas sensitive material and preparation method and application thereof

PendingCN113511646ALower resistanceReduce power consumptionMaterial nanotechnologyFullerenesPhysical chemistryOxide composite

The invention relates to the field of materials, and discloses a gas-sensitive material and a preparation method and application thereof, and a Joule principle-based self-heating gas sensor using the gas-sensitive material. The gas-sensitive material is a carbon material and metal oxide composite nano material formed by compounding a carbon material and a metal oxide, wherein the content of the carbon material in the carbon material and metal oxide composite nano material is 0.5-20 wt%, and the content of the metal oxide is 80-99.5 wt%. The gas-sensitive material disclosed by the invention is relatively low in resistance, can respond to various gases at a relatively low working temperature, does not need external heating, realizes self-heating only by Joule heat of a measuring circuit, and is relatively low in power consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self-heating overhead in-tank pump valve system

InactiveCN108869232AAvoid electric shockFree from pollutionPositive displacement pump componentsPump controlThreaded fastenerEngineering

The invention relates to a self-heating overhead in-tank pump valve system which comprises a motor, a pump and an asphalt pipe. The motor is mounted at the top of an asphalt tank through a supportingtube and a supporting flange and located outside the asphalt tank, and the supporting tube and the supporting flange are connected through a threaded fastener. The pump and the asphalt tube are mounted at the top of an inner cavity of the asphalt tank through a bearing cavity. The bearing cavity is provided with a flange edge and is fixed on the top inner wall of the asphalt tank through a bolt. An output shaft of the motor is connected with an input shaft of the pump through a coupling. An inner cavity of the supporting tube is filled with a heat insulation material and is internally providedwith fan blades, and the heat insulation material covers the coupling. According to the self-heating overhead in-tank pump valve system, the motor, the pump and the asphalt tube are all mounted at the top of the asphalt tank, and the pump and the asphalt tube are arranged in a built-in mode; the asphalt tank is usually not fully filled, and the pump and the asphalt tube are packed in the bearingcavity and located at the top of the inner cavity of the asphalt tank, so that the pump and the asphalt tube are prevented from being contaminated by asphalt; the rising hot gas of the asphalt can heat the pump and the asphalt tube, so that self heating is achieved, and extra energy sources are not wasted.

Owner:WUHAN CHANGSHIZHU ROAD MAINTENANCE EQUIP

Cleaning device of automobile front window surface

InactiveCN107757556AAchieve self-heatingDeicing and thawingVehicle cleaningSurface cleaningEngineering

The invention discloses a cleaning device of an automobile front window surface. The cleaning device comprises a swing arm, a support connected to one end of the swing arm and a rubber scraper installed on the surface of the support. An electric heating film is arranged between the support and the rubber scraper. A power interface of the electric heating film is connected with an automobile powersupply system. A power-on switch of the electric heating film is arranged in an automobile. The cleaning device of the automobile front window surface is provided so that the problem that a windscreenwiper cannot be used conveniently after being frozen in winter in the prior art can be solved, and the purpose that the windscreen wiper can be automatically heated, deiced and unfrozen is achieved.

Owner:邱晓霞

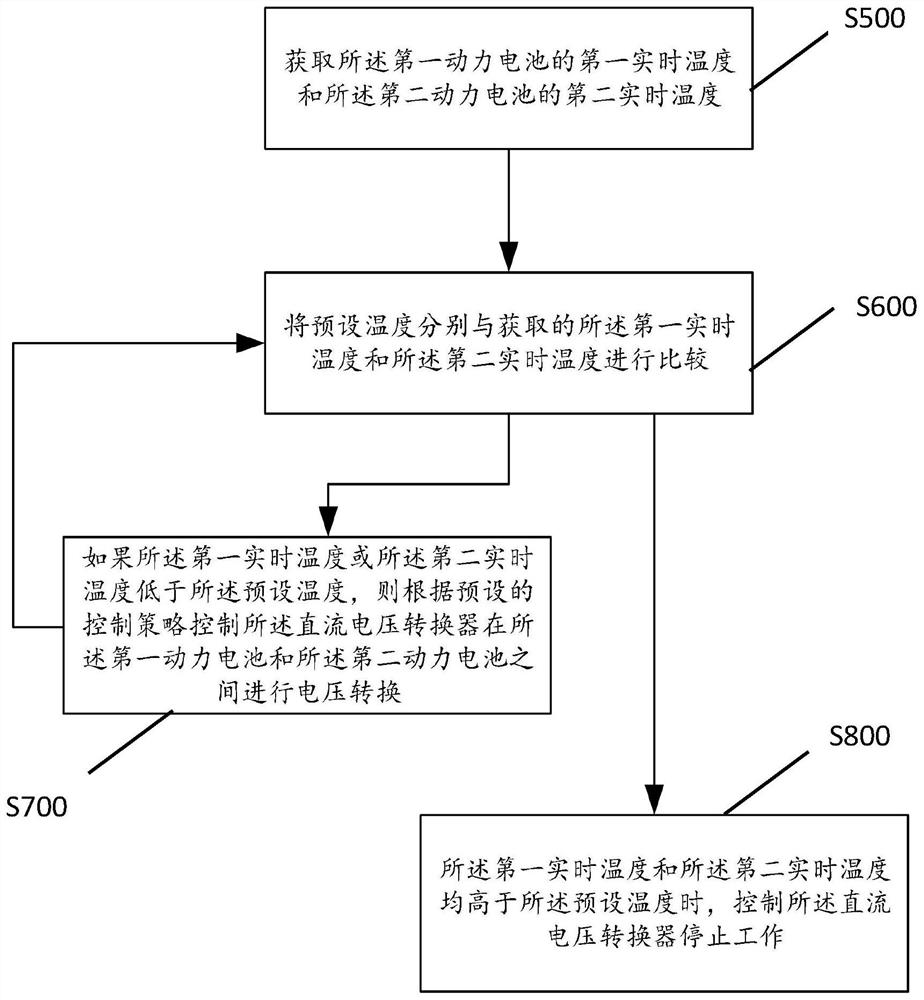

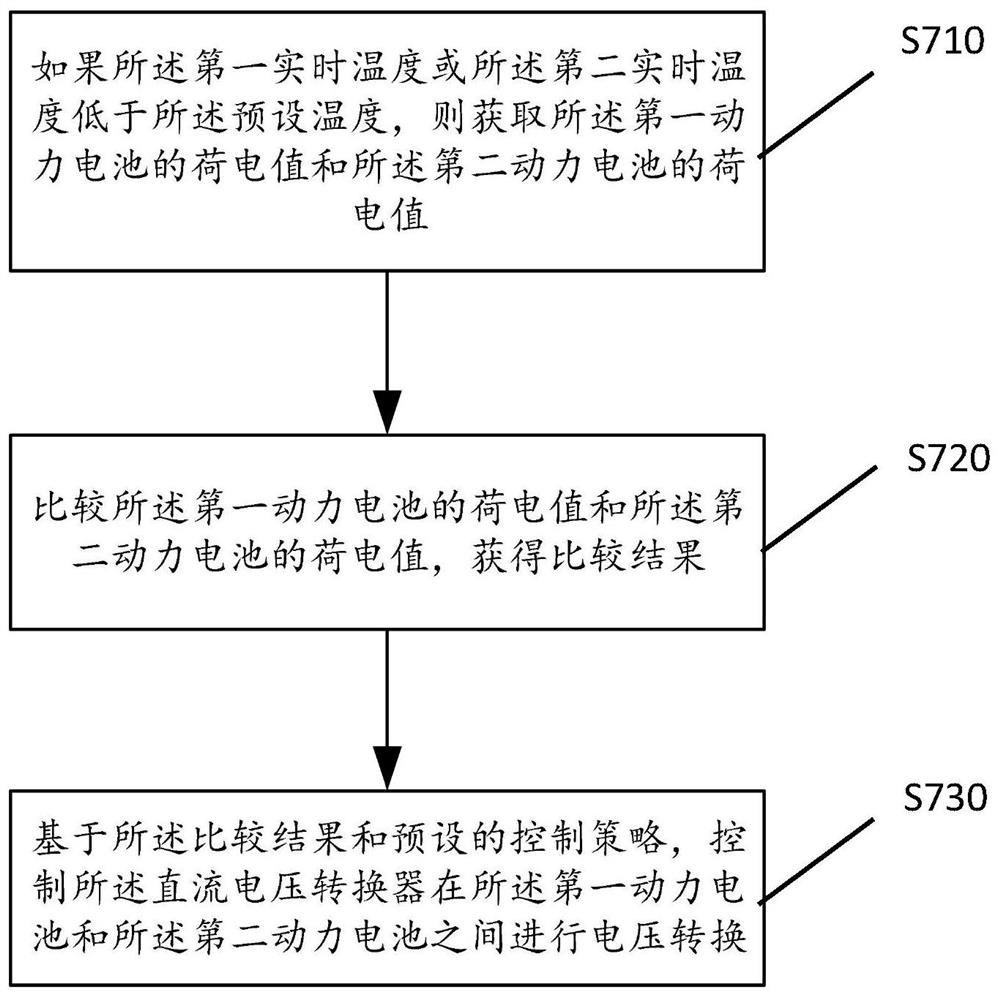

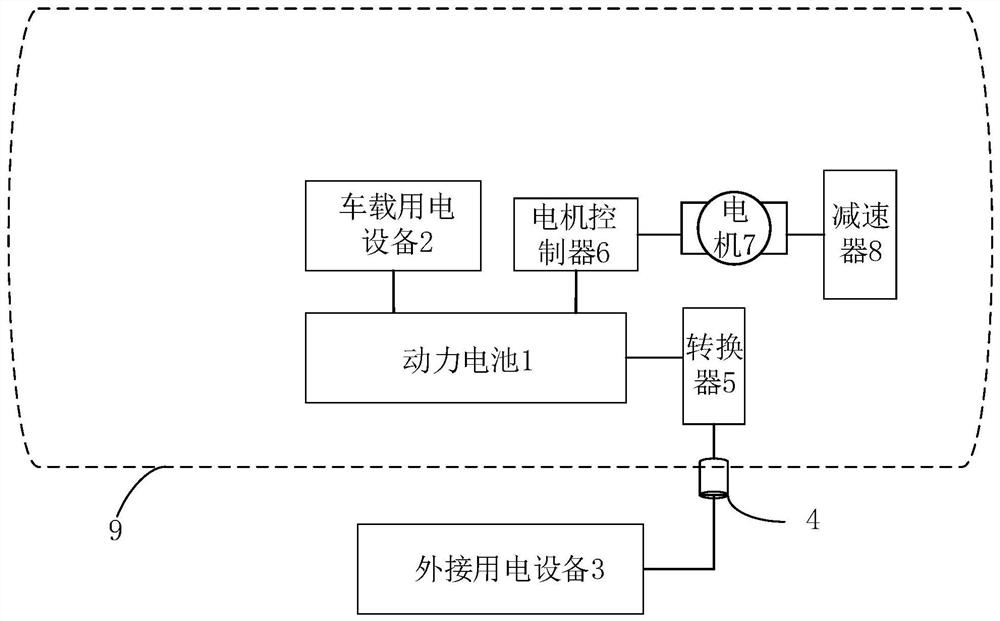

A power battery self-heating method and its system and automobile

ActiveCN111162351BAchieve self-heatingSolve the cooling problemSecondary cells charging/dischargingPower batteryConverters

The invention discloses a power battery self-heating method, its system and an automobile. The method is used in a power battery self-heating system. The system includes a first power battery, a second power battery, a DC voltage converter and a vehicle control system. device, wherein the first power battery and the second power battery are batteries with different types of charging media, and the method is executed by a vehicle controller. The invention utilizes the difference in charging and discharging performance of power batteries with different charging media at low temperatures, and uses the heat generated inside the battery cell during charging and discharging to realize self-heating of the battery, which saves costs, reduces system complexity, and improves reliability. At the same time, the real-time adjustment of the heating power is realized by controlling the charging and discharging current, and then the heating time can be controlled according to the needs.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

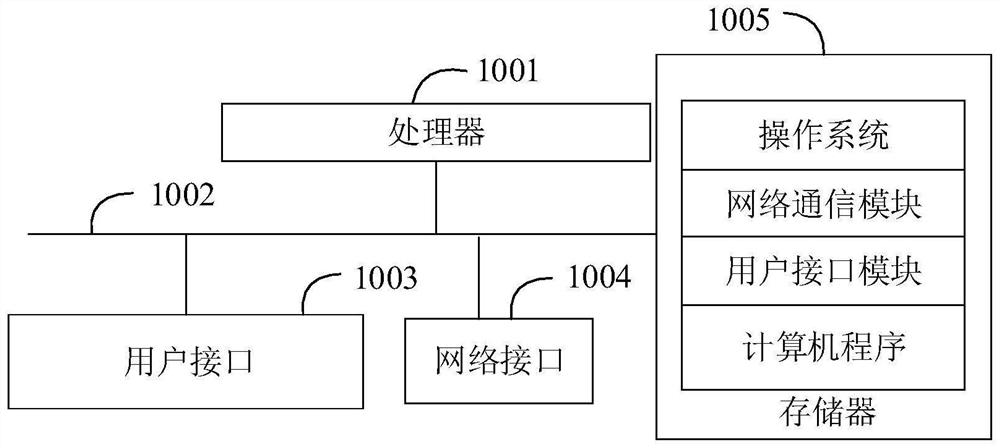

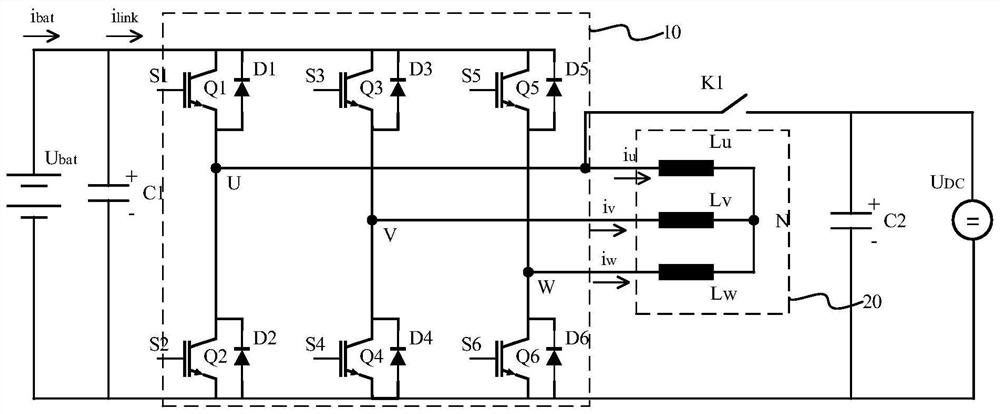

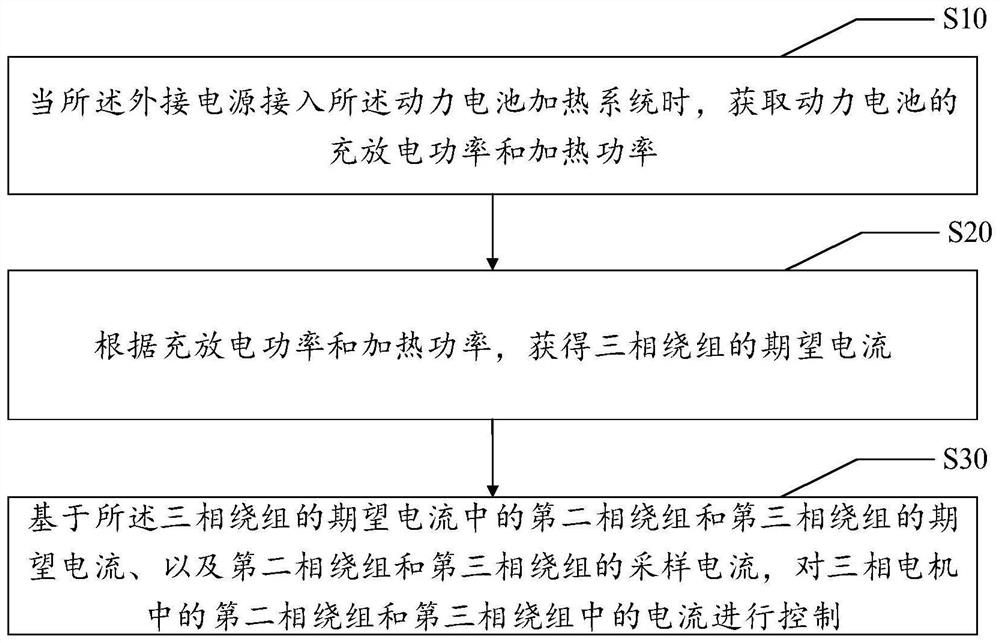

Power battery heating control method, electric vehicle and medium

PendingCN114801894ARealize convenient chargingImprove car experienceBattery/fuel cell control arrangementControl devicesElectric vehicleControl theory

The invention discloses a power battery heating control method, an electric vehicle and a medium, and the method comprises the steps: obtaining the charging and discharging power and heating power of a power battery when an external power supply is connected to a power battery heating system; the expected current of the three-phase winding is obtained according to the charging and discharging power and the heating power; and controlling the current in the second phase winding and the third phase winding in the three-phase motor based on the expected current of the second phase winding and the third phase winding in the expected current of the three-phase winding and the sampling current of the second phase winding and the third phase winding. Through an external power supply and multiplexing a circuit structure during boost charging, the effect of controlling the charging and discharging current of the power battery is achieved, the problem that the self-heating effect of the power battery cannot be carried out when the electric quantity of the power battery is exhausted or is low is solved, and the heating efficiency of the power battery is improved.

Owner:SUZHOU INOSA UNITED POWER SYST CO LTD

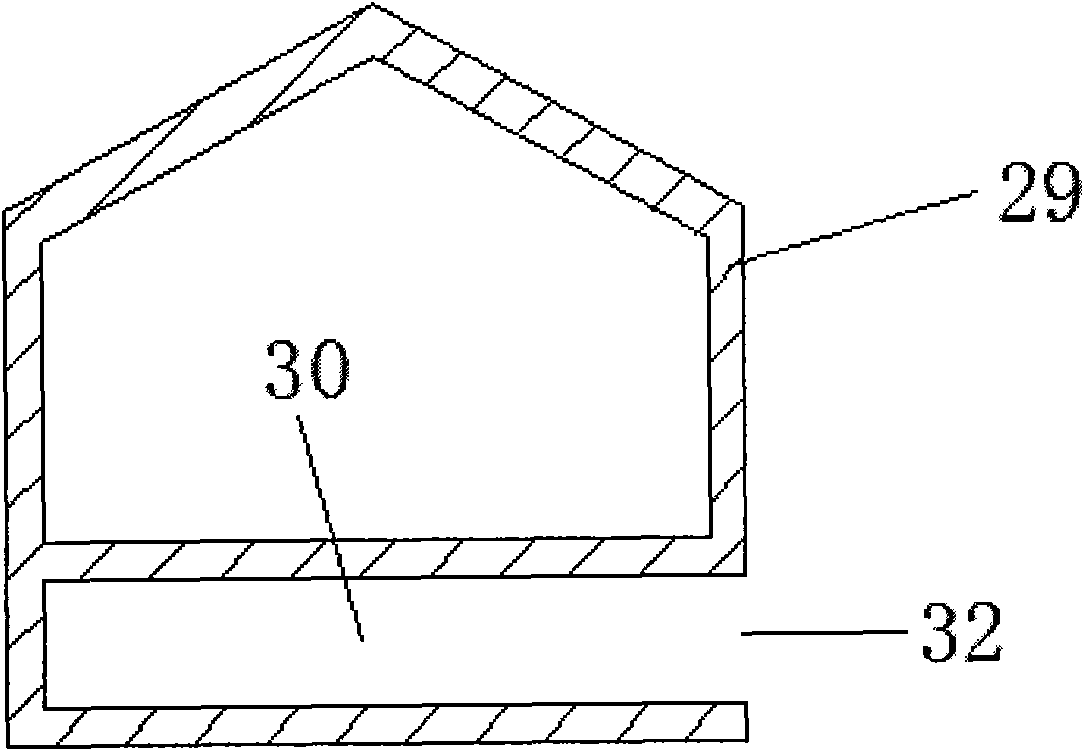

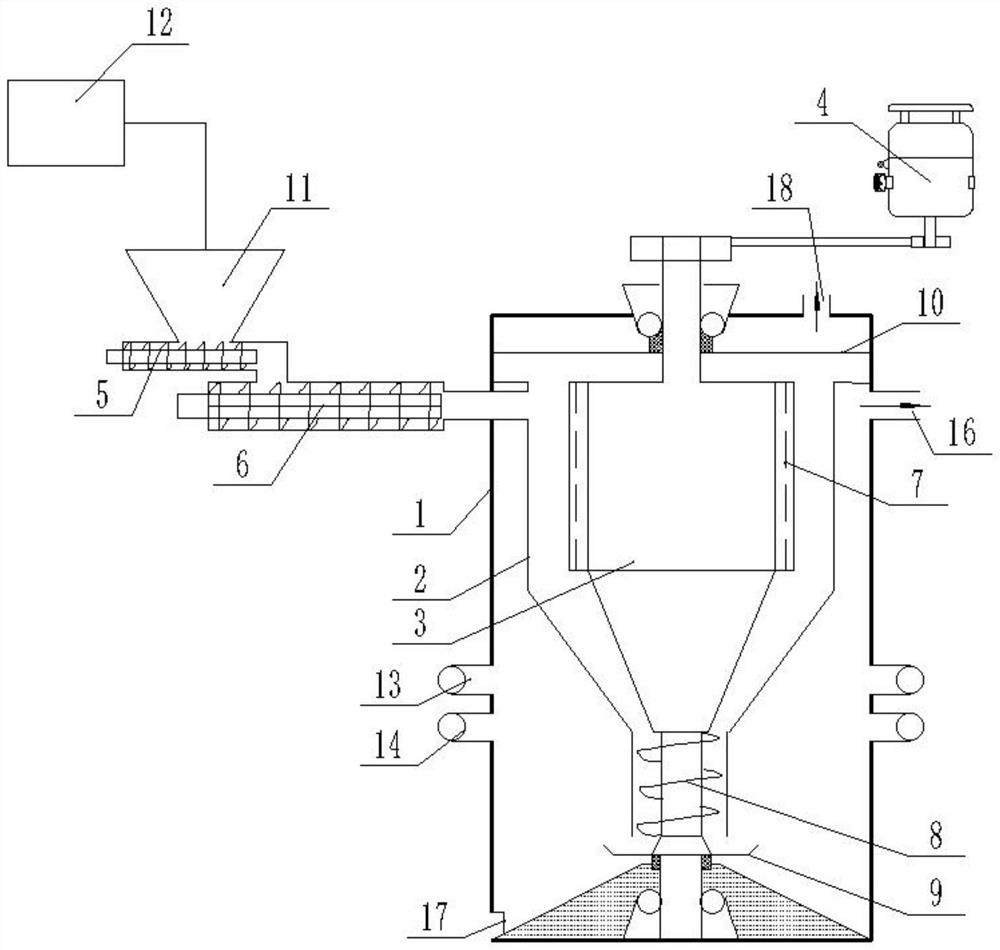

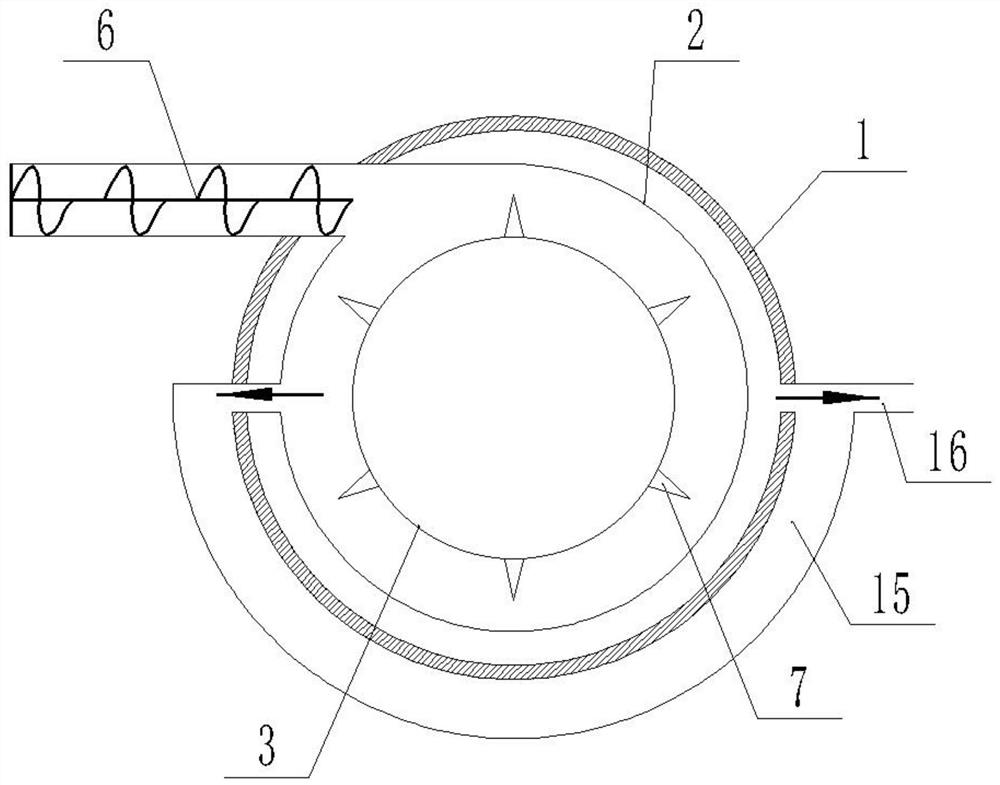

Self-heating vertical axial flow roller ablation pyrolytic reaction device

ActiveCN113025354AReduce moistureReduce oxygen contentBiofuelsEnergy inputThermodynamicsHeat carrier

The invention relates to a self-heating vertical axial flow roller ablation pyrolytic reaction device, and belongs to the technical field of renewable energy utilization. The device comprises a shell and a reaction cylinder arranged in the shell, a rotating shaft is arranged in the reaction cylinder, the upper end of the rotating shaft is connected with a variable frequency motor through a belt, the rotating speed of the rotating shaft can be adjusted, a first-stage spiral feeder and a second-stage spiral feeder are arranged outside the shell, the discharging end of the first-stage spiral feeder is communicated with the feeding end of the second-stage spiral feeder, and the discharging end of the second-stage spiral feeder is communicated with the upper part of the reaction cylinder. The device has the beneficial effects that the pyrolysis efficiency is improved, pushing of carrier gas and heating of a heat carrier are not needed in the reaction process, and the heating and cooling loads of the carrier gas are greatly reduced. Self-heating in the pyrolysis process is achieved, and effective utilization of energy is fully achieved. Different taper angles can adapt to the change of the size of the material, powdery, granular and other biomass raw materials can be pyrolyzed, and gas-solid separation and biomass pyrolysis can be better achieved.

Owner:SHANDONG UNIV OF TECH

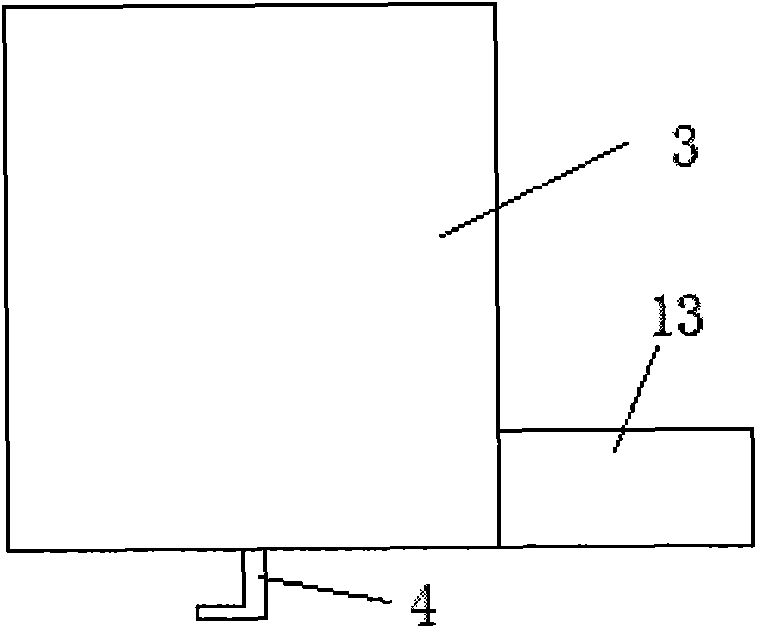

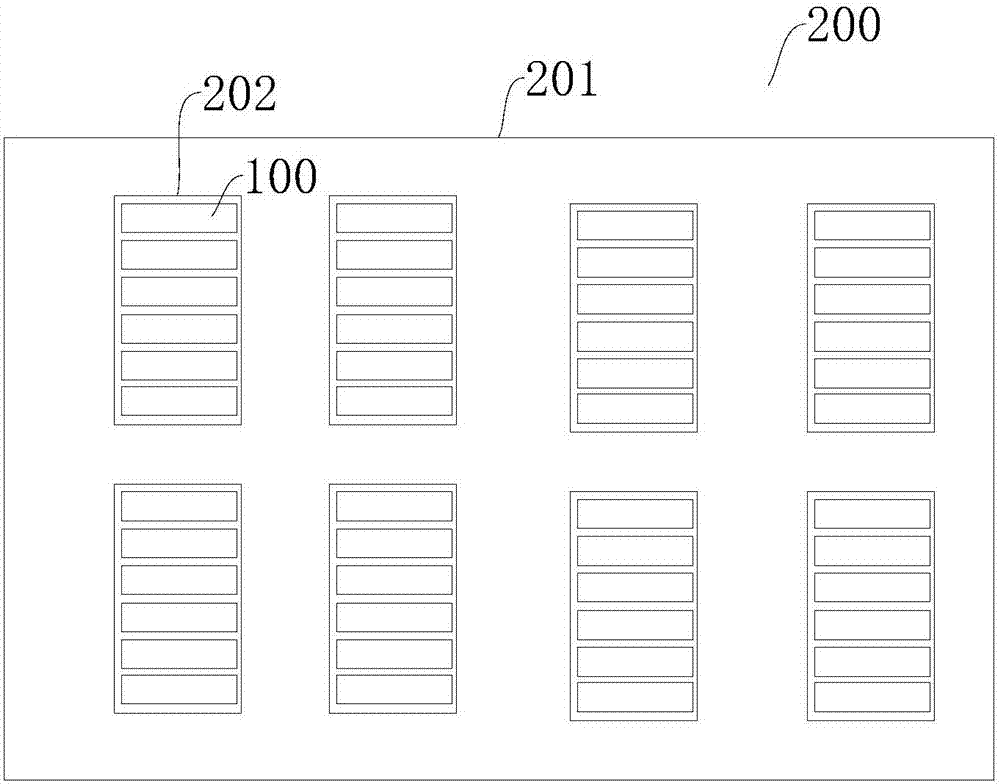

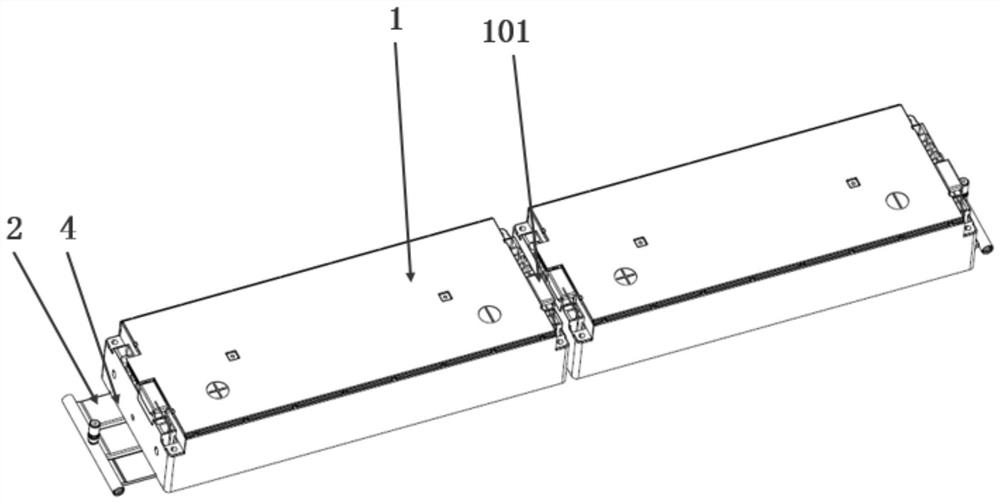

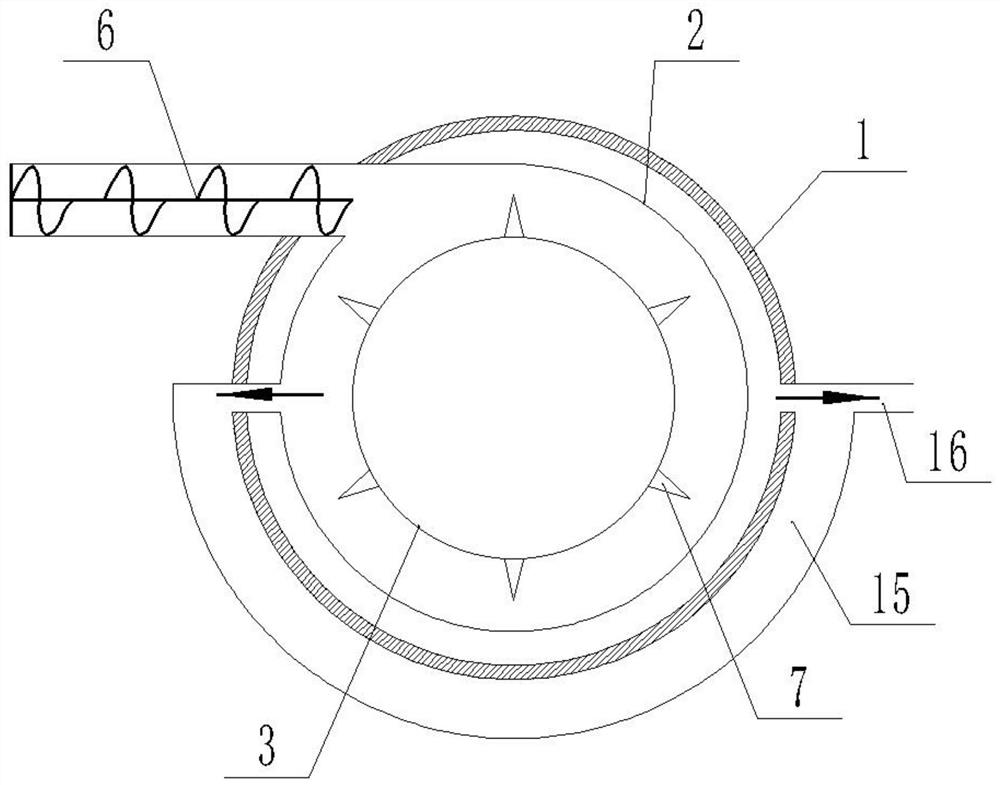

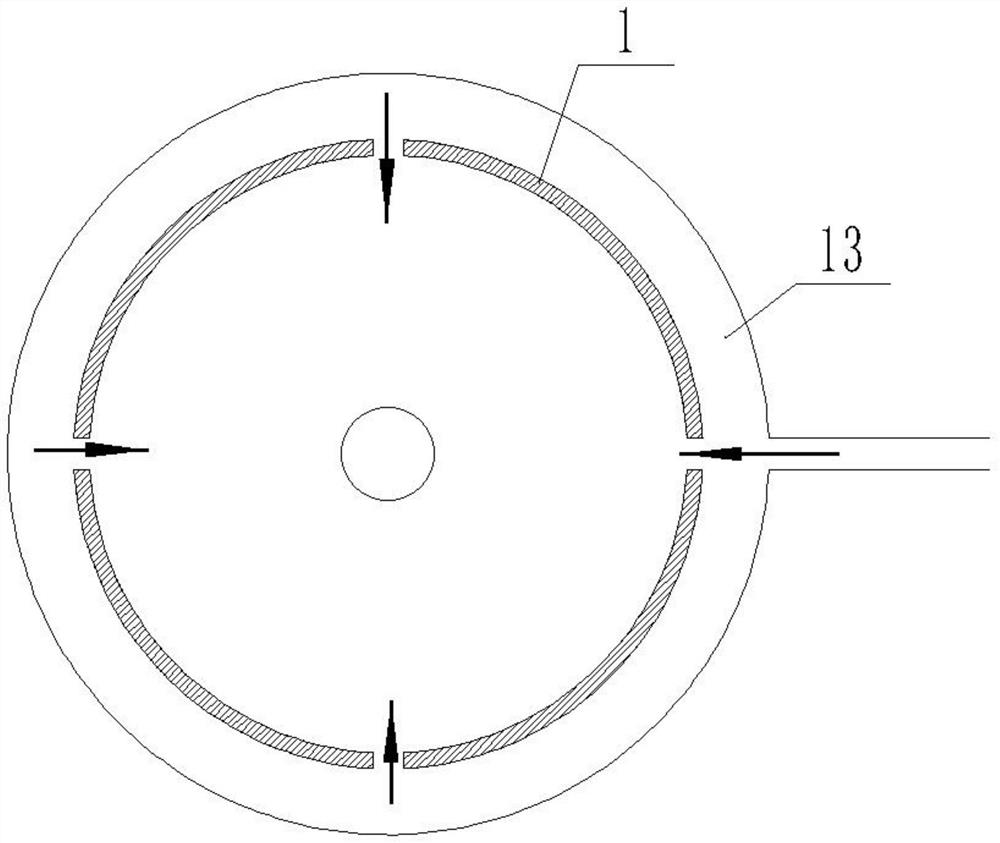

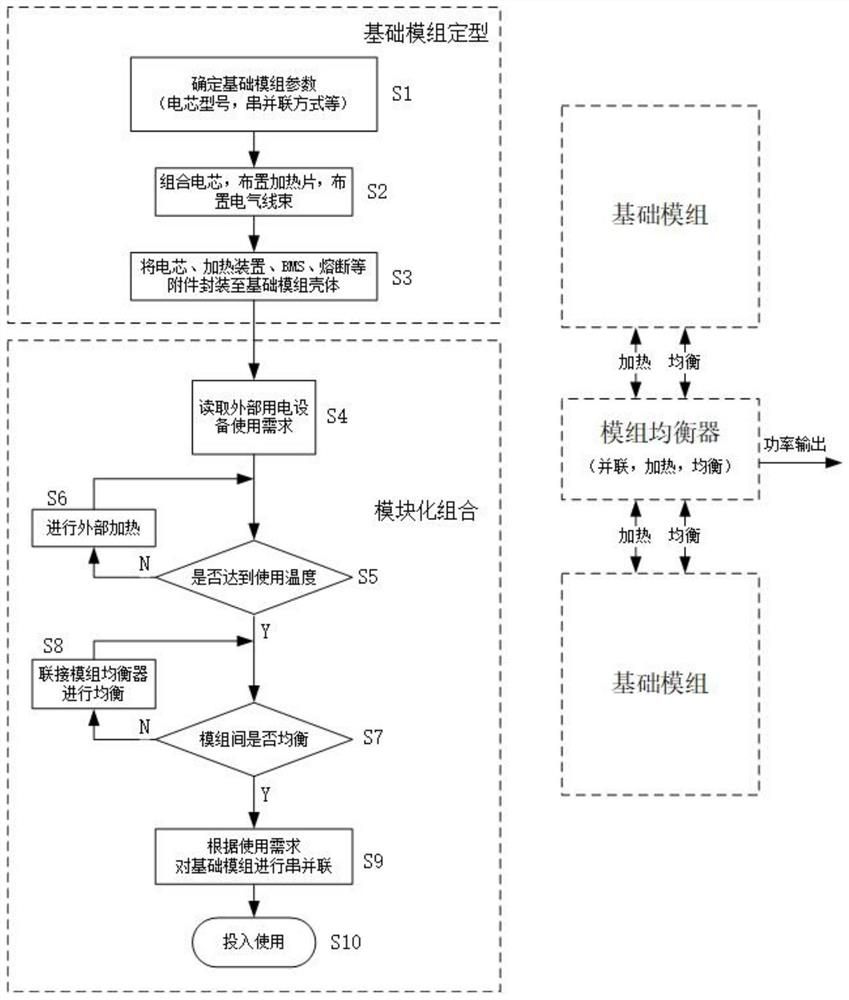

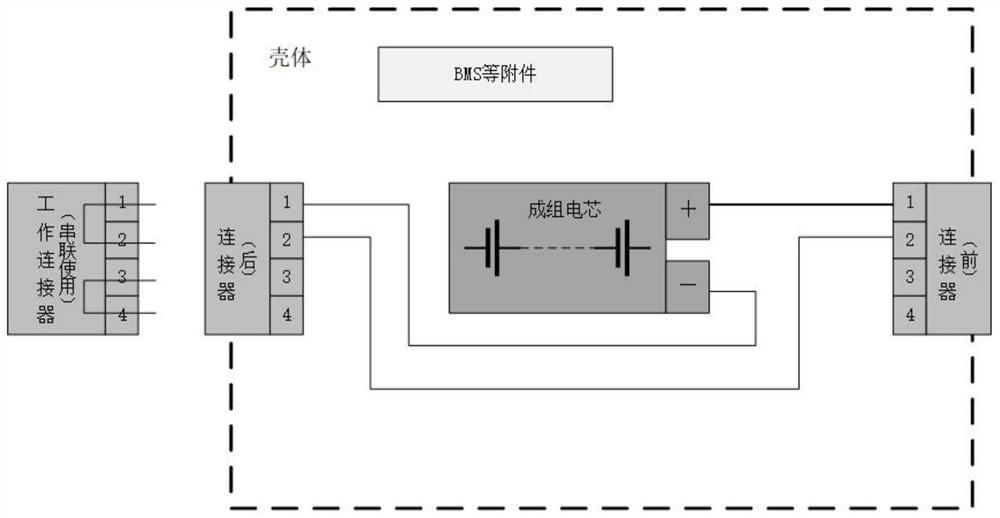

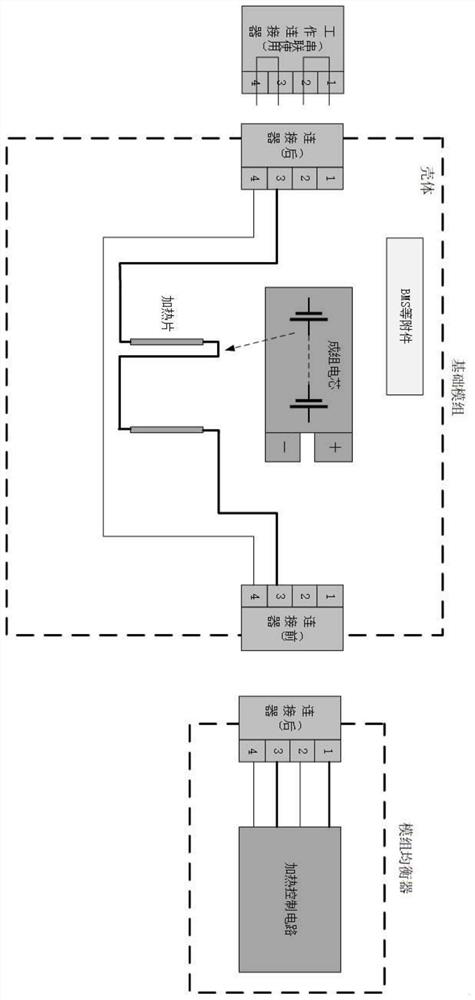

Rapid combination application method of lithium ion battery

PendingCN113054234ALow costSolve complex problemsAssembling battery machinesFinal product manufacturePhysicsProcess engineering

According to a rapid combination application method of ae lithium ion battery, accessories such as a battery cell, a heating sheet and a battery management system which are combined are packaged in a shell to serve as a basic module, and the basic modules can be rapidly combined through a connector and a module equalizer on the shell so that the problem that the form of the current battery module is complex is solved; and complex wiring operation is not needed. By utilizing the method, various types of battery modules with various parameters can be combined, the method is suitable for scenes with various power demands, theoretically, the battery modules suitable for all power demands can be further combined by adjusting the battery core combination form of the basic module, and the cost is greatly saved. The module equalizer designed in a matched mode can heat the modules under a low-temperature condition, and equalization can be carried out in time when the states of the modules are inconsistent.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

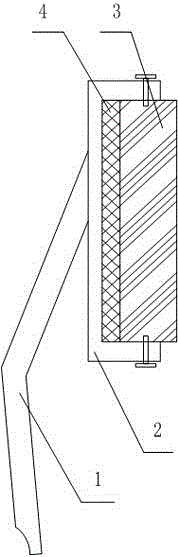

A battery self-heating and heat preservation device

ActiveCN110299580BFix Heating ProblemsEfficient self-preheating and heat preservationSecondary cellsPower batteryThermal insulation

The invention discloses a battery self-heating heat preservation device. The battery self-heating and heat preservation device includes: a power battery cell, a heating diaphragm, an airgel shell, a temperature sensor and a switch circuit; the outer surface of the power battery monomer is covered with a heating diaphragm; the outer surface of the heating diaphragm Covered with an airgel shell; the temperature sensor is set on the power battery unit, and the temperature sensor is set between the power battery unit and the heating diaphragm; the temperature sensor and the switch circuit are connected through the signal line; the power battery unit, the heating The diaphragm and the switch circuit are connected to each other in pairs. The switch circuit is used to connect the power battery unit and the heating diaphragm to form a heating circuit; for heating. The battery self-heating and heat preservation device provided by the present invention enables the battery to be efficiently self-preheated and heat-preserved under low temperature conditions, thereby improving the charging and discharging performance of the battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

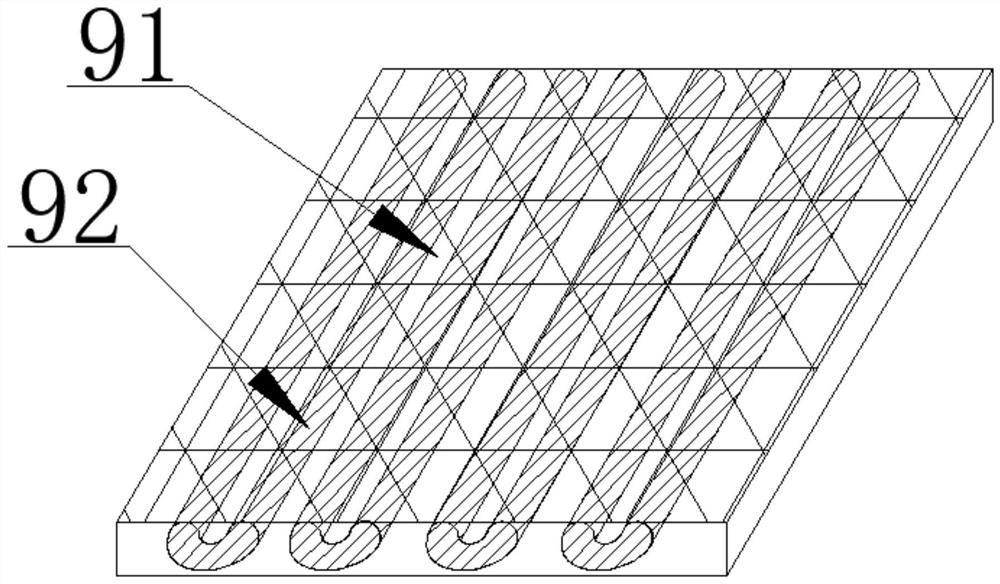

Self-heating full-contact type air dehumidifying device

ActiveCN103363591AIncrease temperatureImprove heat transfer efficiencyEnergy recovery in ventilation and heatingLighting and heating apparatusCold airEngineering

The invention discloses a self-heating full-contact type air dehumidifying device, and particularly discloses an air dehumidifying device which uses high-temperature wet hot air heat. The dehumidifying device is composed of a plate type heat exchanger, an air flowing duct and a cooling dehumidifying tower. The cooling dehumidifying tower is arranged in a standing mode, a shell of the plate-type heat exchanger is fixed on the upper portion of the cooling dehumidifying tower, an air outlet of the dehumidifying tower is connected with a cold air inlet of the plate-type heat exchanger in an opposite mode, a high-temperature wet air outlet of the plate-type heat exchanger shell is connected with one end of the C-shaped air flowing duct, the other end of the air flowing duct is connected to a dehumidifying tower air inlet formed in the lower portion of the dehumidifying tower, cooling and dehumidifying are conducted in the cooling dehumidifying tower, and condensed water is collected. According to the self-heating full-contact type air dehumidifying device, cooled cold air is used for lowering the temperature of the high-temperature wet air, the humidity of the cold air is increased at the same time, and dry cold air is obtained, self heating is achieved, comprehensive utilization of energy is achieved. Compared with a traditional cooling dehumidifying device, the self-heating full-contact type air dehumidifying device saves energy by more than 90 percent, and improves utilization rate of water.

Owner:SHANDONG BEICHEN MECHANICAL & ELECTRICAL EQUIP

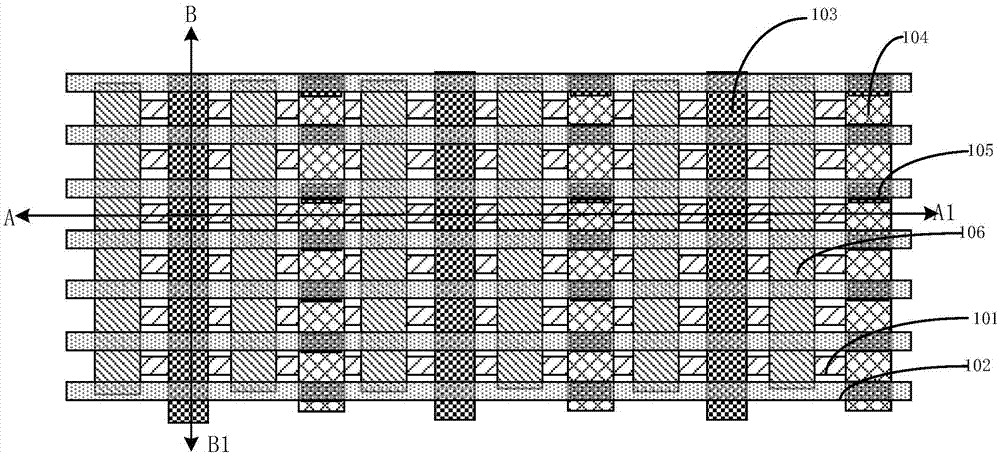

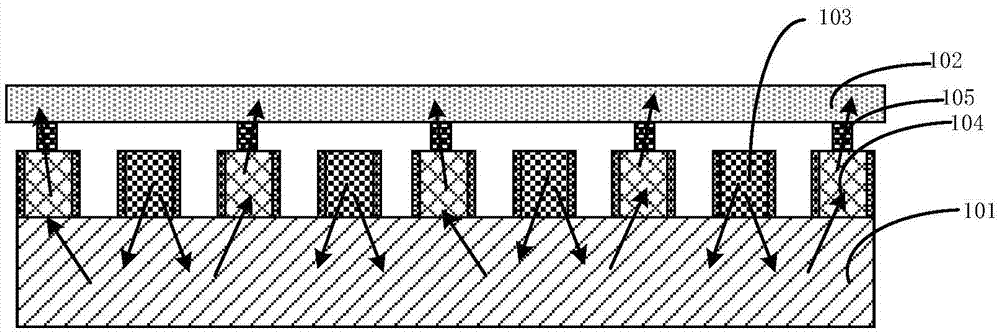

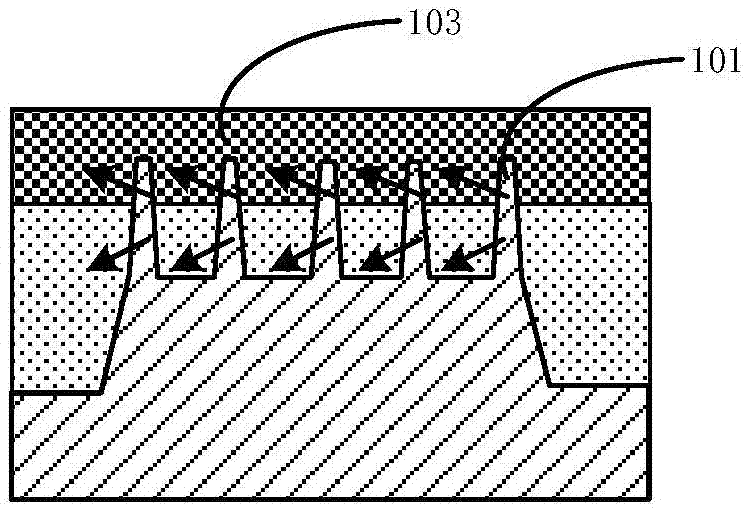

Self-heating measuring structure and measuring method for FinFET device, and electronic device

ActiveCN106910734AAchieve self-heatingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical resistance and conductanceEngineering

The invention relates to a self-heating measuring structure and measuring method for an FinFET device, and an electronic device. The self-heating measuring method for the FinFET device comprises a step S1 of switching off the FinFET device in order to make the grid be in an open circuit state, and measuring the resistance value R0 of thermal variable resistance layers; step S2 of switching on the FinFET device in order to make the grid be in a conduction state, and measuring the resistance value R of the thermal variable resistance layers; and a step S3 of calculating the temperature of the thermal variable resistance layers after the temperature is increased in dependence on the increase of the resistance of the thermal variable resistance layers and the resistance temperature coefficient [alpha]. In the measuring structure, virtual grids are arranged among grids, and several rows of the thermal variable resistance layers connected with the virtual grids through a heat conduction material are arranged above a grid array, heat radiated from the grids are transmitted to the thermal variable resistance layers through the virtual grids, after the temperature of the thermal variable resistance layers is changed, the resistance is changed, and detection of the self-heating condition of the FinFET device is achieved by measuring the resistance of the thermal variable resistance layers.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Three-component composite spinning experiment spinning manifold

InactiveCN113755957AAchieve heating efficiencyEvenly heatedFilament/thread formingSpinningEngineering

The invention discloses a three-component composite spinning experiment spinning manifold which comprises a heat preservation box, a first heat preservation bin, a second heat preservation bin, a spinning manifold body, a first oil guide pipe inlet, a first solution pipeline, a second solution pipeline, a second oil guide pipe inlet and a long oil guide pipe. A first metering pump, a second metering pump and a third metering pump are installed in the spinning manifold body; a first solution distribution base is arranged at the bottom of the first metering pump; and a second solution distribution base is arranged at the bottom of the second metering pump. According to the three-component composite spinning experiment spinning manifold provided by the invention, the two sides of the spinning manifold body are electrically heated through the three metering pumps and two short pipes of the spinning manifold body, and the long guide pipe is used in the middle of the spinning manifold body to heat an internal solvent, so that the internal heating efficiency of the whole spinning manifold body is achieved, and meanwhile, the solvent of the spinning manifold body is heated more evenly; and the spinning manifold is small in volume structure, does not need to occupy too large space, does not need to be matched with multiple sets of complex biphenyl systems, and is suitable for being used in cooperation with a spinning testing machine.

Owner:苏州展衡智能科技有限公司

Milk maker

InactiveCN101589913BRealize the stirring functionAchieve self-heatingBeverage vesselsDrive motorEngineering

The invention discloses a milk maker, which comprises a support cylinder, a base for placing a milk making bottle, and a water barrel, wherein the inside of the support cylinder is provided with a driving motor, the support cylinder is provided with a powdered milk barrel, a rotating shaft is inserted into the bottom surface of the powdered milk barrel, and the rotating shaft is linked with an output shaft of the driving motor; the inside of the powdered milk barrel is provided with a link mechanism, the link mechanism is connected with a powder pushing block, and the powder pushing block cantravel to the outer wall, which is provided with a powder falling cavity, of the powdered milk barrel; the milk making bottle is arranged below the powder falling cavity, a stirring shaft is insertedinto the bottom surface of the milk making bottle and is provided with stirring blades, and the stirring blades are positioned in the milk making bottle; the inside of the base is provided with a mechanism for driving the rotation of the stirring shaft; and the inside of the water barrel is provided with a water pump, the water pump is connected with a water outlet pipe, and a tail-end water outlet of the water outlet pipe aligns with a bottle mouth of the milk making bottle. The milk maker realizes the integrated automation of automatic and quantificational powdered milk taking, water feeding and automatic stirring.

Owner:王光力

Self-heating casing string

PendingCN111663905AAchieve self-heatingGuaranteed liquidityDrilling rodsCleaning apparatusElectrical connectionCasing string

The invention provides a self-heating casing string. The self-heating casing string comprises a heating coil and at least one electric power device, a cavity is formed between the outer wall and the inner wall of the casing string, the heating coil is spirally arranged in the cavity, the electric power device is erected in the casing string in a suspended mode, the electric power device comprisesa rotating part and fixed parts, the two ends of the rotating part are connected with the fixed parts correspondingly, the fixed parts are arranged in the cavity, the fixed parts are electrically connected with the heating coil, and when liquid passes through the casing string, the rotating part is driven by the liquid to rotate and cooperates with the fixed parts to provide power supply for the heating coil. According to the self-heating casing string, through the mutual cooperation of the electric power device and the heating coil, self-heating of the casing string is realized, the supply ofexternal energy is not needed, the loss of a large amount of energy is avoided, and the oil extraction cost is reduced.

Owner:PETROCHINA CO LTD

A battery self-heating method and device

ActiveCN110336099BEasy to useAchieve self-heatingCell temperature controlThermodynamicsProcess engineering

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

Self-heating vertical axial-flow drum ablative pyrolysis reactor

The present invention involves a self -heating vertical axis roller ablation, which is a technical field of renewable energy utilization.Including the shell and the reaction cylinder located inside the shell, there is a shaft inside the reactor, the upper end of the rotating shaft is connected to the inverter motor through the belt, and the speed of the rotation shaft can be adjusted., The raw end of the first -level spiral feeder is connected to the feed end of the second -level spiral feeder, and the raw end of the secondary spiral feeder is connected to the upper part of the reactor.The beneficial effect of the present invention is to improve the efficiency of thermal solution. There is no need to promote the gas and the heating of the heat carrier during the reaction process, which greatly reduces the heating and cooling load of the load.Realize the self -heating process of thermal solution, and fully realize the effective use of energy.Different cone angles can adapt to changes in the size of the material. It can heat up the biomass materials such as powder, granularity and other biomass materials, and better realize gas solid separation and thermal solution of biomass.

Owner:SHANDONG UNIV OF TECH

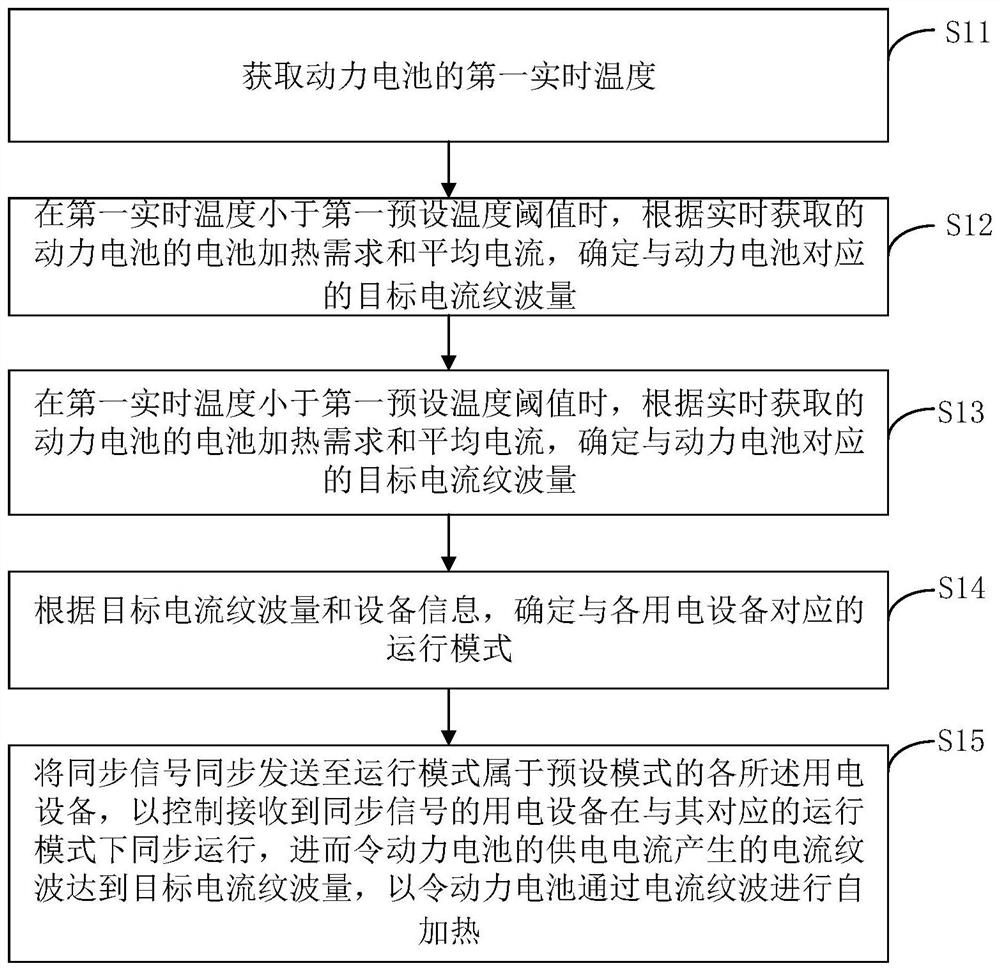

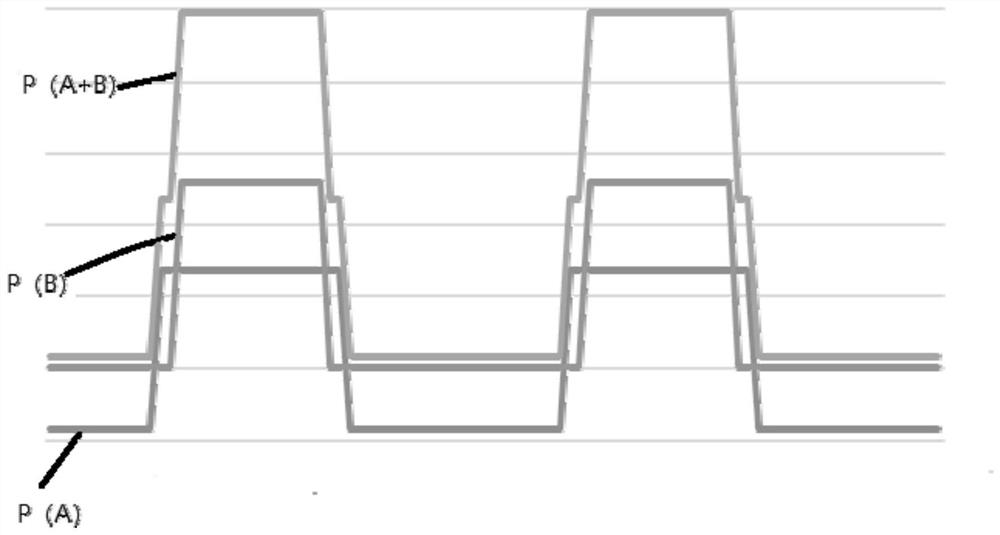

Automobile power battery self-heating method and system, automobile and storage medium

ActiveCN113839124AAchieve self-heatingShorten warm-up timeSecondary cellsVehicular energy storagePower batteryElectrical battery

The invention discloses an automobile power battery self-heating method and system, an automobile and a storage medium. The method comprises the following steps: when a first real-time temperature is smaller than a first preset temperature threshold value, determining a target current ripple quantity corresponding to a power battery according to a battery heating demand and an average current of the power battery which are acquired in real time; determining an operation mode corresponding to each electric device according to the target current ripple quantity and device information of each electric device electrically connected with the power battery; and synchronously sending the synchronizing signal to each electric device of which the operation mode belongs to the preset mode, so as to control the electric device receiving the synchronizing signal to synchronously operate in the corresponding operation mode, so that the current ripple generated by the power battery reaches the target current ripple quantity, and the power battery is self-heated through the current ripple. The power battery is promoted to generate current ripples to increase the internal heating amount of the power battery, the preheating time of the power battery is shortened, and the heating efficiency of the power battery is improved.

Owner:BYD CO LTD

Self-heating type sausage and sausage heater

InactiveCN108201365AEasy to carryAchieve self-heatingWarming devicesFood scienceBarrel ShapedEngineering

The invention provides a self-heating type sausage and a sausage heater. The sausage and the sausage heater are characterized in that the self-heating type sausage is in a circular barrel shape, and the sausage heater is cylindrical and can be inserted into the self-heating type sausage conveniently; the sausage heater is provided with an outer wall and an upper cover, a spiral structure is arranged between the brim of the upper cover of the sausage heater and the inner side of the outer wall of the sausage heater, the upper cover of the sausage heater is provided with a hanging ring and microvent holes, a plastic valve is arranged in the vent holes, and the bottom of the sausage heater is sealed. The sausage heater has the advantage of being convenient to carry and capable of achieving self-heating.

Owner:NANKAI UNIV BINHAI COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com