Self-heating gas sensor, gas sensitive material and preparation method and application thereof

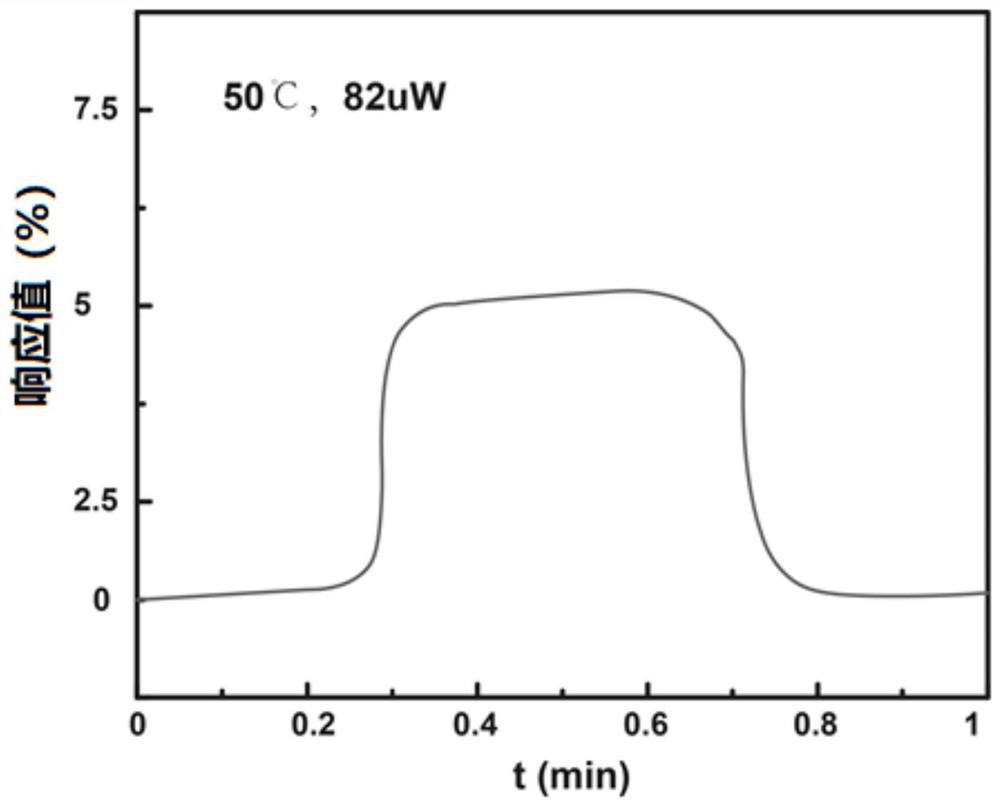

A gas sensor and gas-sensitive material technology, applied in the field of materials, can solve the problems of slow adsorption and desorption process, expensive instruments, cumbersome sensor preparation methods, etc., and achieve the effect of fast response recovery and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

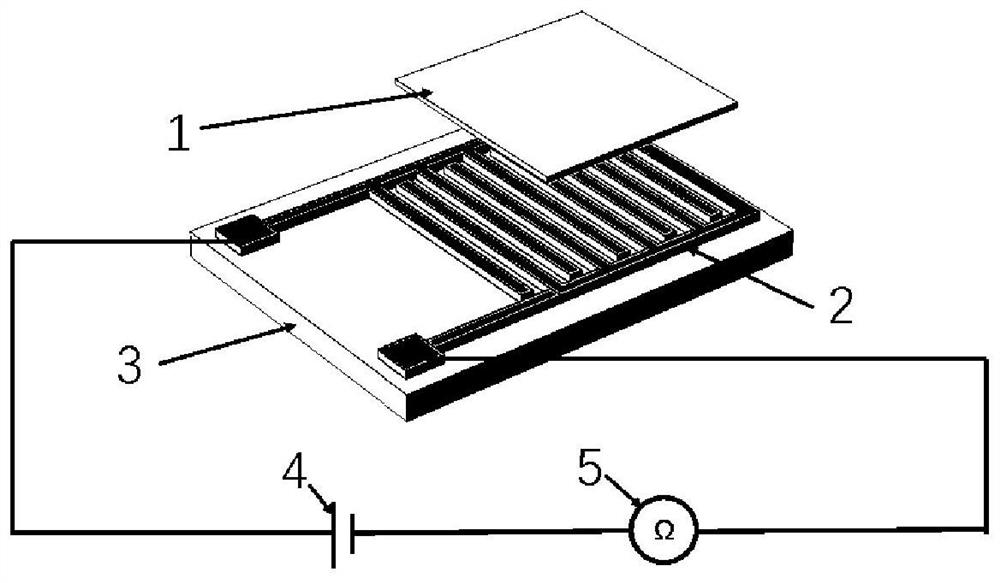

Image

Examples

preparation example Construction

[0054] In a particularly preferred embodiment of the present invention, the preparation method of the gas-sensitive material comprises: in the presence of a solvent, after heat-treating the carbon material, the metal oxide and / or the metal oxide precursor under microwaves, The step of performing solid-liquid separation to obtain a carbon material metal oxide composite nanomaterial (hereinafter also referred to as the first preparation method of the gas-sensing material).

[0055] According to the first preparation method of the gas-sensitive material of the present invention, since the carbon material and the metal oxide and / or metal oxide precursor are heat-treated under microwaves, the raw materials can be heated in a very short time by using microwaves At the same time, the heat is generated by molecular vibration, so the distribution of the reaction heat field is more uniform, and the shape of the product is more uniform, and the carbon material has a high microwave absorpt...

Embodiment 1

[0084] Accurately weigh 15mg of graphene oxide, 1g of tungsten chloride into a 500mL beaker, pour 300mL of absolute ethanol, magnetically stir for about 30min, then use a cell disruptor to sonicate for 30min, and pour the obtained mixed solution into 10 In a 50mL polytetrafluoroethylene reactor, heat it to 200°C with a microwave synthesizer at 800W, and keep the temperature constant for 2h. The product obtained after the reaction was centrifuged and washed three times with deionized water and absolute ethanol. Then put the centrifuged sample into an oven and dry it at 80°C for 6 hours to obtain the reduced graphene WO 3 Nanomaterial A1 (flaky nanomaterial with a thickness of 1-2nm and the longest linear distance between two points is 1-5um), wherein the content of carbon material is 2.5% by weight, the content of metal oxide is 97.5% by weight, The resistance is 40kΩ.

Embodiment 2

[0086] Accurately weigh 15mg of carbon nanotubes, put 1g of tungsten chloride into a 500mL beaker, pour 300mL of absolute ethanol, stir for about 30min with a magnetic force, and then use a cell disruptor to ultrasonically break for 30min, and pour the obtained mixed solution into 10 beakers In a 50mL polytetrafluoroethylene reactor, heat it to 200°C with a microwave synthesizer at 800W, and keep the temperature constant for 2h. The product obtained after the reaction was centrifuged and washed three times with deionized water and absolute ethanol. Then put the centrifuged sample into an oven and dry it at 80°C for 6 hours to obtain carbon nanotube WO 3 Nanomaterial A2 (wire-like nanomaterial with a diameter of 5-15nm and a length of 10-30um), wherein the content of carbon material is 2.5% by weight, the content of metal oxide is 97.5% by weight, and the resistance is 60kΩ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com