Self-heating vertical axial-flow drum ablative pyrolysis reactor

A pyrolysis reaction, vertical axis technology, applied in indirect heating dry distillation, special form dry distillation, energy input, etc., can solve the problem of reducing the quality of bio-oil or other pyrolysis products, lack of biomass material baking equipment, large fluidization air volume, etc. problems, achieve the effect of gas-solid separation and pyrolysis of biomass, reduce heating and cooling load, and increase pyrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

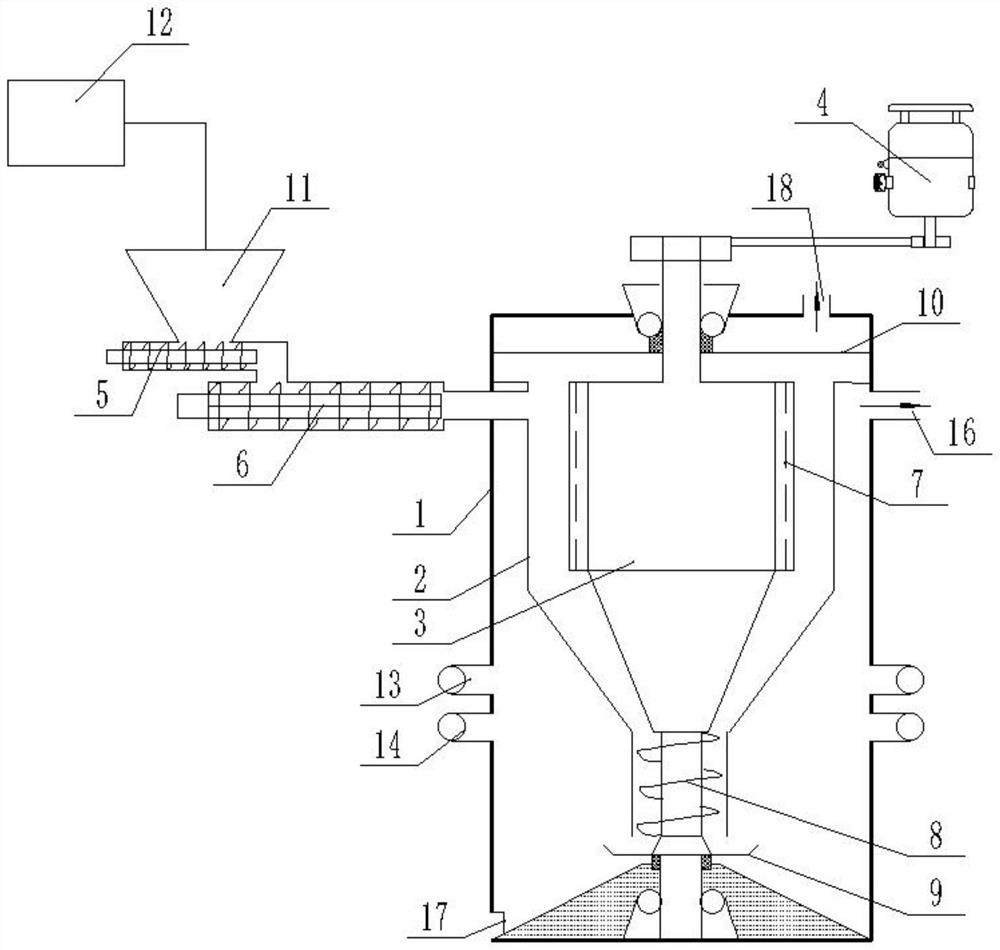

[0041] The self-heating vertical axial flow drum ablation reaction device of the present invention can not only be used for biomass pyrolysis and liquefaction to produce bio-oil, but also can be used for biomass gasification to produce pyrolysis gas. When the reaction device is used for different functions, only This can be achieved by adjusting the rotational speed of the rotating shaft 3 and the temperature of the reaction cylinder 2 .

[0042] like figure 1 As shown, the self-heating vertical axial-flow drum ablation pyrolysis reaction device includes a drying and baking device 12, the drying and baking device 12 is connected to a storage bin 11, and the storage bin 11 is connected to the primary screw feeder 5 and the secondary screw feeder. 6. The secondary screw feeder 6 is connected to the self-heating vertical axial flow drum ablation pyrolysis reactor.

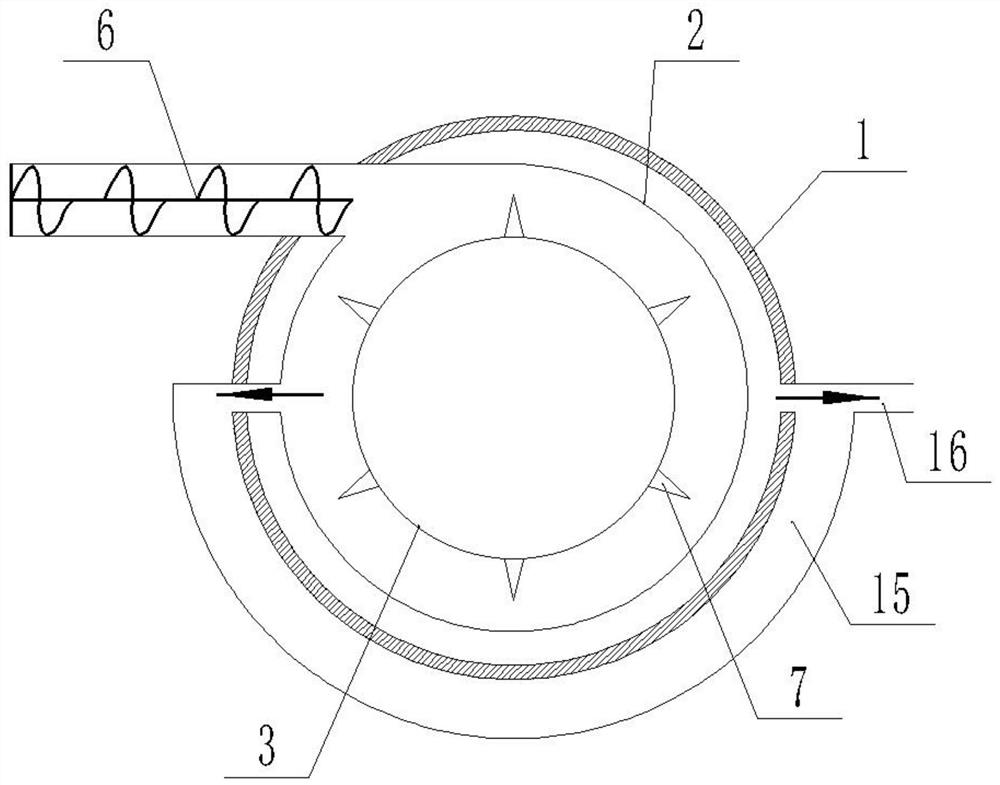

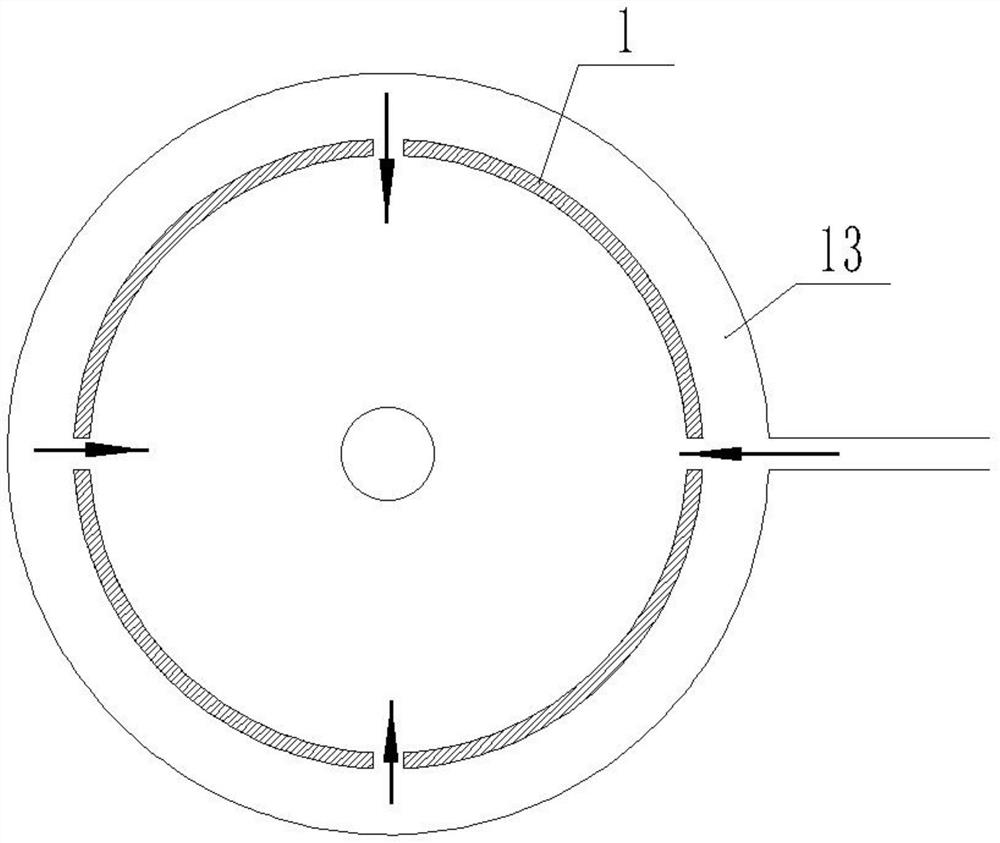

[0043] The self-heating vertical axial-flow drum ablation pyrolysis reactor includes a shell 1 and a reaction drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com