Patents

Literature

53results about How to "Promote pyrolysis reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature vacuum themal dissociation waste printed wiring board preprocessing method

InactiveCN1919482AAvoid secondary pollutionPromote pyrolysis reactionSolid waste disposalElectronic waste recyclingFurnace temperaturePretreatment method

The invention discloses a predisposing method of low-temperature vacuum pyrolytic waste print circuit in the resource recycling technological domain, which comprises the following steps: placing waste print circuit board in the vacuum pyrolytic furnace, starting pyrolytic furnace to heat, starting vacuum pump, maintaining vacuum degree at 30-1000pa, stopping heating after the inner furnace temperature reaches 200-300 deg.c, insulating, cooling, grinding the waste print circuit board, sieving.

Owner:TSINGHUA UNIV

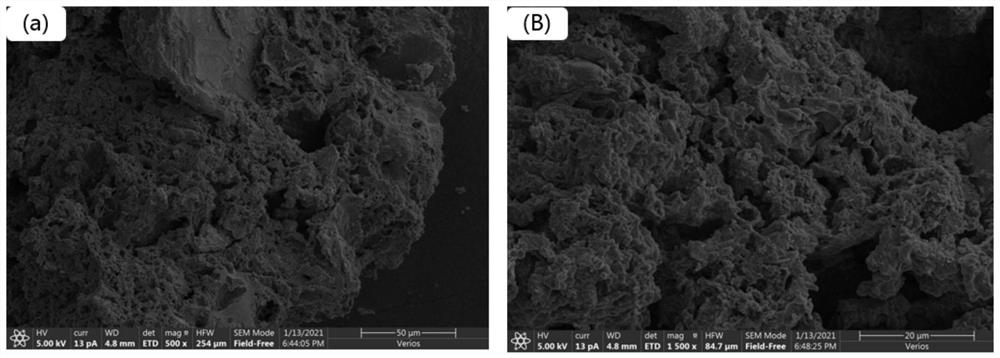

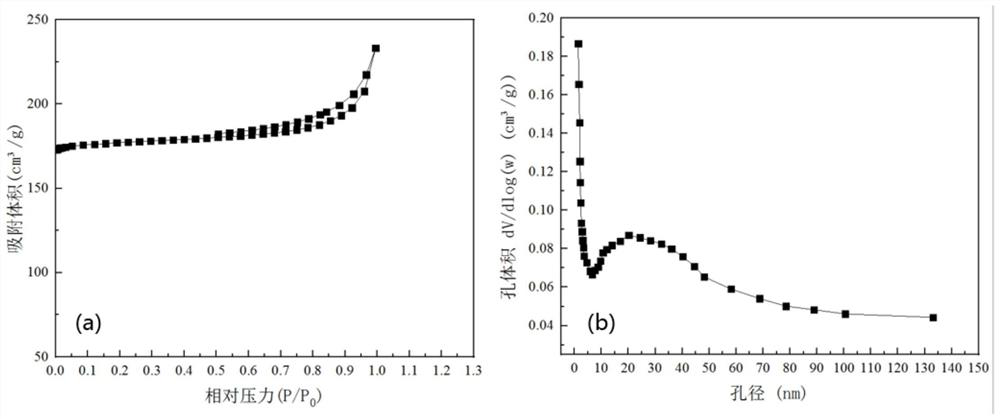

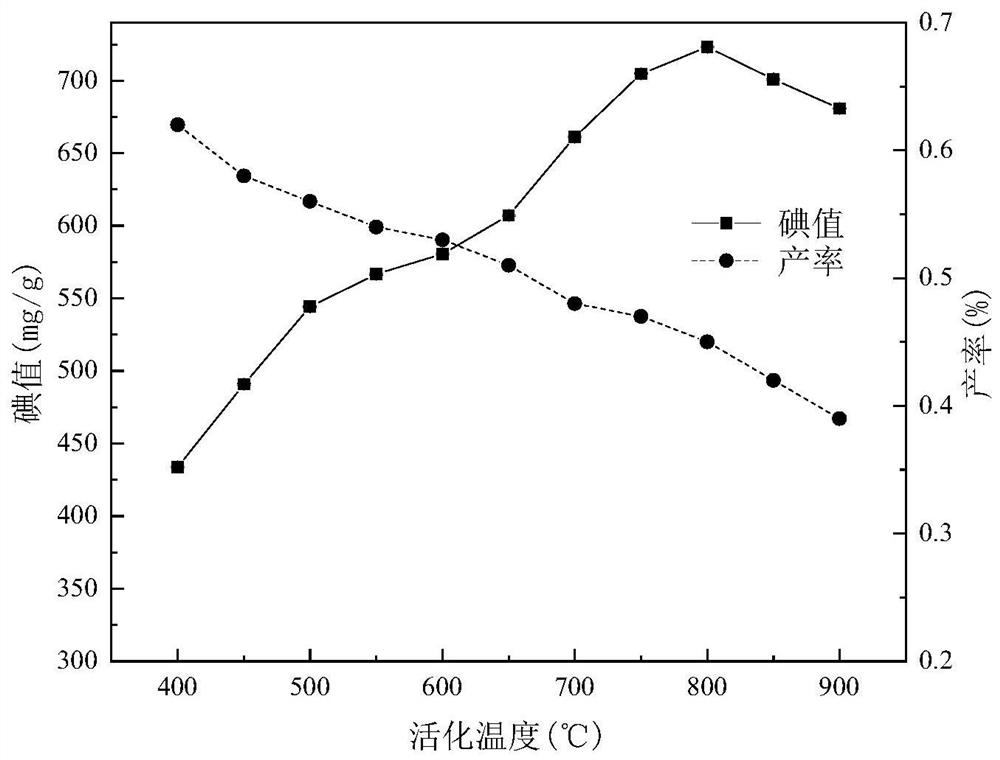

Method for preparing activated carbon by using betel nuts and sludge as materials

ActiveCN113753895ARich pore structureLarge specific surface areaCarbon compoundsBetel nutsActivated carbon

The invention provides a method for preparing activated carbon by using betel nuts and sludge as materials, which comprises the following steps: S1, raw material preparation: mixing betel nuts and sludge, and conducting drying, crushing and sieving to obtain betel nut and sludge mixed particles; S2, high-temperature carbonization: putting the mixed raw material into a tubular furnace, and performing carbonization initial treatment in a nitrogen atmosphere; S3, activator soaking: mixing the carbonized betel nuts and sludge mixed particles with an activating agent aqueous solution prepared from phosphoric acid, zinc chloride and water, and conducting soaking after even stirring, so as to obtain a mixed product; S4, high-temperature activation: putting the mixed product into a tubular furnace, conducting activating in a nitrogen atmosphere, and conducting cooling to obtain a crude product; and S5, obtaining of a finished product: carrying out acid pickling, water washing and drying on the crude product to obtain a target activated carbon product. The prepared betel nut sludge activated carbon has the advantages of abundant pore structures, large specific surface area, high iodine adsorption capacity, high yield and the like. The method has the characteristics of low energy consumption and simplicity in operation.

Owner:HAINAN UNIVERSITY

Domestic waste pyrolyzing and charring method

ActiveCN105542803APromote generationImprove catalytic performanceSpecial form destructive distillationLitterEngineering

The invention belongs to the technical field of domestic waste treatment, and concretely relates to a domestic waste pyrolyzing and charring method. A certain amount of a charring promotion catalyst is added to domestic wastes, above materials are uniformly mixed, the obtained mixture is added to a pyrolyzing furnace, and the temperature and the time are controlled to obtain pyrolyzed coke. The cheap and easily available raw material is used as the charring promotion catalyst, so the carbon fixation rate in the waste pyrolyzing process is improved as possible, and formation of volatile organic products is inhibited, thereby harmless and reducing treatment of the domestic wastes is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

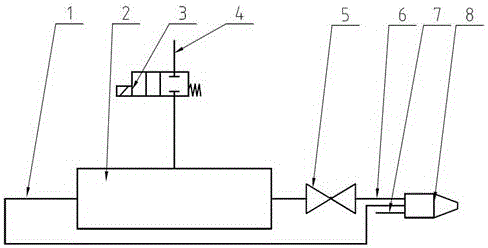

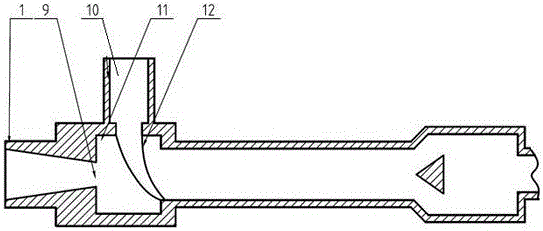

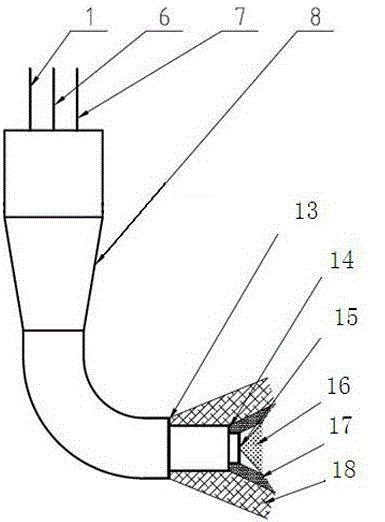

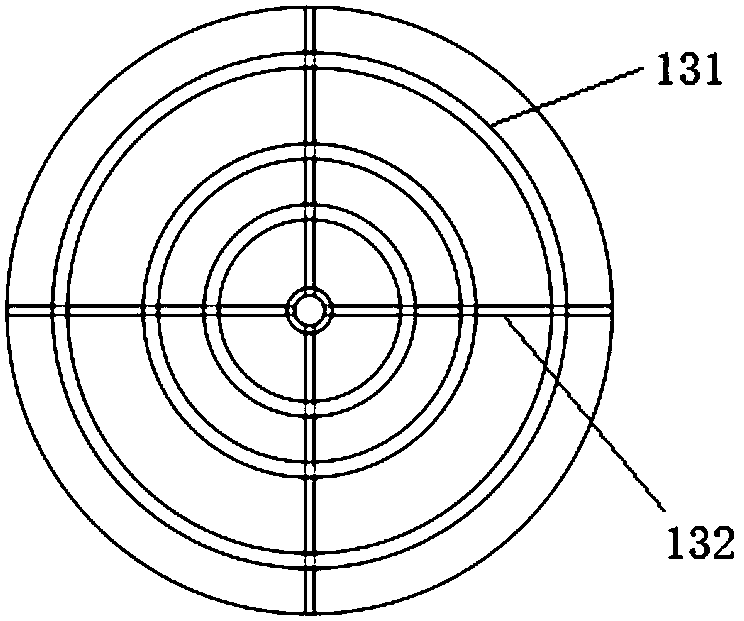

Anti-crystallization device for carbamide nozzle of selective catalytic reduction (SCR) system

ActiveCN105041432AReduced risk of crystal pluggingPromote pyrolysis reactionExhaust apparatusSilencing apparatusSolenoid valveHeating effect

Disclosed is an anti-crystallization device for a carbamide nozzle of a selective catalytic reduction (SCR) system. The anti-crystallization device comprises a solenoid valve, a vortex tube assembly and a spray head assembly. A gas inlet of the vortex tube assembly is provided with the solenoid valve. One end of the vortex tube assembly is connected with the spray head assembly through a cool gas pipeline, and the other end of the vortex tube assembly is connected with the spray head assembly through a hot gas pipeline. The spray head assembly is further provided with a carbamide inlet. The tail end of the spray head assembly is provided with a carbamide nozzle orifice, a hot gas nozzle orifice and a cool gas nozzle orifice. The carbamide nozzle orifice is nested in the cool gas nozzle orifice. The cool gas nozzle orifice is nested in the hot gas nozzle orifice. Compressed gas can be transformed into cool gas flow and hot gas flow. The cool gas flow can be used for cooling components in the spray head assembly. The hot gas flow can be used for heating carbamide. The cool gas flow and the hot gas flow finally produce gas curtains through the nozzle orifices and the gas curtains isolate carbamide mist and high-temperature tail gas at the nozzle, and carbamide crystallization produced at the nozzle is avoided to the greatest extent. At the same time, cooling and heating effects are achieved in different positions simply and reliably; the production and maintenance cost of the system is low.

Owner:山东艾泰克环保科技股份有限公司

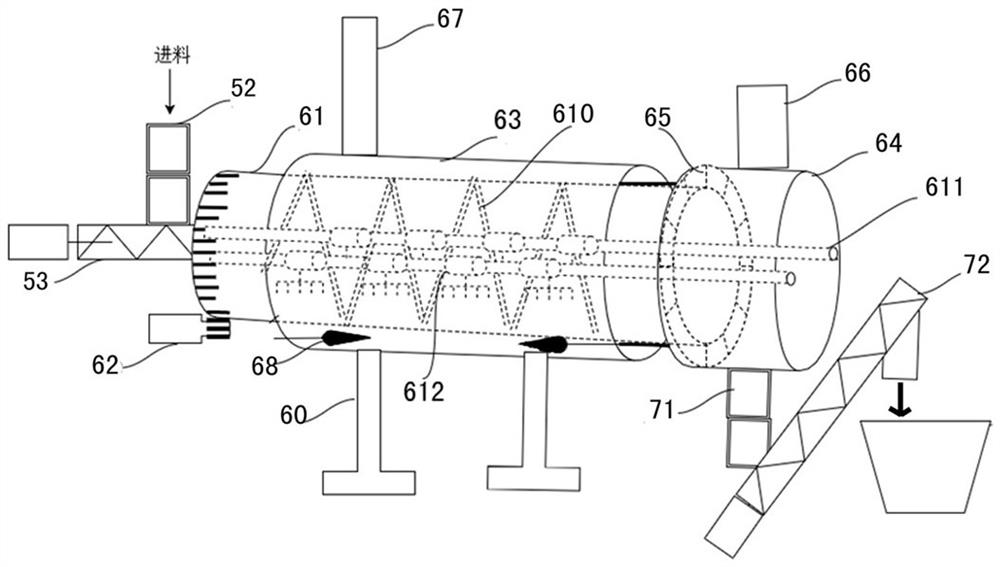

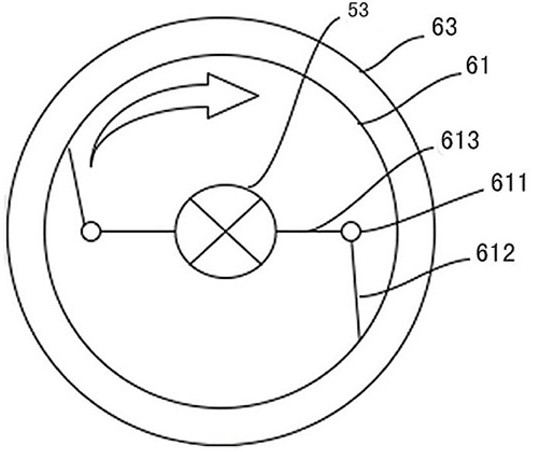

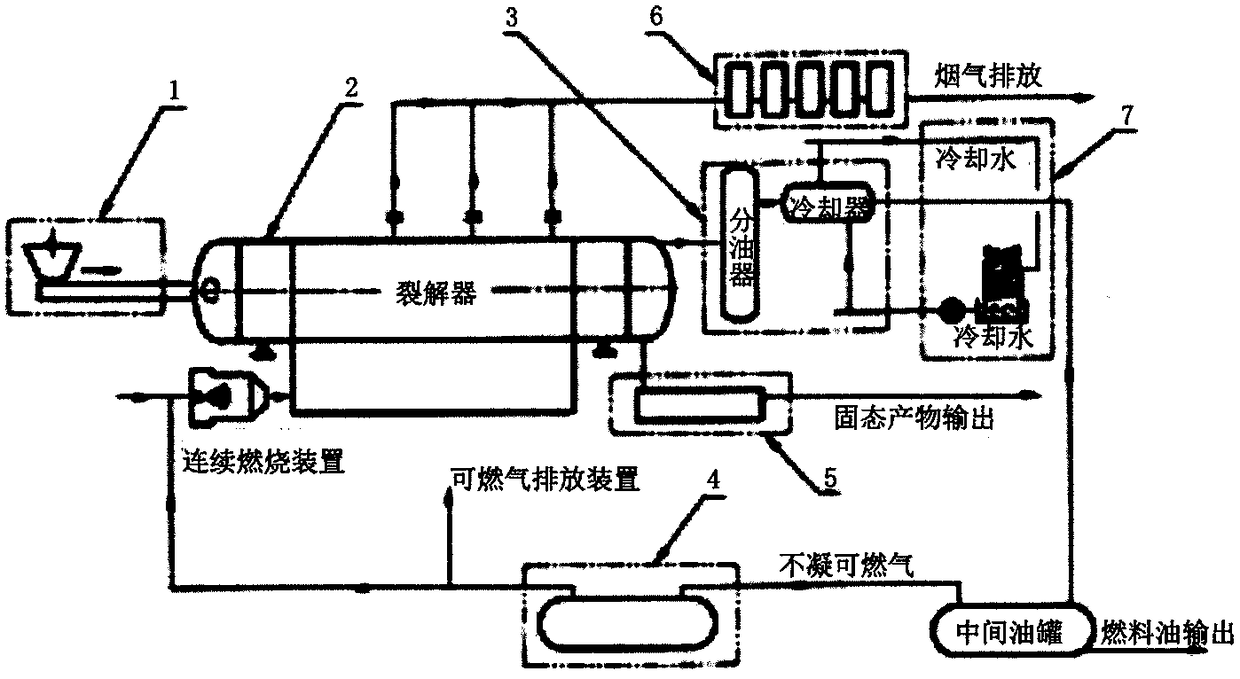

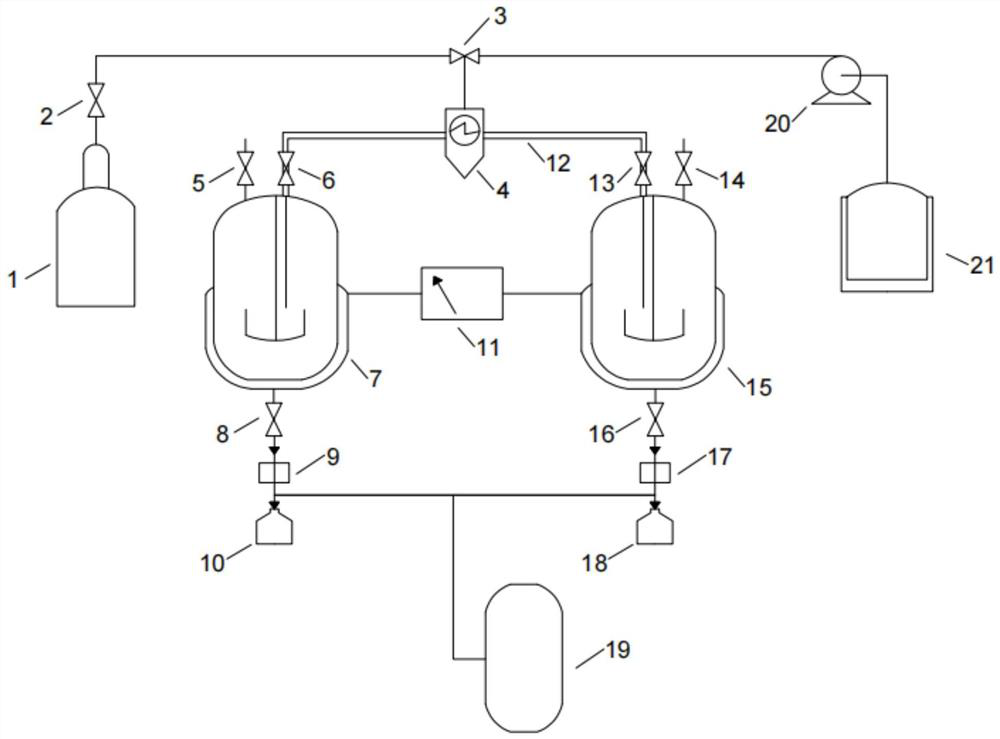

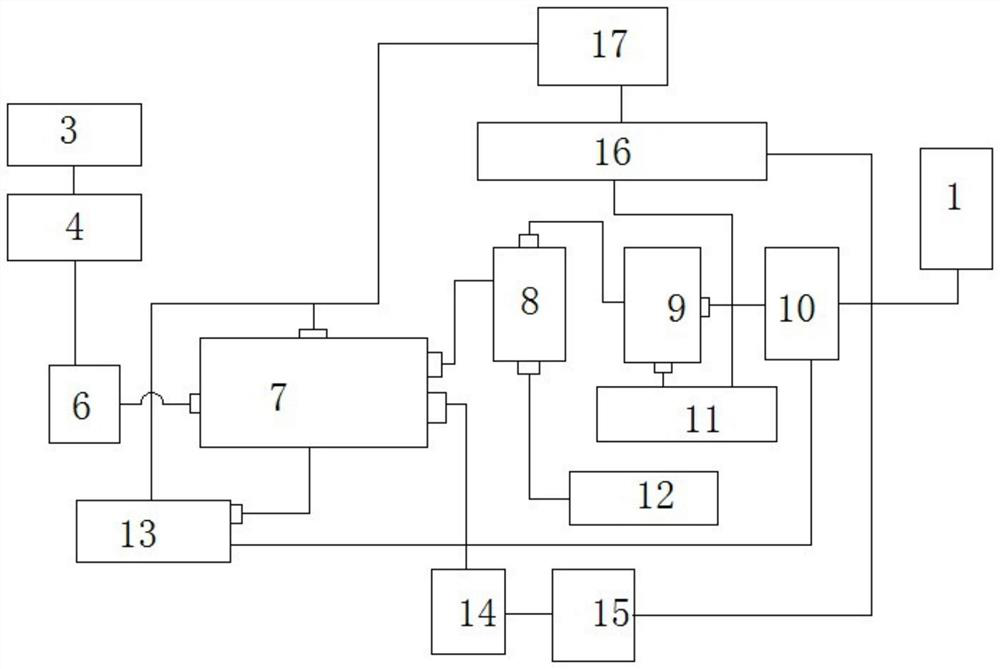

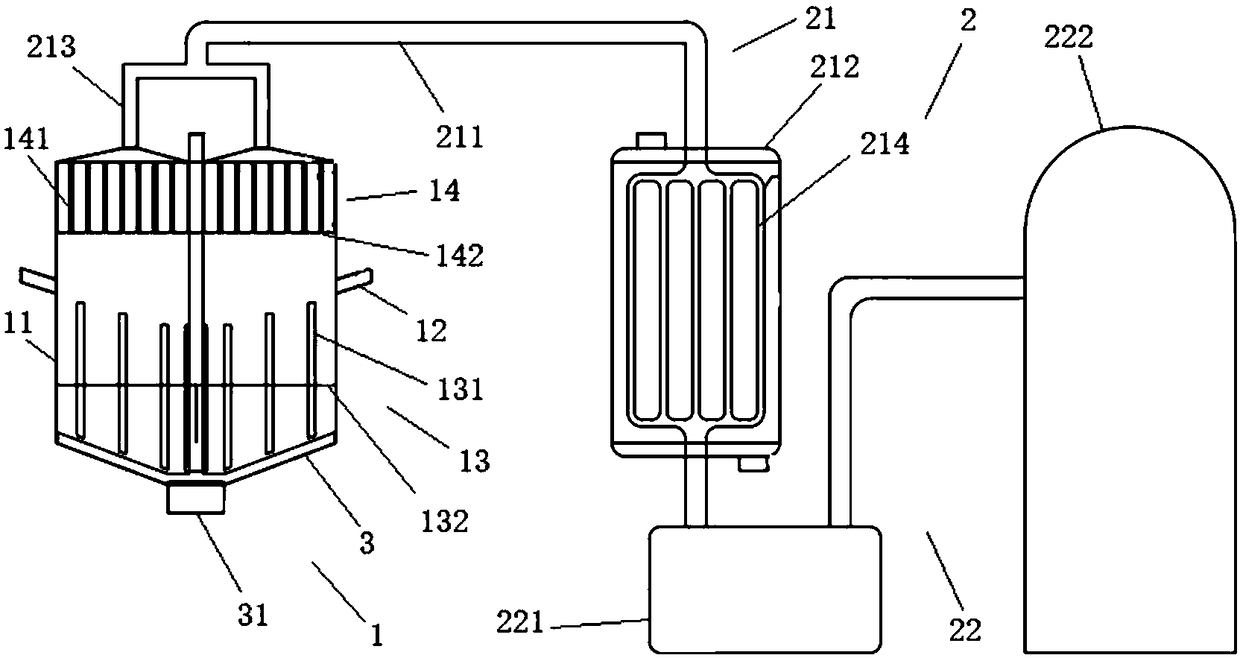

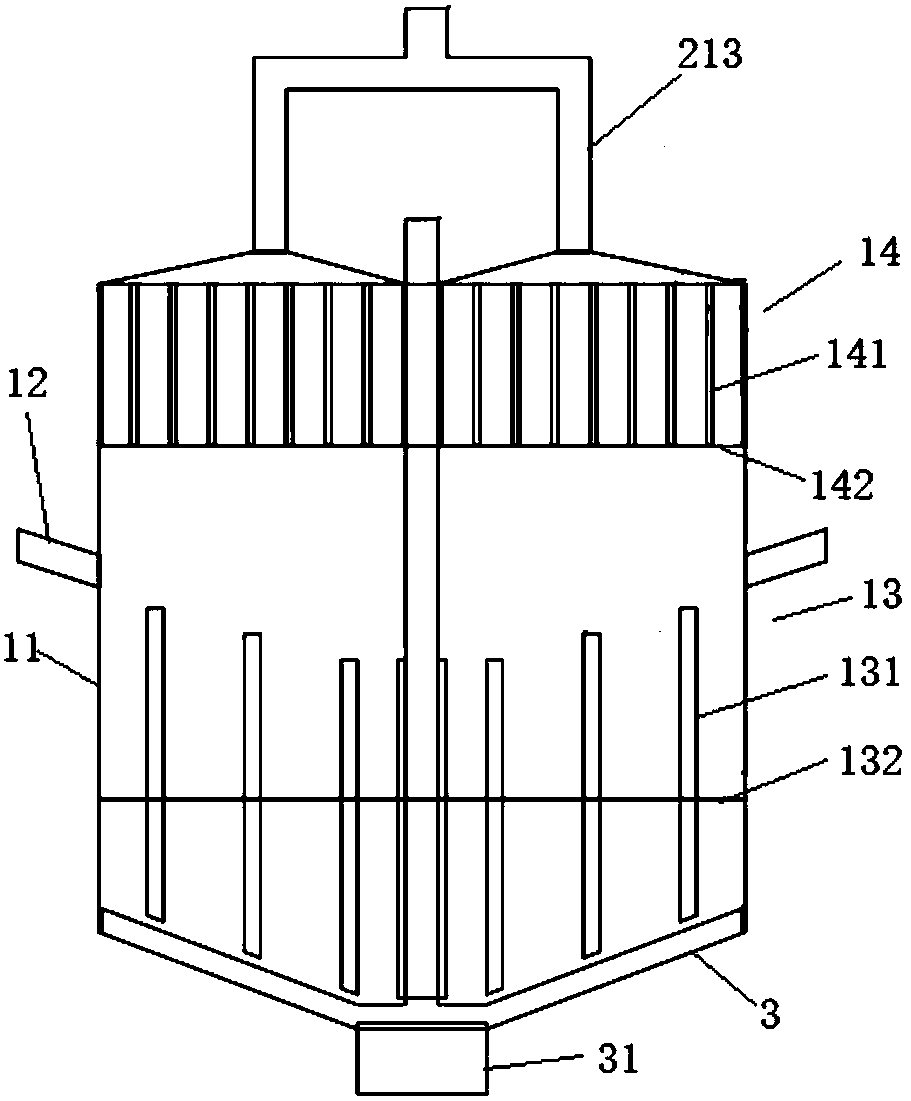

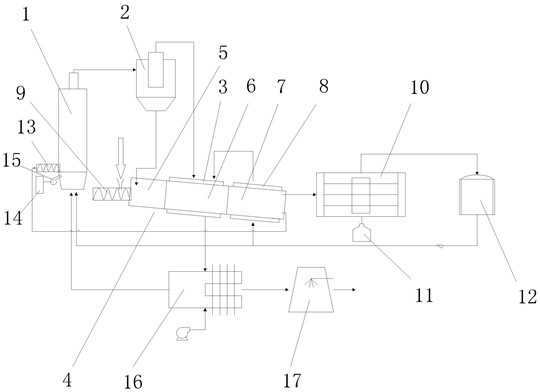

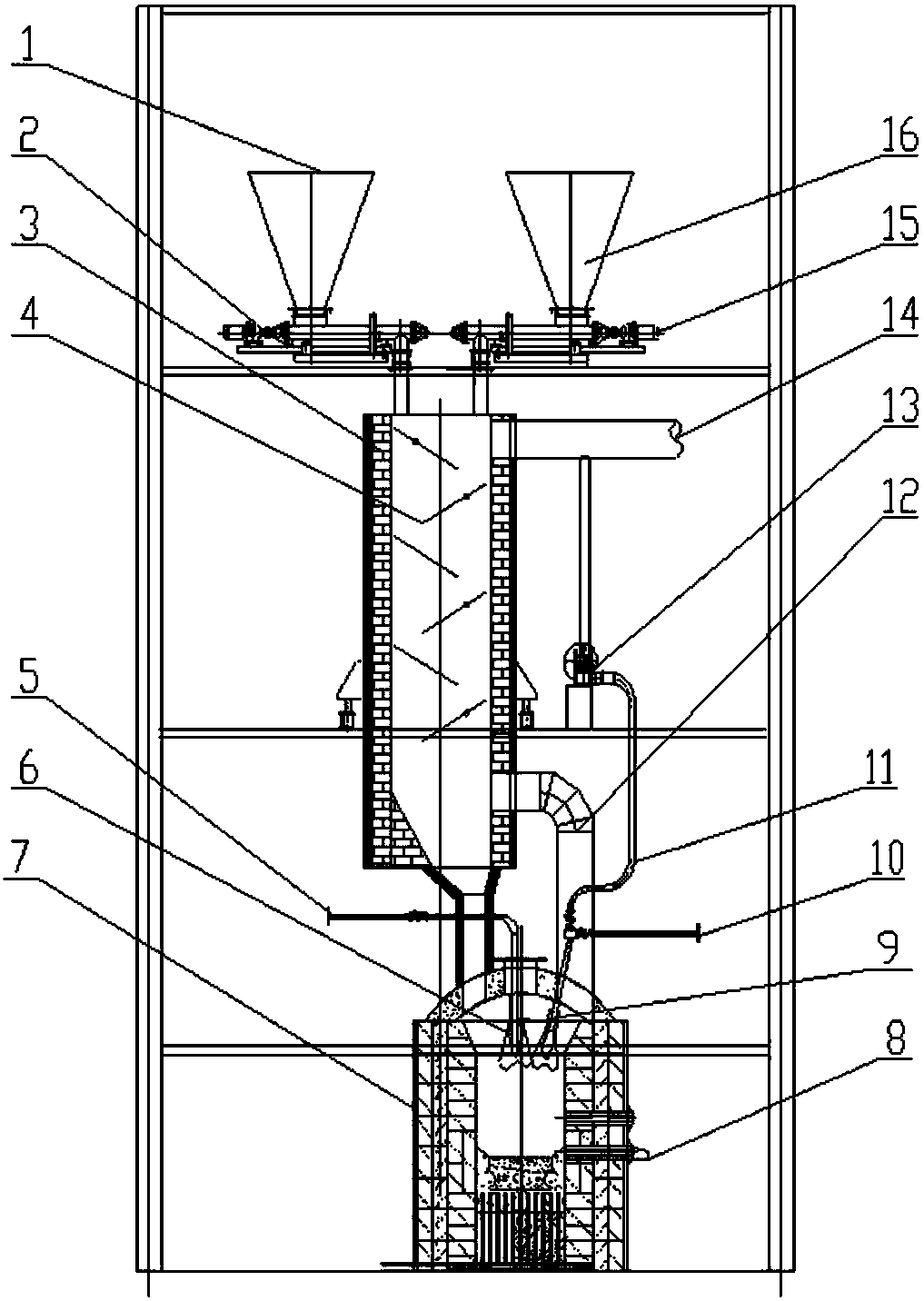

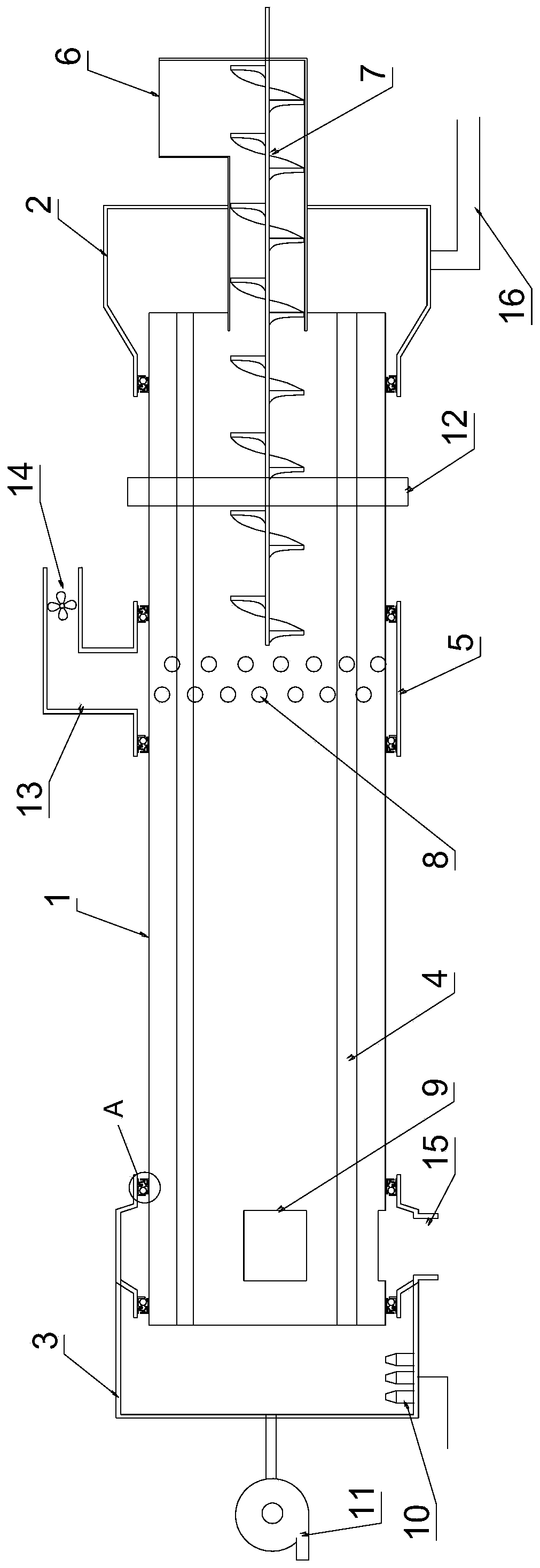

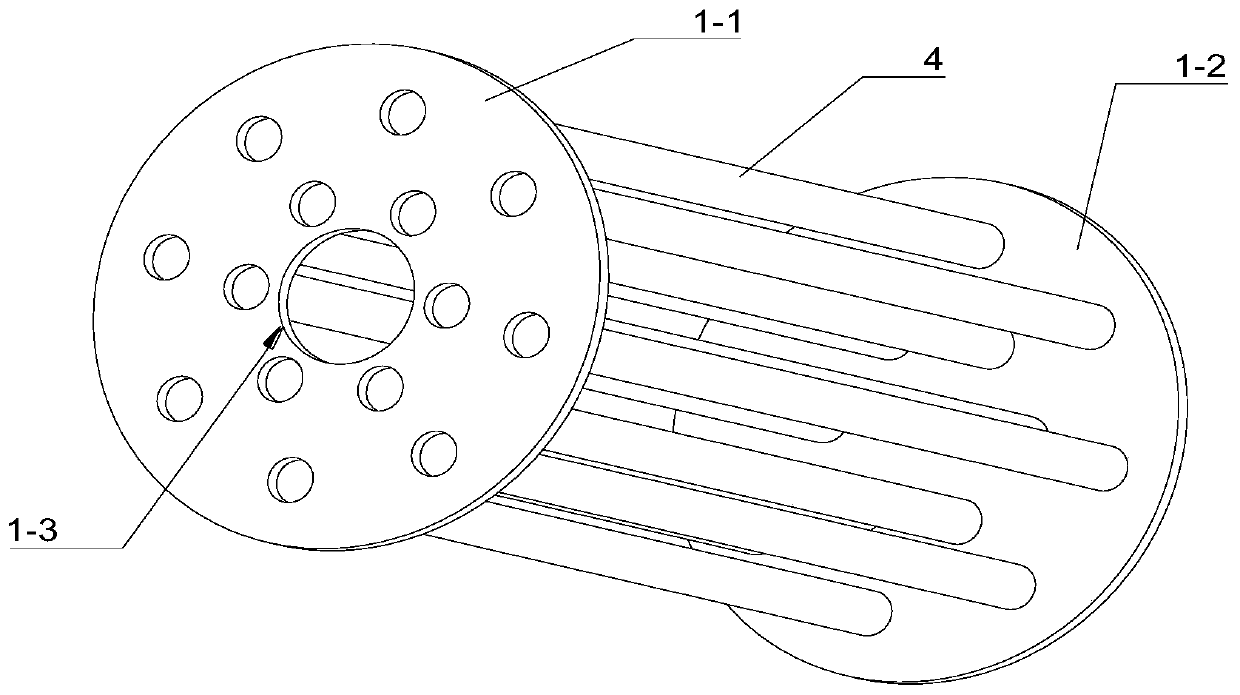

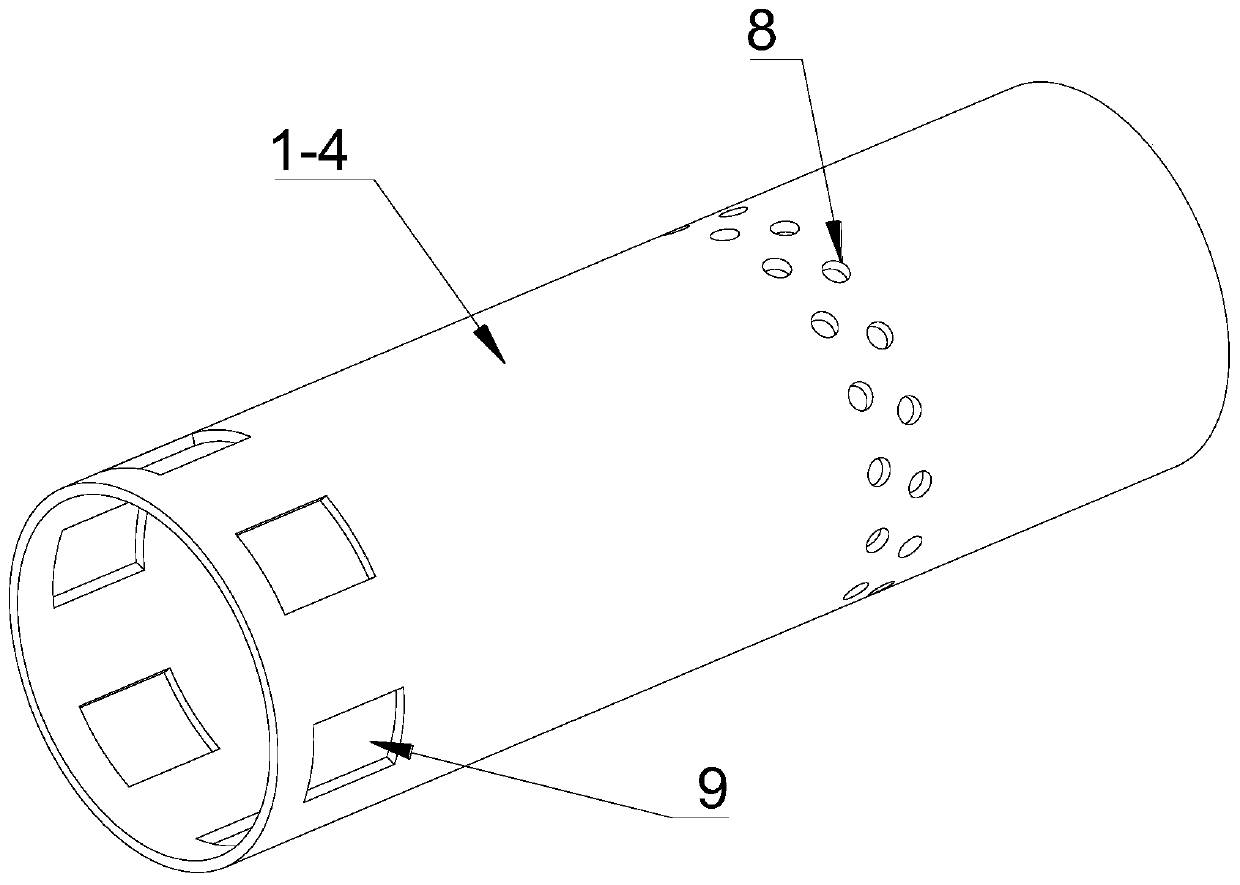

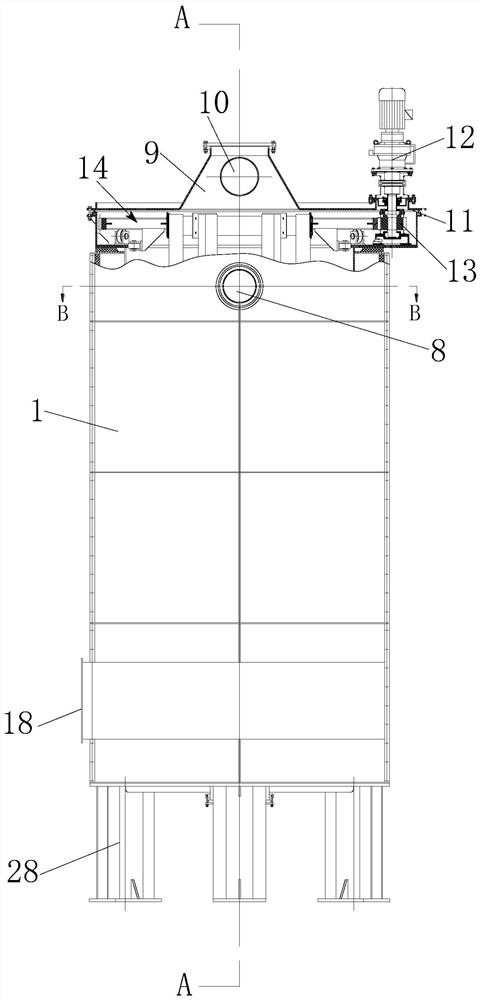

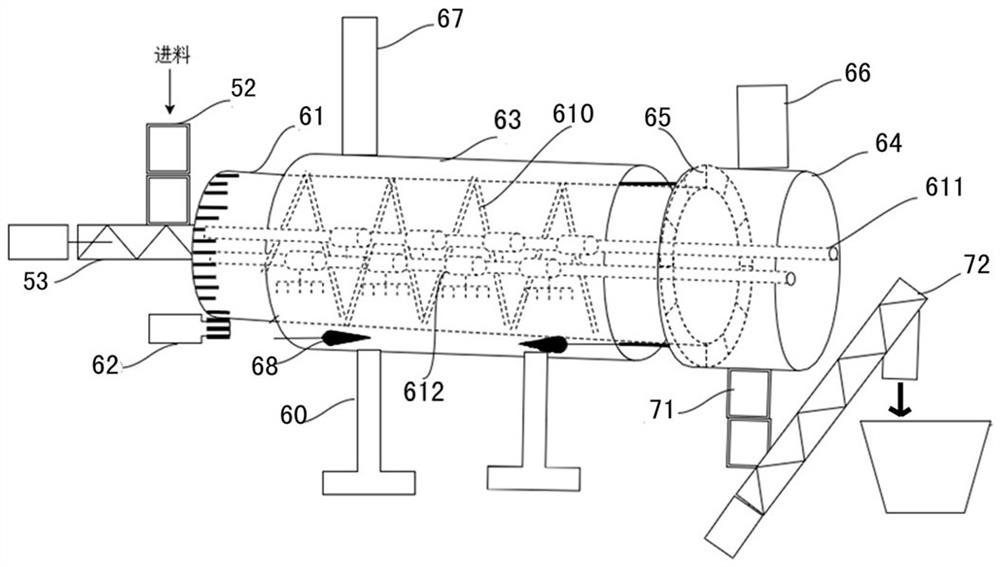

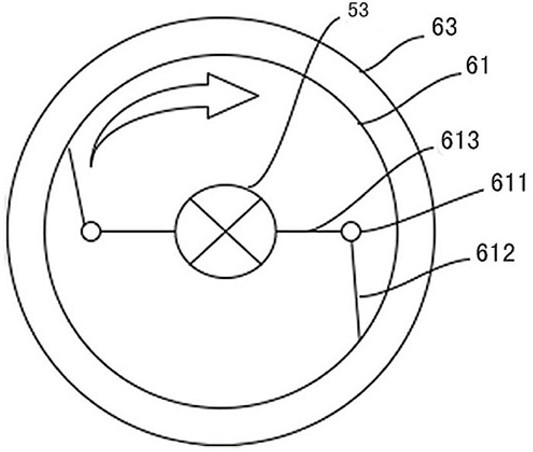

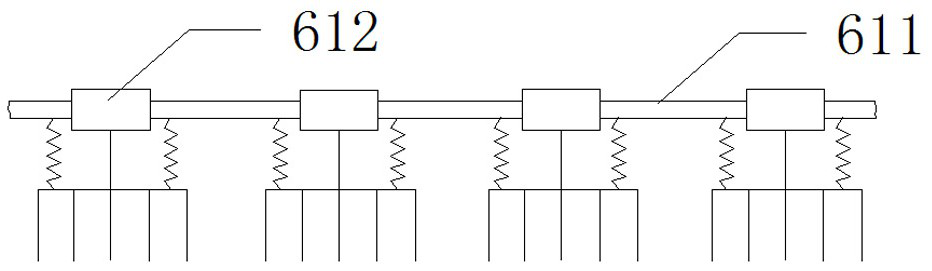

Production method and production system for extracting oil in oil sludge

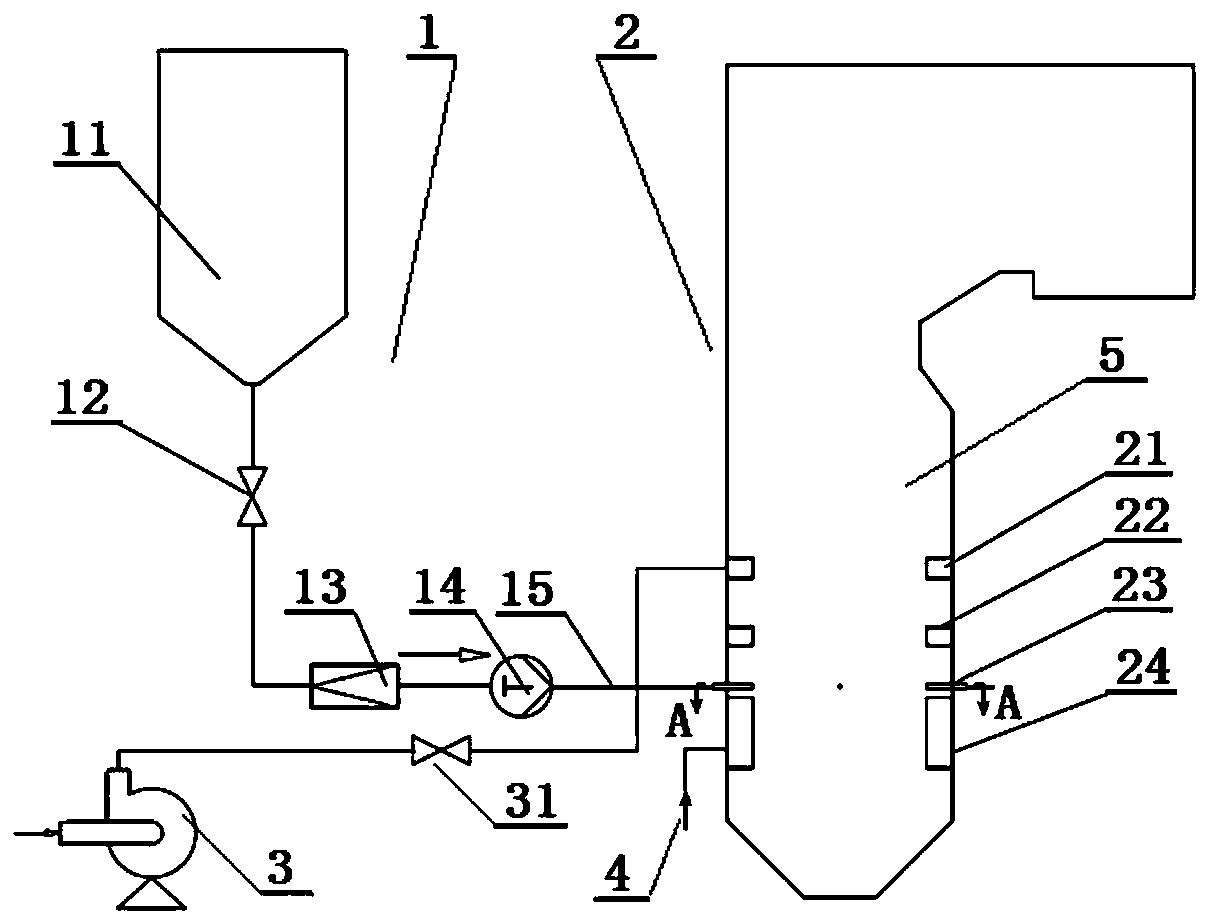

ActiveCN111875208ARealize continuous industrial productionSuitable for harmless treatmentSludge treatment by pyrolysisByproduct vaporizationThermodynamicsCoke

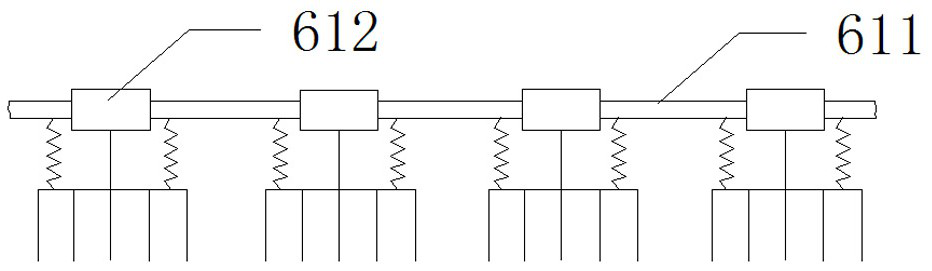

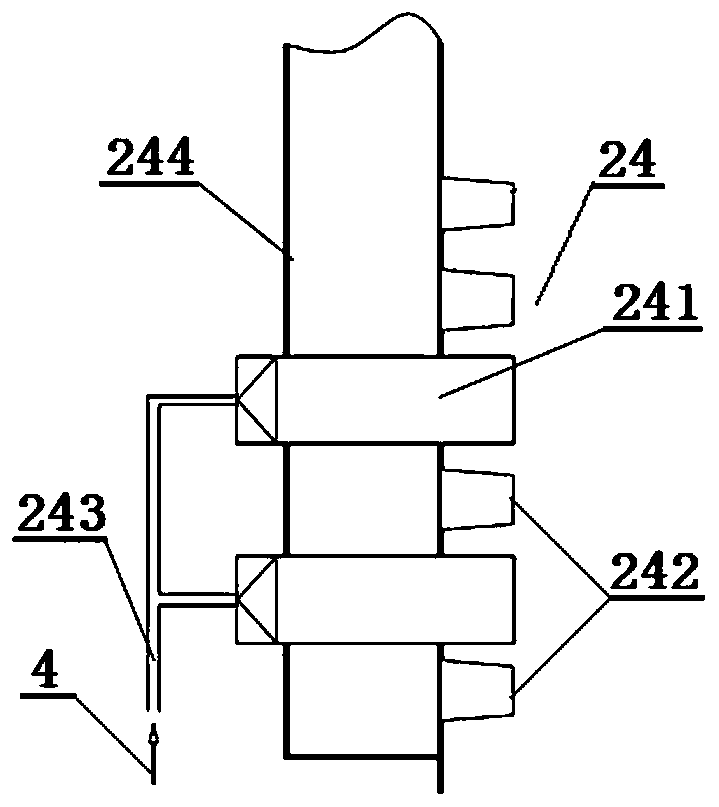

The invention discloses a production method and a production system for extracting oil in oil sludge. An oil sludge pyrolysis device comprises a rotary drum, wherein the open end of the rotary drum iscommunicated with a fixed cylindrical discharge end socket, and the rotary drum is in rotary sealing fit with the discharge end socket; a spiral guide plate is fixedly arranged on the inner wall of the rotary drum, the rotary drum rotates, and the spiral guide plate pushes and throws oil sludge; oil steam and residues after pyrolysis are discharged from the discharging seal head; a decoking and crushing device in the rotary drum comprises a fixed shaft parallel to the axis of the rotary drum, a plurality of decoking tooth claws are arranged on the fixed shaft at intervals in the axial direction, the handle ends of the decoking tooth claws are rotatably arranged on the fixed shaft in a sleeving mode, the claw ends elastically press and contact the inner wall of the rotary drum through springs, and the rotating direction of the claw ends is opposite to that of the rotary drum under the action of the springs; the decoking tooth claws grab and dig the inner wall of the rotary drum along with the rotation of the rotary drum to remove inner wall cokes and crush oil sludge blocks. The method realizes continuous industrial production of extracting the oil in the oil sludge, and is high inpyrolysis efficiency, thorough in harmless treatment of the oil sludge and high in oil recovery rate.

Owner:舟山麦哲伦环保科技有限公司

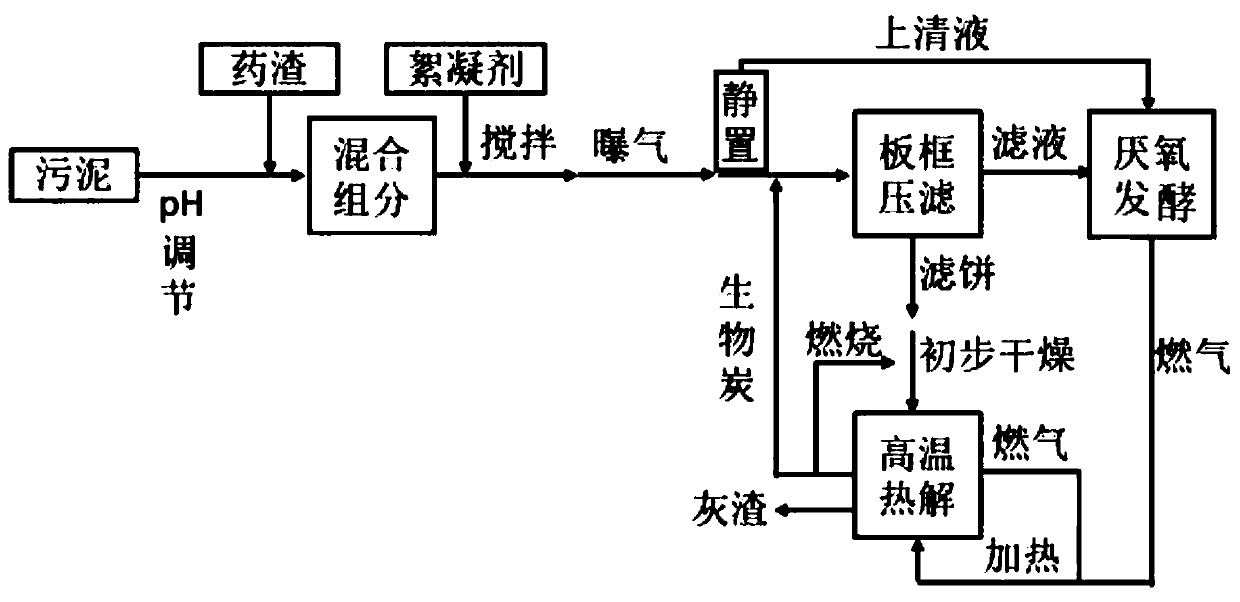

Method for synergetic drying pyrolysis of sludge and medicine residues

PendingCN110724547AReduce adsorptionReduce the binding forceSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBiotechnologyMicroorganism

The invention discloses a method for synergetic drying pyrolysis of sludge and medicine residues. The method comprises four steps of composition compounding, specific resistance regulation, synergeticdehydration and high-temperature pyrolysis. In a mode that traditional Chinese medicine residues or non-medicinal parts of traditional Chinese medicine plants of a specific ratio are put into sludge,the specific resistance of components to be treated and the ratio of sand in components to be pyrolyzed can be reduced, breakage of microbial cells in the sludge can be promoted through sterilizationcomponents in the traditional Chinese medicine residues, the dehydration efficiency of components to be treated can be improved, and the yield of pyrolysis ash of raw materials of a unit mass can bereduced. By adopting the method disclosed by the invention, synergetic pyrolysis of the sludge and the medicine residues is achieved, the treatment difficulty of single components of sludge and medicine residues can be reduced, and the method has a wide application prospect in synergetic pyrolysis treatment on organic solid wastes with high water contents.

Owner:ADVANCED FOR MATERIALS & EQUIP +1

Combustion device facilitating directly injecting water-coal slurry into low-oxygen flames to reduce NOx

PendingCN110925747AReduce Flame PeakReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlue gasProcess engineering

The invention relates to a combustion device facilitating directly injecting water-coal slurry into low-oxygen flames to reduce NOx. A water-coal slurry supplying mechanism provided with a water-coalslurry convey-out mother pipe, and a combustion mechanism provided with a high position separating air spray port, a low position separating air spray port, a water-coal slurry spray gun, a powder supplying air powder spray port and a gas supplying hot air spray port are included. Due to the reasonable structure innovation design, it is achieved that a method that only the water-coal slurry made from the conventional use coal of a boiler is utilized for generating a pyrolytic reaction in a furnace to generate active pyrolysis gas is utilized for reducing the NOx generated in the furnace and inhibiting generation of thermal NOx, the concentration of NOx in flue gas is effectively lowered, limitation of a traditional NOx reducing technology is broken through, and it is also guaranteed that the low nitrogen emission requirement of the boiler is met under the low-cost situation. The method is scientific and reasonable, the structure is simple and easy to implement, work is reliable, the daily using cost is low, operating management and low-cost efficient production of enterprises is facilitated, and very high practicability is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Waste tire handling technology

The invention belongs to the technical field of tire handling, and specifically relates to a waste tire handling technology. The technology comprises the following steps: S1, preprocessing, namely, cleaning a tire to remove dirt; S2, cutting the preprocessed tire into rubber blocks; S3, processing the rubber blocks for the second time; and crushing to obtain rubber scraps; and S4, feeding the rubber scraps into a reaction kettle; catalytically heating; distilling to obtain oil steam; processing the oily gas through a light and heavy component separating device; feeding a light component into acondenser; synchronously discharging carbon black during combustion; condensing to obtain liquid oil; conveying non-liquefied part into a heating system through a gas purifying system; combusting; removing dust of the waste gas produced in combustion through a dust removing system; and then discharging. According to the technology, the impurities on the tire can be cleaned by preprocessing; afterthe tire is cut into the rubber blocks, the rubber blocks are cooled and crushed under low temperature so as to obtain small rubber scraps; the rubber scraps are subjected to thermally decomposed, the inside is heated fast, so that the thermal decomposing reaction is correspondingly improved, and as a result, the yield of thermal decomposing oil is increased.

Owner:山西晋邦企业服务有限公司

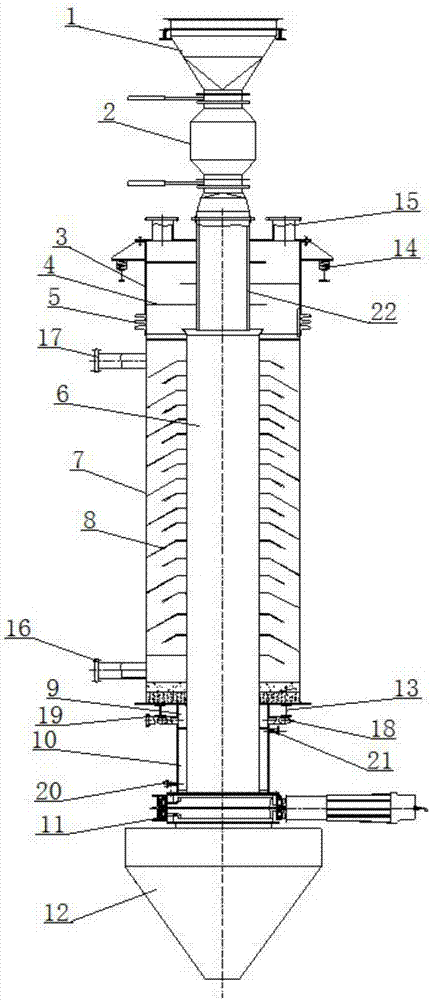

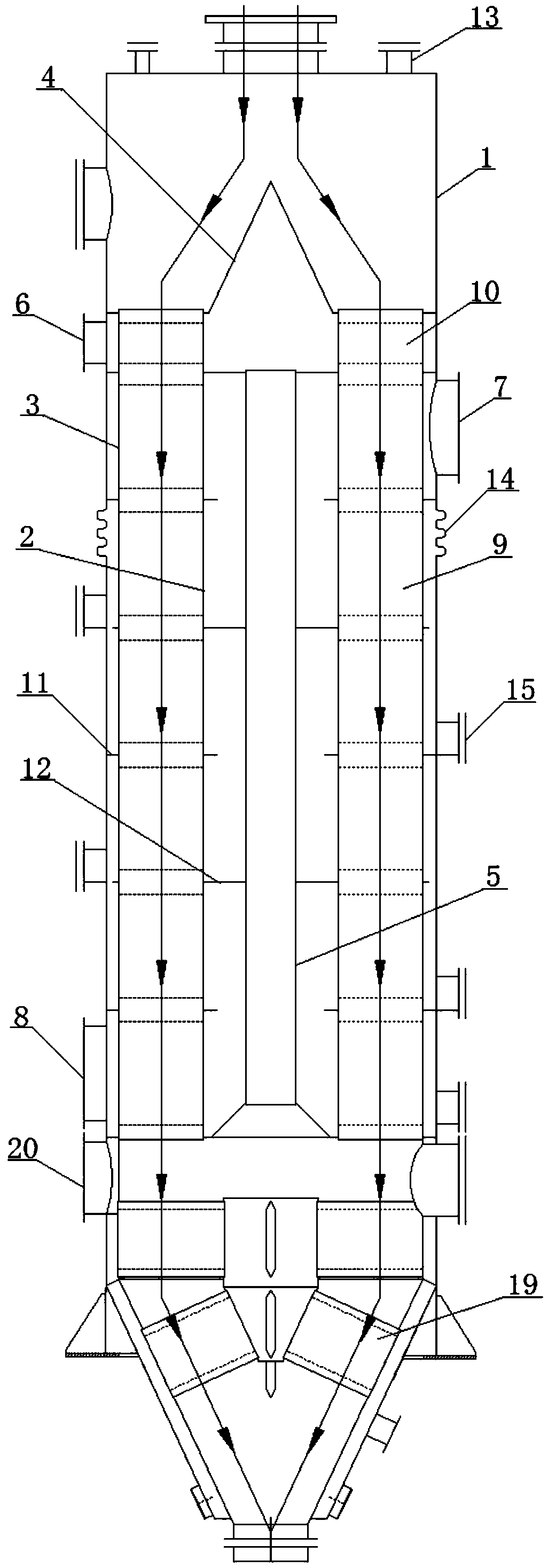

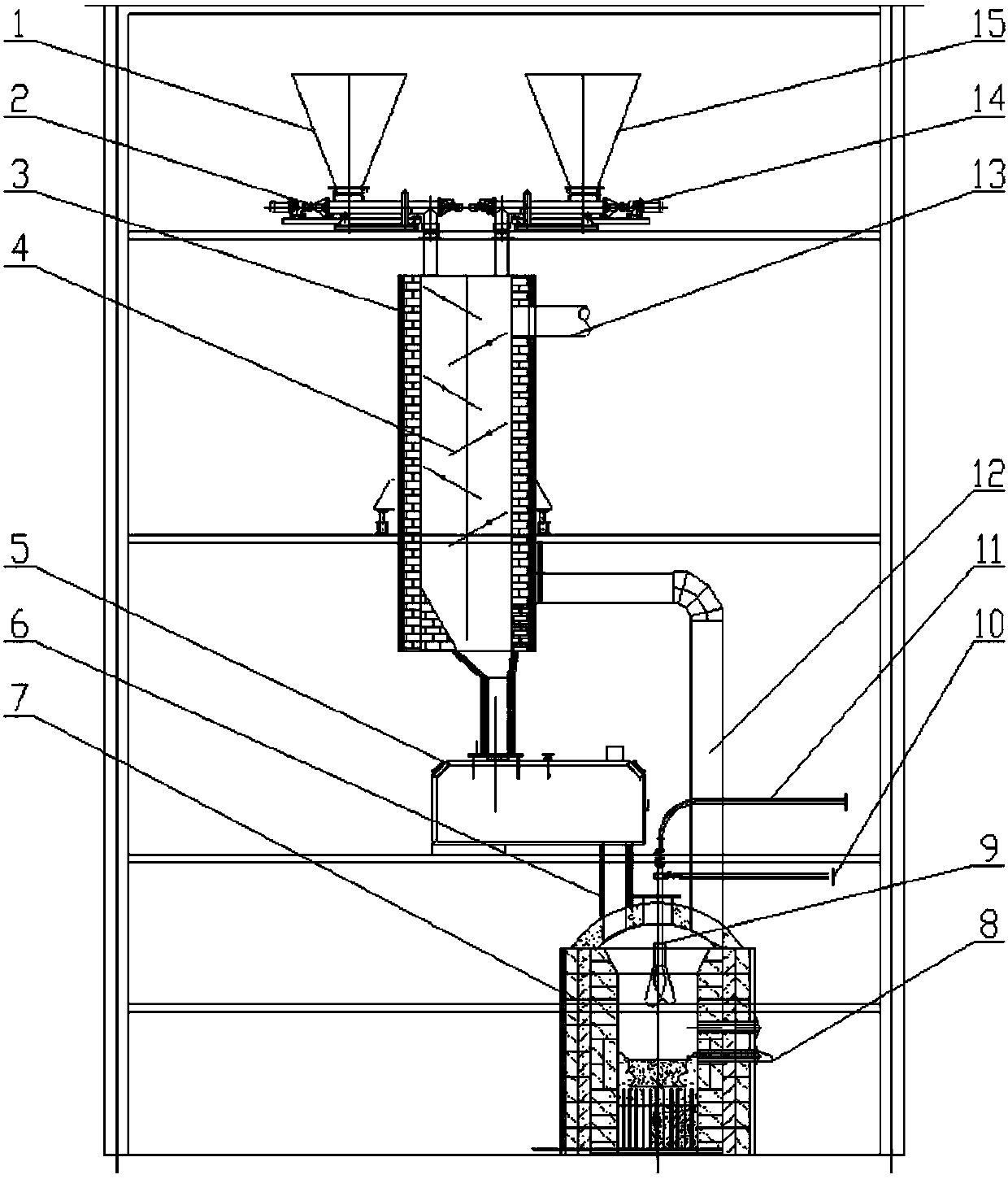

High-efficiency biomass treatment tar poly-generation pyrolysis furnace

InactiveCN107267176AReduce coking rateRealize gas-solid separationBiofuelsGasification processes detailsCooling chamberTar

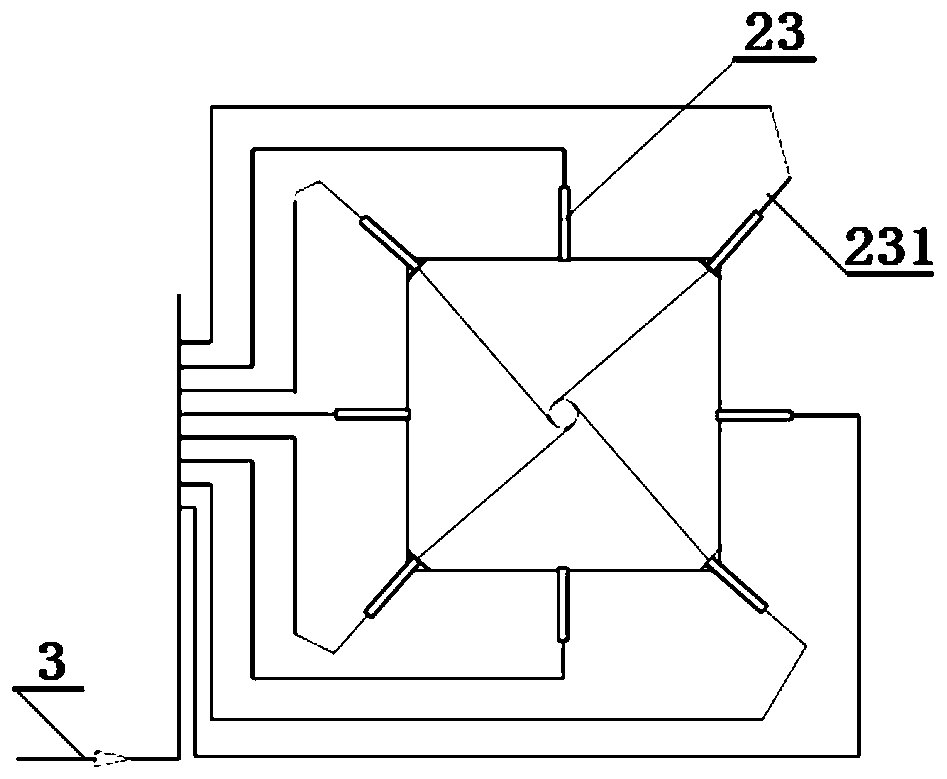

A high-efficiency biomass treatment tar poly-generation pyrolysis furnace comprises a feed bunker (1), a lock bucket (2), a settling chamber (3), a reaction chamber, a cooling chamber and a discharged charcoal bunker (12), the lower end of the settling chamber (3) is connected with the reaction chamber, the lower end of the reaction chamber is connected with the cooling chamber, the bottom end of the cooling chamber is connected with the discharged charcoal bunker (12), a feed hose tube (22) is arranged in the settling chamber (3), the top end of the lock bucket (2) is connected with the outlet of the feed bunker (1), the bottom end of the lock bucket (2) is connected with the inlet of the feed hose tube (22) of the settling chamber (3), the inner wall of the settling chamber (3) is provided with a deflector separator (4), the deflector separator (4) is connected with the outer wall of the feed hose tube (23), and the top of the settling chamber (3) is provided with a pyrolysis gas outlet (15). The deflector separator (4) realizes gas-solid separation, so dusts in combustible gas are separated, the combustible gas is purified, and the coking rate of a purification system is reduced.

Owner:武汉光谷蓝焰新能源股份有限公司

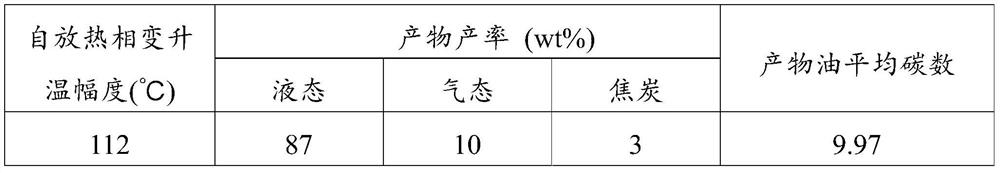

Polyolefin waste plastic self-exothermic phase change thermal cracking process

ActiveCN113429994APromote pyrolysis reactionConducive to pyrolysis reaction for more complete pyrolysis reactionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPolyolefinCracking reaction

The invention relates to the technical field of waste plastic recycling, and particularly discloses a polyolefin waste plastic self-exothermic phase change thermal cracking process which comprises the following steps: placing polyolefin waste plastic in a high-pressure reactor, and introducing inert gas to replace air in the high-pressure reactor; inputting a phase construction agent into the high-pressure reactor, wherein the phase construction agent comprises inert gas with an initial pressure value greater than 0.5 MPa and / or hydrocarbon liquid with a boiling point lower than 125 DEG C; heating the high-pressure reactor to 340-380 DEG C, enabling the pressure value in the high-pressure reactor to be 2-6 MPa, subjecting the polyolefin waste plastic to a self-exothermic phase change thermal cracking reaction, and obtaining a thermal cracking product. The self-exothermic phase change of the polyolefin waste plastic long-chain hydrocarbon is realized by establishing a specific phase state condition, so that the thermal cracking reaction temperature is greatly increased, the deep cracking of the polyolefin waste plastic is promoted, and the energy consumption in the heat treatment process can be obviously reduced.

Owner:佛山市科恒博环保技术有限公司

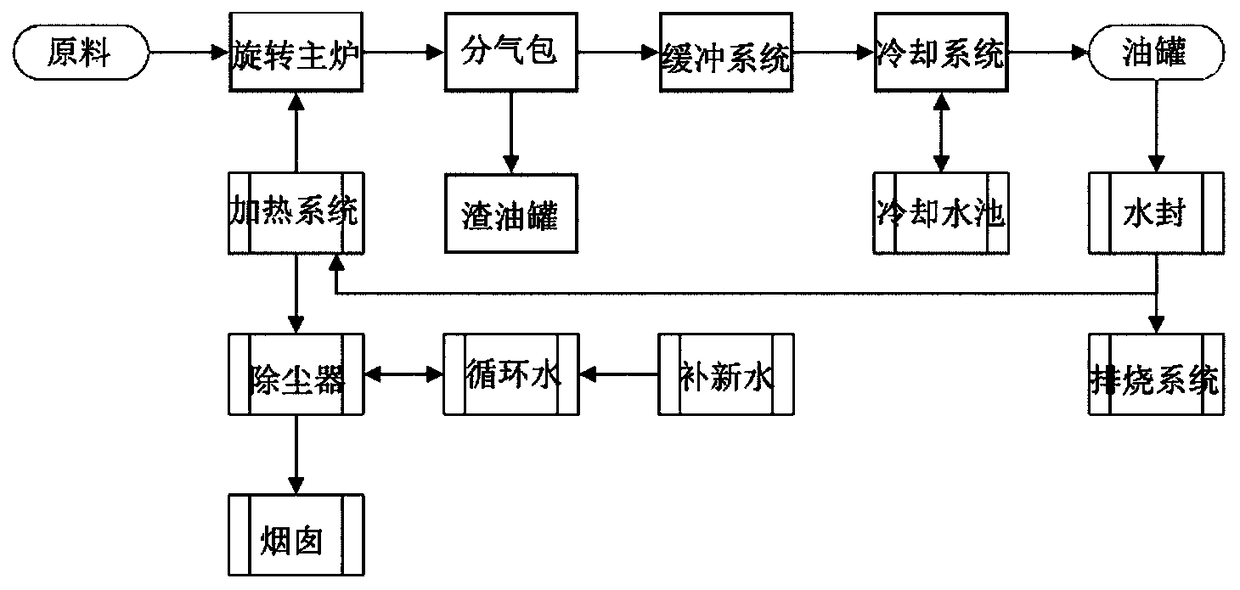

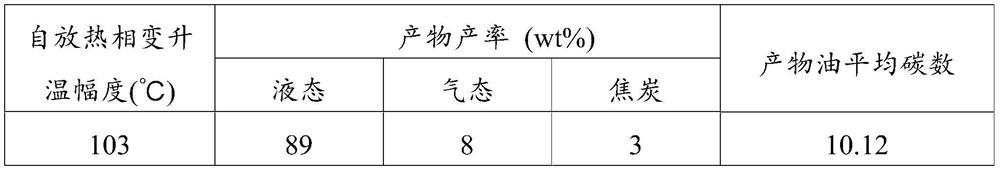

Thermal cracking comprehensive utilization method for iron and steel industry solid waste and hazardous waste resources

InactiveCN112063395AAchieving zero emissionsSave investment in environmental protectionSpecial form destructive distillationLiquid productFuel oil

The invention relates to the technical field of iron and steel industry, solid waste and hazardous waste treatment and thermal cracking, in particular to a thermal cracking comprehensive utilization method for iron and steel industry solid waste and hazardous waste resources. Cracking raw materials obtained after pretreatment of iron and steel industry solid waste and hazardous waste resources enter a thermal cracking main machine through a feeding system and are heated to 200-600 DEG C in an air-isolated environment for a continuous thermal cracking reaction, and a high-temperature gaseous product and a solid product (ash residues) are generated; the high-temperature gaseous product generated by cracking passes through an oil-gas separation cooler to obtain a gaseous product (combustiblegas) and a liquid product (fuel oil); and flue gas discharged from an iron and steel industry solid waste treatment rotary kiln enters a rotary kiln flue gas treatment system, and the treated flue gasis discharged after reaching the standard. By adopting the method disclosed by the invention, the crackable solid waste and hazardous waste products in the iron and steel industry can be recycled andutilized in a high-valued manner, up-to-standard emission of waste gas and zero emission of waste water and waste residues are realized, and meanwhile, considerable economic benefits are obtained.

Owner:SHANDONG IRON & STEEL CO LTD

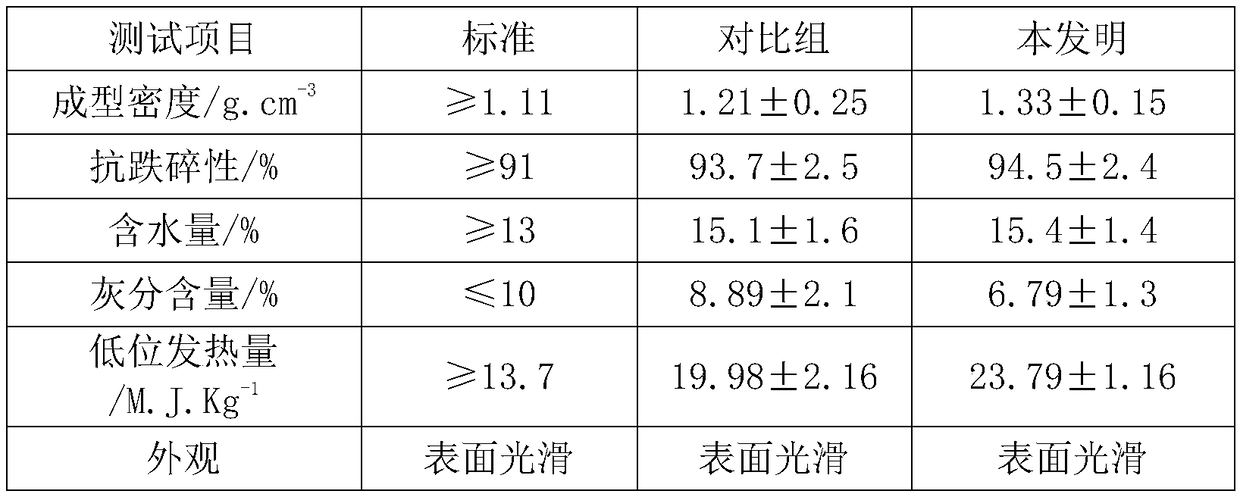

Smashing process of biomass fuel

ActiveCN109082322APromote absorptionImprove crushing efficiencyBiofuelsSolid fuelsEngineeringUltra fine

The invention discloses a smashing process of a biomass fuel, and belongs to the field of processing of biomass fuels. In the preparation method, straws are treated in different physical and chemicalaspects by ultrasonic soaking and hot rolling pretreatment, grinding pre-crushing, half anerobic roasting secondary treatment and ultrafine secondary crushing, the compactness of the straws is improved favorably, filling operation of crushing is facilitated, meanwhile, the crushing efficiency is improved, finally, ultra-fine crushing is centrifugal knife type crushing, air flow is generated in a crushing process, particles in small fineness are separated from particles in large fineness under the centrifugal effect, meanwhile, the particles in large fineness can be secondarily crushed, doubleeffects of separating and crushing are achieved, the crushed particles are uniform, and in the whole crushing process, an effect of increasing heat of combustion and energy density of the prepared biomass fuel is achieved.

Owner:安徽聚焰生物科技股份有限公司

Environment-friendly integrated kitchen ware

InactiveCN102183053APromote pyrolysis reactionEasy dischargeDomestic stoves or rangesLighting and heating apparatusCombustorCombustible gas

The invention discloses an environment-friendly integrated kitchen ware. The kitchen ware comprises a stove and a range hood, wherein the range hood comprises a flow guide plate, an oily fume inlet and an induced draft fan; the kitchen ware is also provided with a range hood oil-gas separator and a dirty oil thermal cracker; a gas inlet of the range hood oil-gas separator is communicated with thefume inlet; a draft pipe of the induced draft fan is communicated with an exhaust port of the range hood oil-gas separator; an oil discharge outlet of the range hood oil-gas separator is communicatedwith the dirty oil thermal cracker; the dirty oil thermal cracker is arranged at the periphery of a stove combustor and is provided with a dirty oil thermal cracking enzyme feeding pipe and a thermalcracking oil gas outlet; and the thermal cracking oil gas outlet is communicated with a fuel gas pipe of the stove. Compared with the prior art, the kitchen ware has the advantages of: thermal cracking reaction of oil stain can be promoted by heating the dirty oil thermal cracker with waste heat emitted to the periphery from the stove; the oil stain produced by kitchens, restaurants, food processing plants and the like can be recovered and cracked into combustible gas; environment is protected; and energy of the dirty oil is utilized.

Owner:SHAOXING UNIVERSITY

Method for producing oil by co-pyrolysis of house refuse and forestry and agricultural residues

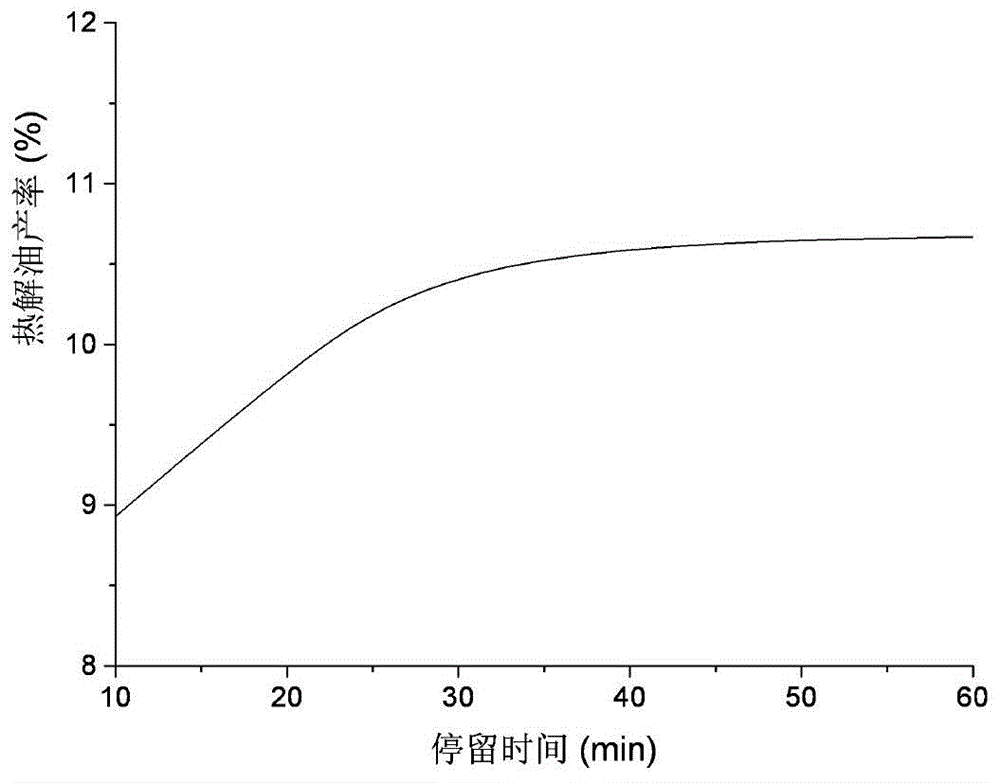

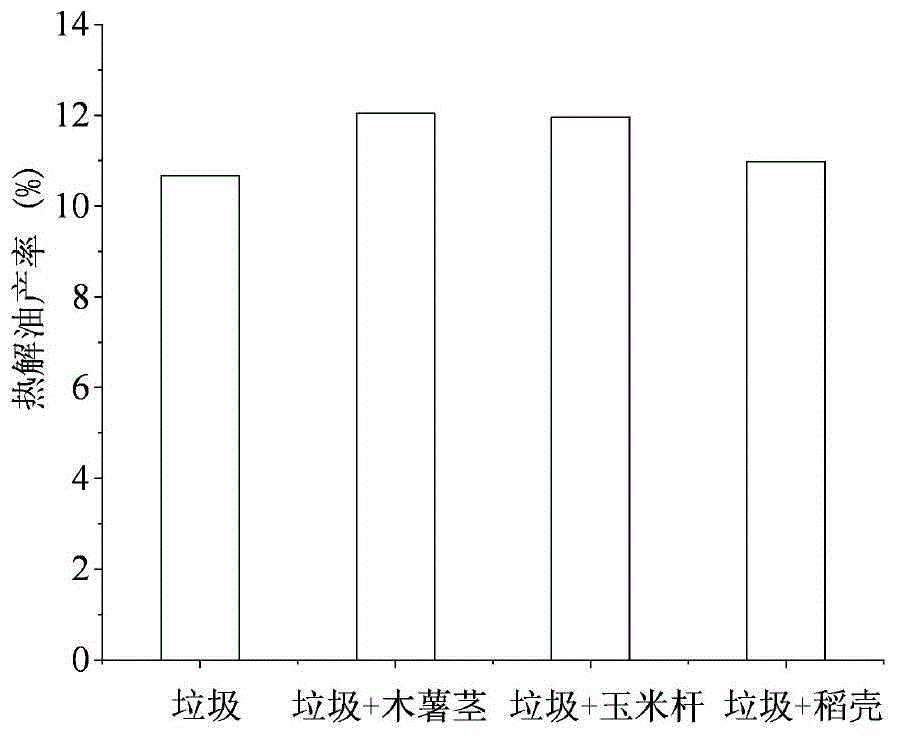

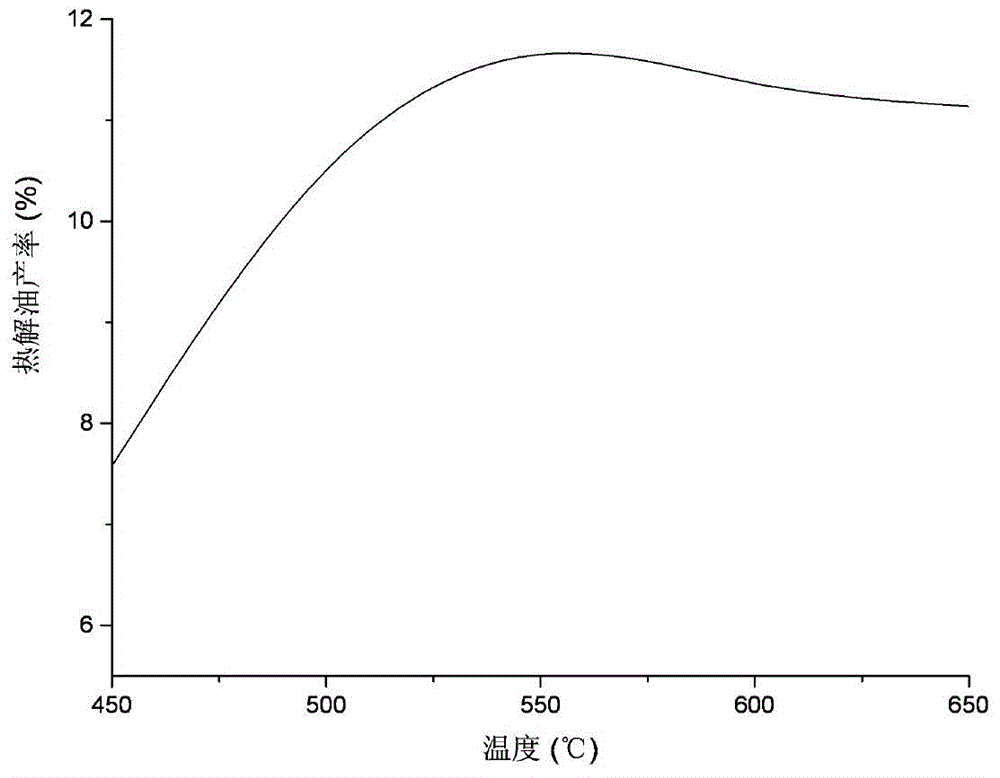

InactiveCN106256876AImprove pyrolysis hydrogen supply shortagePromote pyrolysis reactionBiofuelsLiquid hydrocarbon mixture productionSocial benefitsAgricultural residue

The invention provides a method for producing oil by co-pyrolysis of house refuse and forestry and agricultural residues. According to the invention, the house refuse and the forestry and agricultural residues are crushed and dried, the materials are uniformly mixed according to certain proportion, a mixture is put into a pyrolysis reactor, the mixture is heat from room temperature to certain temperature under anoxic condition for pyrolysis, the mixture is stayed at pyrolysis final temperature for a while, the volatilization products are introduced into a condensation apparatus in a gaseous state, the non-condensing gas and pyrolytic coke are reburned for providing energy for pyrolysis and drying processes, the condensation gas is recovered as a pyrolysis solution, the pyrolysis solution is subjected to oil-water separation to obtain the pyrolysis oil and water-soluble liquid, the pyrolysis oil is used as the fuel oil, and the water-soluble liquid is used as a chemical raw material. The co-pyrolysis mode is employed for processing house refuse and forestry and agricultural residues, the self-sufficient heat energy problem required for pyrolysis of house refuse can be solved, synergism is generated during co-pyrolysis of house refuse and forestry and agricultural residues, the pyrolysis oil yield is increased, and synergism can generate good social benefit and economic benefit.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

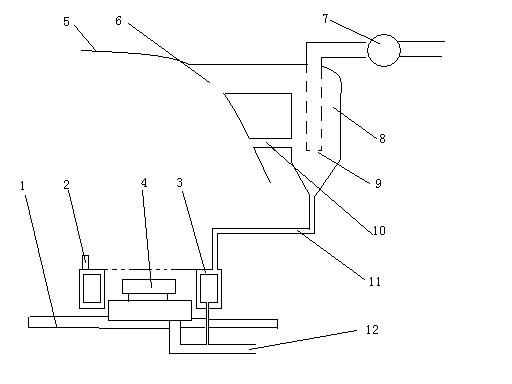

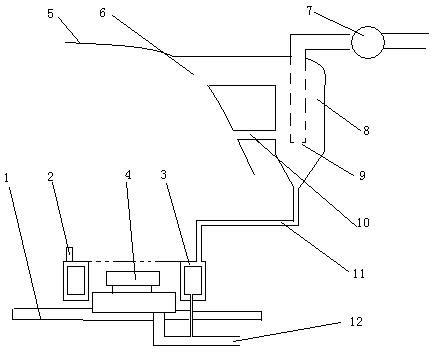

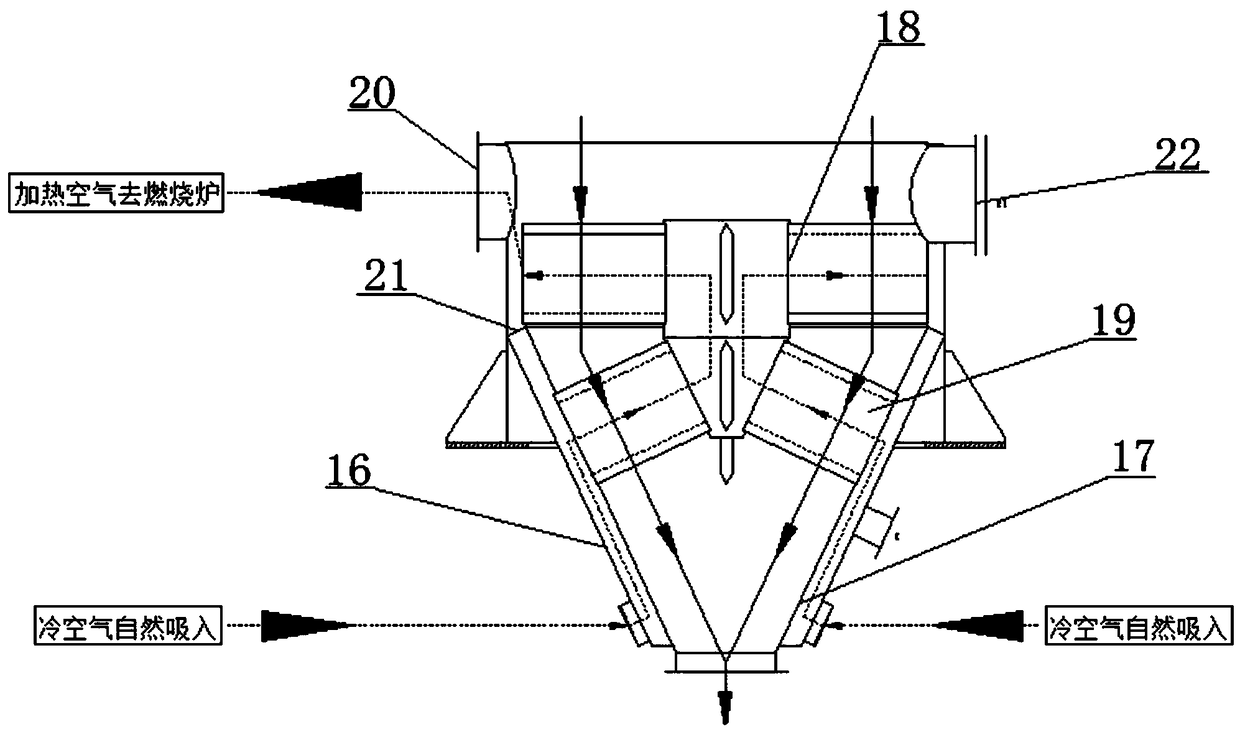

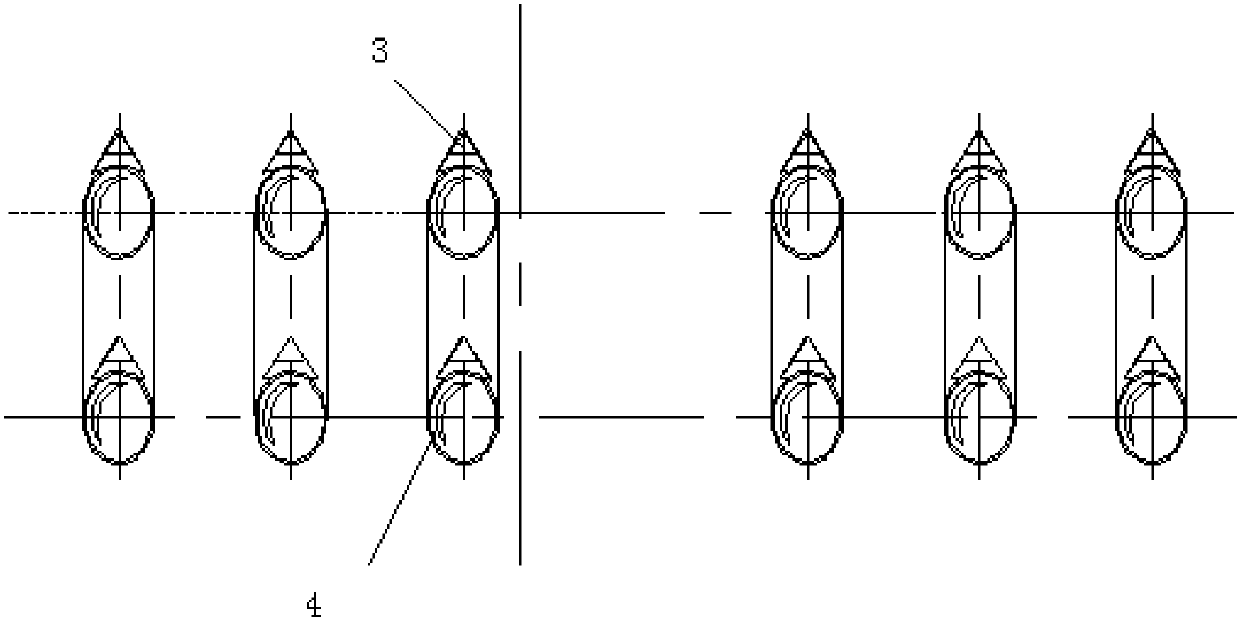

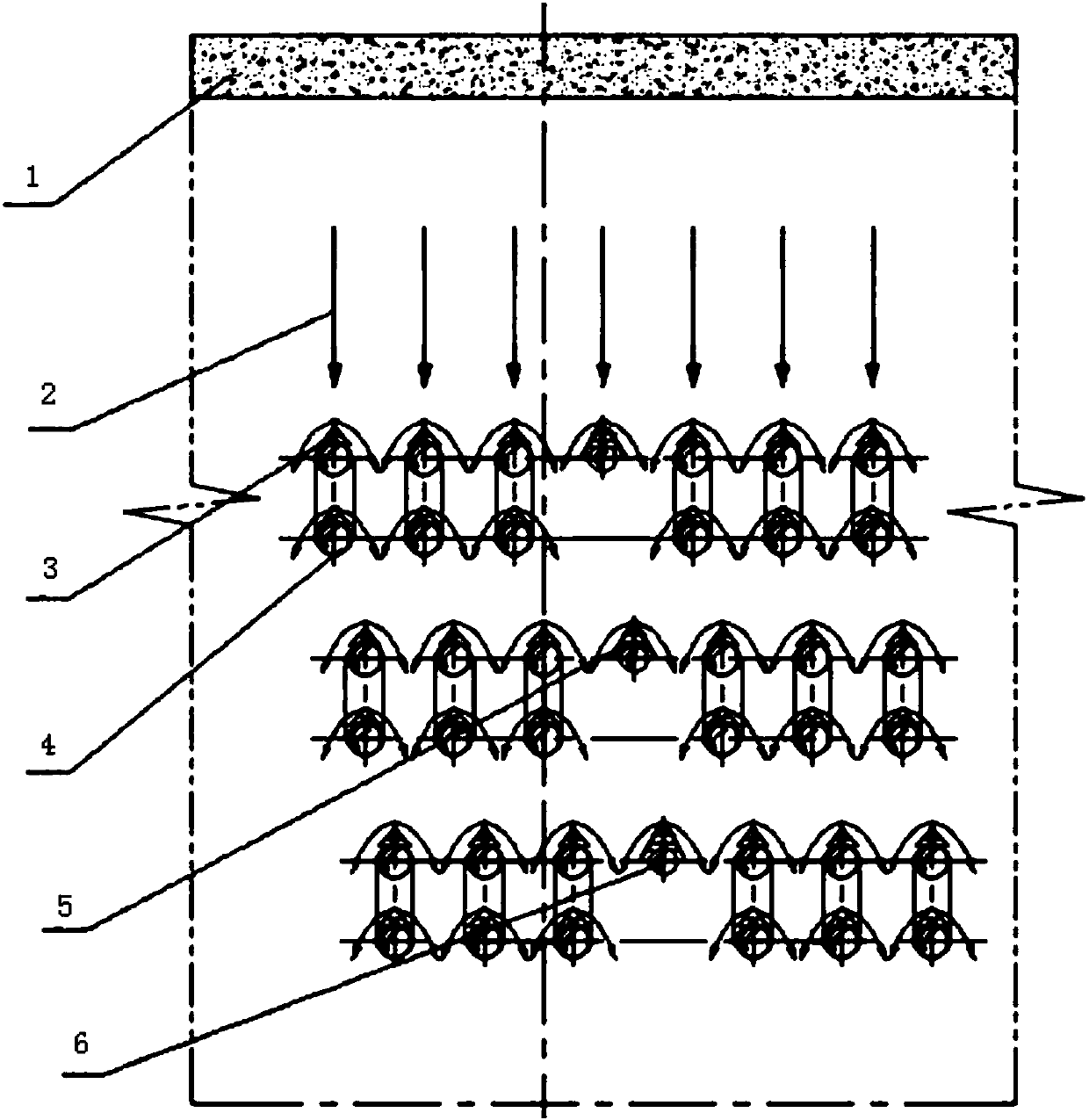

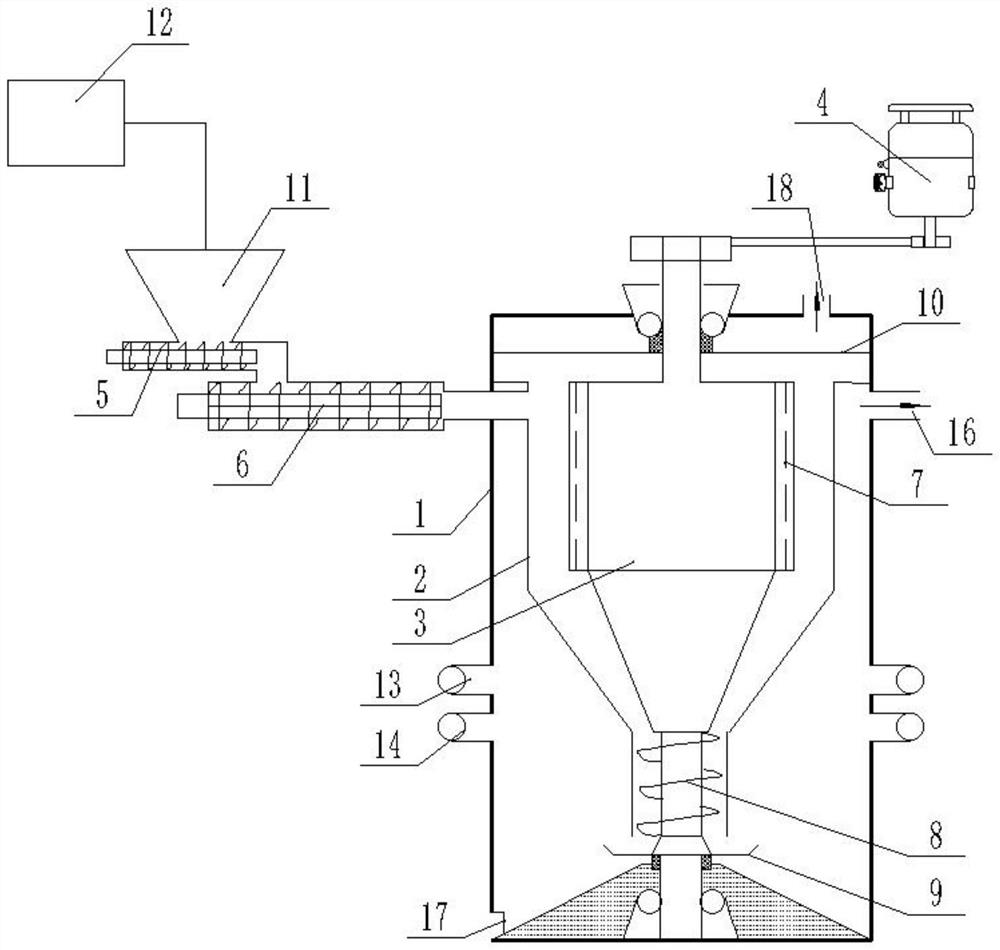

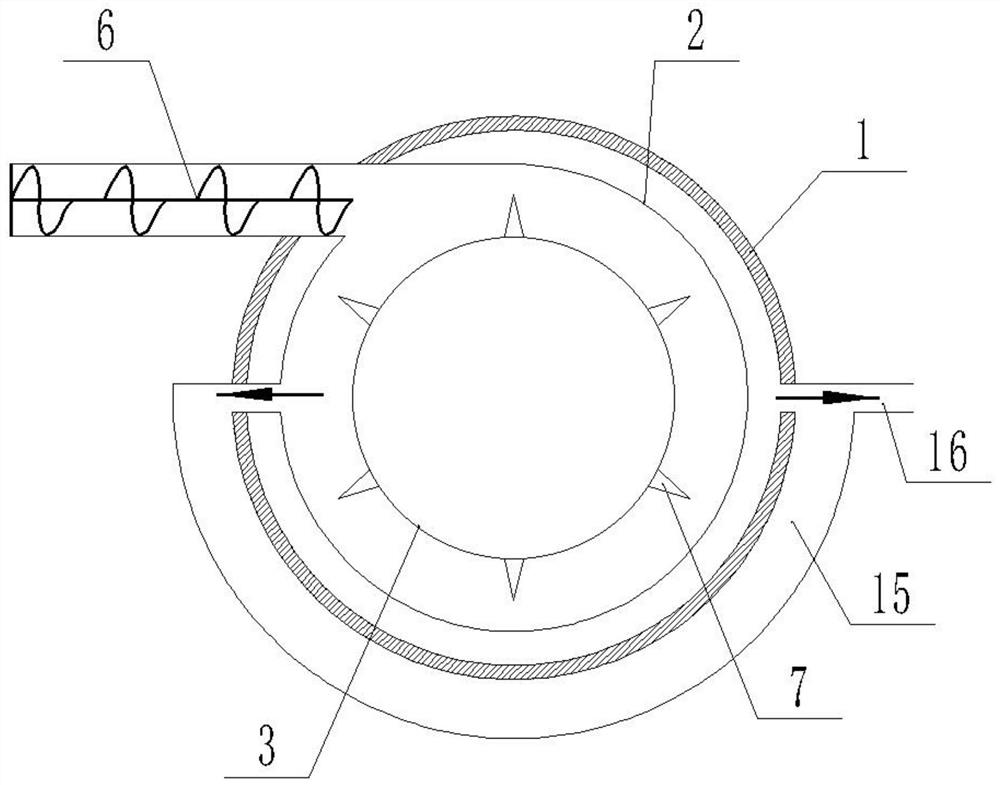

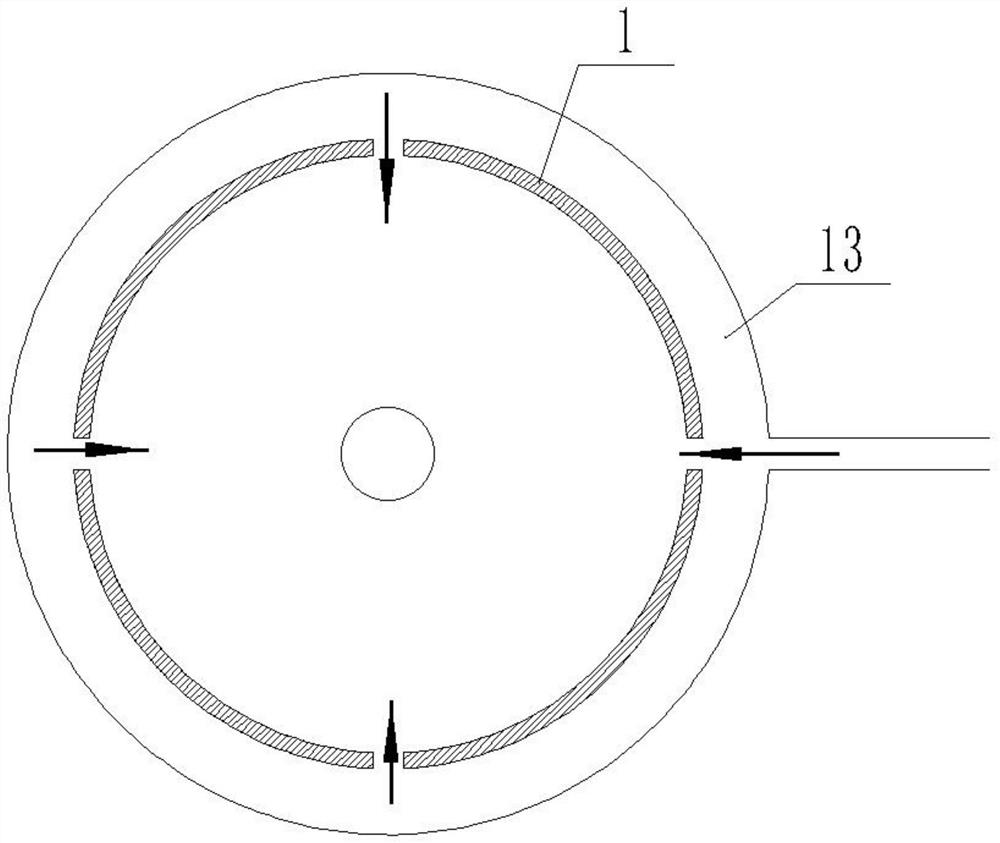

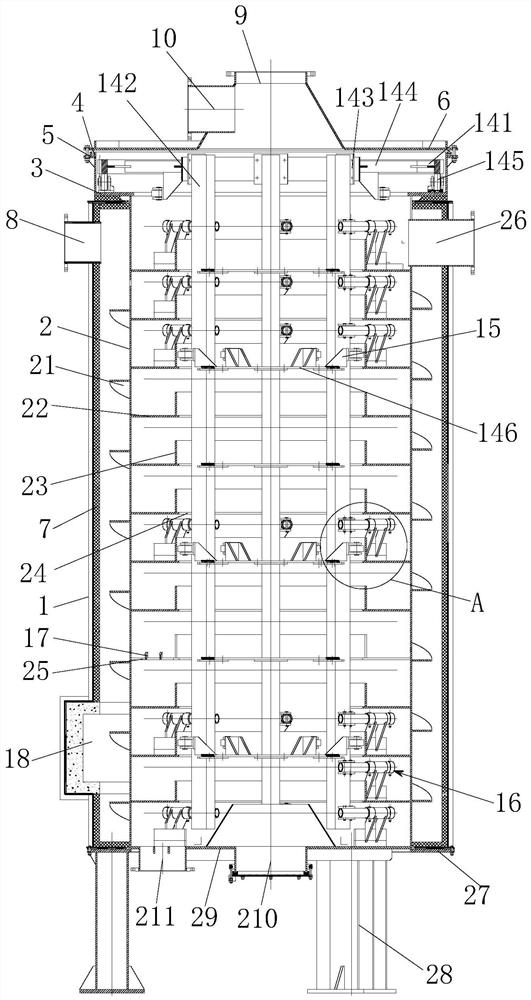

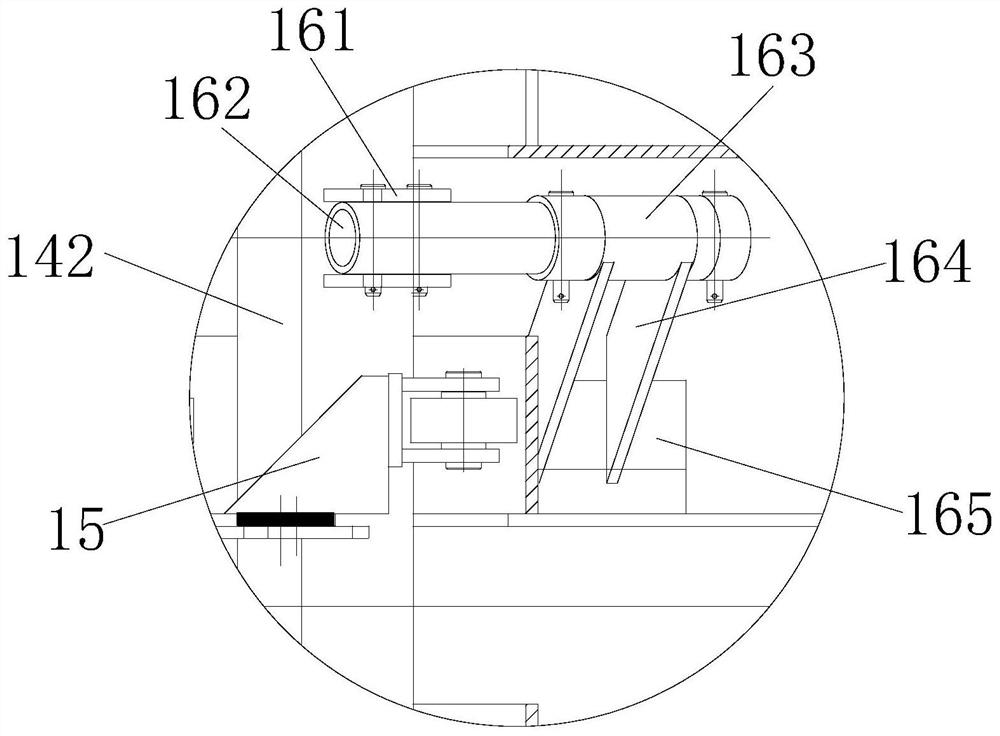

Self-weight spiral progressive type high-efficiency and energy-saving biomass pyrolysis furnace device

ActiveCN109022001ARealize continuous productionIncrease the heat exchange areaBiofuelsSpecial form destructive distillationEngineeringDistributor

A self-weight spiral progressive type high-efficiency and energy-saving biomass pyrolysis furnace device comprises a pyrolysis furnace and an air cooler, a closed cavity is formed between the outer box body (16) and the inner box body (17) of the air cooler, a closed cylindrical shell (18) is arranged in the inner box body (17), a plurality of layers of air cooling flow deflectors (19) are arranged between the inner box body (17) and the cylindrical shell (18), an opening at one end of every air cooling flow deflector (19) is communicated with the inner chamber of the cylindrical shell (18), and an opening at the other end of the air cooling flow deflector (19) is communicated with the cavity between the outer box body (16) and the inner box body (17); and an inner cylinder (2) and an outer cylinder (3)are arranged in the inner part of the furnace body (1) of the pyrolysis furnace, a conical distributor (4) is arranged at a position, corresponding to the charging port of the furnace body (1), of the top of the inner cylinder (2), and a pyrolysis gas secondary pyrolysis tube (5) is arranged in the inner cylinder (2). The device has the advantages of heat transfer and interaction, high heat utilization efficiency, and realization of cascade utilization of energy.

Owner:HUBEI NORMAL UNIV

Reaction apparatus of microwave pyrolysis biomass

PendingCN108587653AIncrease the proportion of pyrolysis gasImprove economyGasification catalystsChemical industryMicrowave pyrolysisGas phase

The invention discloses a reaction apparatus of a microwave pyrolysis biomass. The reaction apparatus comprises a microwave pyrolysis unit, the microwave pyrolysis unit comprises a microwave thermal decomposition furnace, and at least a feed inlet arranged outside the microwave thermal decomposition furnace, the microwave thermal decomposition furnace comprises a solid-phase pyrolysis part and a gas-phase pyrolysis part connected in order from down to up, the solid-phase pyrolysis part comprises a solid-phase hollow circular column composed of metal mesh, and the solid-phase hollow circular column is filled with a solid-phase microwave absorbent and a catalyst. The reaction apparatus increases the pyrolysis heating rate, reduces the generation amount of solid carbon residue, increases theproportion of pyrolysis gas in products, and optimizes the pyrolysis reaction process, has the advantages of simple equipment, less land occupation, and convenient operation, can complete operation ofcontinuous feeding and deslagging, and is convenient for operation and management.

Owner:司宸

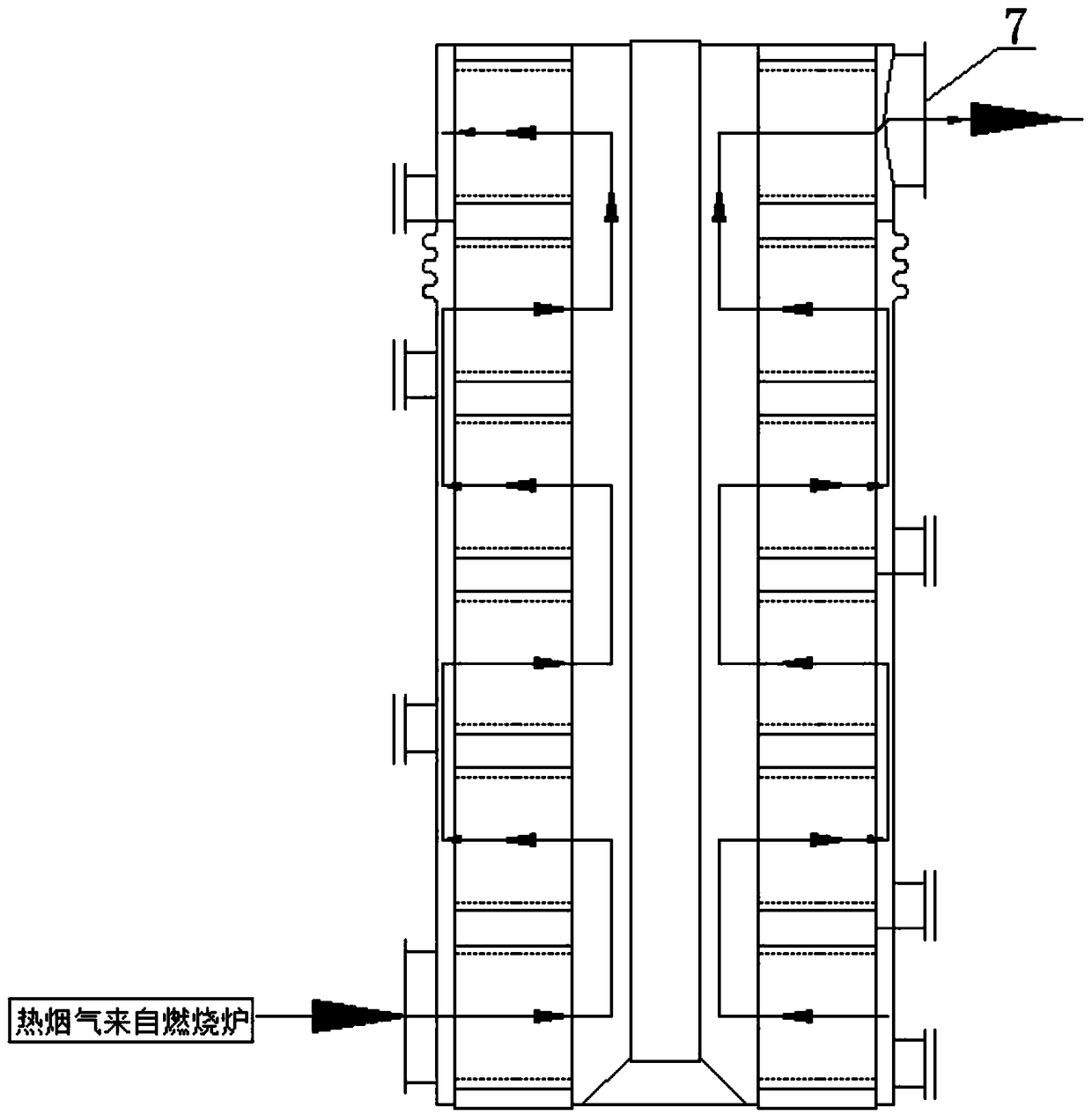

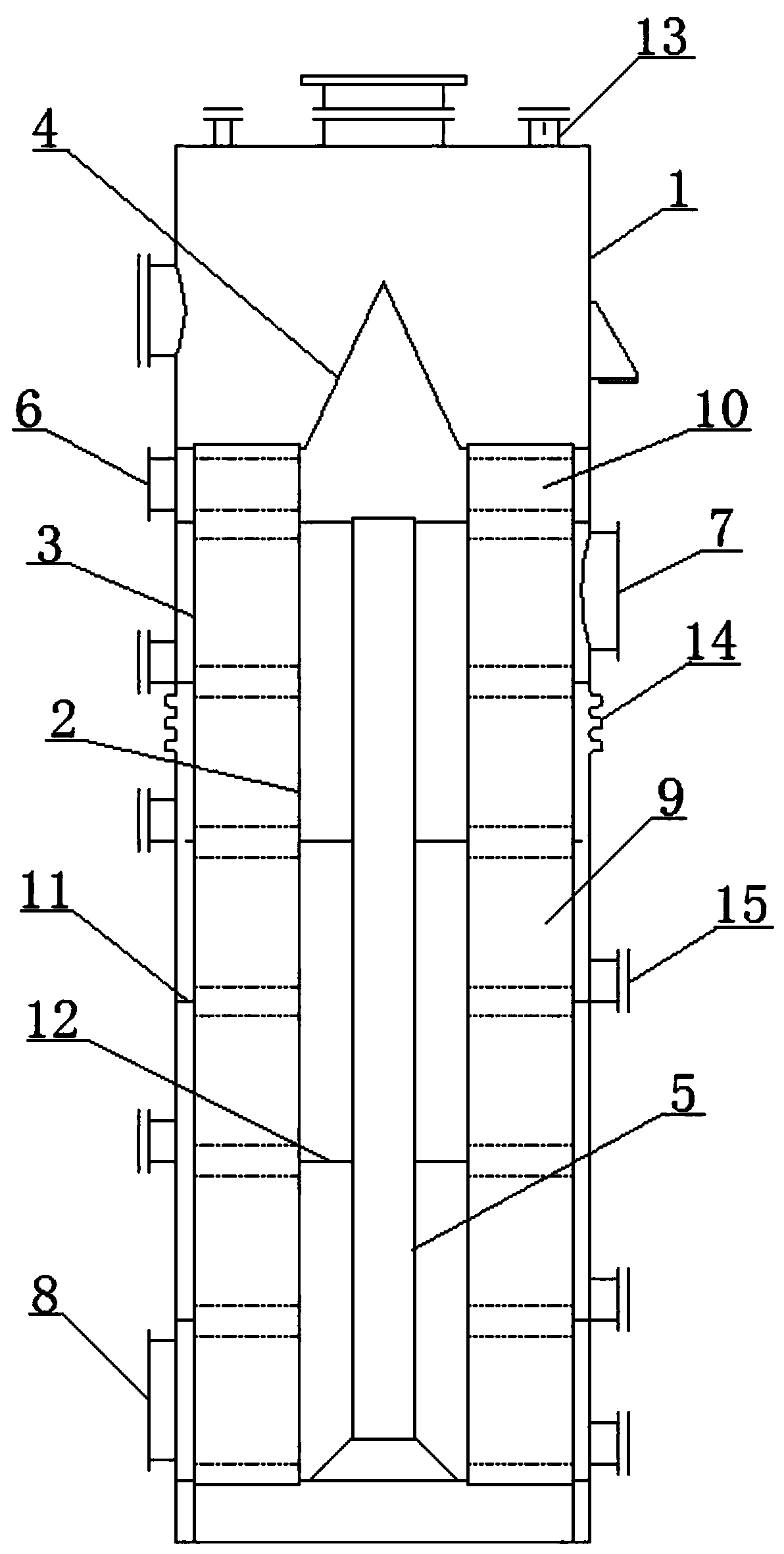

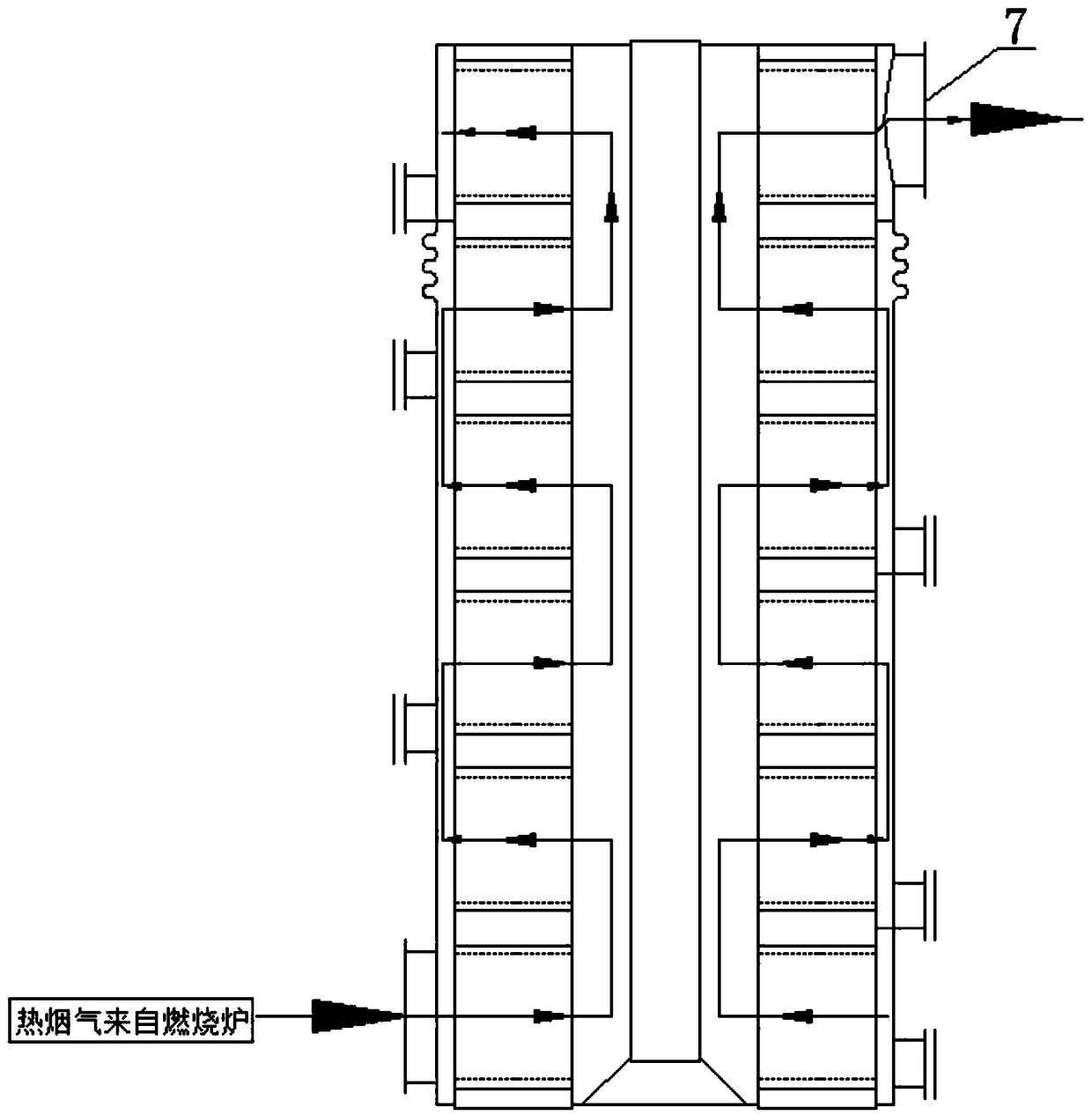

Progressive high-efficiency energy-saving biomass pyrolyzing furnace

ActiveCN109266370ARealize continuous productionIncrease the heat exchange areaBiofuelsSpecial form destructive distillationProcess engineeringDistributor

The invention relates to a progresasive high-efficiency energy-saving biomass pyrolyzing furnace. An internal barrel (2) and an external barrel (3) are arranged in a furnace body (1), a conical distributor (4) which corresponds to the feed inlet of the furnace body (1) is arranged on the top of the internal barrel (2), a secondary pyrolyzed gas pyrolysis pipe (5) is arranged in the internal barrel(2), the cavity of the internal barrel (2) is not communicated with the cavity of the secondary pyrolyzed gas pyrolysis pipe (5), the top of the secondary pyrolyzed gas pyrolysis pipe (5) is an outlet, the bottom of the secondary pyrolyzed gas pyrolysis pipe (5) is an inlet, the upper part of the furnace body (1) is provided with a pyrolyzed gas outlet (6) and an exhaust gas outlet (7), the lowerpart of the furnace body (1) is provided with a hot exhaust gas inlet (8), the outlet of the secondary pyrolyzed gas pyrolysis pipe (5) is communicated with the pyrolyzed gas outlet (6), and both theexhaust gas outlet (7) and the hot exhaust gas inlet (8) are communicated with the cavity of the internal barrel (2). Heat transfers interact with each other, the efficiency of heat utilization is high, and gradient energy utilization is realized.

Owner:武汉光谷蓝焰新能源股份有限公司

Oily sludge treatment system based on three-section rotary kiln

PendingCN111978966ASimple structureIngenious designSludge treatment by pyrolysisVapor condensationSludgeCyclonic separation

The invention discloses an oily sludge treatment system based on a three-section rotary kiln. The system is characterized by comprising a fluidized bed, the outlet end of the fluidized bed is connected with a cyclone separator through a pipeline; the air outlet end of the cyclone separator communicates with the inner cavity of a heat transfer jacket through a pipeline; the ash discharge end of thecyclone separator is connected with the inlet end of the three-section rotary kiln through a pipeline; the three-section rotary kiln is sequentially divided into a mixing section, a heat transfer section and a combustion section from an inlet end to an outlet end of the three-section rotary kiln. The heat transfer jacket is arranged on the outer side of the heat transfer section; a combustion jacket is further arranged on the outer side of the combustion section; a feeding spiral conveyor is also arranged in the three-section rotary kiln; the outlet end of the three-section rotary kiln is connected with an oil-gas separation condenser through a pipeline, an oil outlet in the bottom end of the oil-gas separation condenser is connected with an oil storage tank located below the oil-gas separation condenser through a pipeline, and a gas outlet in the top end of the oil-gas separation condenser is connected with a gas storage tank through a pipeline with a gas pump.

Owner:大工能源环境科技(大连)有限公司

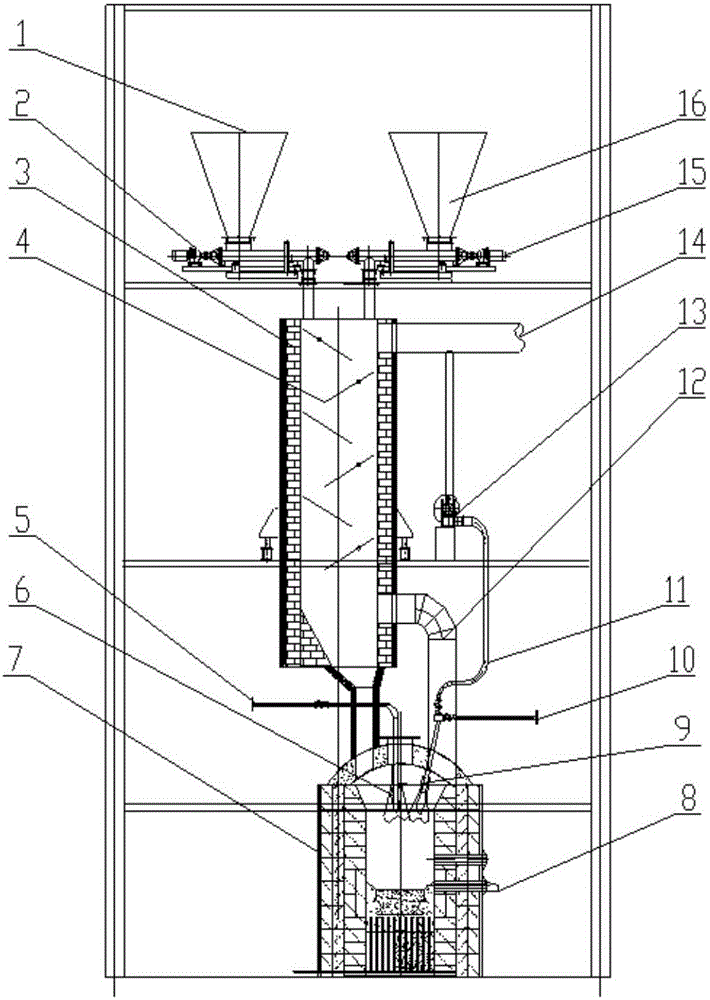

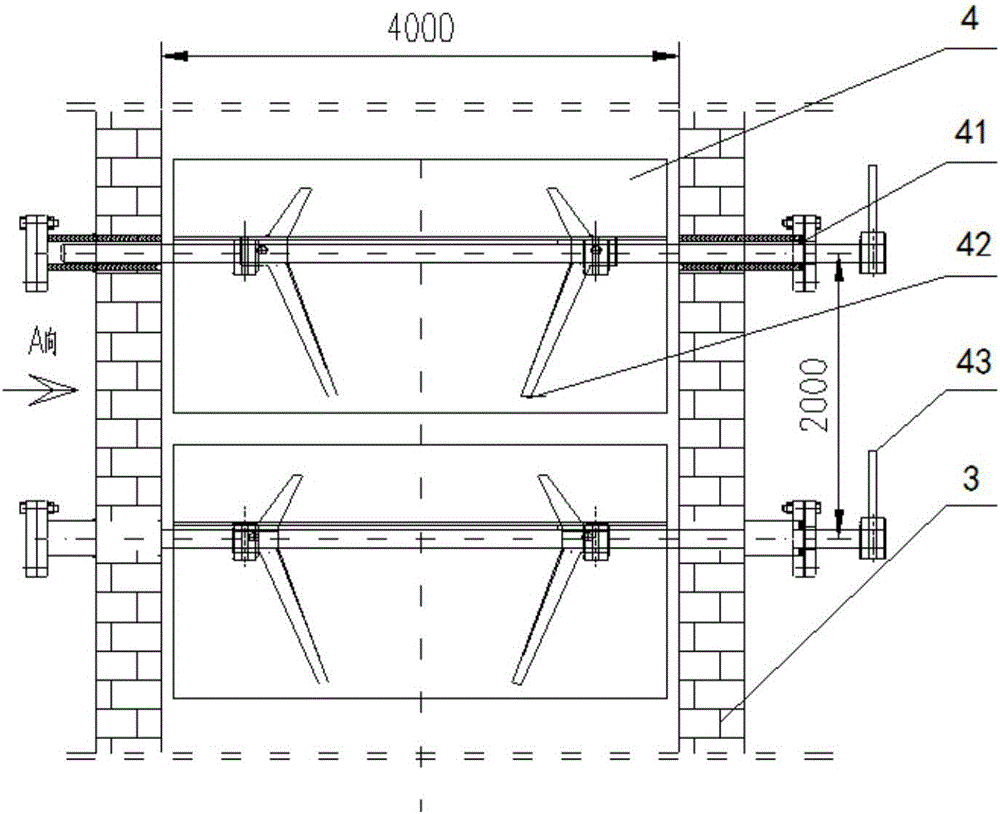

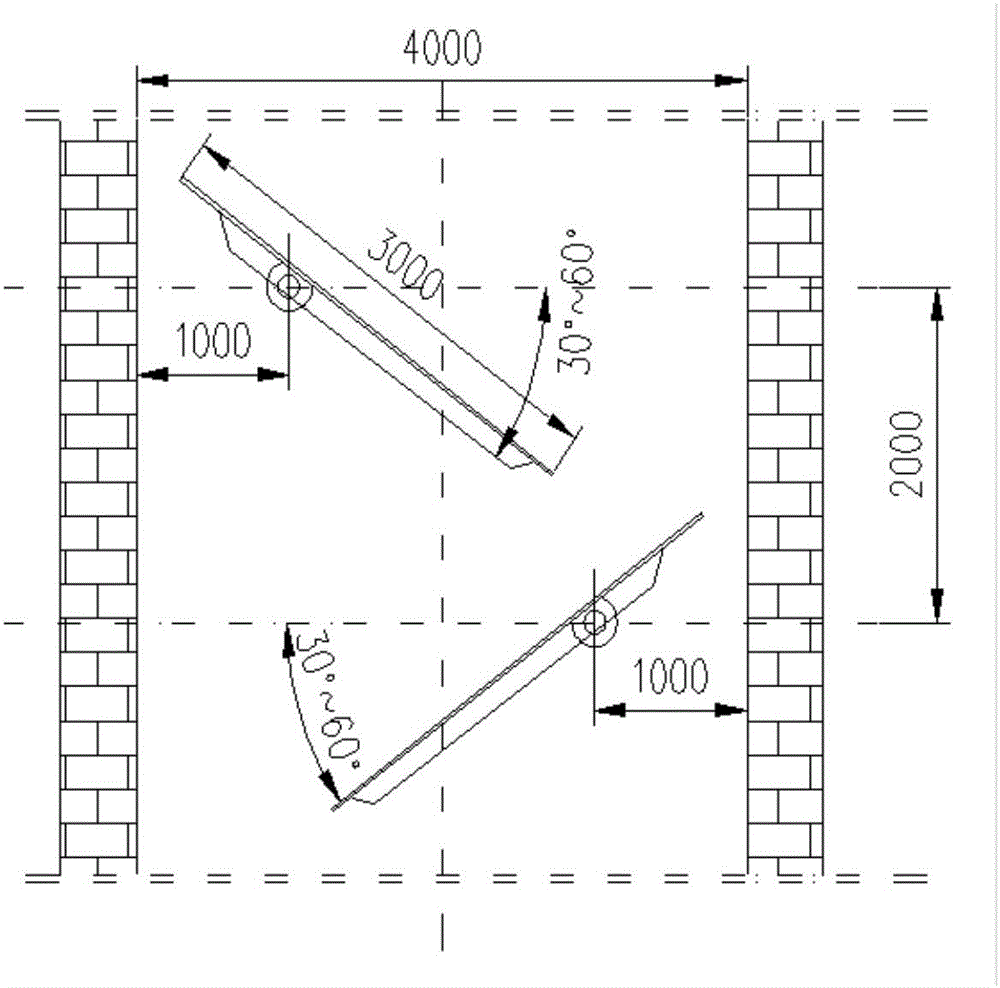

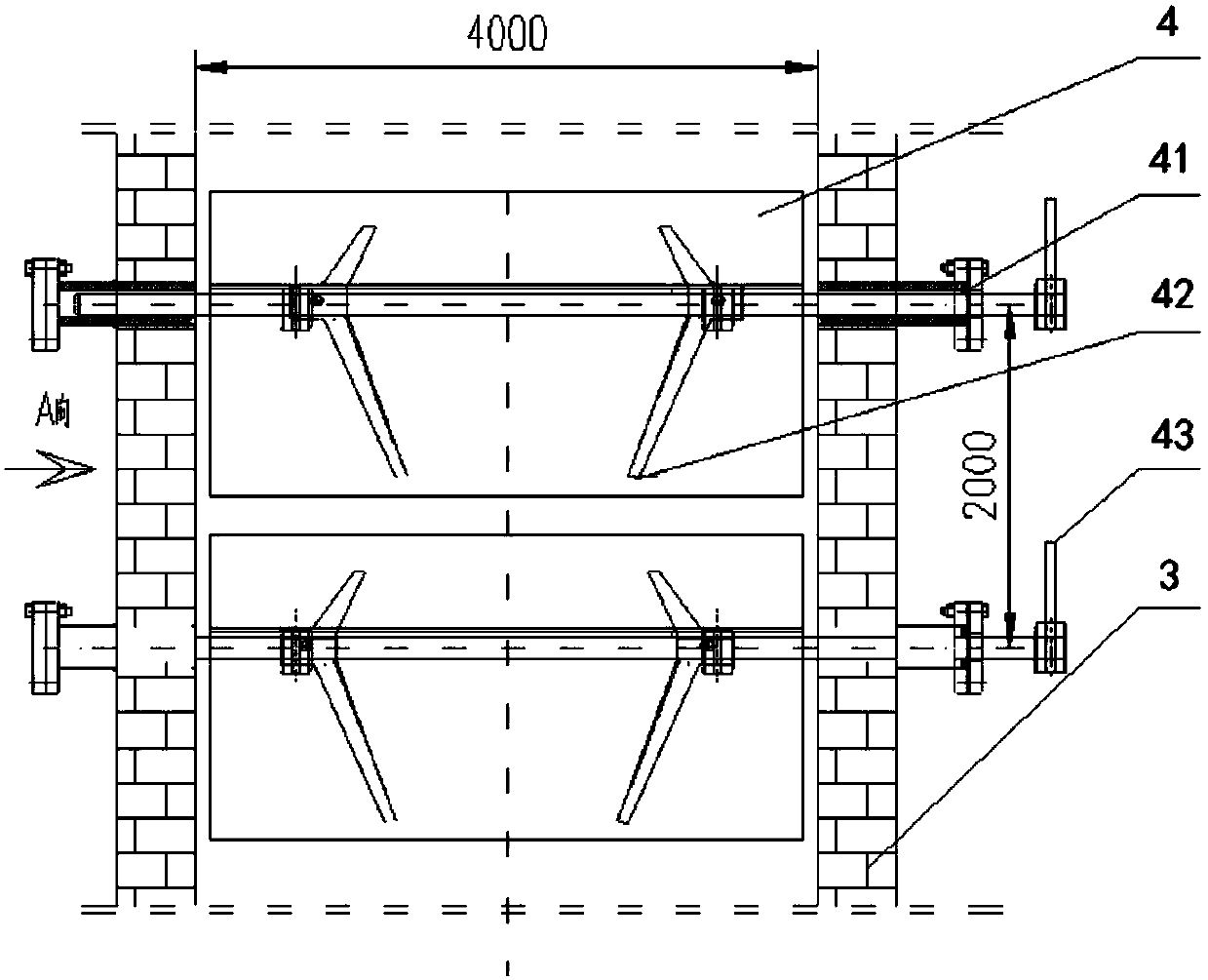

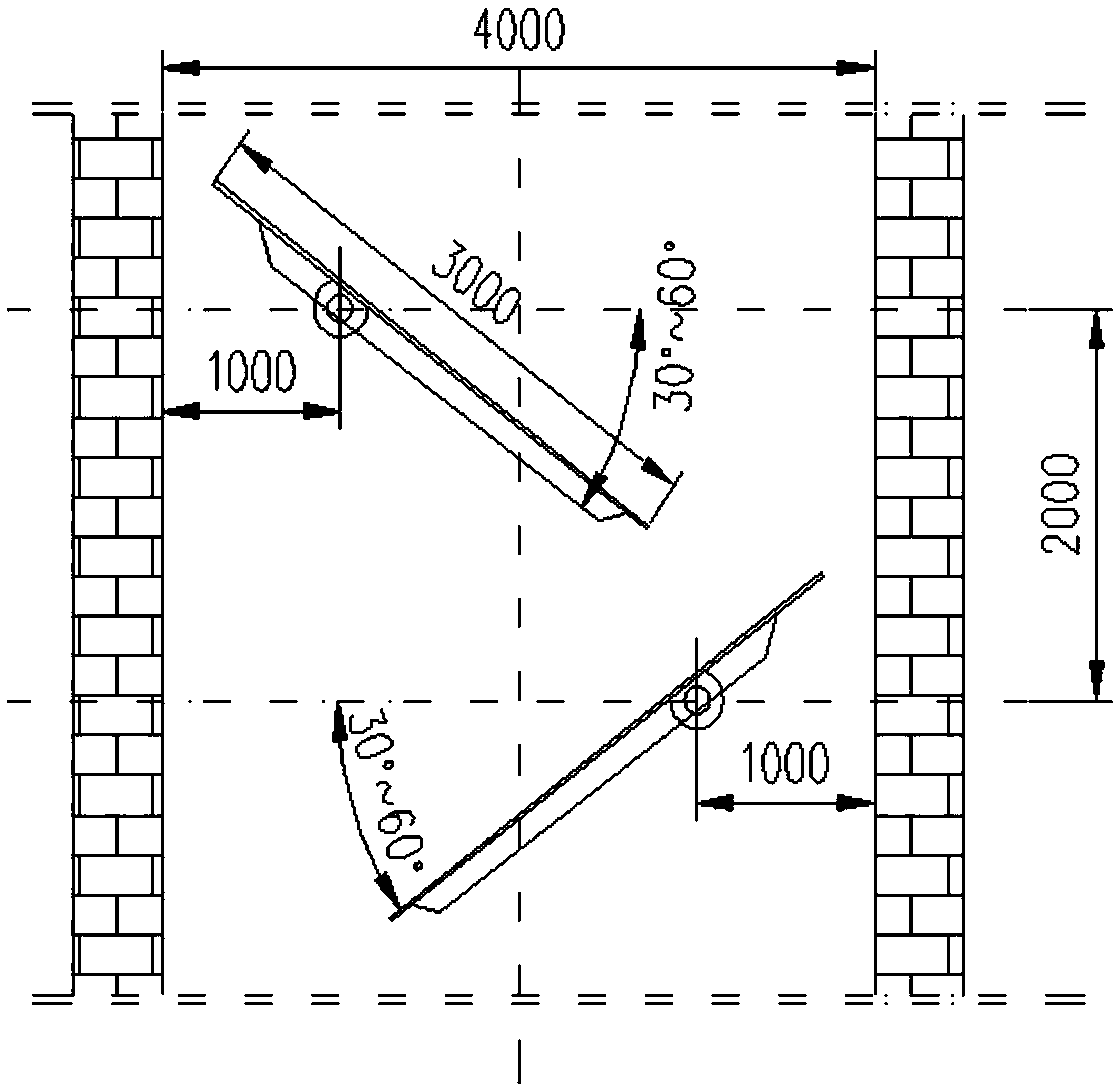

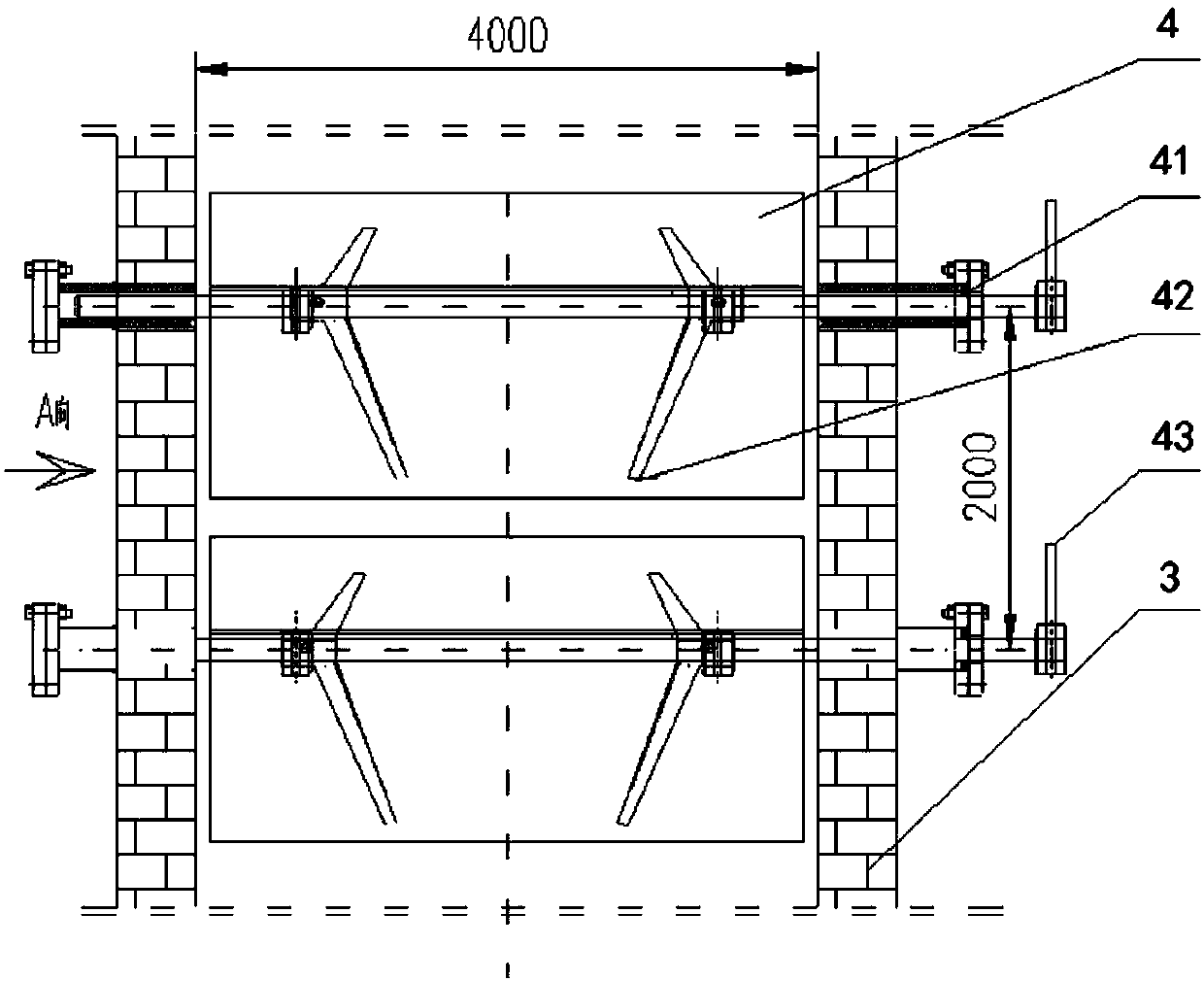

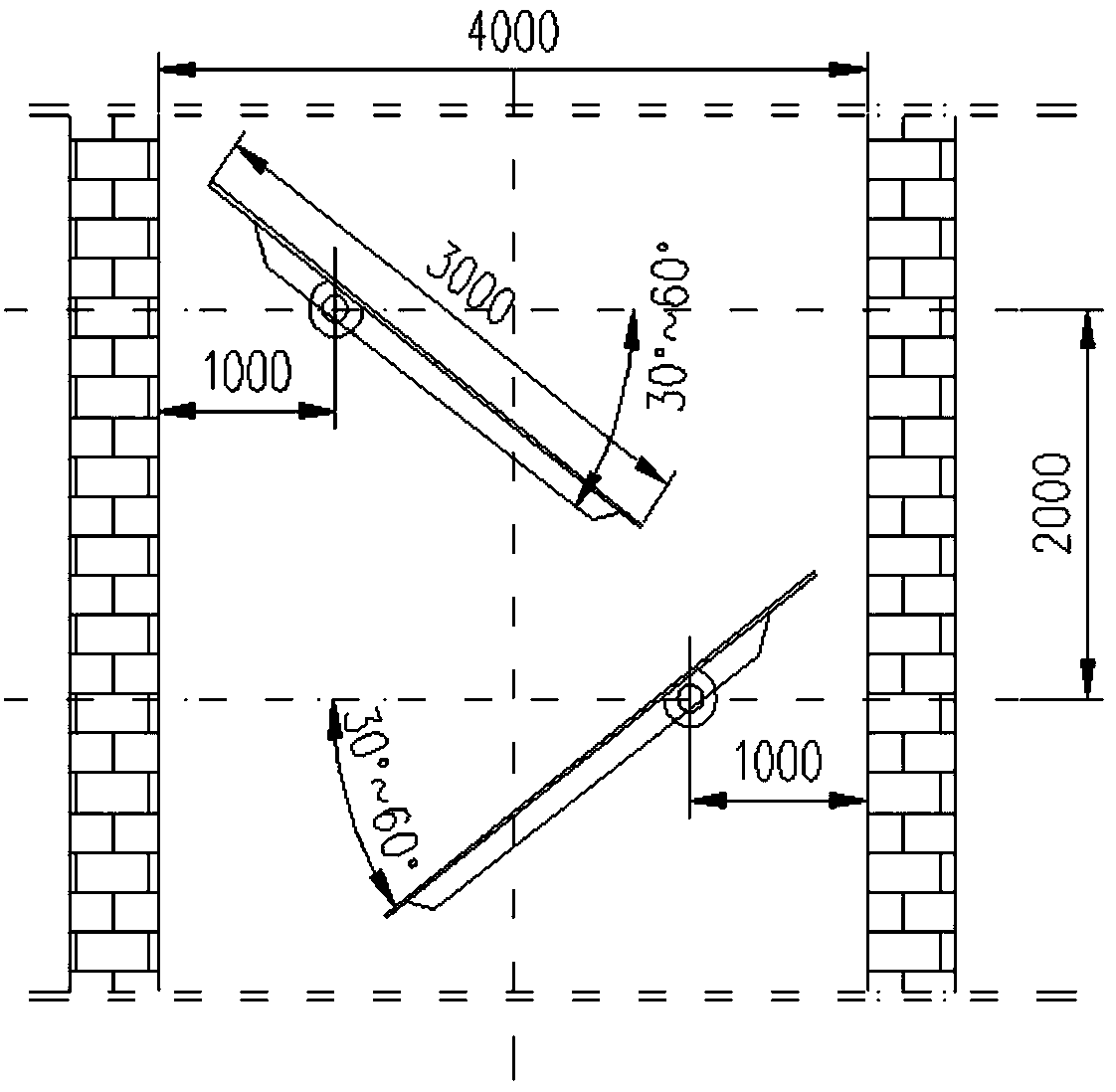

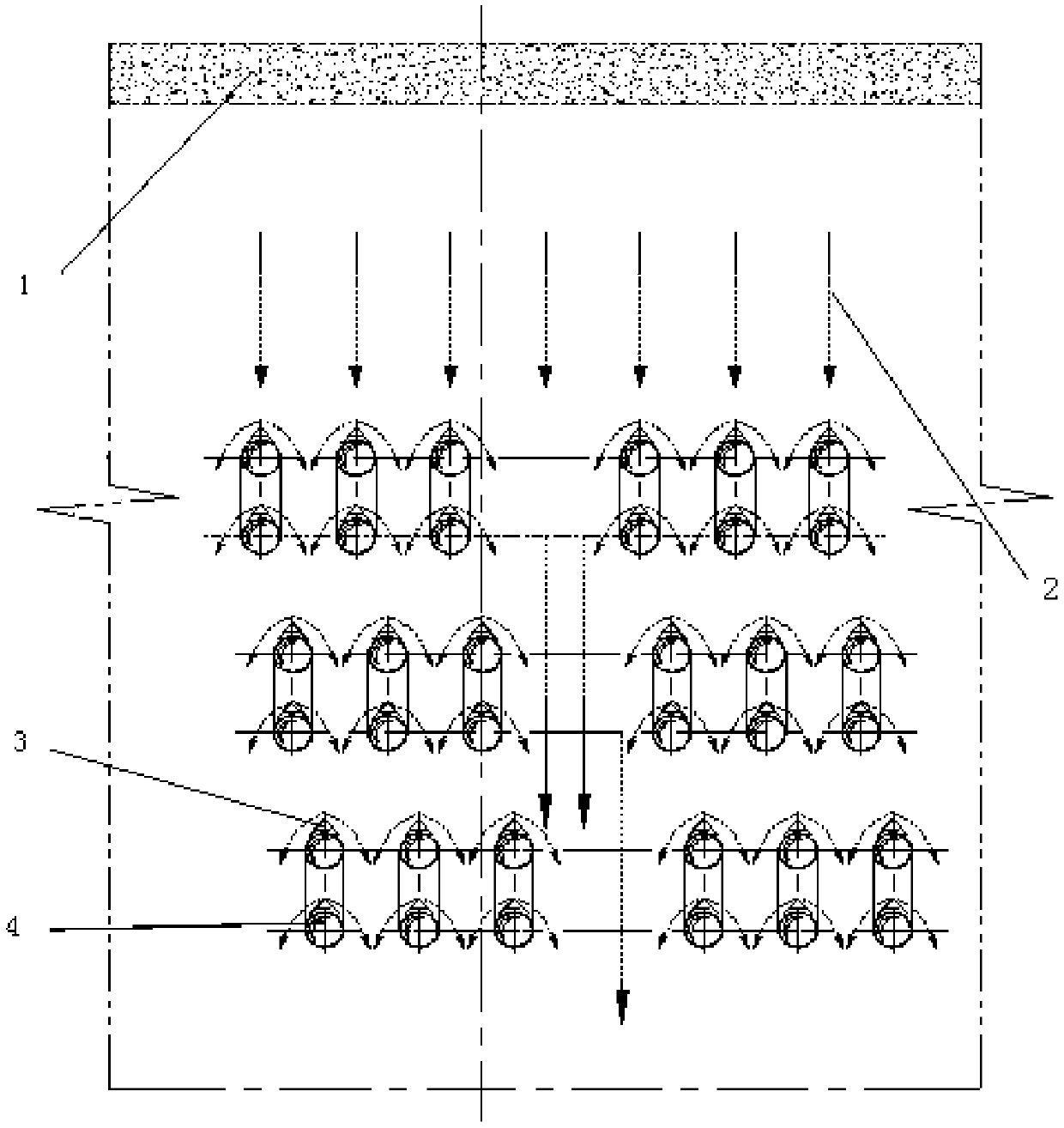

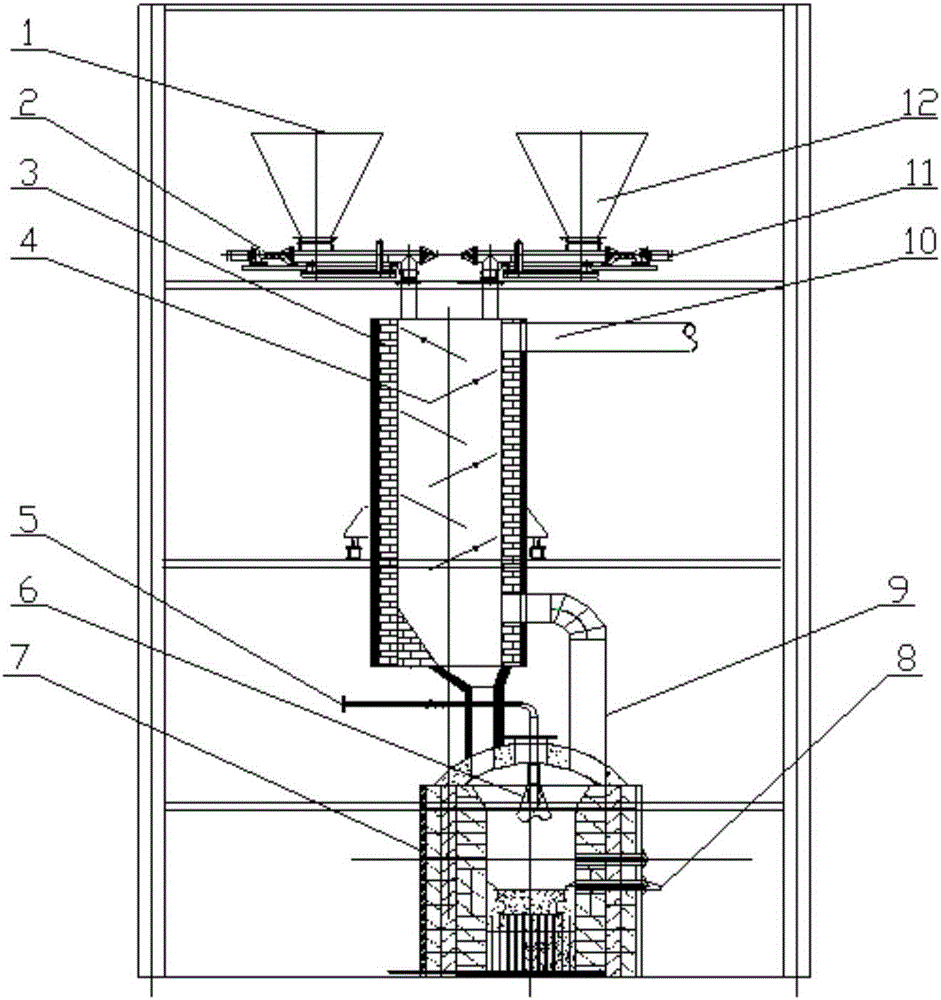

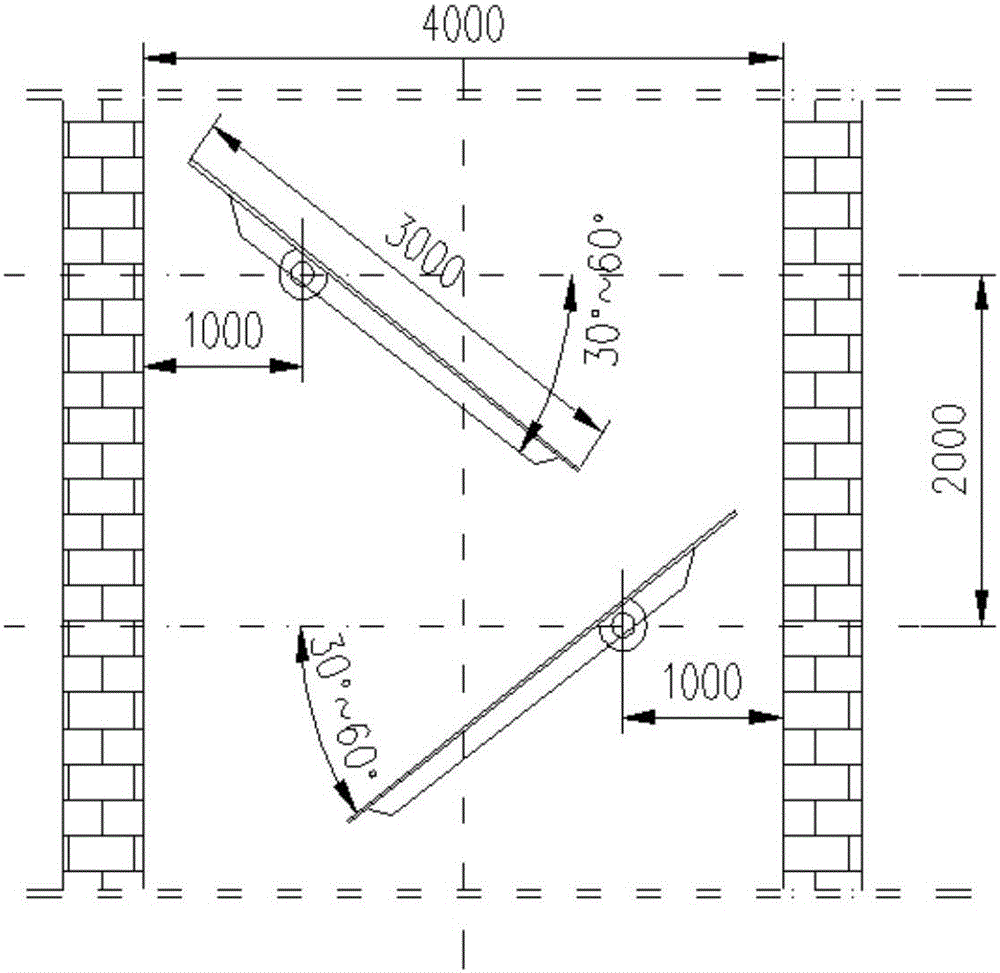

Calcium carbide production system and method capable of cyclically utilizing pyrolysis gas

The invention relates to a calcium carbide production system and method capable of cyclically utilizing pyrolysis gas. The system comprises an adjustable pyrolysis furnace, an oxygen-heat-process calcium carbide furnace oxygen lance and a natural gas-oxygen spraying lance; the adjustable pyrolysis furnace comprises a limestone powder feeding hole, a coal powder feeding hole, a discharging hole, a flue gas inlet and a pyrolysis gas outlet; a hearth of the adjustable pyrolysis furnace is internally provided with a baffle with an adjustable inclined angle; a gap is reserved between the baffle and an inner wall of the adjustable pyrolysis furnace; small holes are formed in the baffle; an oxygen-heat-process calcium carbide furnace comprises a feeding hole, a flue gas outlet and a discharging hole; a spraying lance head of the oxygen lance is arranged in the oxygen-heat-process calcium carbide furnace; a spraying lance head of the natural gas-oxygen spraying lance is arranged in the oxygen-heat-process calcium carbide furnace. According to the calcium carbide production system and method capable of cyclically utilizing the pyrolysis gas, the baffle with the adjustable inclined angle is arranged in the adjustable pyrolysis furnace, so that reaction time of raw materials in the furnace can be conveniently controlled, and reaction degree and efficiency of the raw materials are guaranteed.

Owner:SHENWU TECH GRP CO LTD

Method for removing potassium ions, calcium ions and magnesium ions in fast-growing eucalyptus

InactiveCN110813206AEfficient removalPromote pyrolysis reactionProcess control/regulationBiofuelsCellulosePotassium ions

The invention discloses a method for removing potassium ions, calcium ions and magnesium ions in fast-growing eucalyptus. The method comprises: peeling fast-growing eucalyptus, cutting into eucalyptussheets with a length of 10-15 mm, a thickness of 3-5 mm and a width of not more than 10 mm, carrying out air drying, carrying out sealed storing, balancing the moisture, adding ultrapure water, regulating the pH value of the mixed material to 3-9, reacting for 10-90 min at 140-180 DEG C, and separating the eucalyptus sheets from the reaction solution after the reaction is finished so as to obtainthe eucalyptus sheets free of potassium ions, calcium ions and magnesium ions. According to the invention, in a research process, innovatively hydrothermal pretreatment can remove metal ions from eucalyptus, so that potassium, calcium and magnesium in fast-growing eucalyptus are efficiently removed by utilizing an environment-friendly hydrothermal pretreatment process so as to easily achieve thesubsequent lignocellulose pyrolytic reaction, achieve the high-valued utilization of lignocellulose and provide a new thought for controlled obtaining of chemical components of the bio-oil.

Owner:GUANGXI UNIV

A system and method for producing calcium carbide by high-temperature pressure balls

The invention relates to a system and method for producing calcium carbide by high-temperature pressure balls. The system includes an adjustable pyrolysis furnace, a briquetting machine, an oxythermal calcium carbide furnace and an oxygen coal gun, wherein the adjustable pyrolysis furnace includes a limestone powder inlet, a coal powder inlet, a discharge outlet, The flue gas inlet; the furnace chamber of the adjustable pyrolysis furnace is provided with a baffle plate with an adjustable inclination angle, and there is a gap between the baffle plate and the inner wall of the adjustable pyrolysis furnace, and small holes are arranged on the baffle plate; the ball pressing machine Including lime powder and carbon powder inlet and feeding port; oxythermal calcium carbide furnace includes material inlet, flue gas outlet and material outlet; the spray gun head of oxygen coal gun is set in oxythermal calcium carbide furnace, The furnace roof of the calcium carbide furnace extends into the oxythermal calcium carbide furnace. The system and method for producing calcium carbide by high-temperature pressure balls of the present invention can conveniently control the reaction time of raw materials in the furnace by setting a baffle plate with adjustable inclination angle in the adjustable pyrolysis furnace, so as to ensure the degree of reaction of raw materials and efficiency.

Owner:SHENWU TECH GRP CO LTD

A kind of production system and method of pyrolysis gas recycling calcium carbide

The invention relates to a production system and method of calcium carbide for recycling pyrolysis gas. The system includes an adjustable pyrolysis furnace, an oxythermal calcium carbide furnace oxygen lance and a natural gas-oxygen spray lance, and the adjustable pyrolysis furnace includes a limestone powder inlet, a coal powder inlet, a material outlet, and a flue gas inlet and the pyrolysis gas outlet; the furnace of the adjustable pyrolysis furnace is provided with a baffle plate with an adjustable inclination angle, and there is a gap between the baffle plate and the inner wall of the adjustable pyrolysis furnace, and the baffle plate is arranged with Aperture; the oxythermal calcium carbide furnace includes a feed inlet, a flue gas outlet and a discharge port, the spray gun head of the oxygen lance is arranged in the oxygen thermal calcium carbide furnace, and the spray gun head of the natural gas-oxygen spray gun Set in the oxythermal calcium carbide furnace. The calcium carbide production system and method for pyrolysis gas recycling of the present invention can conveniently control the reaction time of raw materials in the furnace by setting a baffle plate with adjustable inclination angle in the adjustable pyrolysis furnace to ensure the smoothness of the raw material reaction. extent and efficiency.

Owner:SHENWU TECH GRP CO LTD

Biomass pyrolysis horizontal converter with bearable sealing structure

ActiveCN111575030AEasy to installEasy maintenanceSpecial form destructive distillationCombustorEngineering

The invention aims to provide a biomass pyrolysis horizontal converter with a bearable sealing structure. According to the horizontal converter, pyrolysis and drying are completed in the same furnace;internal components of a converter barrel are simple and concise, the sealing performance between the horizontal converter and a static part is good; a bearing piece of a horizontal converter cylinder body does not need to be additionally arranged; installation, maintenance and replacement are simplified. The converter comprises a converter cylinder body, a front end socket arranged at the frontend of the converter cylinder body and a rear end socket arranged at the rear end of the converter cylinder body, wherein two ends of the cylinder body respectively extend into the front end socket and the rear end socket and are in relatively rotatable sealing connection with the front end socket and the rear end socket; a pyrolysis pipe for circulating heating gas is arranged in the cylinder body; the bottom of the front end socket is communicated with an exhaust pipe used for exhausting tail gas; a combustor is arranged at the bottom of the interior of the rear end socket; an air blower isfurther installed on the rear end socket, and the air blower is used for blowing heat energy generated by combustion of the combustor into the pyrolysis pipe.

Owner:广州市博乐锅炉有限公司

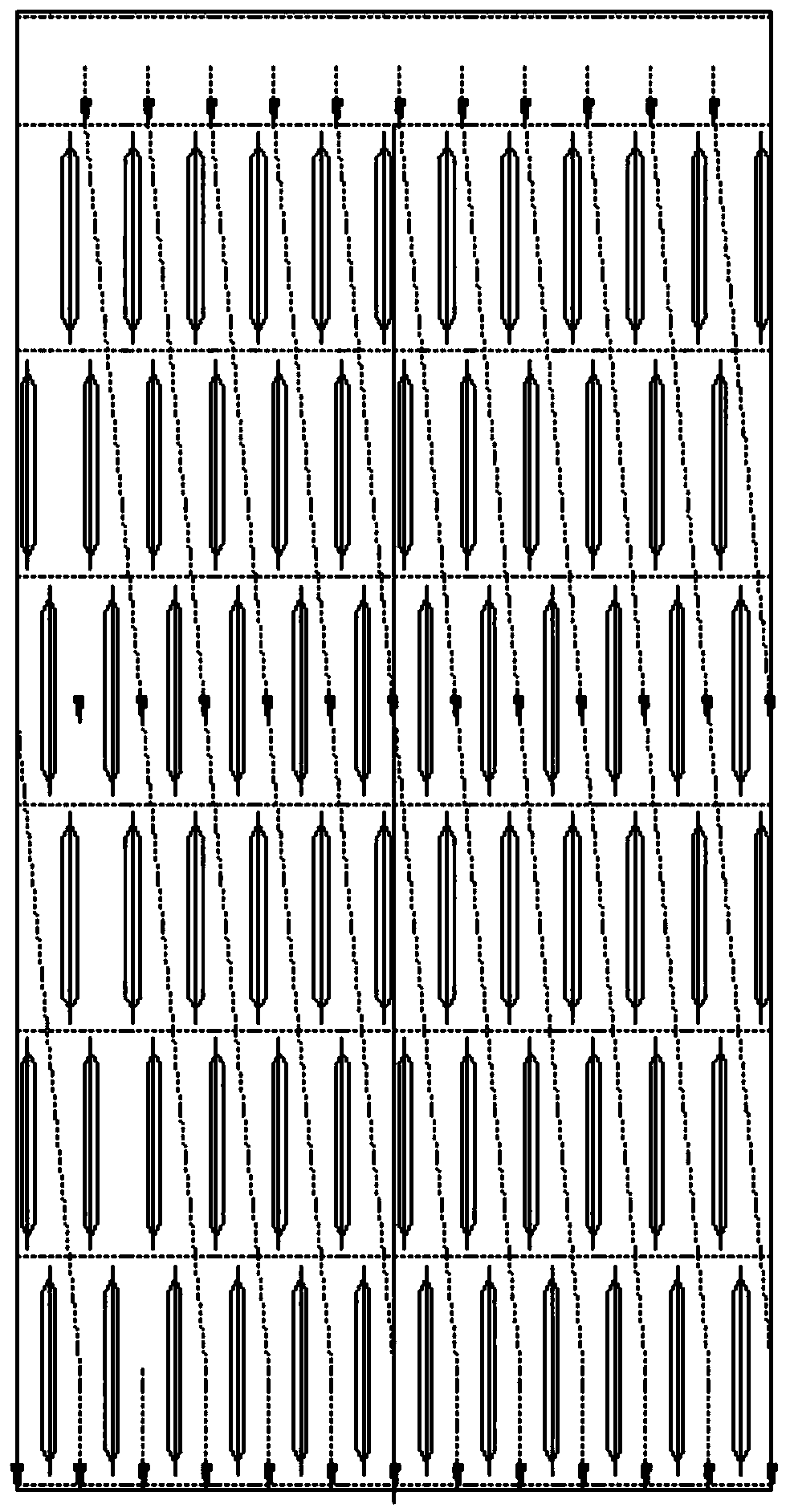

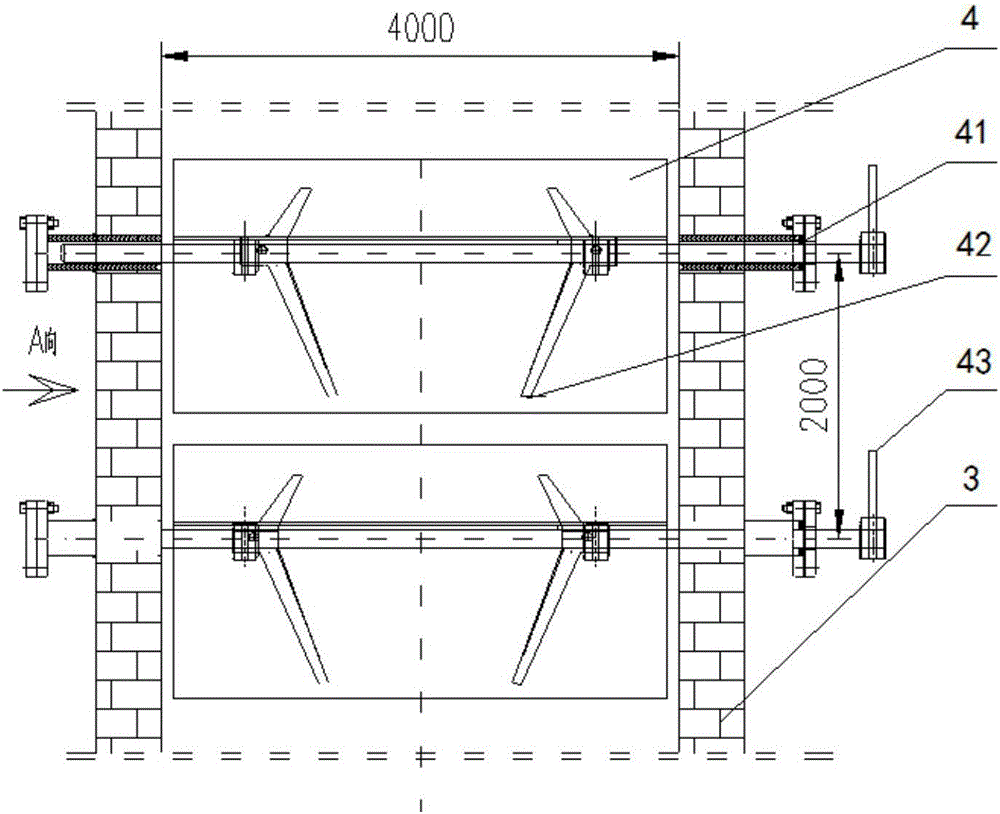

Pulverized coal pyrolyzing furnace with material homogenizing and pressure bearing structure

PendingCN107841329AShorten speedExtend your lifeSpecial form destructive distillationEngineeringCoal pyrolysis

The invention relates to a pulverized coal pyrolyzing furnace with a material homogenizing and pressure bearing structure. The pulverized coal pyrolyzing furnace with the material homogenizing and pressure bearing structure mainly comprises a furnace body, radiant pipes and the material homogenizing and pressure bearing structure, wherein the multiple layers of radiant pipes are arranged in a furnace chamber so as to form an empty area; the material homogenizing and pressure bearing structure is arranged in the empty area, and comprises a support part, a distributing cap and a connecting part;the support part is arranged along a horizontal direction; the head part of the distributing cap is in a circular arc shape; the bottom part of the distributing cap is arranged on the support part; the connecting part is fixed onto a furnace wall and is connected with two ends of the support part through pin shafts so as to fix the support part onto the furnace wall. According to the pulverized coal pyrolyzing furnace with the material homogenizing and pressure bearing structure provided by the invention, the material homogenizing and pressure bearing structure is arranged in the empty area,so that pulverized coal is homogenized and buffered, and the collision loss of equipment and the furnace body caused by the pulverized coal is reduced; meanwhile, a furnace operation pressure bearingability of the furnace body is improved, and an effect on stabilizing the furnace body is achieved.

Owner:北京神雾电力科技有限公司

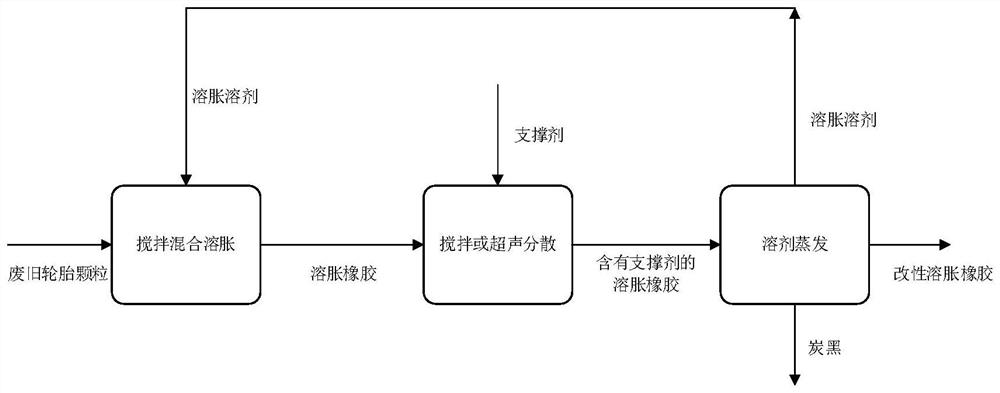

A treatment method for waste tires based on pyrolysis

ActiveCN112063405BEvenly heatedLarge specific surface areaProductsReagentsPolymer sciencePolymer chemistry

A method for treating waste tires based on pyrolysis, comprising the following steps: step 1: sending swelling solvent and waste tire rubber particles into a swelling tank for swelling treatment; step 2: pouring proppant powder into swelling treatment after completion of swelling treatment In the mixture of the rubber and the swelling solvent, stir and mix so that the proppant can enter the pores of the swollen rubber; Step 3: Evaporate the swelling solvent on the mixture obtained in Step 2; Step 4: Obtain the swollen rubber particles after completing the evaporation treatment , a mixture of carbon black and residual proppant, and filter the mixture to separate the swollen rubber particles; Step 5: Use the swollen rubber particles obtained by filtration as a pyrolysis raw material, and perform a pyrolysis operation to complete the harmless treatment of the swollen rubber. ; By adding proppant powder after the waste tire rubber particles are swollen, the volume shrinkage of the swollen rubber during solvent evaporation is avoided.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

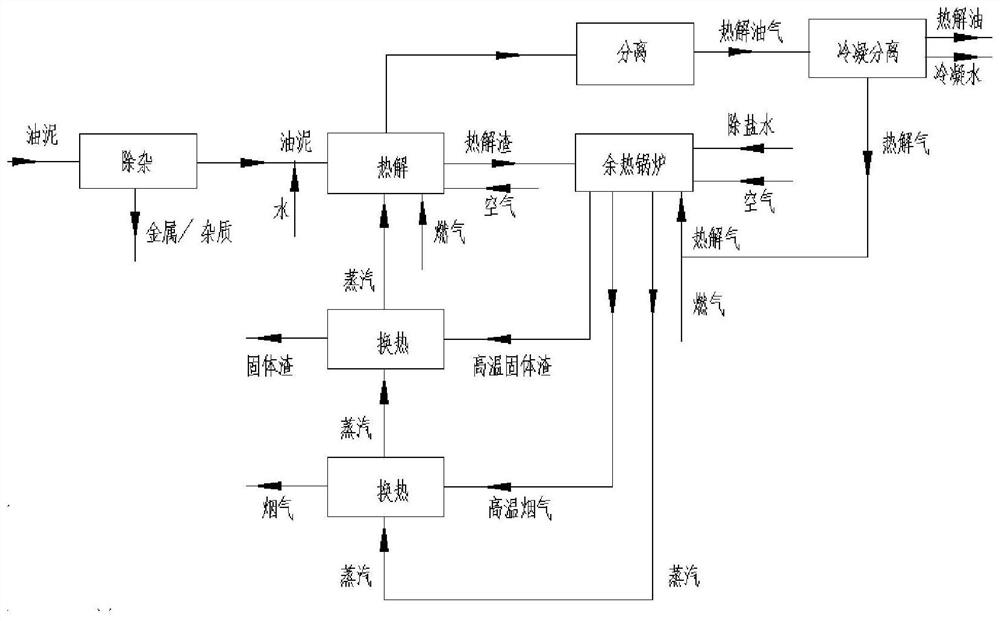

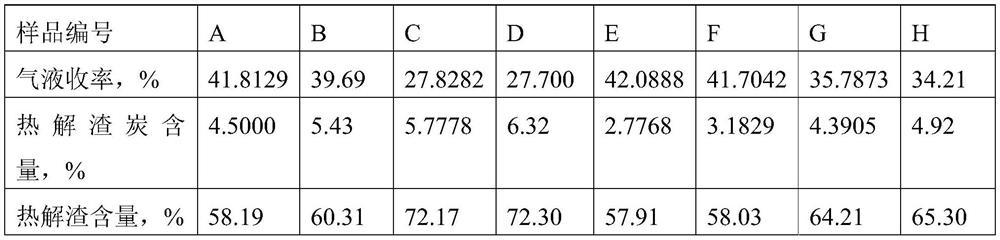

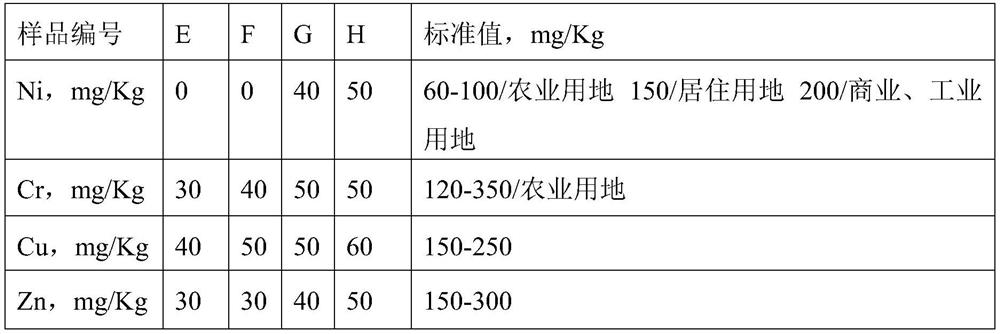

A kind of treatment method of hazardous solid waste oil sludge

ActiveCN110451753BPromote pyrolysis reactionEasy control of pyrolysis reactionSludge treatment by pyrolysisByproduct vaporizationSlagOil sludge

The invention relates to a method for treating dangerous solid waste oil sludge, which comprises the steps of: removing impurities; removing metals and bulk impurities. Pyrolysis: The sludge after removal of impurities enters the pyrolyzer, and is pyrolyzed under the action of steam to obtain the pyrolysis residue and pyrolysis oil and gas of carbon deposits. Separation: The pyrolysis oil and gas are separated by the condensation separation system to obtain pyrolysis oil and pyrolysis gas, and the pyrolysis oil products are recycled. Energy recovery: the pyrolysis gas and the pyrolysis slag of carbon deposits enter the waste heat boiler for combustion and heat supply, and the heat is used to generate steam for the pyrolysis process. The method for pyrolysis of oil sludge improves the yield of oil products in the pyrolysis process and reduces the carbon deposition amount of pyrolysis residues. The pyrolysis residue after the sludge is pyrolyzed and coke is incinerated, which avoids the generation of dioxins during the direct combustion of the sludge. The technological process rationally utilizes the gas and carbon deposits produced by pyrolysis, recovers high-quality oil products, and realizes the resource utilization of oil sludge.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Self-heating vertical axial flow roller ablation pyrolytic reaction device

ActiveCN113025354AReduce moistureReduce oxygen contentBiofuelsEnergy inputThermodynamicsHeat carrier

The invention relates to a self-heating vertical axial flow roller ablation pyrolytic reaction device, and belongs to the technical field of renewable energy utilization. The device comprises a shell and a reaction cylinder arranged in the shell, a rotating shaft is arranged in the reaction cylinder, the upper end of the rotating shaft is connected with a variable frequency motor through a belt, the rotating speed of the rotating shaft can be adjusted, a first-stage spiral feeder and a second-stage spiral feeder are arranged outside the shell, the discharging end of the first-stage spiral feeder is communicated with the feeding end of the second-stage spiral feeder, and the discharging end of the second-stage spiral feeder is communicated with the upper part of the reaction cylinder. The device has the beneficial effects that the pyrolysis efficiency is improved, pushing of carrier gas and heating of a heat carrier are not needed in the reaction process, and the heating and cooling loads of the carrier gas are greatly reduced. Self-heating in the pyrolysis process is achieved, and effective utilization of energy is fully achieved. Different taper angles can adapt to the change of the size of the material, powdery, granular and other biomass raw materials can be pyrolyzed, and gas-solid separation and biomass pyrolysis can be better achieved.

Owner:SHANDONG UNIV OF TECH

Vertical type regenerative oil furnace

PendingCN112303650AControl dwell timeAdequate reaction conditionIncinerator apparatusTemperature controlEngineering

The invention belongs to the technical field of regenerative oil furnaces, and discloses a vertical type regenerative oil furnace. The vertical type regenerative oil furnace comprises a furnace body,wherein a trough barrel is arranged in the furnace body; and the top of the trough barrel extends out of the furnace body and is welded with the lower surface of a special-shaped supporting plate. According to the vertical type regenerative oil furnace, by measures of regulating the number of movable scraping cake assemblies, regulating rotation speed of a scraping mechanism and the like, mechanical movement speed of materials on a trough bottom plate (furnace bed) is regulated, and retention time of the materials in the trough barrel (furnace hearth) is precisely controlled, so that retentiontime of the materials in each temperature section (a temperature control section is formed by several sections of furnace hearths) can be realized, and retention time of the materials in each furnacehearth also can be controlled; and a gentle material stirring and turning method is adopted, so that abrasion of products is reduced, uniformity of the products can be guaranteed, a mass transfer process is facilitated, great contribution is made to distribution characteristics of temperature in the whole furnace hearth, and sufficient reaction conditions of the materials are guaranteed.

Owner:江苏森茂能源发展有限公司

Calcium carbide production system provided with adjustable pyrolyzing furnace and calcium carbide production method

The invention relates to a calcium carbide production system provided with an adjustable pyrolyzing furnace and a calcium carbide production method. The system comprises the adjustable pyrolyzing furnace, an oxygen thermal method calcium carbide furnace and an oxygen lance, wherein the adjustable pyrolyzing furnace comprises a limestone powder feeding inlet, a pulverized coal feeding inlet, a discharge outlet and a flue gas inlet; dip angle adjustable baffles are arranged in a hearth of the adjustable pyrolyzing furnace; gaps are reserved between the baffles and the inner walls of the adjustable pyrolyzing furnace; small holes are formed in the baffles; the oxygen thermal method calcium carbide furnace comprises a feeding inlet, a flue gas outlet and a discharge outlet; a nozzle of the oxygen lance is arranged in the oxygen thermal method calcium carbide furnace; and the oxygen lance stretches into the oxygen thermal method calcium carbide furnace from the top of the oxygen thermal method calcium carbide furnace. The calcium carbide production system provided with the adjustable pyrolyzing furnace and the method have the beneficial effects that the reaction time of the raw materials in the furnace can be conveniently controlled by arranging the dip angle adjustable baffles in the adjustable pyrolyzing furnace, thus ensuring the raw material reaction degree and efficiency.

Owner:SHENWU TECH GRP CO LTD

Production method and production system for extracting oil from sludge

ActiveCN111875208BRealize continuous industrial productionSuitable for harmless treatmentSludge treatment by pyrolysisByproduct vaporizationThermodynamicsOil sludge

Owner:舟山麦哲伦环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com