Reaction apparatus of microwave pyrolysis biomass

A reaction device and biomass technology, which is applied in the heating of coke ovens, special forms of dry distillation, gasification processes, etc., can solve the problems of difficult operation, complicated microwave pyrolysis device, low working efficiency, etc. The effect of decomposing the reaction process and reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

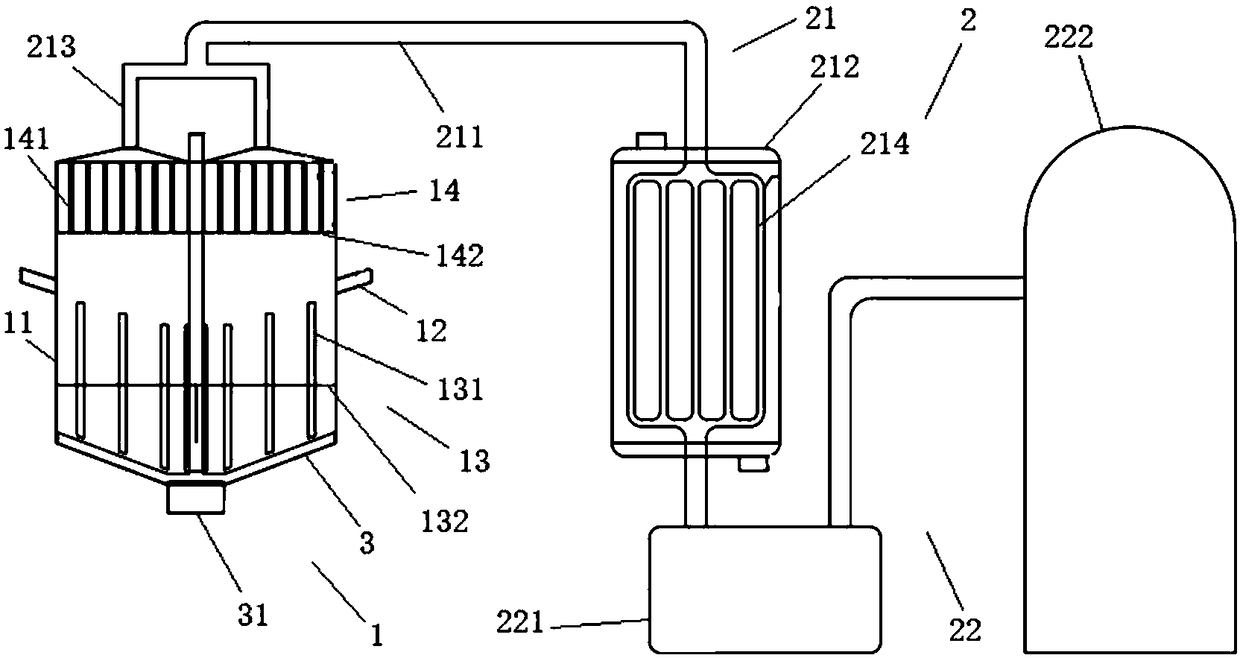

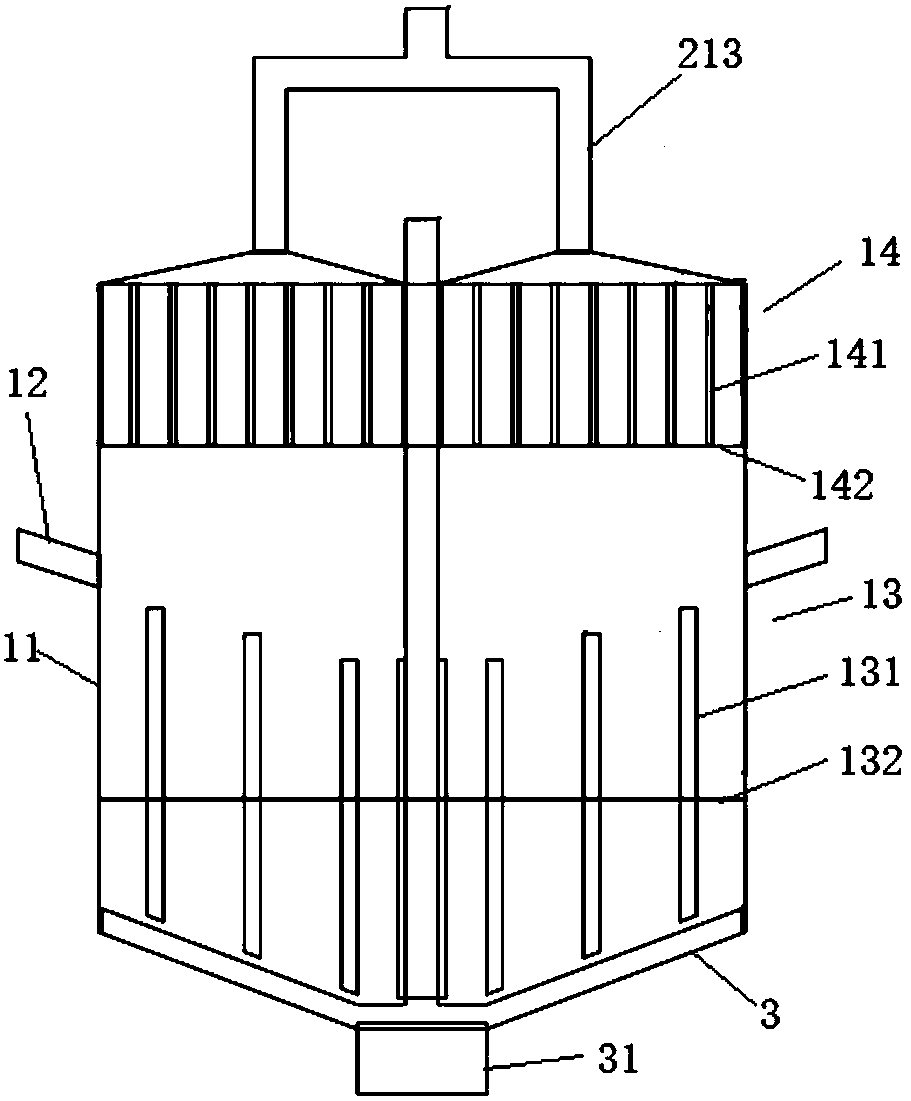

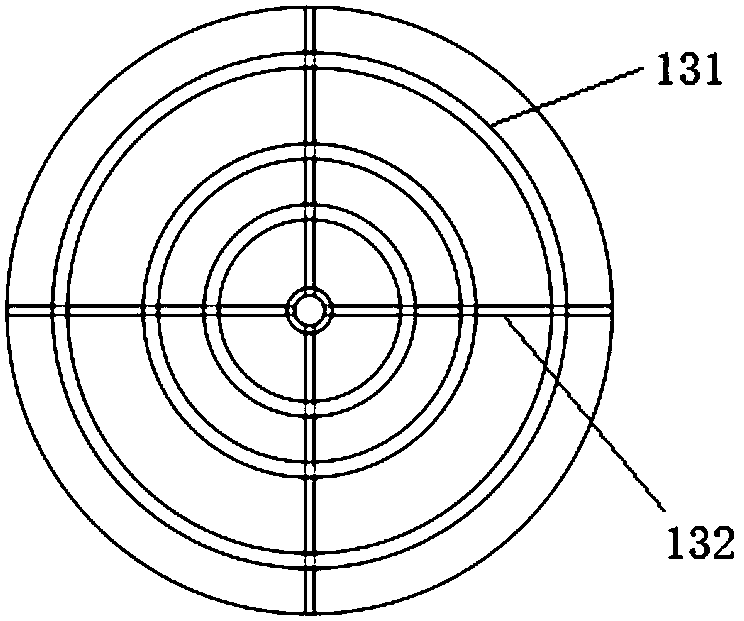

[0030] see Figure 1 to Figure 5, The reaction device for microwave pyrolysis of biomass according to an embodiment of the present invention mainly includes two parts: biomass pyrolysis and product separation and collection, specifically: microwave pyrolysis unit 1, microwave pyrolysis unit 1 includes microwave pyrolysis Decomposition furnace 11, and 3 feeding ports 12 that are arranged on the outer periphery of microwave pyrolysis furnace 11, microwave pyrolysis furnace 11 comprises solid-phase pyrolysis part 13 and gas-phase pyrolysis part 14 connected successively from bottom to top, solid-phase pyrolysis Part 13 includes several socketed solid-phase hollow cylinders 131 made of metal mesh, and is filled with solid-phase microwave absorbers and catalysts; gas-phase pyrolysis part 14 includes several socketed gas-phase hollow cylinders made of metal mesh Body 141, and it is filled with gas-phase microwave absorber and catalyst. Below the solid-phase pyrolysis unit 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com