Patents

Literature

33results about How to "Save investment in environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

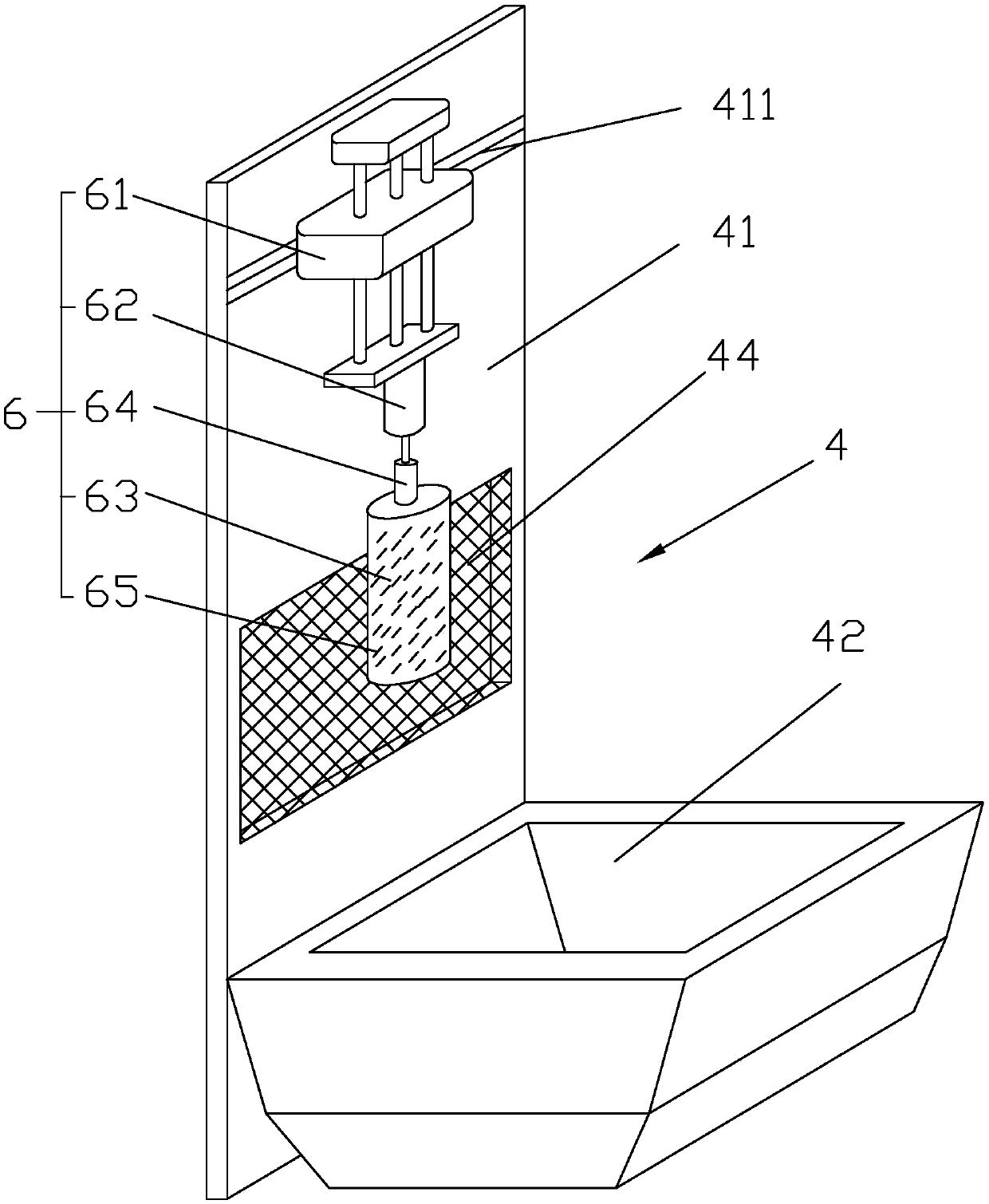

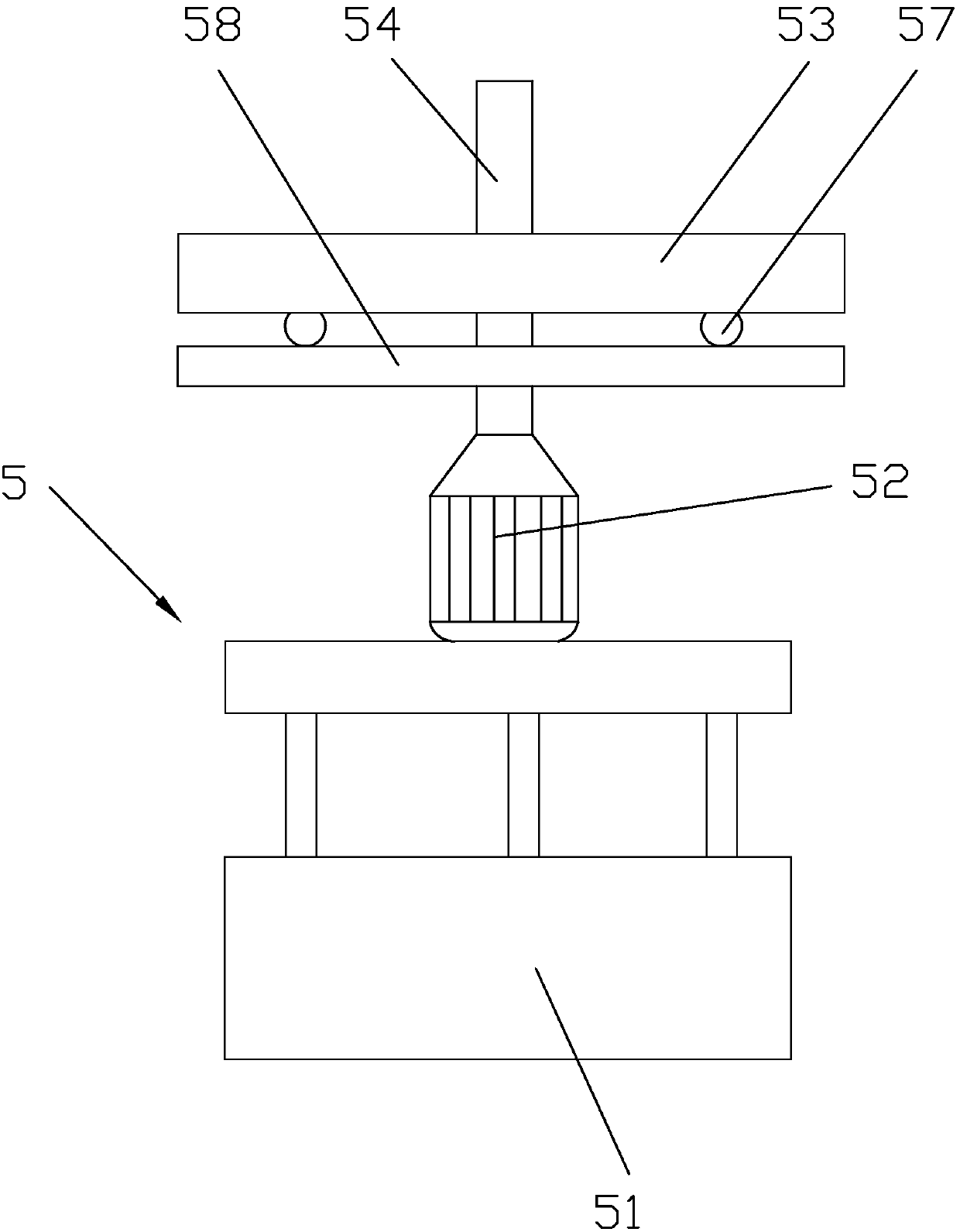

Aeration type sewage treatment device and method

InactiveCN106698823AStrong storageAvoid cloggingTreatment using aerobic processesSpecific water treatment objectivesHazardous substanceSewage

The invention mainly discloses an aeration type sewage treatment device and method. The technical scheme is as follows: the device comprises a primary sedimentation tank, a biodegradation tank and a disinfection tank, wherein a filtering device is arranged in the primary sedimentation tank and comprises a filtering plate and a collection box; the biodegradation tank comprises a facultative tank, an aerobic tank and a clarifying tank in mutual connection; a biological packing frame is arranged in the facultative tank; an aeration device is arranged in the aerobic tank and comprises a lifting cylinder, a spiral aerator and a rotating disk; the spiral aerator is mounted on the upper side of the lifting cylinder; a rotating shaft of the spiral aerator penetrates the rotating disk; and aerobic microbial packing is arranged on the rotating disk. Particle impurities of sewage are removed by the primary sedimentation tank, and then the sewage enters the biodegradation tank for reacting and finally is subjected to disinfection treatment. In the invention, through multi-stage treatment of the sewage, harmful substances in the sewage are separated and degraded better, the blocking phenomenon does not happen frequently, the treatment efficiency is high while the effect is good, and the treated sewage reaches the national discharge standard.

Owner:ZHEJIANG BUSINESS TECH INST

Method for making sugar from sugar-cane by membrane separation

InactiveCN1451765AReduce chromaHigh clarityPurification by physical meansSeparation technologyWastewater

A process for preparing sugar from cane by membrane separation technique is characterized by that after the cane juice is obtained, the microfilter (or ultrafilter) membrane system is used to remove impurities, gum and pigment from the cane juice. Its advantages are high purity, high output rate of sugar, and less environmental pollution.

Owner:凯能高科技工程(上海)有限公司

Active peptide fruity beer and its preparing method

InactiveCN1858174ALong soaking timeLow costAlcoholic beverage preparationFood ingredientsFruit juicePhosphoric acid

The present invention relates to beer, and especially active peptide and fruity beer and its preparation process. The active peptide and fruity beer is superior to available peptide beer and fruity beer. The active peptide and fruity beer is prepared with soybean protein peptide powder 0.2-0.5 wt%, sodium carboxymethyl cellulose 0.05-0.15 wt%, fructose syrup 1.5-2.5 wt%, sweetener 0.05-0.15 wt%, citric acid 0.01-0.1 wt%, phosphoric acid 0.005-0.025 wt%, sodium citrate 0.001-0.02 wt%, CO2 0.4-0.65 wt% and water for the rest. The mixed mash is pumped into the CO2 mixing tank while maintaining tank pressure in 0.15-0.6 Mpa. The active peptide and fruity beer is cool, tasty and refreshing, and good for health, and the preparation process is simple and low in resource consumption.

Owner:哈尔滨三乐生物工程有限公司

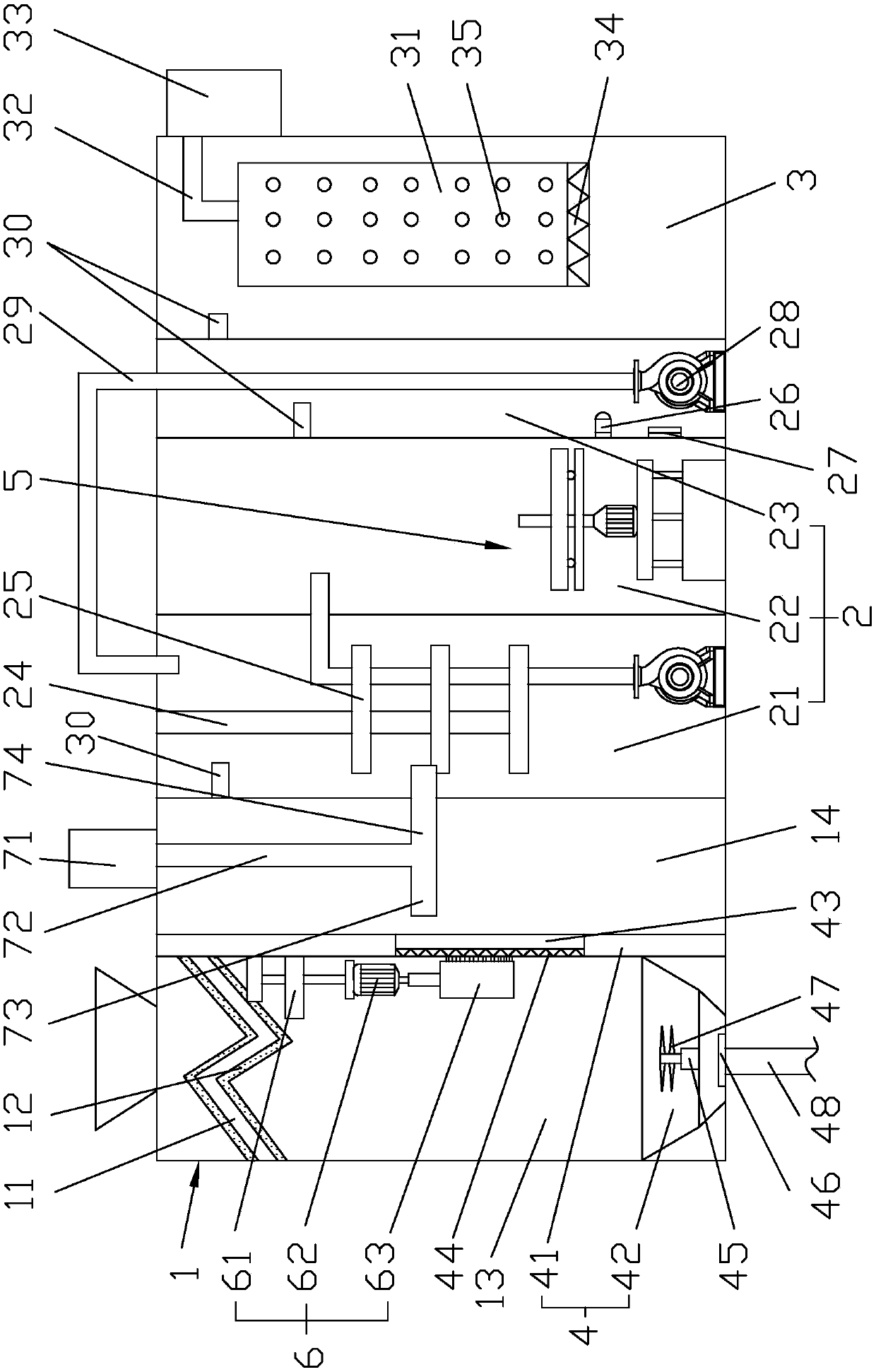

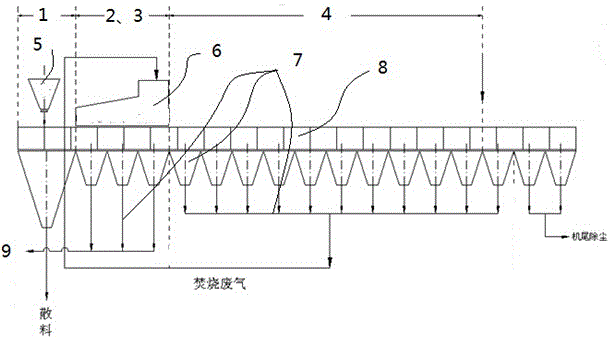

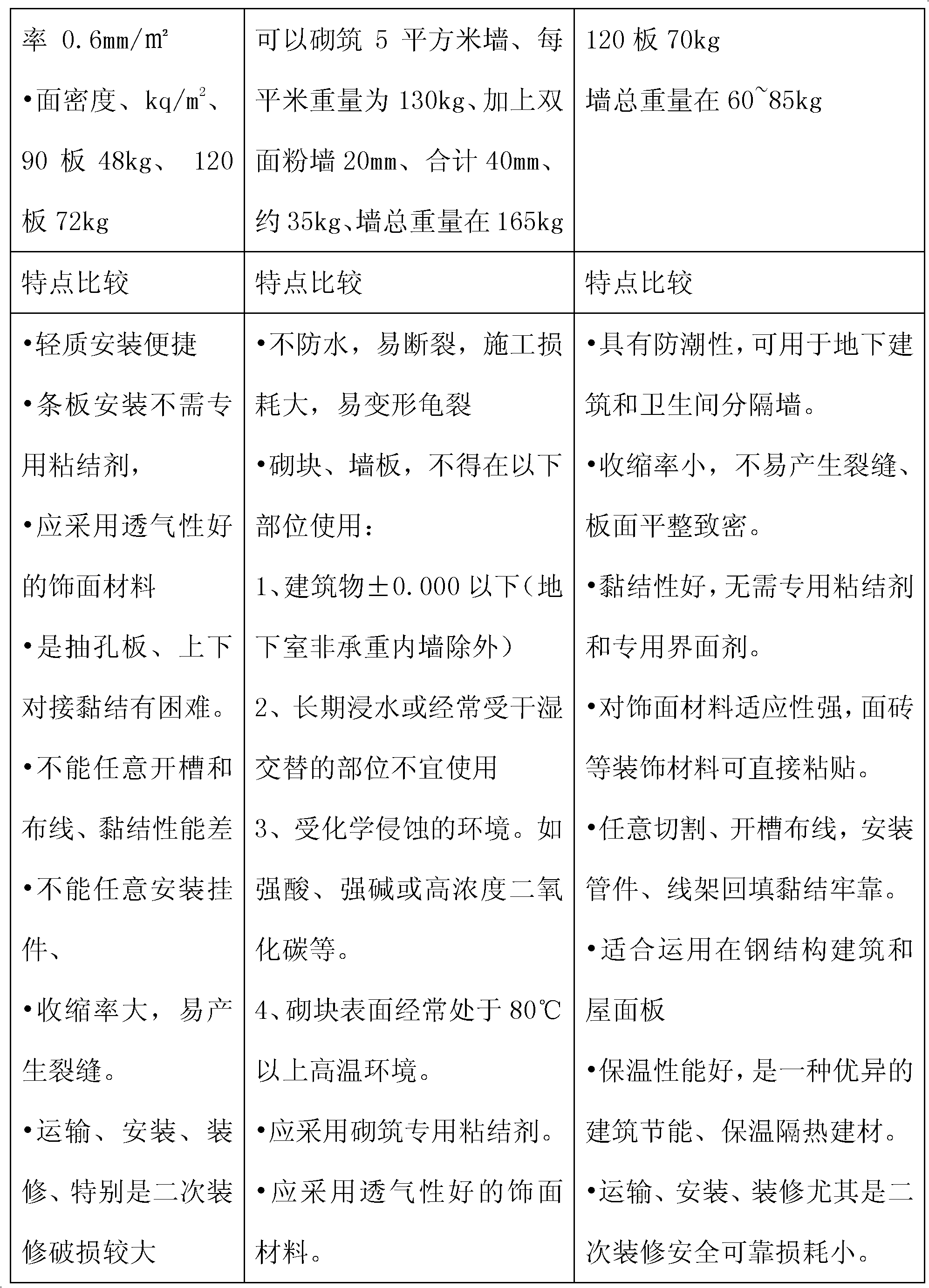

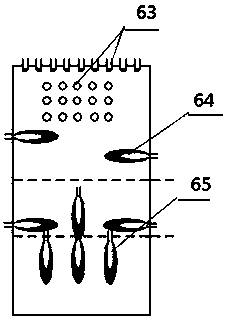

Solid waste incineration system with exhaust gas secondary combustion drying ignition device and treatment method thereof

ActiveCN105910111ALow investment costReduce operating expensesIncinerator apparatusCombustion chamberFlue gas

The invention discloses a solid waste incineration system with an exhaust gas secondary combustion drying ignition device and a treatment method thereof. The solid waste incineration system comprises an incineration device and an air extraction system, wherein the incineration device comprises a cloth section, a drying section, an ignition section and an incineration section; operation at the drying section and the ignition section is achieved through the exhaust gas secondary combustion drying ignition device; the exhaust gas secondary combustion drying ignition device is in a cover body form, covers sintering materials, and is divided into an exhaust gas secondary combustion drying part at the front section and an ignition part arranged at the tail end; the incineration exhaust gas returns to the ignition device and burns in the situation that gas fuel is externally added, and a secondary combustion chamber is formed; and combustible matters in the flue gas are completely combusted, and harmful substances such as CO, NOx and dioxin in the flue gas are decomposed and are effectively treated. According to the solid waste incineration system, a high temperature gas generated during combustion ignites the materials, and waste heat of the exhaust gas dries and preheats the materials before ignition.

Owner:CHONGQING ANGRUIYUE SCI & TECH

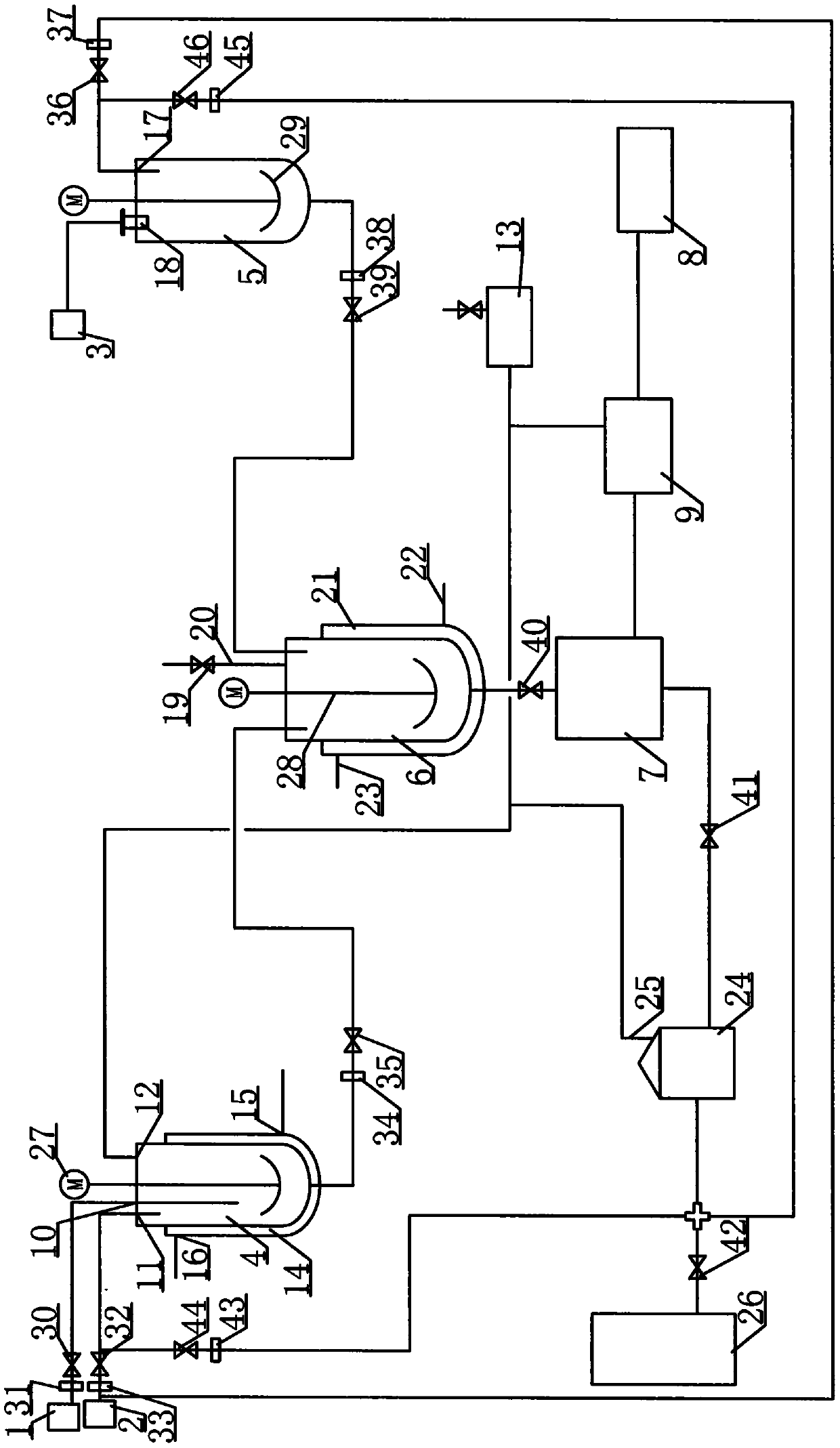

Oxamide synthesizing production device and method

PendingCN109569480AAvoid cloggingAvoid reaction over temperature and pressureOrganic compound preparationCarboxylic acid amides preparationEnvironmental resistanceOperability

The invention belongs to an oxamide synthesizing production device and method. The oxamide synthesizing production device comprises an ammonia absorbing unit and a dimethyl oxalate dissolving, which are connected with an oxamide synthesizing reaction unit, and the bottom of the oxamide synthesizing reaction unit is connected with an oxamide storage tank through a solid-liquid separator. The oxamide synthesizing production device has the advantages of being simple in structure, reasonable in technical design, convenient to generalize, mild in operation condition, high in operability and safetyindex, low in energy consumption, capable of facilitating treatment of produced exhaust, low in environmental protection investment and broad in industrialization prospect.

Owner:HENAN XINLIANXIN FERTILIZER

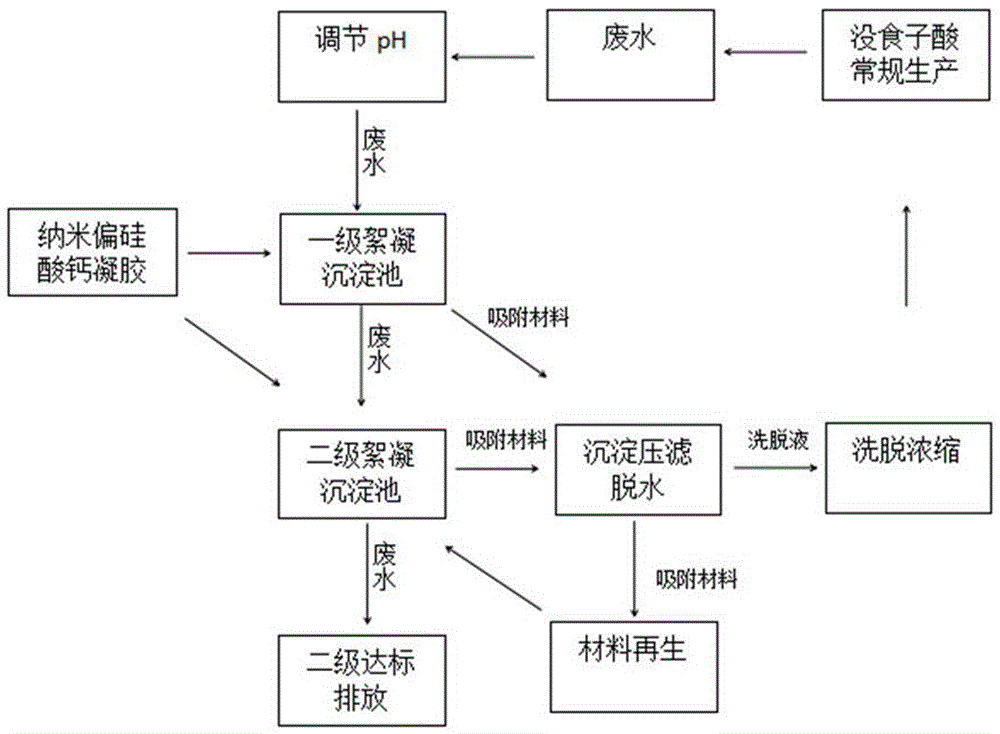

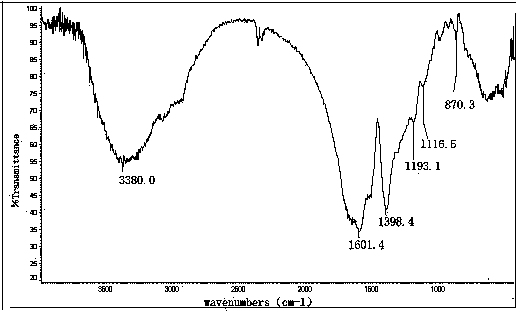

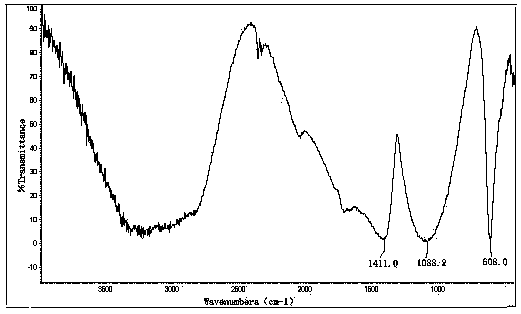

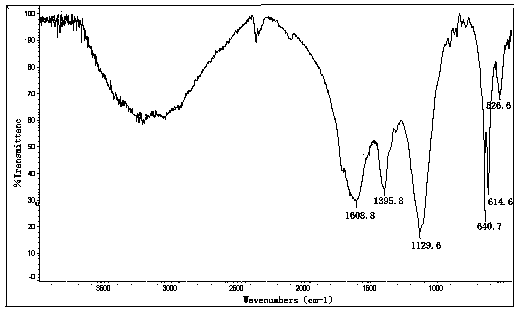

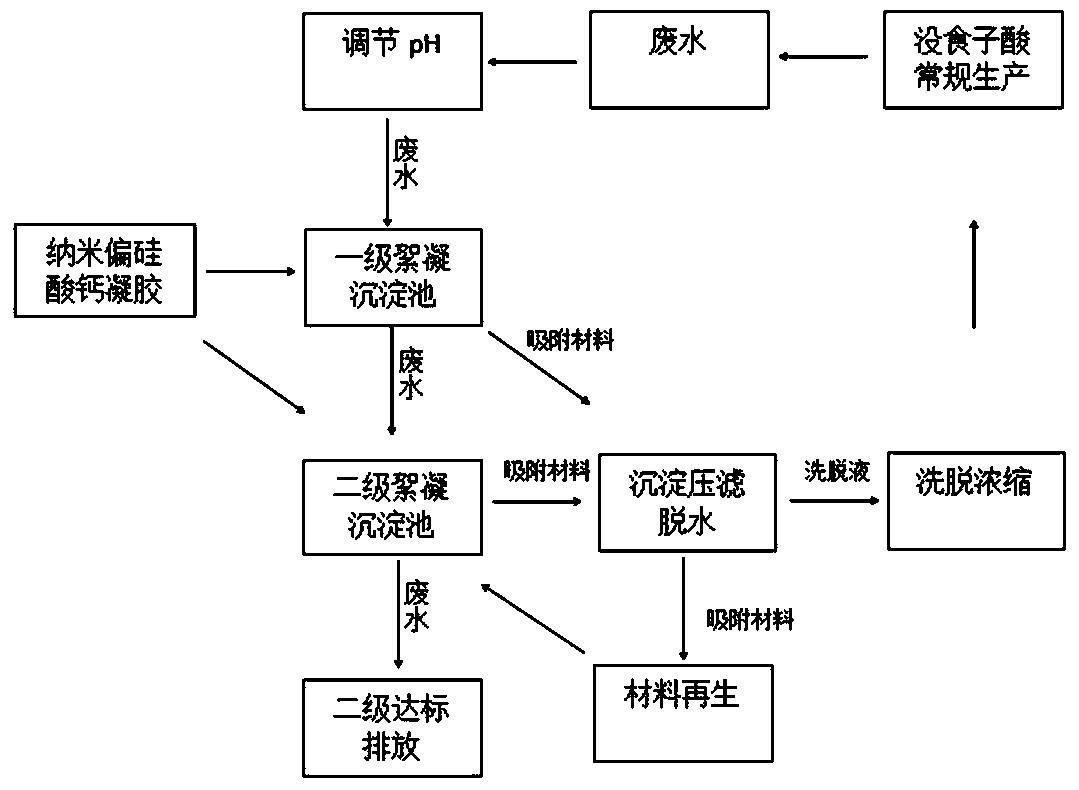

Method for purifying gallic acid production waste water through nanometer silica gel

InactiveCN106477663AReduce COD valueImprove adsorption capacityNature of treatment waterWater/sewage treatment by neutralisationEnvironmental resistanceChemical oxygen demand

The invention provides a method for purifying gallic acid production waste water through nanometer silica gel. The method comprises steps as follows: the waste water is neutralized with lime milk until the pH value of the waste water is appropriate; gallic acid and other organic ingredients in the waste water are adsorbed with calcium metasilicate nanogel; the gel material adsorbing the organic ingredients in the waste water is acidized through hydrochloric acid, so that gallic acid and other ingredients are subjected to desorption; the pH value of the nanogel subjected to desorption is adjusted through lime milk, and the adsorption capacity of the nanogel is regenerated under the condition of a proper pH value. With the adoption of the method, at least 92% of gallic acid in the gallic acid production waste water can be recycled, color-generating organic ingredients in the waste water can also be adsorbed, accordingly, the COD (chemical oxygen demand) value of the waste water can be effectively reduced, the chromaticity of the waste water is reduced remarkably, the water quality of discharged waste water meets the GB21905-2008 second-grade discharge standard, and the difficult technical problem about meeting the standards of good treatment effect, little environment investment and low operation cost for treatment of waste water during production of gallic acid can be better solved.

Owner:JISHOU UNIVERSITY

Method for preparing compound denitrification agent by means of waste organic solvents

ActiveCN105797568ASolve the technical problems of disposalThe technical method is simpleDispersed particle separationOrganic solventResource saving

A method for preparing a compound denitrification agent by means of waste organic solvents includes the steps that the waste water-borne organic solvents serve as raw materials to prepare the denitrification agent, solid mechanical impurities are removed from the waste organic solvents through filtering, 50-90 parts of the waste water-borne organic solvents and 10-50 parts of an amino denitrification agent are prepared by mass ratio and evenly mixed, and the compound denitrification agent is obtained.The technical method is simple, safe, practical, small in investment and low in processing and operation energy consumption, can completely solve the technical problem about disposal of waste organic solvents, especially waste organic solvents in the automobile manufacturing industry, and is free of secondary pollution.All material components in the waste organic solvents, including all hydrocarbon and water, are used in a recycling and harmless mode, resources can be saved, and environment-friendly and resource-saving society construction is facilitated.

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

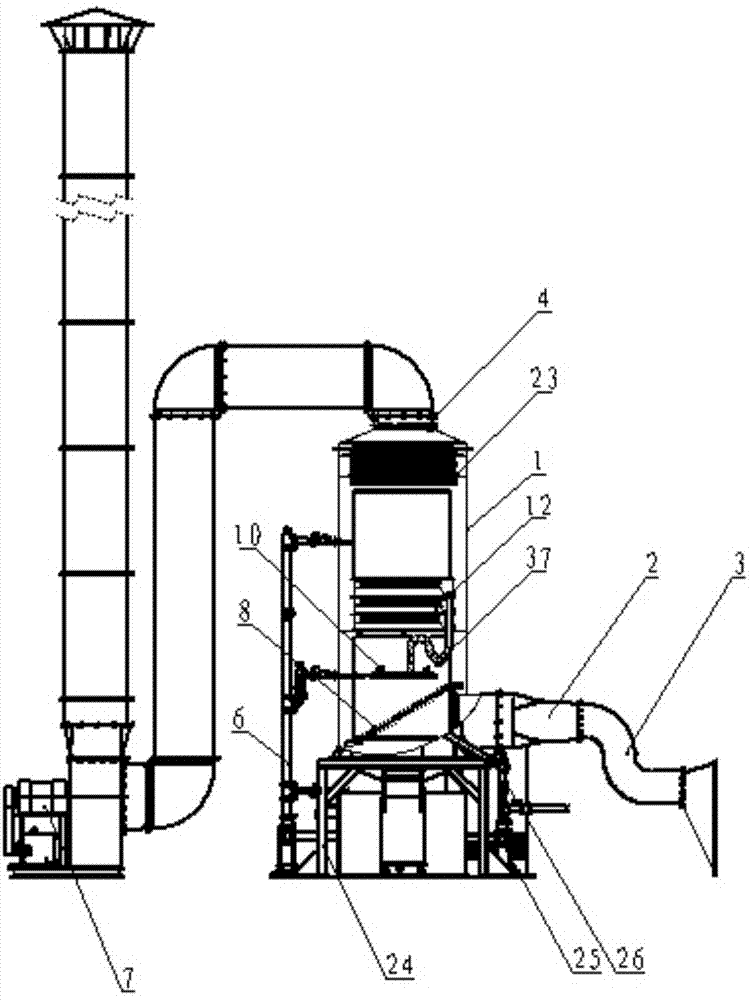

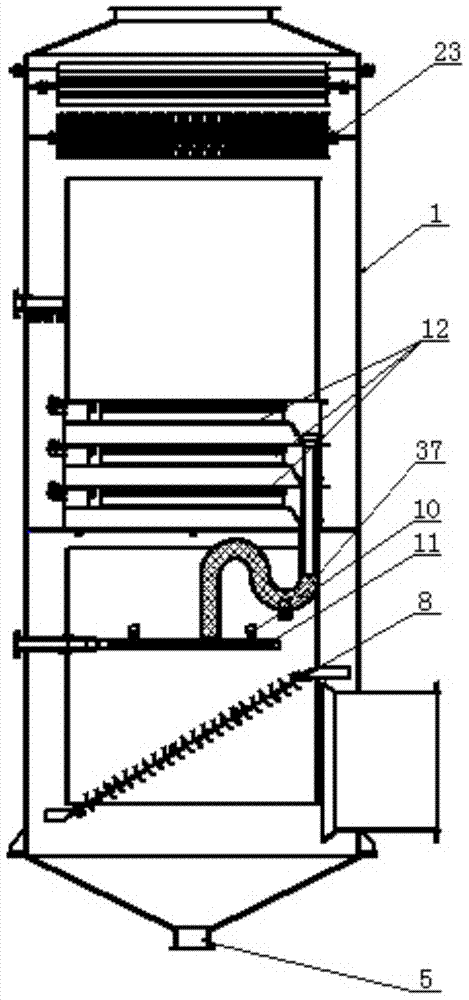

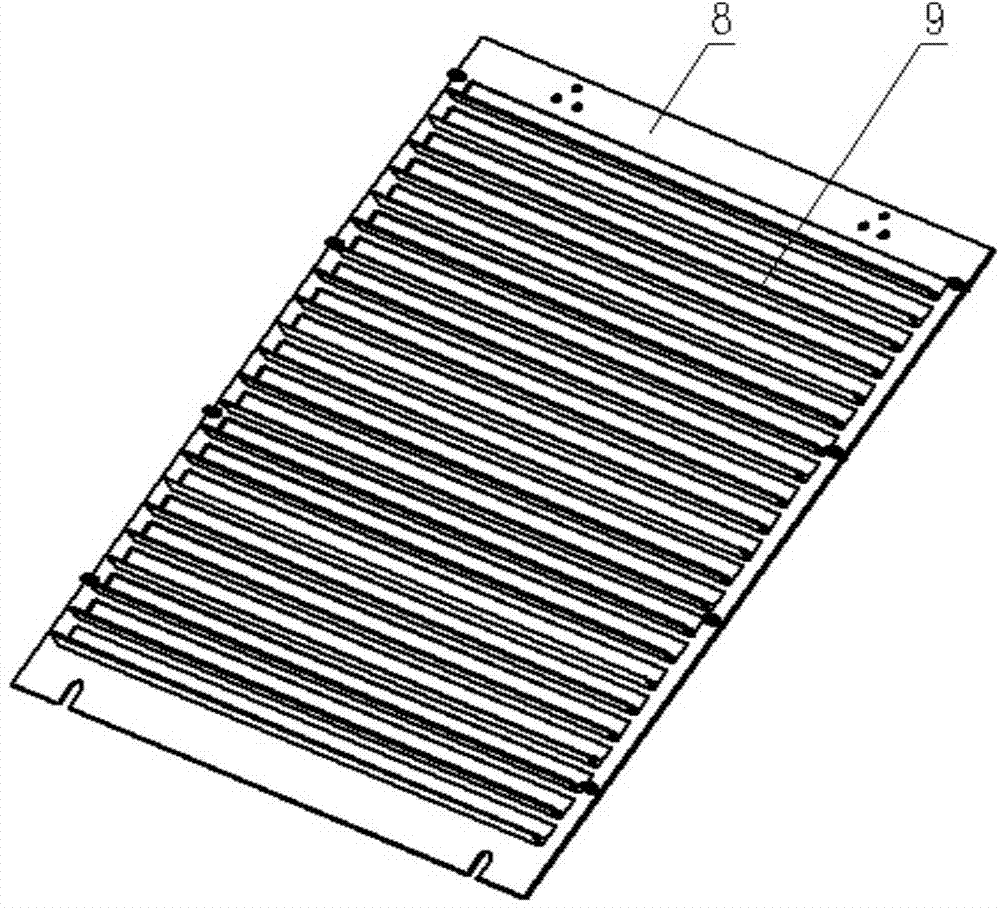

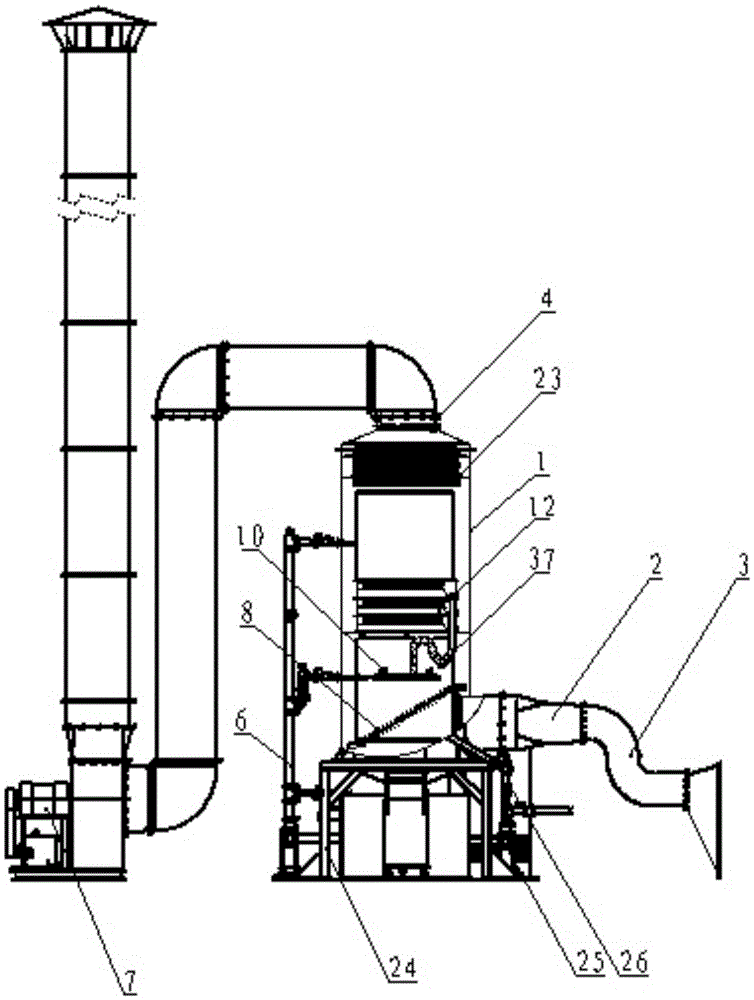

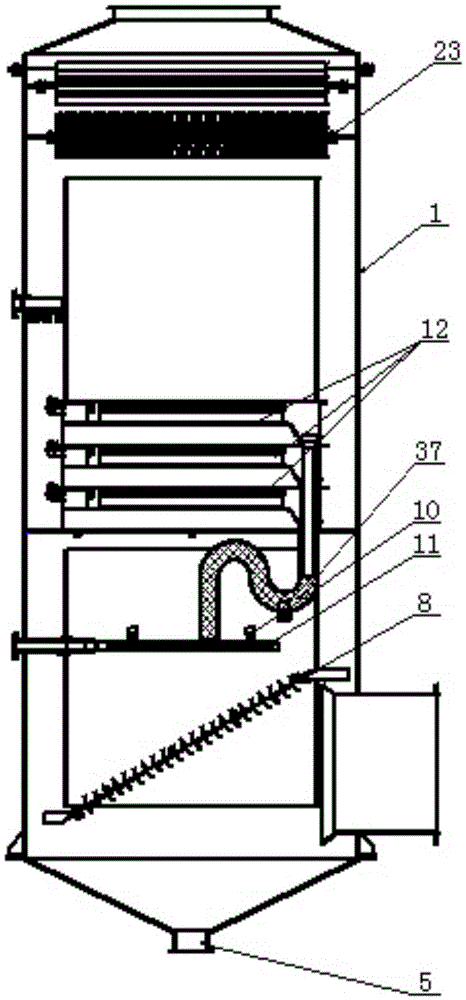

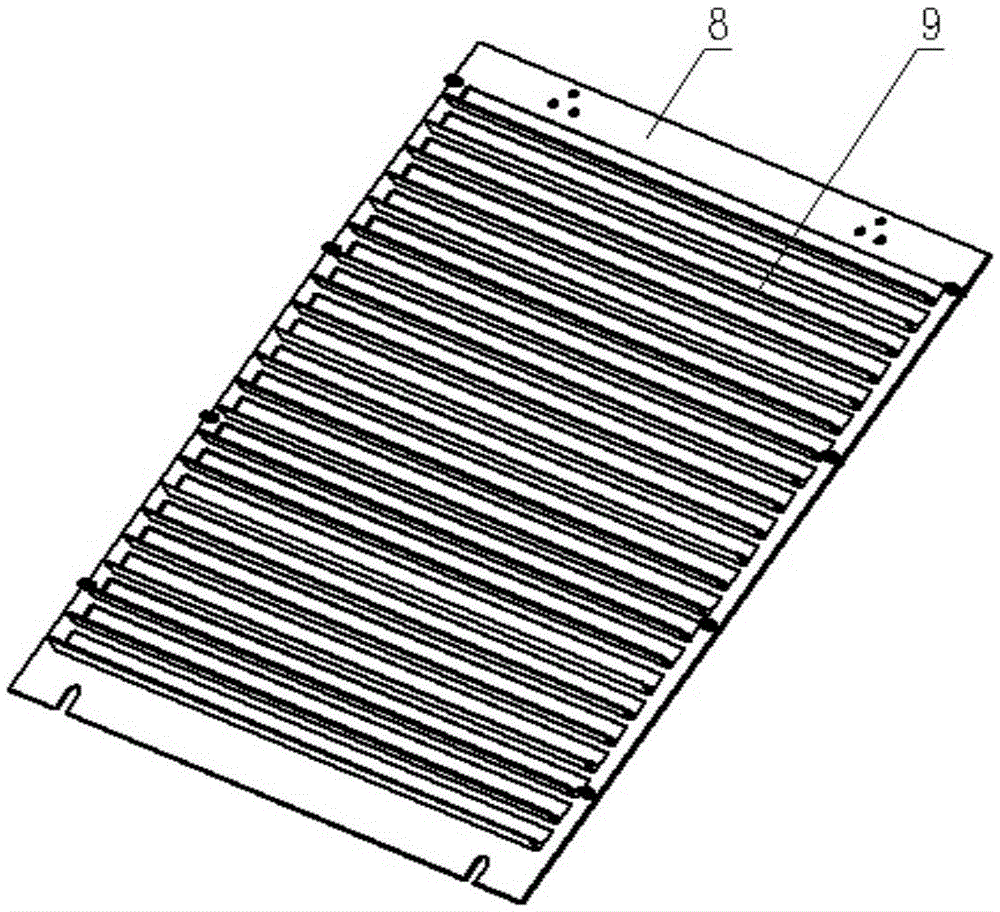

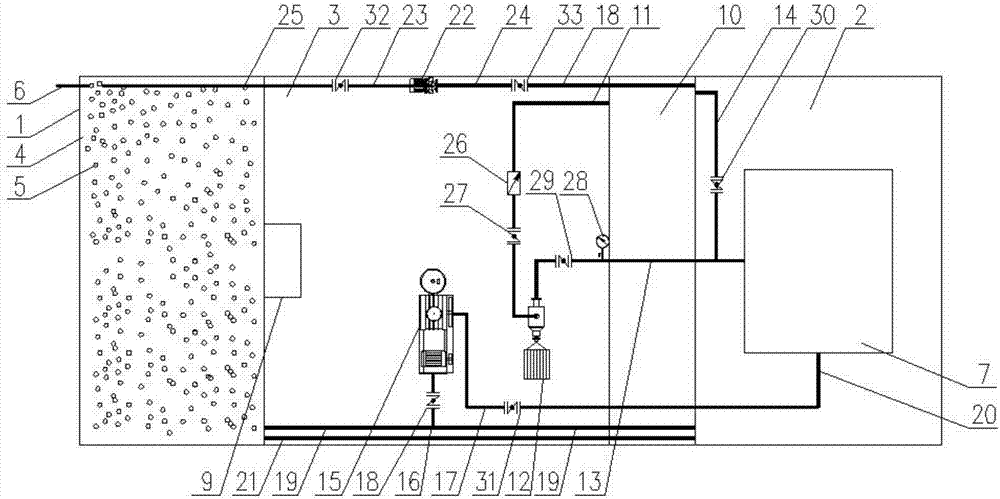

Wet-type dust removal device

The invention discloses a wet-type dust removal device consisting of a dust removal system and a sewage treatment system; the dust removal system is composed of an air deflector, a spray pipe, a smoke dust capture mechanism and a demister which are sequentially installed in a tower body from the bottom up; the air deflector is composed of a set of fin-shaped flow deflectors that are transversely arranged in a plane; the smoke dust capture mechanism is composed of a dust capture plate on which meshes are densely distributed and an inverse Y-shaped dust collection plate. The sewage treatment system is composed of a sewage box, a sewage pump, a filter paper tape, a pure water recycling mechanism, a sludge drying mechanism and a dust slag collecting mechanism. According to the wet-type dust removal device, dusty air has been subjected to dust removal for five times, thus being high in dust removal rate; number of the layers of the smoke dust capture mechanism, the dust removal rate of the air including particles of more than 5 microns is up to more than 98%; the dusty air is small in resistance and low in energy consumption; the wet-type dust removal device integrates the functions of dust removal and sewage treatment, and can reduce occupied area and investment of environmental protection equipment; the dust removal sewage can be recyclable after treatment, thus being saving in water resources.

Owner:辽宁银捷装备科技股份有限公司

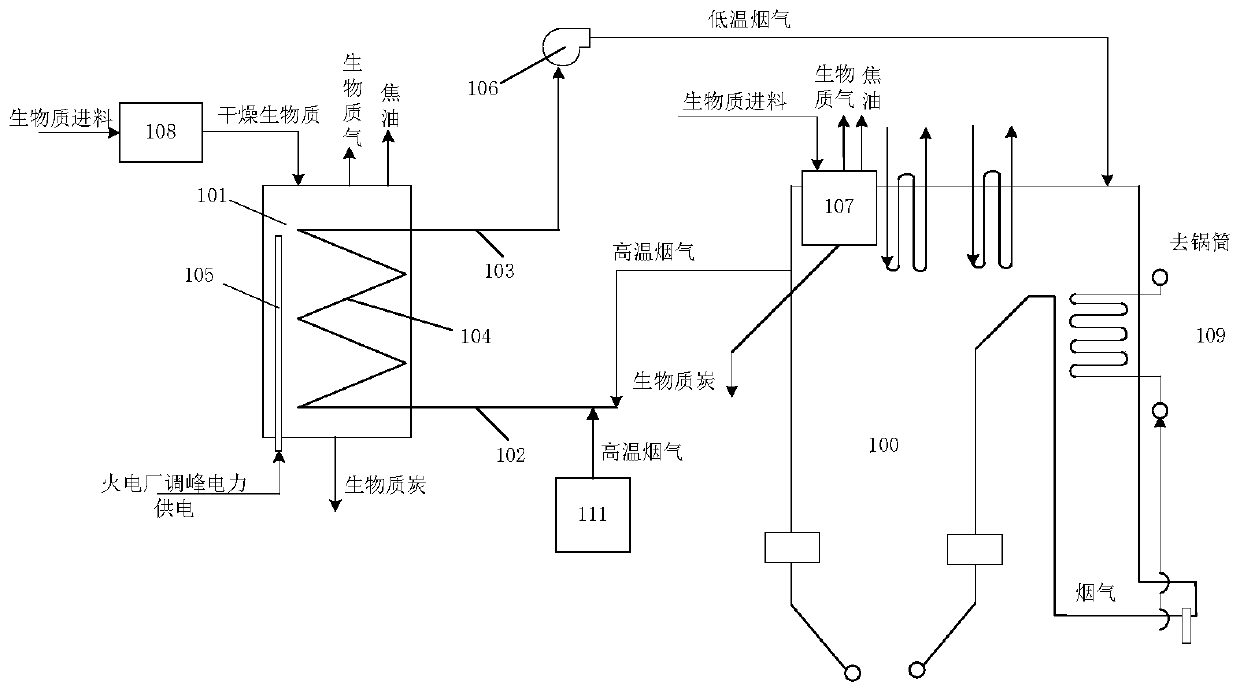

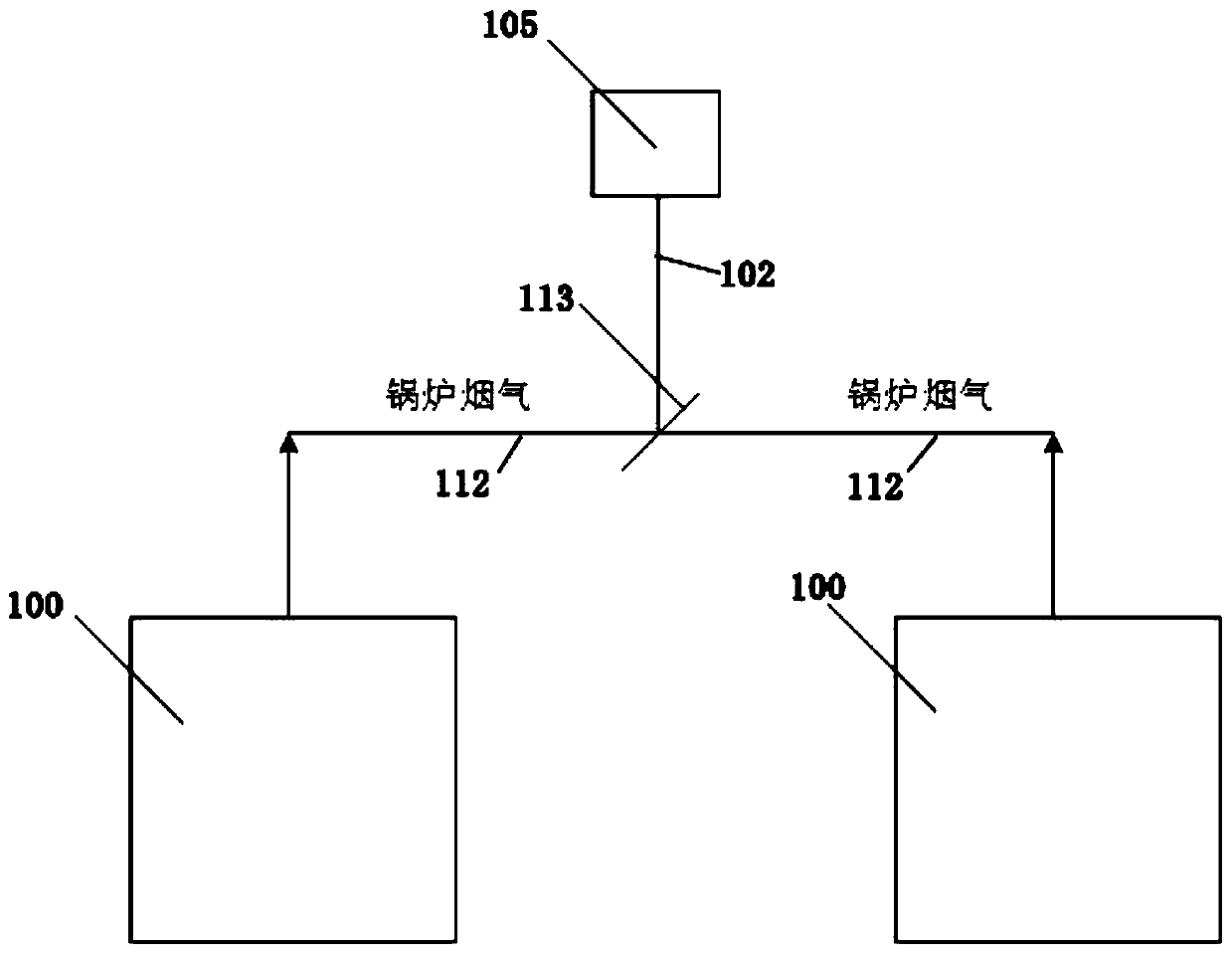

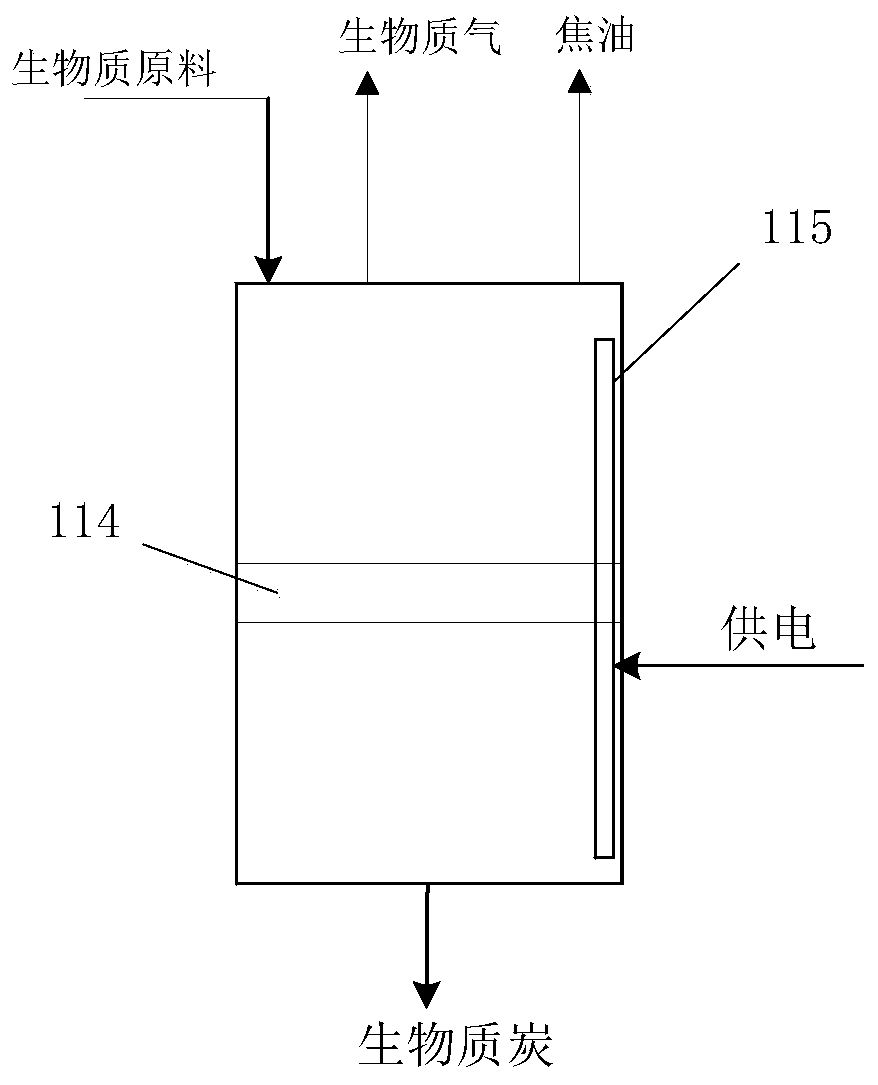

System and method for producing biomass charcoal by utilizing flue gas of power station boiler

PendingCN110387250AReduce consumptionReduce loadBiofuelsIndirect heating destructive distillationBiomass carbonPower station

The invention discloses a system and method for producing biomass charcoal by utilizing flue gas of a power station boiler. The system comprises a pyrolyzing furnace; the pyrolyzing furnace is provided with a biomass inlet, a biomass carbon outlet and a biomass gas outlet, and flue gas generated by a power station boiler of a fire power plant provides a main heat source for the pyrolyzing furnace;and the system further comprises a heat supplementing device which is used for supplementing heat source to the pyrolyzing furnace when the temperature in the pyrolyzing furnace cannot reach a presetpyrolysis temperature. According to the system disclosed by the invention, the high-temperature flue gas of the power station boiler is used for directly carrying out high-temperature pyrolysis on biomass, so that fuel consumption of biomass pyrolysis is saved.

Owner:HEPU ENERGY ENVIRONMENTAL TECHNOLOGY CO LTD

Treatment method for mother liquid generated in preparation process of aspartic acid

The invention discloses a treatment method for a mother liquid generated in the preparation process of aspartic acid, and belongs to the field of green chemical synthesis. The treatment method uses the mother liquid to prepare a polyaspartic acid product. The method provided by the invention has no waste discharge, is safe environmentally friendly and pollution-free, and meets the requirements ofclean production; and the method has a simple production process, needs less equipment, has a high resource utilization rate, and is suitable for large-scale production.

Owner:HEBEI THINK DO ENVIRONMENT CO LTD

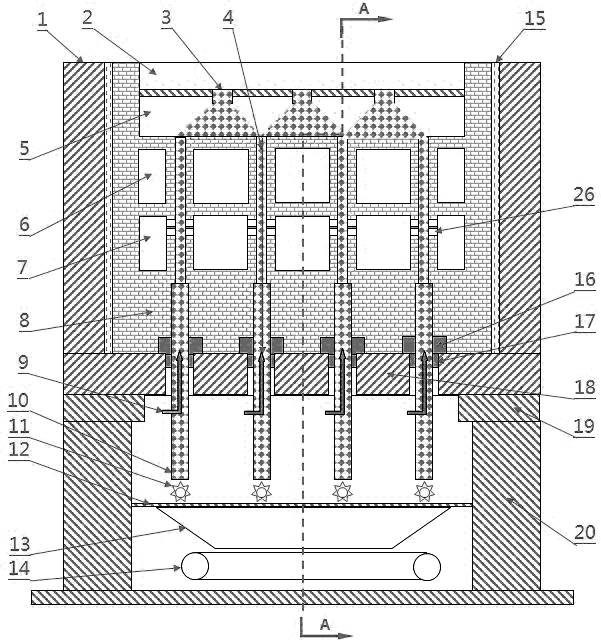

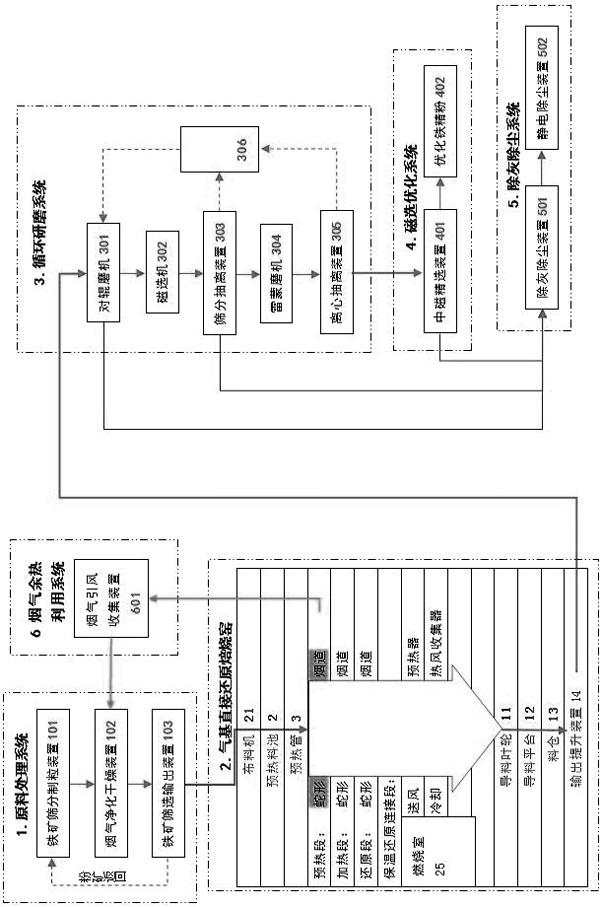

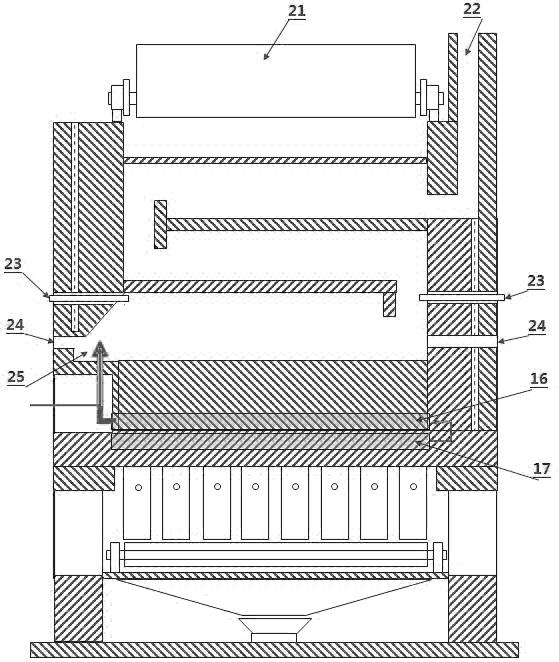

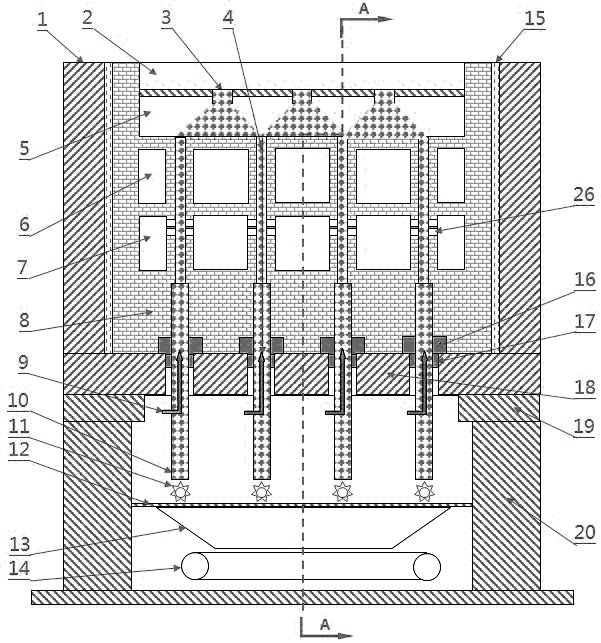

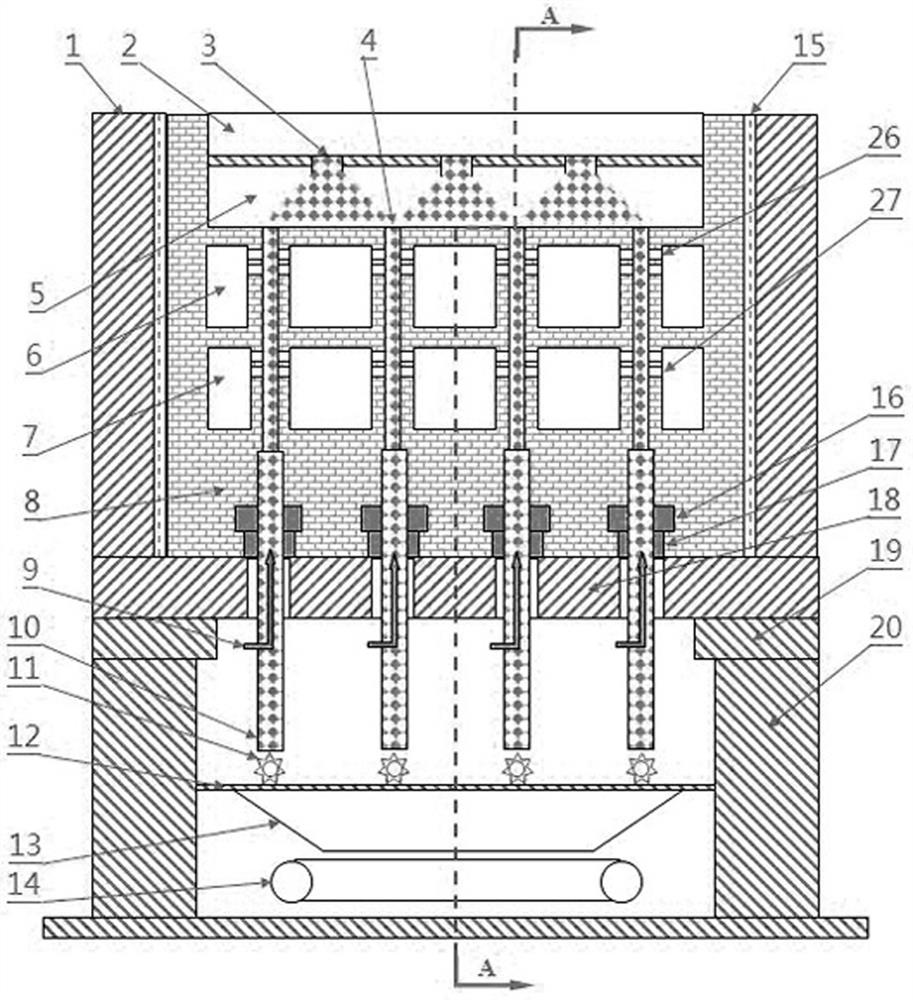

Device and method for optimizing iron ore through gas-based direct reduction magnetic separation

PendingCN113684338AEscape in timeIncreased concentrationElectrostatic separationMagnetic separationThermodynamicsProcess engineering

The invention relates to the technical field of energy-saving comprehensive utilization of mineral resources, in particular to a device and method for optimizing iron ore through gas-based direct reduction magnetic separation. The device comprises a kiln body, wherein a roundabout snake-shaped flue is arranged in the kiln body from top to bottom, and the snake-shaped flue is divided into a preheating section, a heating section and a reduction section from top to bottom; a preheating material pool is arranged above the preheating section, the bottom of the preheating section is communicated with a blanking channel, and the blanking channel penetrates through the heating section and the reduction section and is isolated from the heating section and the reduction section; the bottom end of the blanking channel is communicated with an air cooling pipeline, and a reducing gas preheating reduction device is arranged in the air cooling pipeline; the bottom of the air cooling pipeline is connected with a circulating grinding system and a magnetic separation optimizing system. According to the method, a final optimized product is obtained through raw material treatment, gas-based direct reduction roasting and grinding magnetic separation optimization; and the problems of low reduction efficiency, long reduction heating time, a high heating temperature and poor heat preservation effect in the prior art are solved.

Owner:张雷

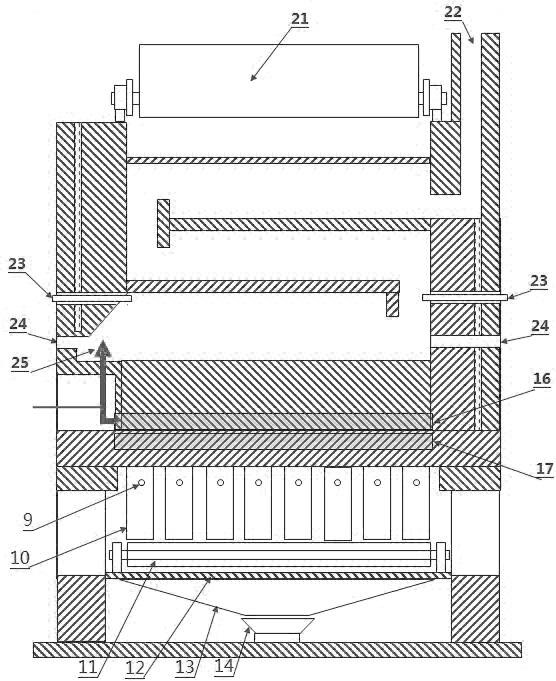

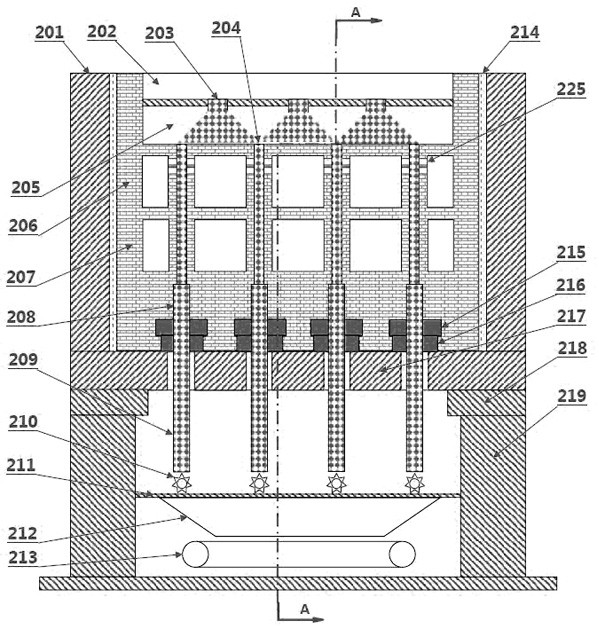

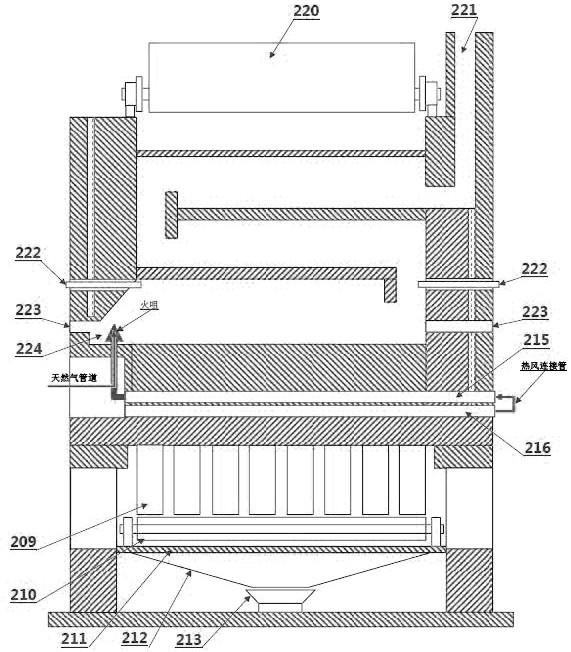

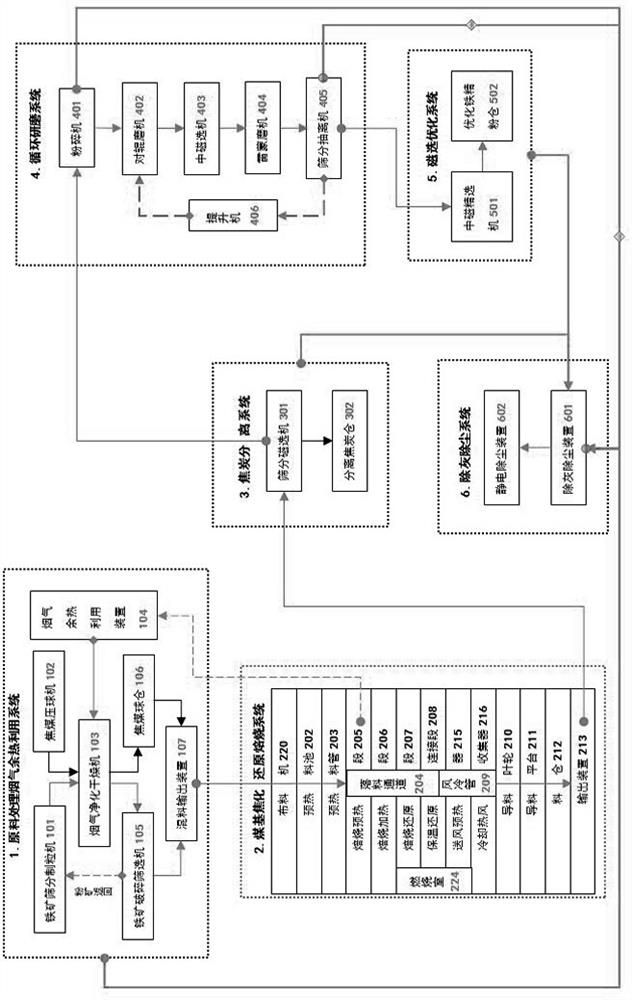

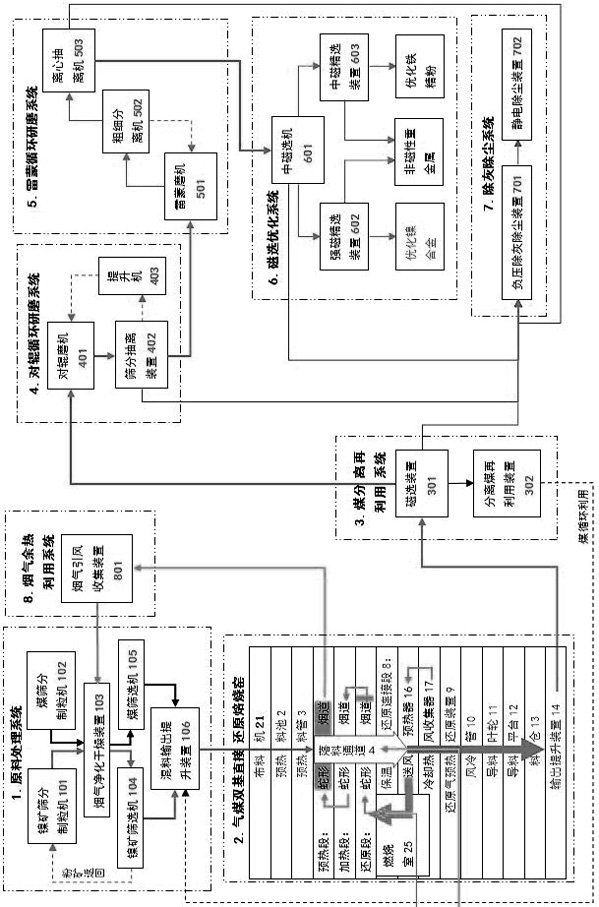

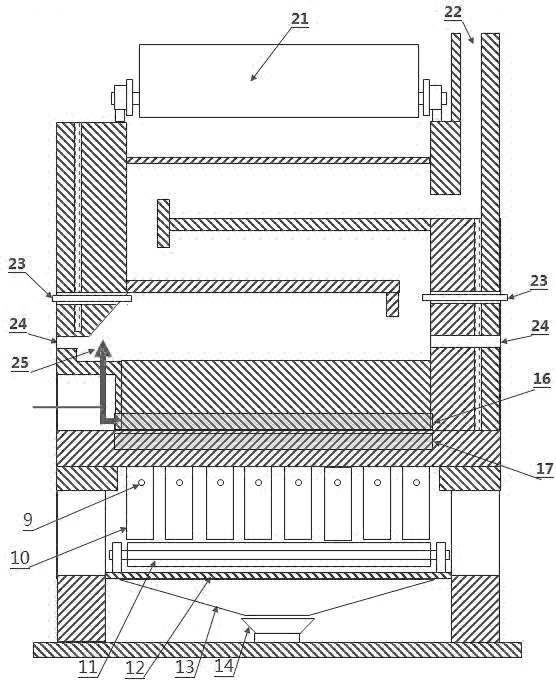

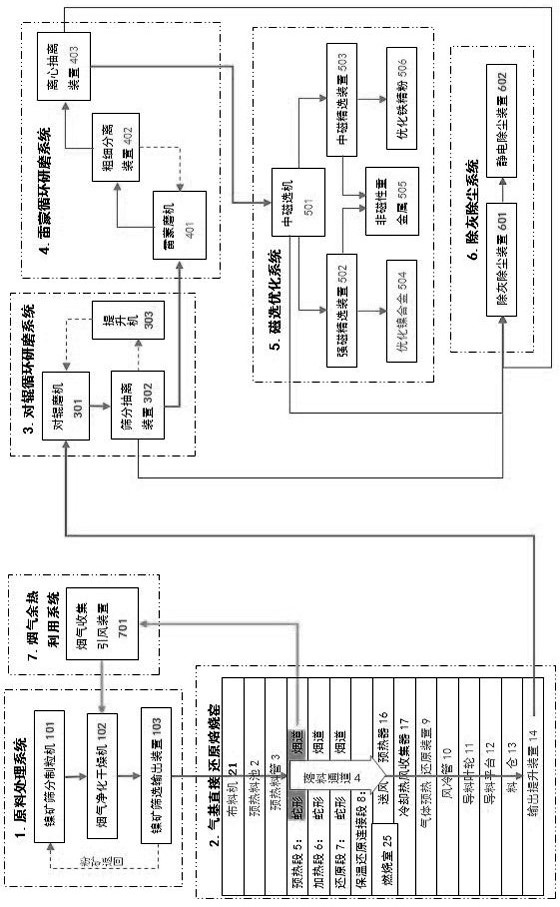

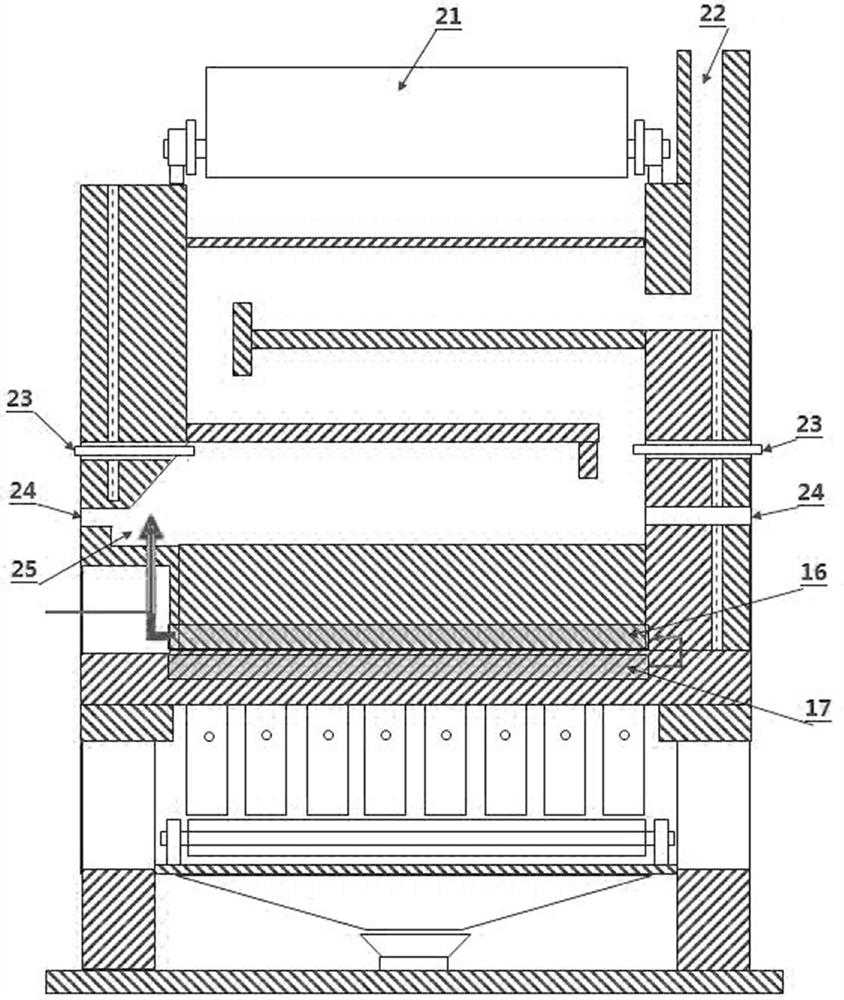

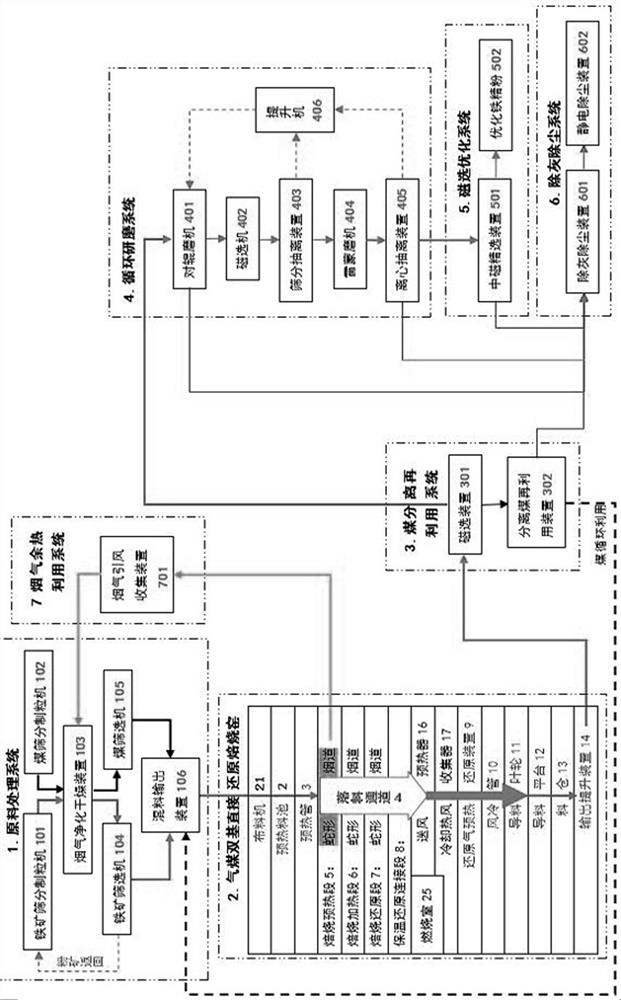

Method and device for optimizing iron ore through coal-based coking reduction roasting coke magnetic separation

PendingCN113976310AReduce wearImprove dust removal efficiencyIncreasing energy efficiencyMagnetic separationFlue gasMagnetic separation

The invention relates to the technical field of energy-saving comprehensive utilization of mineral resources, in particular to a method and device for optimizing iron ore through coal-based coking reduction roasting coke magnetic separation. The device comprises a raw material treatment flue gas waste heat utilization system, a coal-based coking reduction roasting system, a coke separation system, a circulating grinding system, a magnetic separation optimization system and an ash and dust removal system. An optimized iron fine powder product is finally obtained through the steps of raw material treatment, coal-based coking reduction roasting, iron ore reduction catalysis coking coal coking, coke separation, circulating grinding and magnetic separation optimization. The method is suitable for treating various types of iron oxide ores with TFe greater than 38%, coking reduction roasting coke volatile matter less than 1.2% meets the ironmaking and steelmaking requirements, the iron recovery rate is obviously improved, the grade of optimized fine iron powder can reach more than 76% of TFe, the sulfur and phosphorus removal efficiency is greater than 60%, energy is saved by greater than 50%, and the problems of high energy consumption, low reduction efficiency, difficulty in thermotechnical control, unstable product quality and shortage of reduced iron raw materials in the existing process are solved.

Owner:张雷

Method for optimizing low-grade laterite-nickel ore through gas-coal double-base direct reduction magnetic separation

PendingCN113699367ALess investmentDoes not affect recoveryProcess efficiency improvementGrindingCoal

The invention relates to the technical field of energy-saving comprehensive utilization of mineral resources, in particular to a method for optimizing low-grade laterite-nickel ore through gas-coal double-base direct reduction magnetic separation. The method comprises the following specific steps of raw material treatment, carrying out reduction roasting on a material and reduction coal mixture by using a gas-coal double-base direct reduction roasting kiln; cooling a laterite-nickel ore particle material subjected to reduction roasting and sequentially passes through a coal separation recycling system, a double-roller grinding system, a Raymond grinding system and a magnetic separation system to obtain a nickel alloy product, and the mass percent of nickel contained in the nickel alloy product is that Ni is greater than 8%. According to the method, the problems of low reduction efficiency, long reduction heating time, high heating temperature and poor heat preservation effect in the prior art are solved.

Owner:张雷

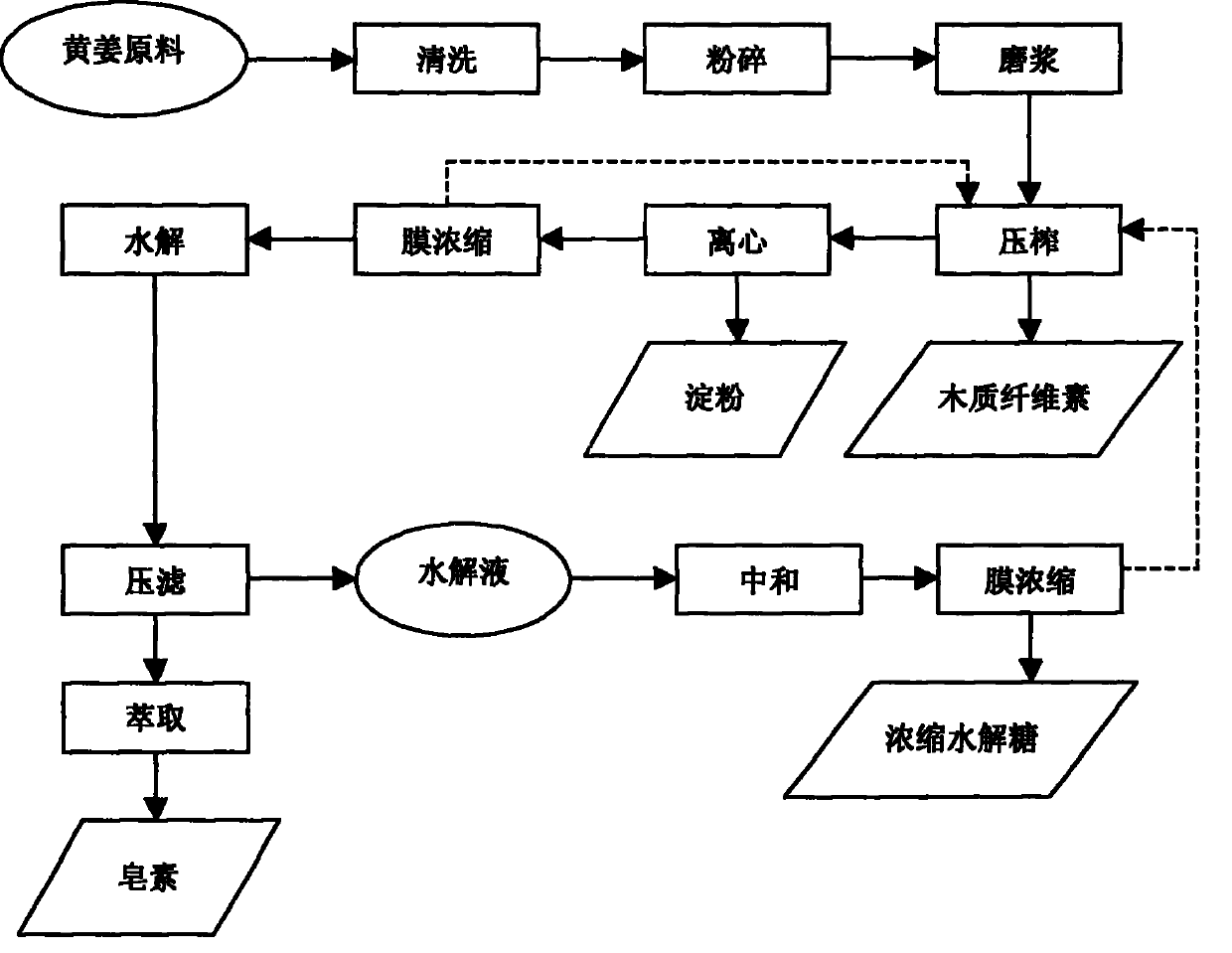

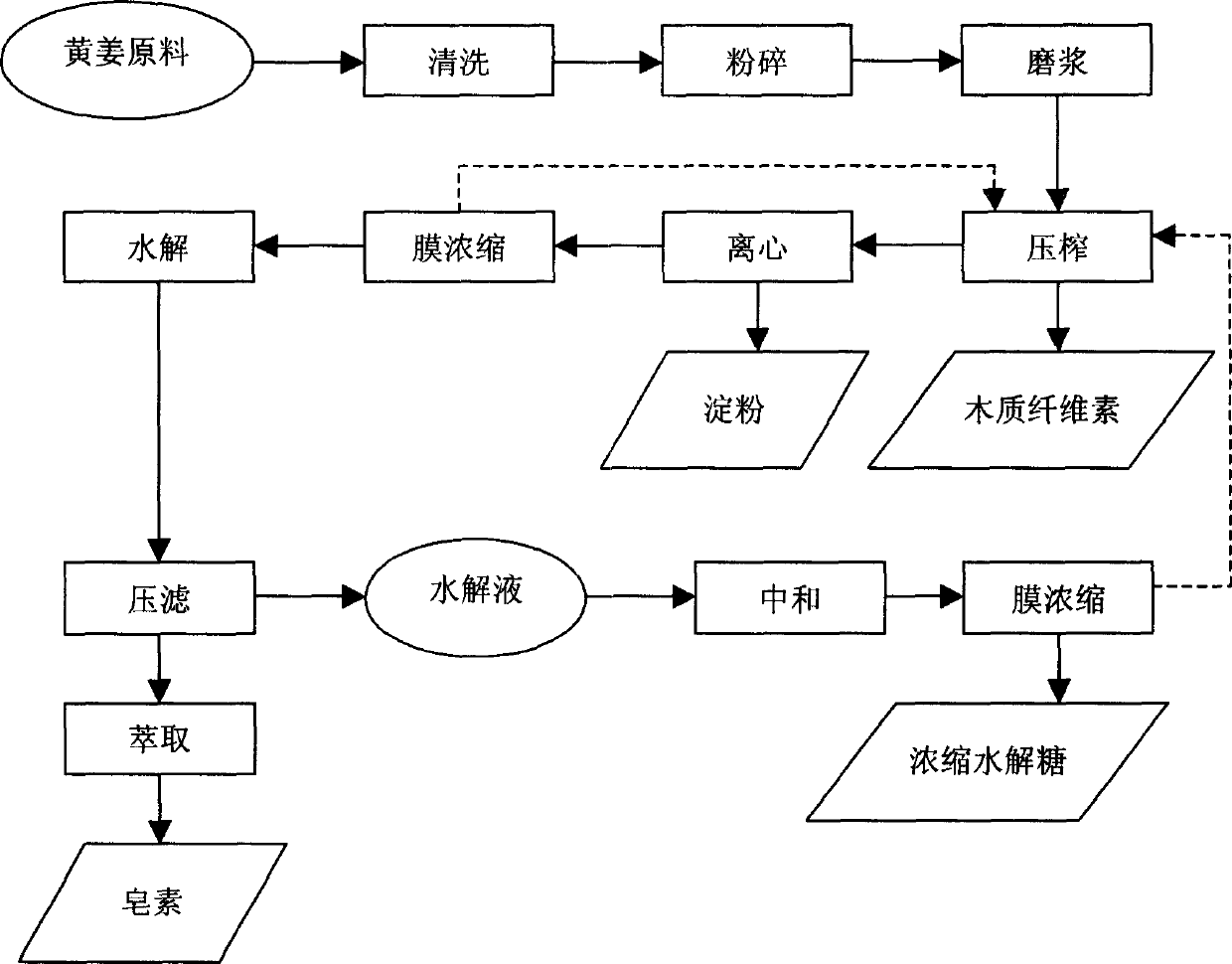

Method for cleanly producing yellow ginger

InactiveCN1849909BAchieving zero emissionsReduce processing costsSteroids preparationFood preparationUltrasonic assistedFiltration

The present invention relates to a clean production processing method of turmeric. Said method includes the following steps: cleaning turmeric raw material, pulverizing, ultrasonic auxiliary grinding, pressing, centrifugal separation, first membrane concentration, hydrolysis, press filtration, extraction, neutralization and secondary membrane concentration.

Owner:朱江

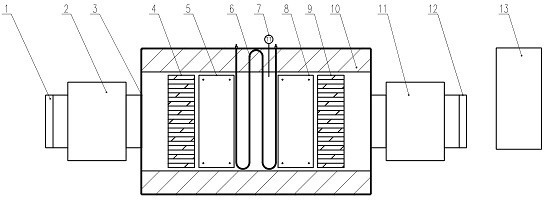

Air heater and air purifier

InactiveCN113203205ASolve the costSolve the economyDispersed particle filtrationElectric heating systemPublic placeAir purifiers

The invention discloses an air heater and air purifier. The heat storage type heat exchange principle is applied, a left fan and a right fan are used for reversing, and therefore the air inlet and outlet flow directions are changed, a reversing valve is replaced, and heat storage type heat exchange is achieved in a simple and low-cost manner. Air is heated and purified in the heating process, the temperature of the heating and disinfecting process is 150-900 DEG C according to needs, the exhaust temperature is increased by 5-50 DEG C, energy consumption is low, the air heater and air purifier can be applied to public places such as stations, hospital halls, classrooms, churches, offices, hotel halls and restaurants and workshops such as paint spraying rooms, paint baking rooms and VOC-polluted newly-decorated rooms where VOC is generated, and indoor waste gas containing bacteria, viruses and VOC is disinfected and incinerated while heating is conducted. If the calorific value of VOC waste gas is high, self-stable combustion can be realized without power consumption after the air heater and air purifier is started, and heat generated by waste gas is effectively utilized while pollutants are treated.

Owner:雍占锋

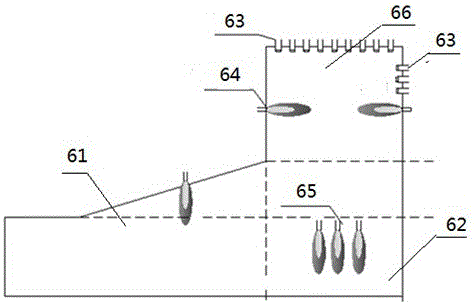

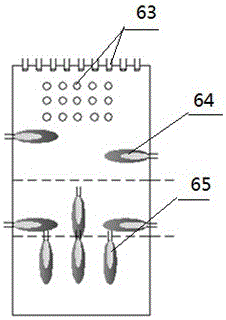

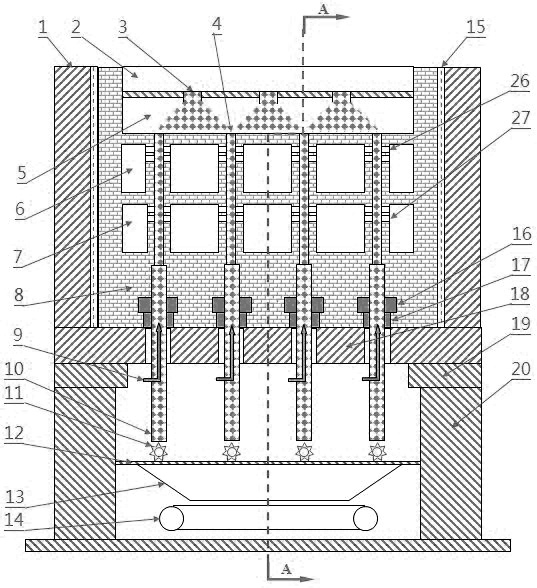

Device and method for optimizing low-grade laterite-nickel ore through gas-based direct reduction magnetic separation

The invention relates to the technical field of energy-saving comprehensive utilization of mineral resources, and particularly relates to a device and method for optimizing low-grade laterite-nickel ore through gas-based direct reduction magnetic separation. The device comprises a kiln body; a roundabout snake-shaped flue is arranged in the kiln body from top to bottom; the snake-shaped flue is divided into a roasting preheating section, a roasting heating section and a roasting reduction section from top to bottom; a preheating material pool is arranged above the roasting preheating section; the bottom of the roasting preheating section is communicated with a vertical blanking passage; the blanking passage penetrates through the roasting heating section and the roasting reduction section and is isolated from the roasting heating section and the roasting reduction section; the bottom end of the blanking passage is communicated with an air cooling pipe; and the bottom of the air cooling pipe is connected with a material output device and a grinding magnetic separation system. According to the method disclosed by the invention, a final optimized product is obtained through raw material treatment, gas-based direct reduction roasting and grinding magnetic separation optimization; and the invention solves the problems of low reduction efficiency, long reduction heating time, high heating temperature and poor heat preservation effect in the prior art.

Owner:张雷

Heat-insulation wallboard with low heat transfer coefficient

The invention discloses a heat-insulation wallboard with a low heat transfer coefficient, containing the following materials in parts by weight: 80-120 parts of cement, 30-50 parts of prefabricated expanded perlite, 40-60 parts of styrene-acrylic emulsion, 20-40 parts of poly-acrylonitrile base carbon fiber, 30-40 parts of glass fiber, 8-16 parts of gypsum, 15-20 parts of ultra-high molecular weight polyethylene fiber, 5-10 parts of steel fiber, 2-8 parts of kieselguhr, 15-25 parts of esterified starch, 10-20 parts of coal ash, 8-16 parts of talcum powder, 10-20 parts of calcium carbonate, and5-10 parts of mica powder. The prefabricated expanded perlite is prepared by adopting the following process: uniformly mixing gelatin, expanded perlite and hydrogen peroxide solution, filtering, adjusting the system to be neutral, adding ammonium persulfate and sodium hydrogen sulfite under nitrogen protection and stirring, adding acrylamide and stirring, precipitating, and drying, thus obtainingthe prefabricated expanded perlite.

Owner:安徽臻烁新材料技术有限公司

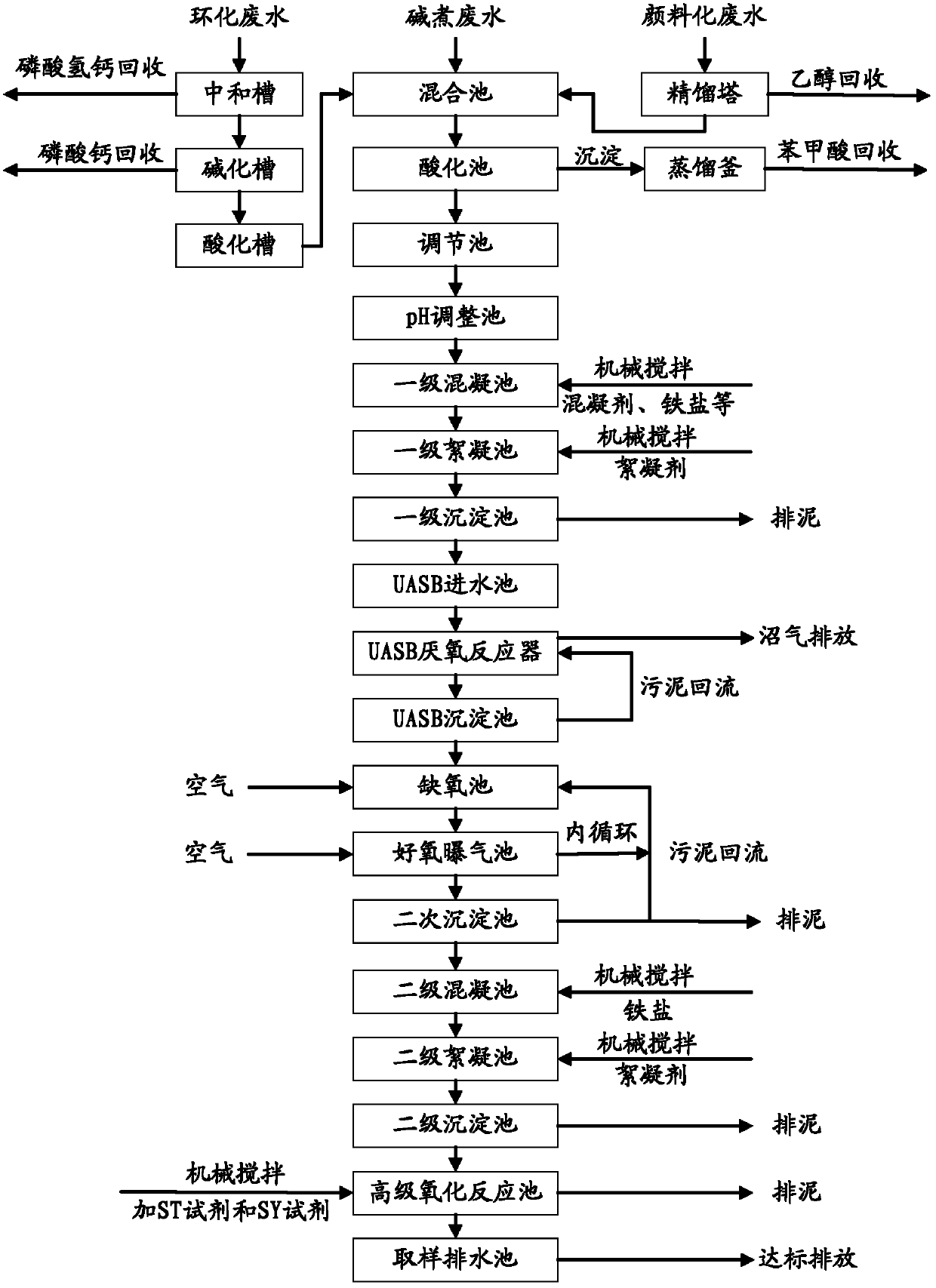

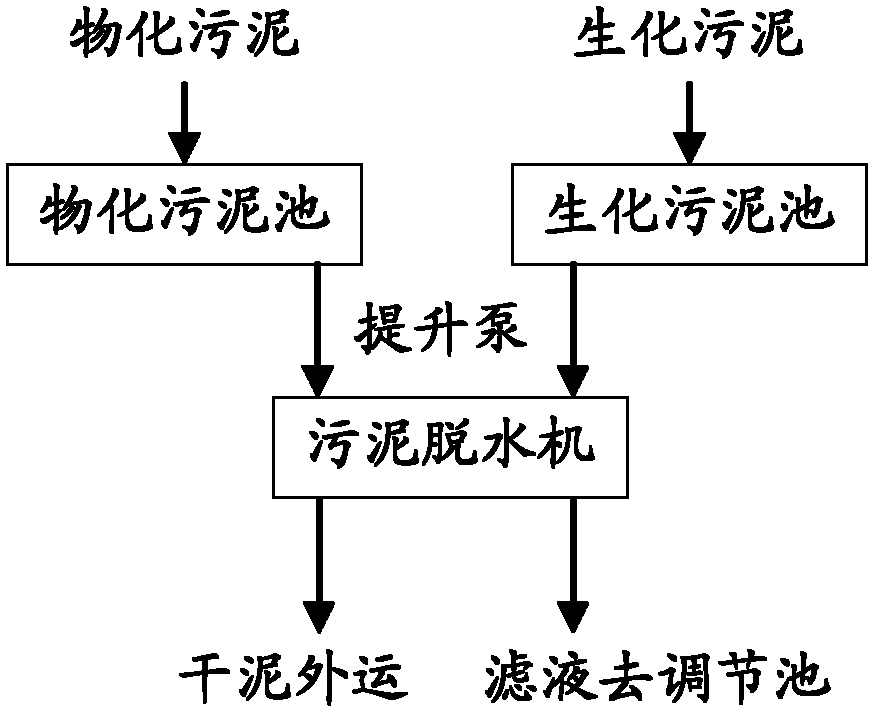

Process for treating and recovering dye industrial wastewater

ActiveCN102659283BA considerable amount of recyclingGuaranteed emission standardsMultistage water/sewage treatmentWaste water treatment from textile industryBenzoic acidDistillation

The invention discloses a process for treating and recovering dye industrial wastewater. The process comprises the following steps of: collecting cyclizing wastewater, adding a calcium hydroxide solution, reacting until the pH value is 5 to 7, and recovering a precipitate to obtain calcium hydrophosphate; adding the calcium hydroxide solution continuously, reacting until the pH value is 10 to 12,and recovering a precipitate to obtain calcium phosphate; adding an acidulant for neutralizing; collecting pigment wastewater, rectifying at the temperature of between 75 and 85 DEG C, and recoveringfractions to obtain ethanol; collecting soda boiling wastewater, mixing the soda boiling wastewater and the treated cyclizing wastewater and pigment wastewater to obtain mixed wastewater, adding the acidulant into the mixed wastewater, regulating the pH value to be 2 to 4, separating a precipitate out, and performing suction filtration and distillation on the precipitate to obtain benzoic acid; and performing primary materialization treatment, biochemical treatment and advanced treatment on the treated mixed wastewater sequentially, and discharging. According to the process, useful substancesin the dye wastewater are recovered, so that the production cost is saved, the load of the subsequent wastewater treatment process is reduced, the discharge of the wastewater can reach the standard, and the economic benefit is improved effectively.

Owner:浙江博世华环保科技有限公司

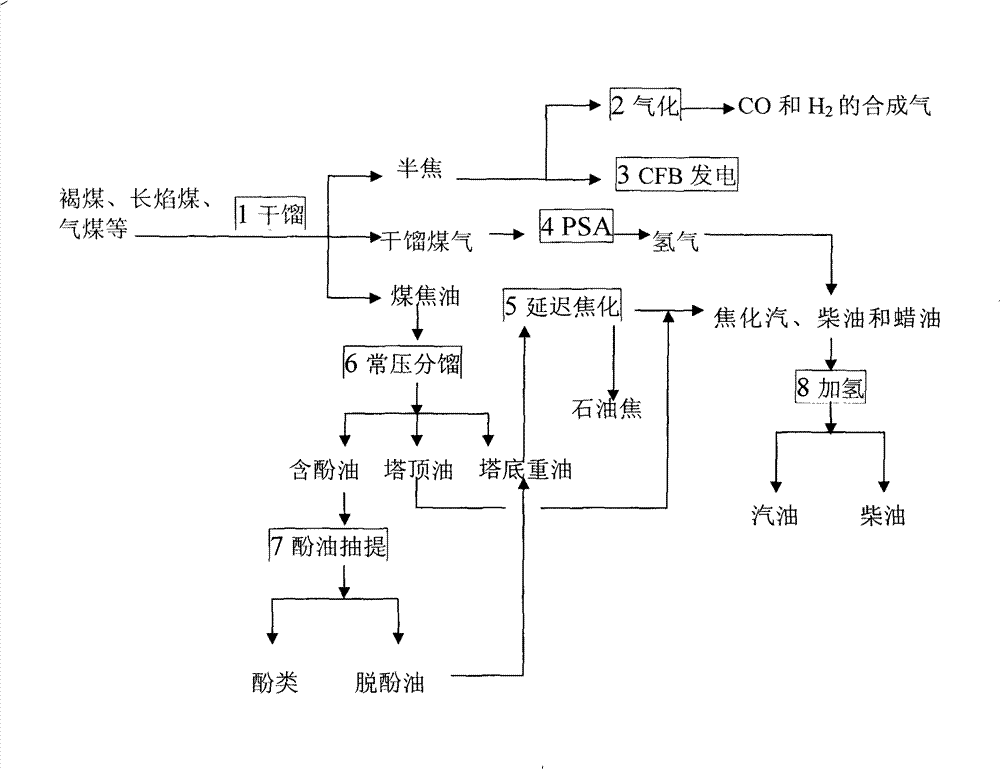

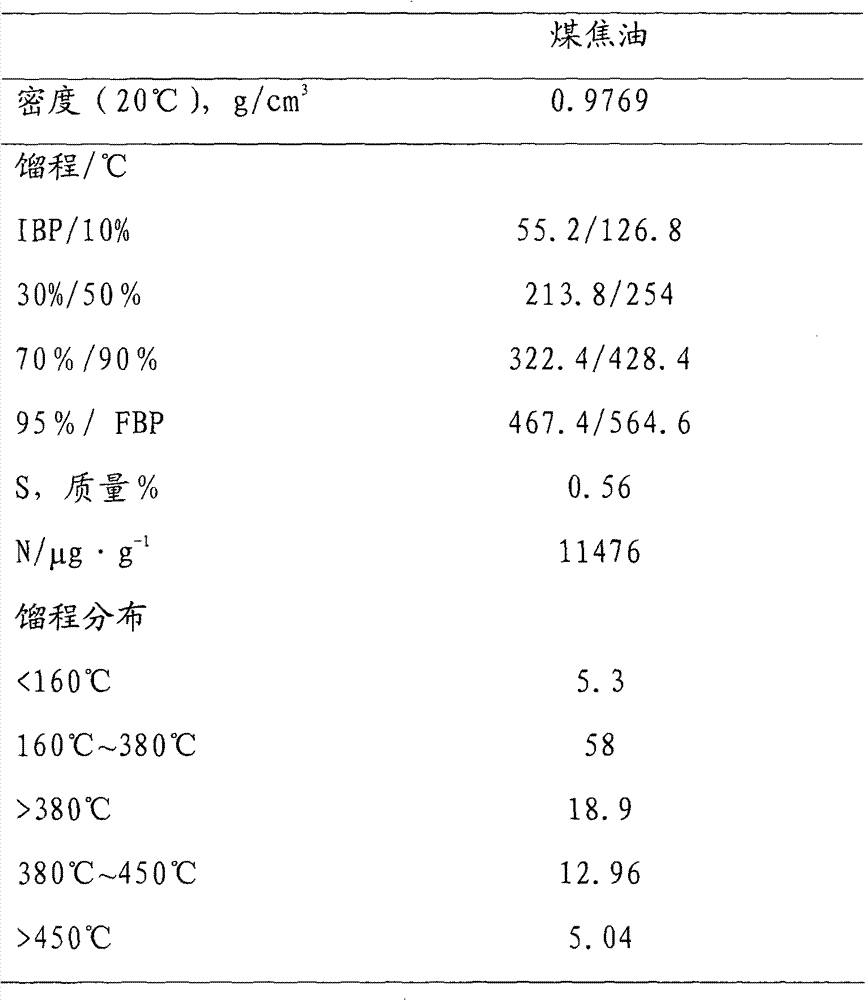

Incoherence or weak caking coal deep processing method

InactiveCN101538473BRealize deep processingHigh yieldTreatment with hydrotreatment processesSpecial form destructive distillationWater vaporCarbonization

The invention discloses an incoherence or weak caking coal deep processing method. Firstly, coking coal is fed into a carbonization reactor to carry out carbonization reaction, thus generating coal gas, carbocoal and coal tar; hydrogen in the coal gas is extracted out by pressure swing absorption; the carbocoal is fed into a coal gas generator and reacts with oxygen and water vapour to generate synthesis gas and coal ash; or the carbocoal is fed into a circulating fluid bed boiler to carry out generating; the coal tar enters a normal pressure fractionating tower to obtain creosoted oil, oil at the top of the tower and heavy oil at the bottom of the tower; wherein the creosoted oil is extracted to obtain crude phenol product and dephenolized oil, the dephenolized oil and heavy oil at the bottom of the tower enter a delayed coking device to carry out thermal cracking reaction. Through the optimization design of the flow, the invention realizes the deep processing of incoherence or weak caking coal such as ignite, long flame coal, gas coal and the like, and effectively improves the utilization factor of the materials.

Owner:胜帮科技股份有限公司

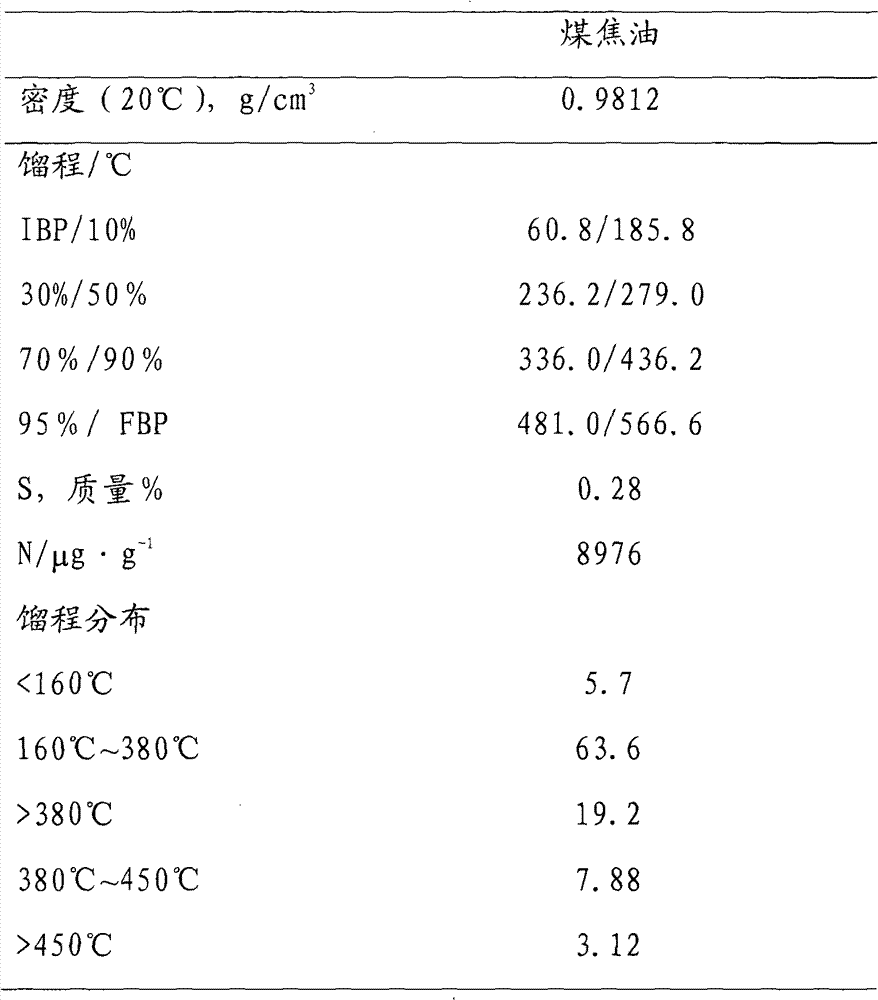

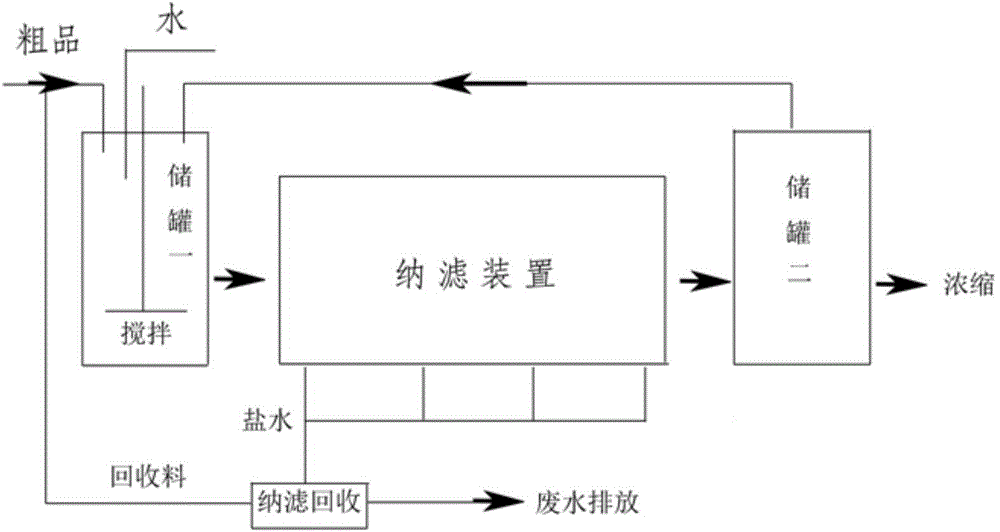

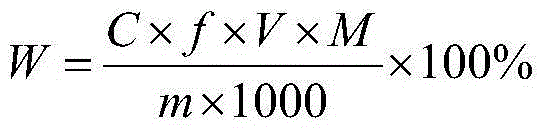

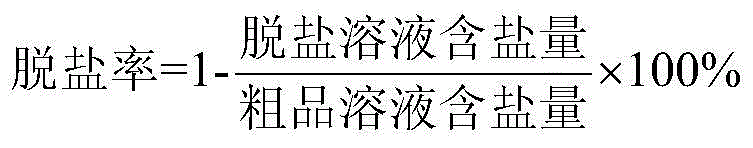

Desalination and purification method of pentasodium diethylenetriamine pentaacetic acid (DTPA)

ActiveCN103601648BReduce pollutionEmission reductionOrganic compound preparationAmino-carboxyl compound preparationPaint thinnerSaline water

Owner:YIXING FENGZE CHEM

Method for preparing high-strength heat-preservation wallboard

InactiveCN108585664AReduce pollutionMeet material quality requirementsConstruction materialFlexural strengthNitrogen gas

The invention discloses a method for preparing a high-strength heat-preservation wallboard. The method comprises the following steps that xanthan gum, expanded perlite and a hydrogen peroxide aqueoussolution are uniformly mixed and filtered, a system is adjusted to be neutral, ammonium persulfate and sodium bisulfite are added and stirred under the protection of nitrogen, acrylamide is added andstirred, and precipitating and drying are conducted to obtain a prefabricated material; cement, the prefabricated material, a polyurethane emulsion, nylon fibers, coal gangue and glutinous rice flourare stirred, pressed, shaken and then pressed, and then steam maintenance and natural airing are conducted to obtain the high-strength heat-preservation wallboard, wherein the weight ratio of the cement, the prefabricated material, the polyurethane emulsion, the nylon fibers, the coal gangue and the glutinous rice flour is (50-100):(20-40):(20-40):(10-20):(15-23):(2-10). The obtained heat-preservation wallboard has high compressive strength and flexural strength, low heat transfer coefficient and excellent heat preservation performance.

Owner:安徽臻烁新材料技术有限公司

A wet dust removal device

Owner:辽宁银捷装备科技股份有限公司

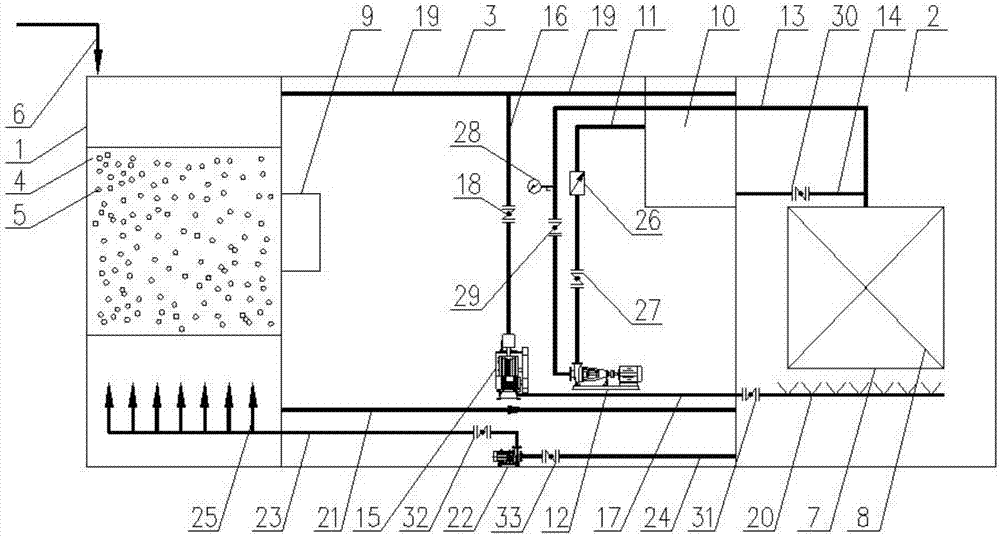

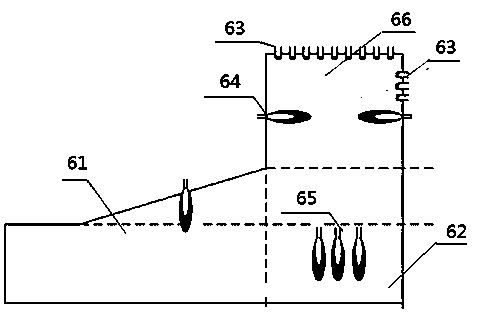

Near-zero-release membrane process sewage treatment system for sludge

InactiveCN107344807AReduce generationReduce the chance of damageTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentDaily operationWater treatment system

The invention discloses a near-zero-release membrane process sewage treatment system for sludge. The system comprises a facultative biochemical system, an MBR membrane assembly system and an equipment room, wherein the MBR membrane assembly system is arranged on one side of the facultative biochemical system, and the equipment room is formed between the facultative biochemical system and the MBR membrane assembly system; and the facultative biochemical system comprises a facultative biochemical tank. The near-zero-release membrane process sewage treatment system is provided with the facultative biochemical system and the MBR membrane assembly system, wastewater with a relatively high COD concentration is firstly subjected to facultative biochemical treatment by a facultative strain, the treated wastewater together with the facultative strain flows into a membrane tank through a sewage connecting pipe, and the facultative strain is attached to an MBR membrane assembly in the membrane tank so as to purify the sewage, so that the volume of the biochemical tank is reduced, the environmental protection investment is saved, the daily operation cost is lowered, the sludge is substantially reduced, and the sludge output is low.

Owner:安徽省科林环境生物技术有限公司

Method and device for optimizing iron ore through gas-coal double-base direct reduction magnetic separation

PendingCN113684337AImprove dust removal efficiencyLess friendlyElectrostatic separationMagnetic separationIron powderEngineering

The invention relates to the technical field of energy-saving comprehensive utilization of mineral resources, and particularly relates to a method and device for optimizing an iron ore through gas-coal double-base direct reduction magnetic separation. The method specifically comprises the steps: carrying out raw material treatment; carrying out reduction roasting on a material and reduction coal mixture by using a gas-coal double-base direct reduction roasting kiln; cooling an iron ore particle material subjected to reduction roasting; and sequentially treating by a coal separation recycling system, a double-roller grinding system, a Raymond grinding system and a magnetic separation optimization system to obtain optimized fine iron powder, wherein the grade Fe of the optimized fine iron powder is greater than 78%. The invention solves the problems of low reduction efficiency, long reduction heating time, high heating temperature and poor heat preservation effect in the prior art.

Owner:张雷

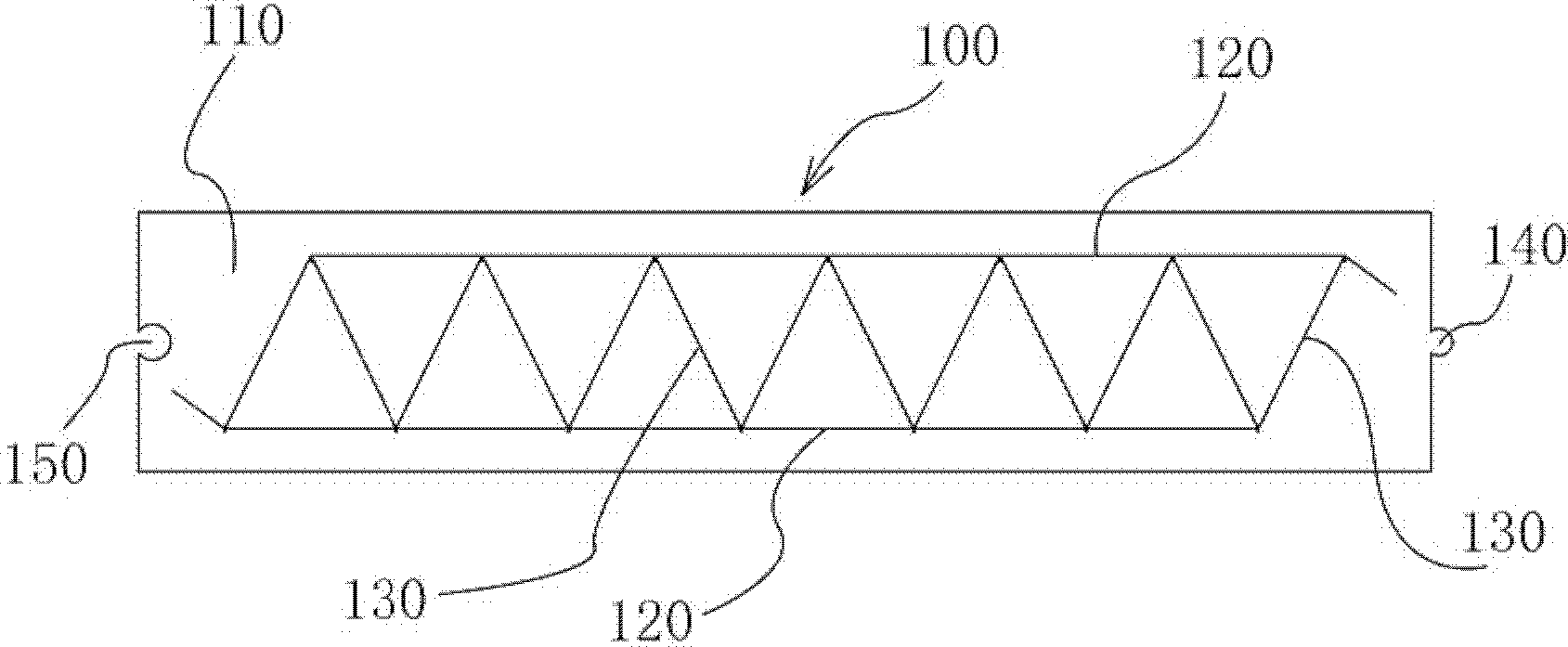

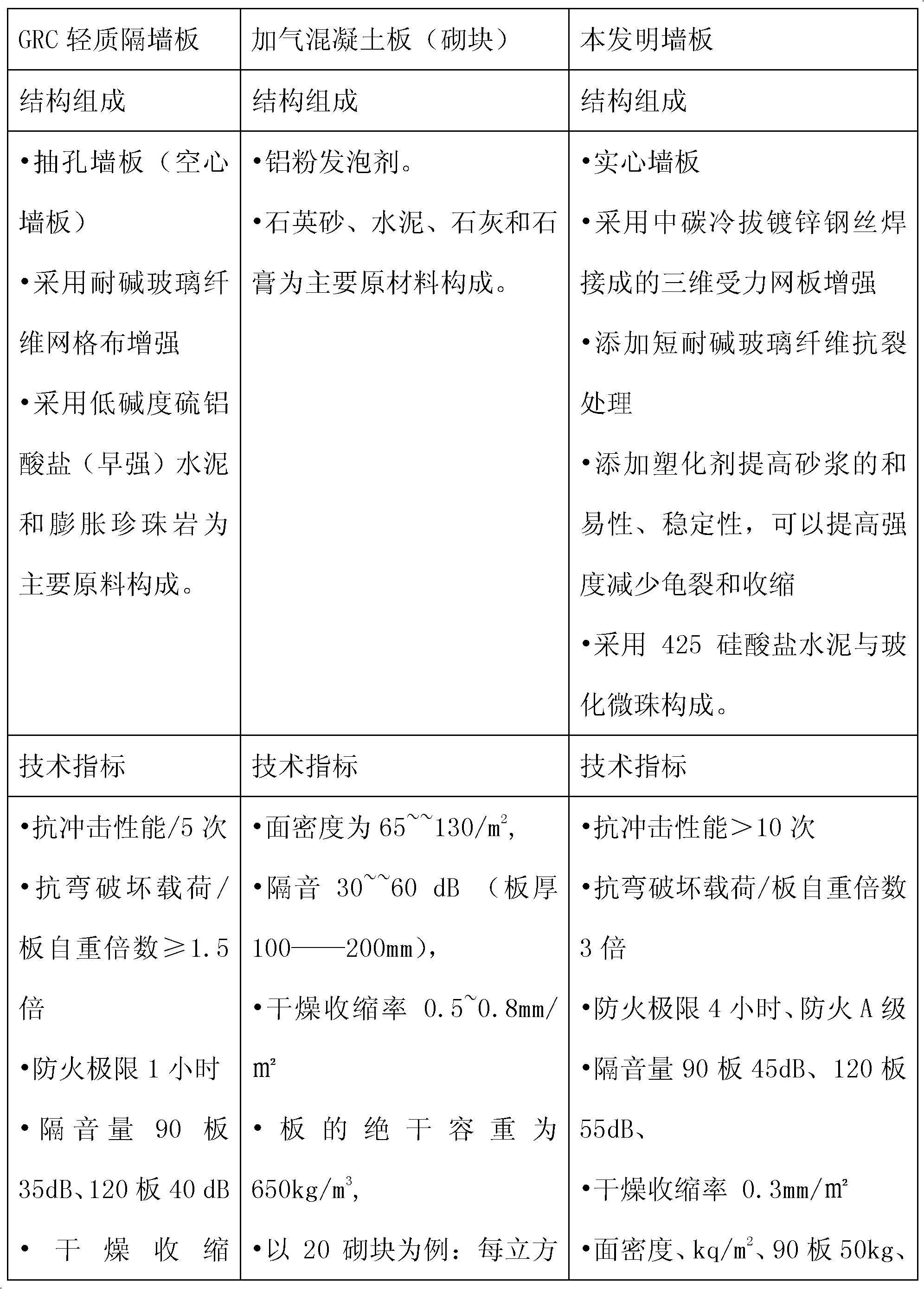

High strength light wall plate

InactiveCN102493594BRecyclable energy saving and environmental protectionImprove performanceConstruction materialPlasticizerMechanical engineering

Owner:上海大秦新型建材有限公司

A solid waste incineration system and treatment method with waste gas secondary combustion dry ignition device

ActiveCN105910111BReduce processing loadDecompose fullyIncinerator apparatusCombustion chamberFlue gas

The invention discloses a solid waste incineration system with an exhaust gas secondary combustion drying ignition device and a treatment method thereof. The solid waste incineration system comprises an incineration device and an air extraction system, wherein the incineration device comprises a cloth section, a drying section, an ignition section and an incineration section; operation at the drying section and the ignition section is achieved through the exhaust gas secondary combustion drying ignition device; the exhaust gas secondary combustion drying ignition device is in a cover body form, covers sintering materials, and is divided into an exhaust gas secondary combustion drying part at the front section and an ignition part arranged at the tail end; the incineration exhaust gas returns to the ignition device and burns in the situation that gas fuel is externally added, and a secondary combustion chamber is formed; and combustible matters in the flue gas are completely combusted, and harmful substances such as CO, NOx and dioxin in the flue gas are decomposed and are effectively treated. According to the solid waste incineration system, a high temperature gas generated during combustion ignites the materials, and waste heat of the exhaust gas dries and preheats the materials before ignition.

Owner:CHONGQING ANGRUIYUE SCI & TECH

Low-nitrogen-source pure oxygen combustion method

InactiveCN108019739AEliminate nitrogenReduce emission concentrationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberLow nitrogen

Owner:UNIV OF SCI & TECH BEIJING

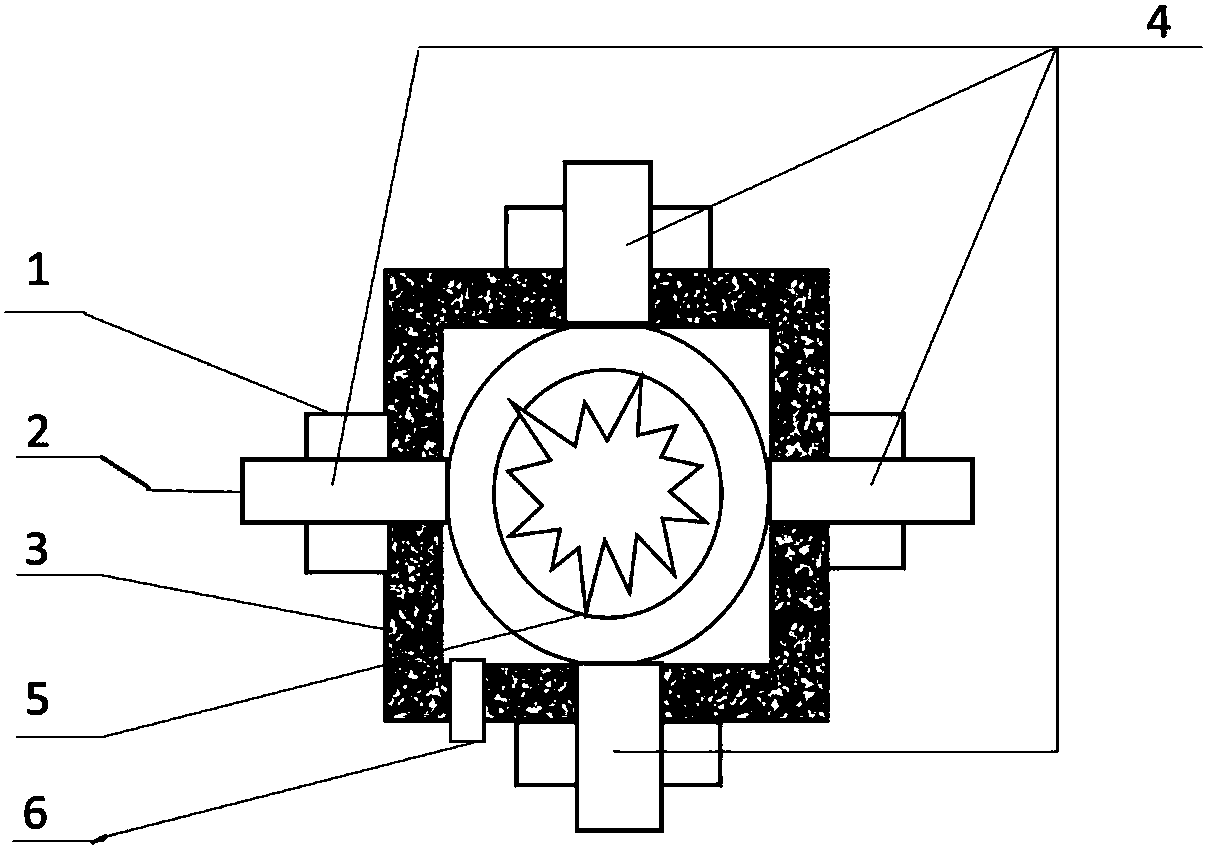

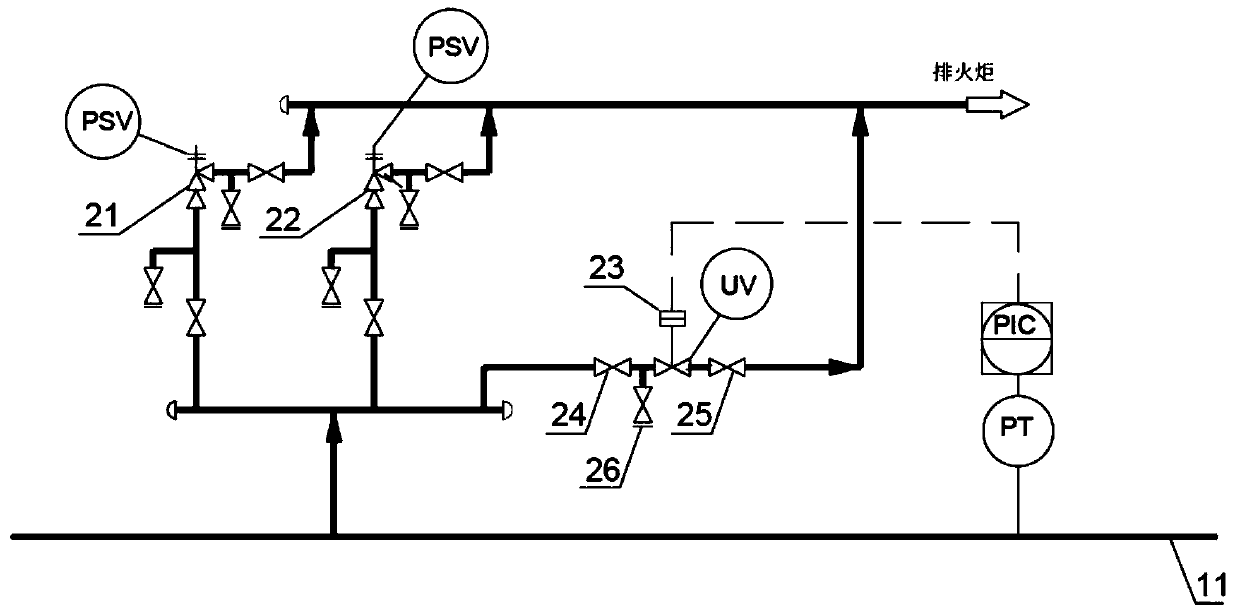

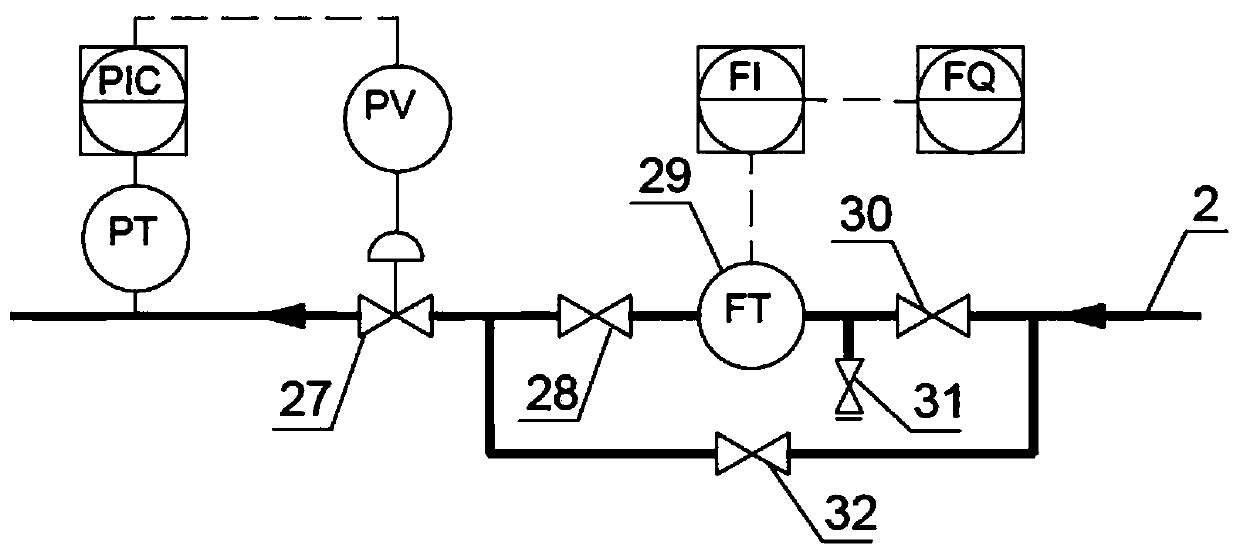

Treatment system for exhaust with high oxygen content and treatment method thereof

PendingCN111536419ALow costReduce design throughputGaseous fuel feeder/distributionPipeline systemsEngineeringVALVE PORT

The invention discloses a treatment system for exhaust with high oxygen content and a treatment method thereof. The treatment system comprises two stages of pressure operating systems, namely a firstsystem and a second system; a natural gas introduction control device is arranged at the front end of the first system, and is used for controlling natural gas introduced from the outside of a boundary region; the tail end of the first system is connected with the front end of the second system; a pressure regulating valve a is arranged between the tail end of the first system and the front end ofthe second system; the pressure of the first system is controlled to be higher than that of the second system by the pressure regulating valve a; the first system is provided with a plurality of gasfeed pipelines connected to ethylene oxide and glycol devices; the second system is provided with a plurality of gas supply pipelines and a plurality of exhaust emission pipelines for receiving exhaust from the ethylene oxide and glycol devices; and the second system is also provided with a safety release device. The treatment system and the treatment method have the advantages of reducing environmental protection investment, being capable of efficiently recycling exhaust with high oxygen content, reducing the production cost, improving the production benefits and the like.

Owner:连云港石化有限公司

A method for purifying and treating waste water produced by gallic acid with nano-silica gel

InactiveCN106477663BReduce COD valueImprove adsorption capacityWater/sewage treatment by neutralisationNature of treatment waterChemical oxygen demandGallic acid ester

The invention provides a method for purifying gallic acid production waste water through nanometer silica gel. The method comprises steps as follows: the waste water is neutralized with lime milk until the pH value of the waste water is appropriate; gallic acid and other organic ingredients in the waste water are adsorbed with calcium metasilicate nanogel; the gel material adsorbing the organic ingredients in the waste water is acidized through hydrochloric acid, so that gallic acid and other ingredients are subjected to desorption; the pH value of the nanogel subjected to desorption is adjusted through lime milk, and the adsorption capacity of the nanogel is regenerated under the condition of a proper pH value. With the adoption of the method, at least 92% of gallic acid in the gallic acid production waste water can be recycled, color-generating organic ingredients in the waste water can also be adsorbed, accordingly, the COD (chemical oxygen demand) value of the waste water can be effectively reduced, the chromaticity of the waste water is reduced remarkably, the water quality of discharged waste water meets the GB21905-2008 second-grade discharge standard, and the difficult technical problem about meeting the standards of good treatment effect, little environment investment and low operation cost for treatment of waste water during production of gallic acid can be better solved.

Owner:JISHOU UNIVERSITY

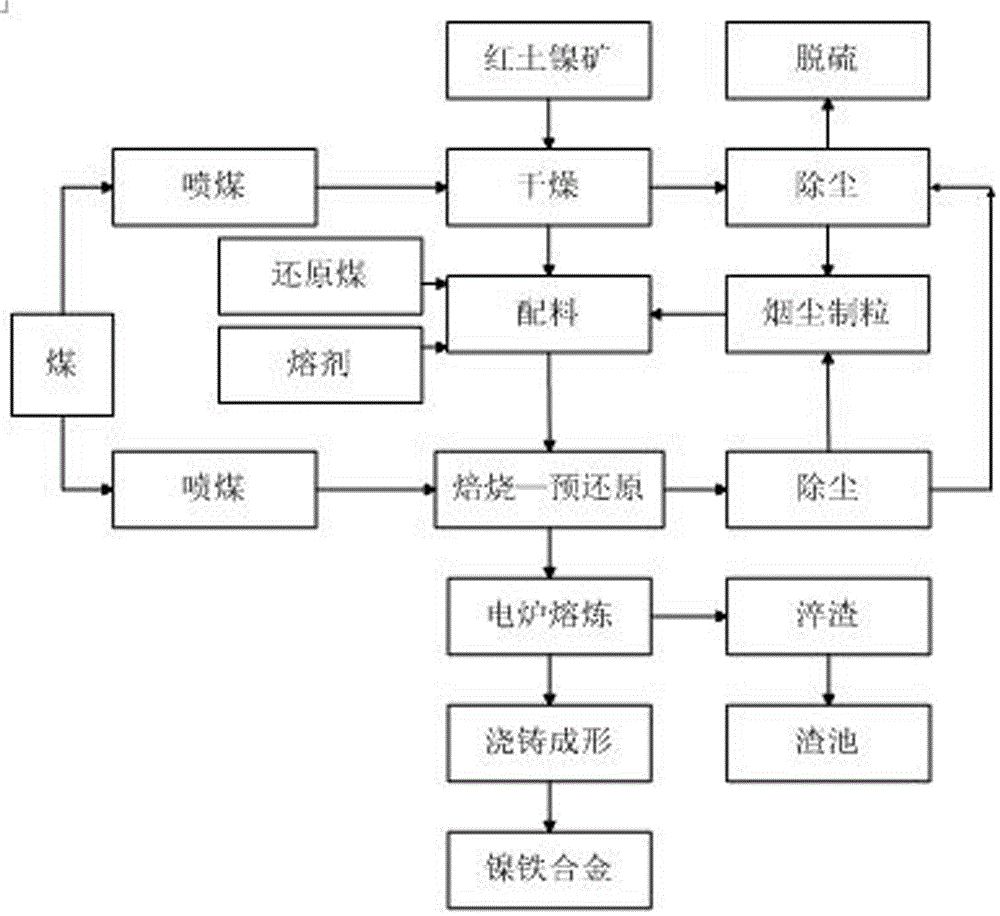

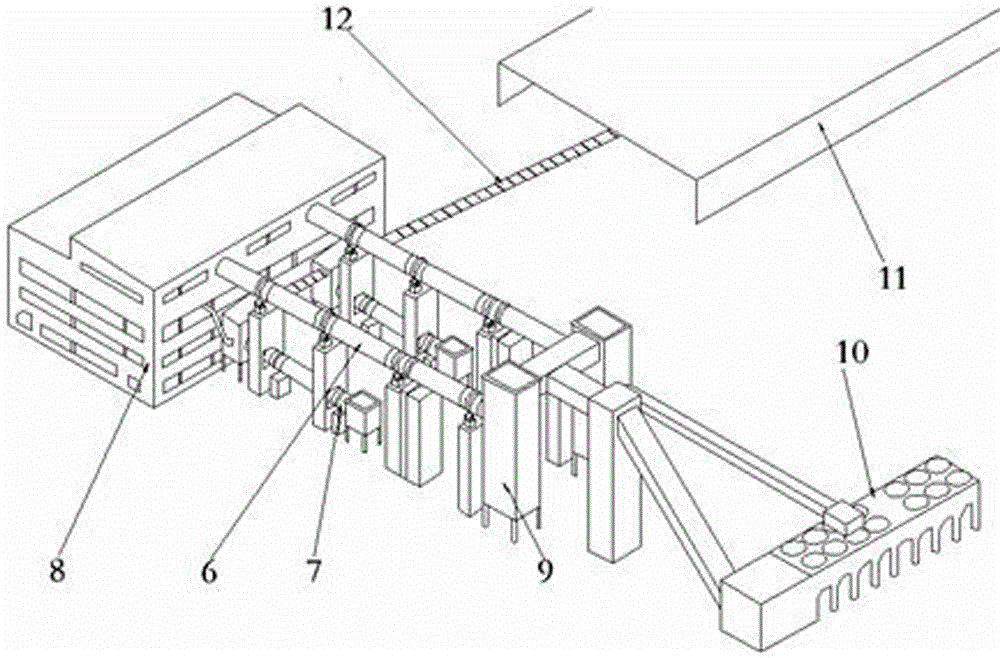

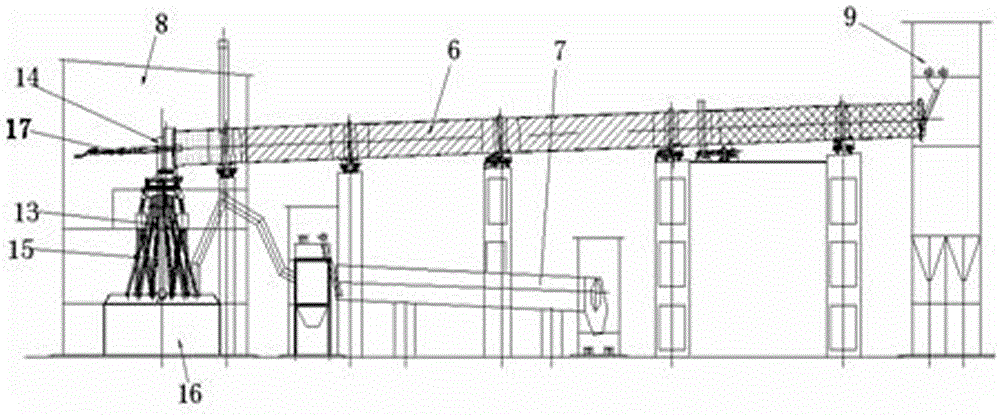

Elevated short process energy-saving rkef nickel-iron alloy production equipment and technology

The invention discloses an elevated short-flow process energy-saving RKEF nickel-iron alloy production process, which includes the following steps: (1) drying; (2) batching; (3) roasting-pre-reduction; (4) electric furnace smelting; (5) casting and forming. The invention also discloses an elevated short-process energy-saving RKEF process nickel-iron alloy production equipment, which is mainly composed of a rotary kiln, a drying kiln, an electric furnace workshop, a transfer station, a batching station, and a raw material warehouse. One end of the rotary kiln is connected to the electric furnace workshop, and the other One end is connected to the transfer station, the drying kiln is located below the rotary kiln, one end of the drying kiln is connected to the electric furnace workshop, the transfer station is connected to the batching station at the end far away from the rotary kiln, and the raw material warehouse is close to the drying kiln through a belt conveyor One end of the electric furnace workshop is connected. The invention improves the temperature of entering the furnace by optimizing the design, reduces the power consumption of smelting, makes full use of energy, reduces energy consumption and reduces environmental pollution.

Owner:四川省冶金设计研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com