Low-nitrogen-source pure oxygen combustion method

A combustion method, pure oxygen technology, applied in the combustion method, the use of a variety of fuel combustion, combustion types and other directions, can solve the problems of high emission concentration, high CO combustion emission concentration, complex denitration system, etc., to reduce CO emission concentration, The effect of reducing environmental protection investment and improving thermal energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

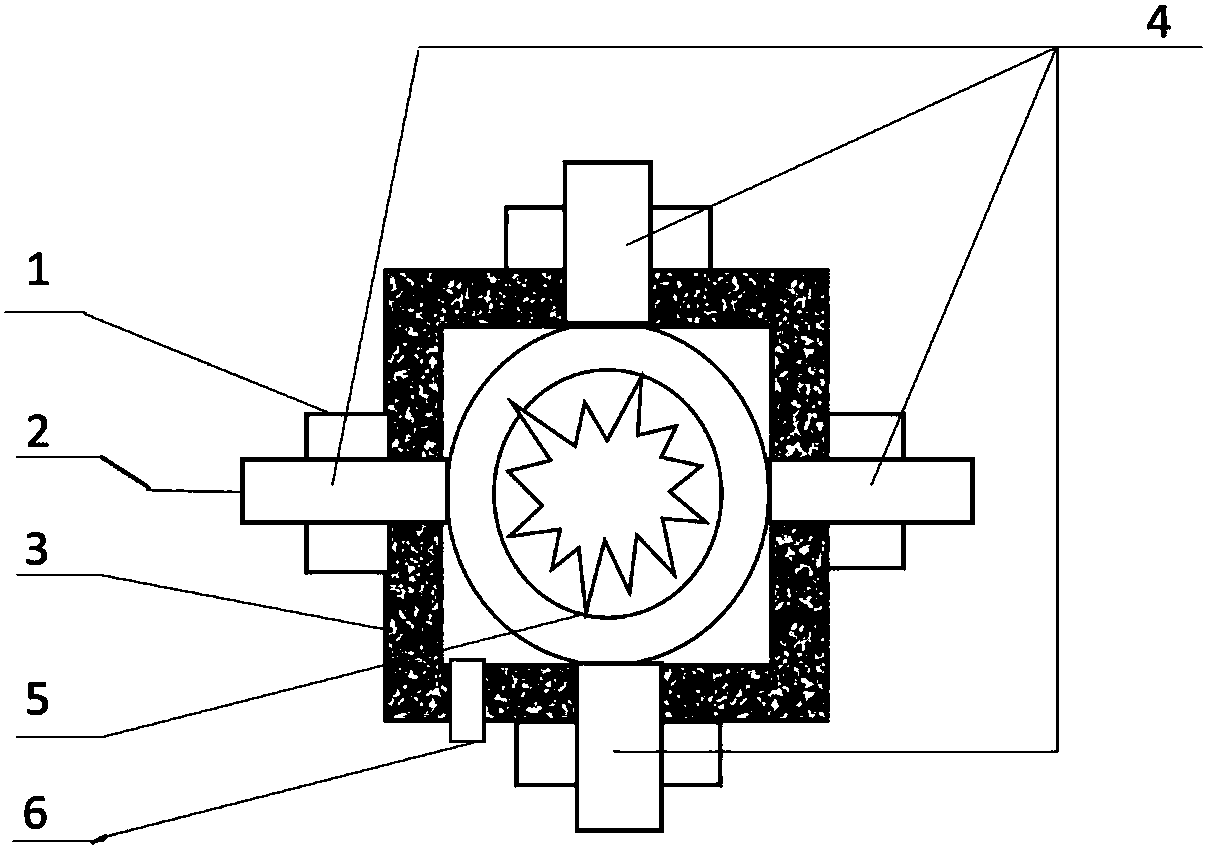

[0021] Example 1 Denitrification of pulverized coal using CO 2 The protection is transported through the low-nitrogen fuel pipeline 1, and the pure oxygen is transported through the pure oxygen transmission pipeline 2, and the stoichiometric ratio of pure oxygen / denitrification pulverized coal is 1 times. Pure oxygen and denitrified coal powder are sprayed into the combustion chamber 3 through the burner 4 to perform four-corner tangential pure oxygen combustion to generate a combustion flame 5 . The NOx emission concentration measured at the combustion flue gas outlet 6 is 5 mg / m 3 , CO emission concentration is 500mg / m 3 , The combustion efficiency is 95.1%. No flue gas denitrification system is required.

Embodiment 2

[0022] Example 2 Denitrification of pulverized coal using CO 2 The protection is transported through the low-nitrogen fuel pipeline 1, and the pure oxygen is transported through the pure oxygen transmission pipeline 2. The stoichiometric ratio of pure oxygen / denitrification coal powder is 1.1 times. Pure oxygen and denitrified coal powder are sprayed into the combustion chamber 3 through the burner 4 to perform four-corner tangential pure oxygen combustion to generate a combustion flame 5 . The NOx emission concentration measured at the combustion flue gas outlet 6 is 10mg / m 3 , CO emission concentration is 450mg / m 3 , The combustion efficiency is 95.5%. No flue gas denitrification system is required.

Embodiment 3

[0023] Example 3 Denitrification of pulverized coal using CO 2 The protection is transported through the low-nitrogen fuel pipeline 1, and the pure oxygen is transported through the pure oxygen transmission pipeline 2. The stoichiometric ratio of pure oxygen / denitrification coal powder is 1.15 times. Pure oxygen and denitrified coal powder are sprayed into the combustion chamber 3 through the burner 4 to perform four-corner tangential pure oxygen combustion to generate a combustion flame 5 . The NOx emission concentration measured at the combustion flue gas outlet 6 is 15 mg / m 3 , CO emission concentration is 400mg / m 3 , The combustion efficiency is 96%. No flue gas denitrification system is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com