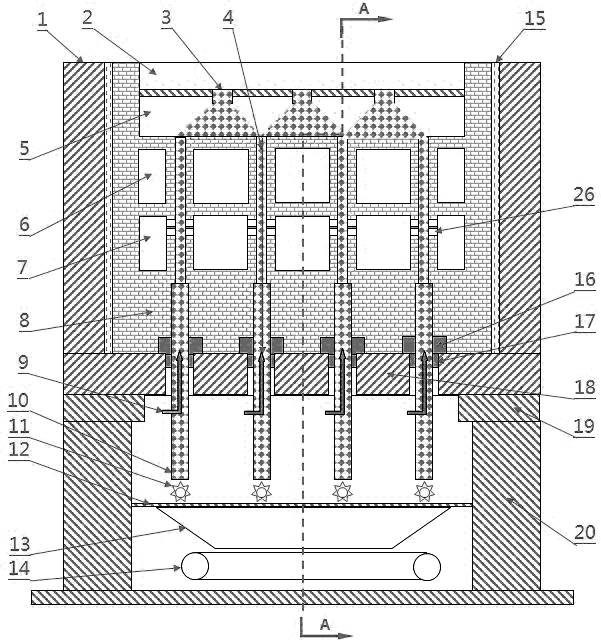

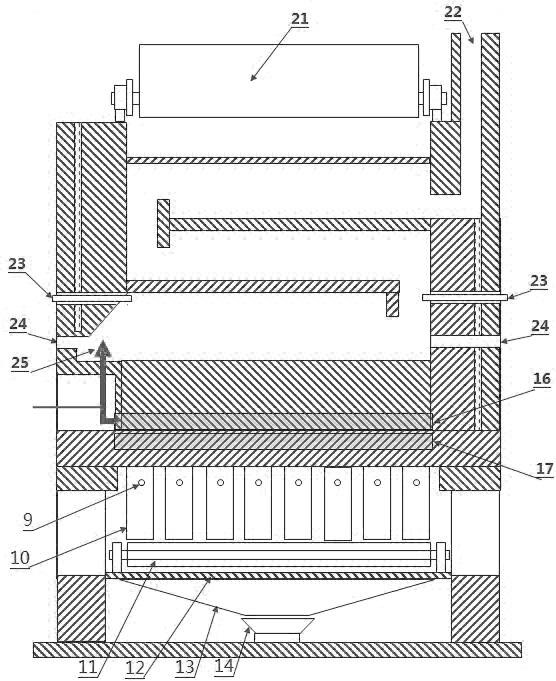

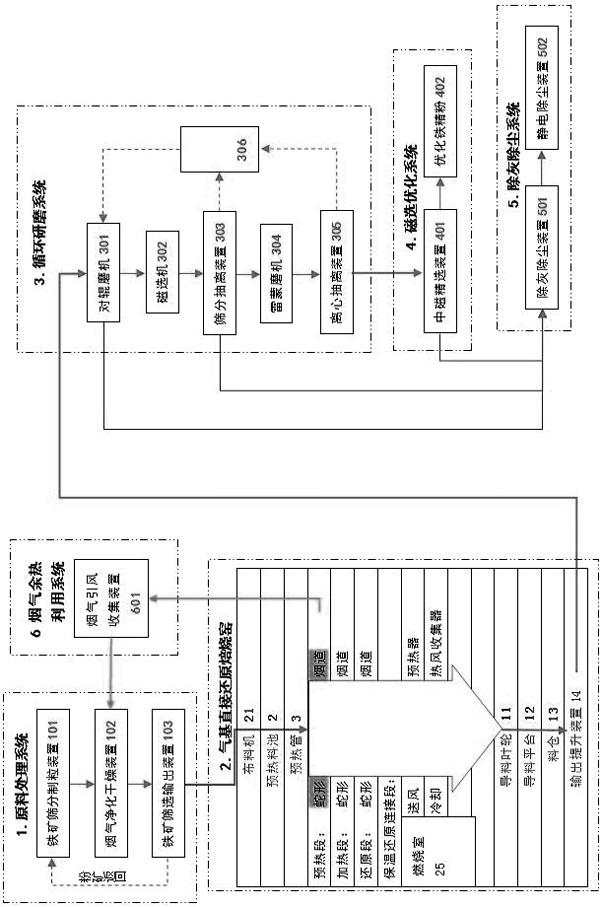

Device and method for optimizing iron ore through gas-based direct reduction magnetic separation

A direct, iron ore technology, applied in gas-based direct reduction roasting kilns and mineral selection, gas-based direct reduction magnetic separation to optimize the field of iron ore devices, and can solve difficult thermal control, furnace agglomeration, raw material shortage, etc. problems, to achieve the effect of precise and easy thermal control, reducing the emission environment, and solving the problem of scarcity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] An iron oxide ore contains Fe38.85%. Follow these steps:

[0069] ①Raw material treatment: crushing, screening, granulation, drying and screening of iron oxide ore containing 38.85% by weight of Fe to obtain iron ore particles of 3 to 40 mm in weight with a water content of less than 10%.

[0070] ②Gas-based direct reduction roasting: Roast 3-40mm iron ore granular materials in a gas-based direct reduction roasting test kiln. The pressure of the gas-based reducing gas hydrogen is controlled at 1000 Pa higher than the marked pressure, and the reduction temperature in the reduction section is controlled at 930°C Left and right, the speed of the material guide impeller is 5 revolutions per hour, and the material is discharged to obtain the roasted reduced material.

[0071] ③Cyclic grinding and magnetic separation: The obtained roasted and reduced materials are successively passed through a roller mill, a magnetic separator, a screening and extraction device, a Raymond mi...

Embodiment 2

[0075] An iron oxide ore contains Fe48.63%. Follow these steps:

[0076] ①Raw material treatment: Crushing, screening, granulating, drying and screening Fe48.63% iron oxide ore to obtain iron ore particles of 3 to 40 mm in weight percentage of moisture <10%.

[0077] ②Gas-based direct reduction roasting: Roast 3-40 mm iron ore granular materials in a gas-based direct reduction roasting test kiln. The gas-based reducing gas pressure is controlled at 1200 Pa higher than the marked pressure, and the reduction temperature in the reduction section is controlled at about 930 ° C. The rotating speed of the material guide impeller is 5 revolutions per hour, and the material is discharged to obtain the roasted reduced material.

[0078] ③Cyclic grinding and magnetic separation: The obtained roasted and reduced materials are successively passed through a roller mill, a magnetic separator, a screening and extraction device, a Raymond mill, a centrifugal extraction device, and a hoist, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com