Preparation method for flame retardant diethyl allylphosphonate

A technology of diethyl allyl phosphonate and flame retardant, which is applied in the field of preparation of flame retardant diethyl allyl phosphonate, can solve problems such as inability to be widely used, no suitable preparation method, etc., and achieves easy scale Chemical production, good application and development prospects, and the effect of improving the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

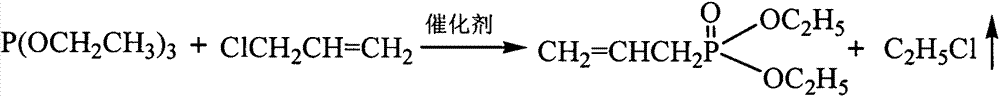

Method used

Image

Examples

Embodiment 1

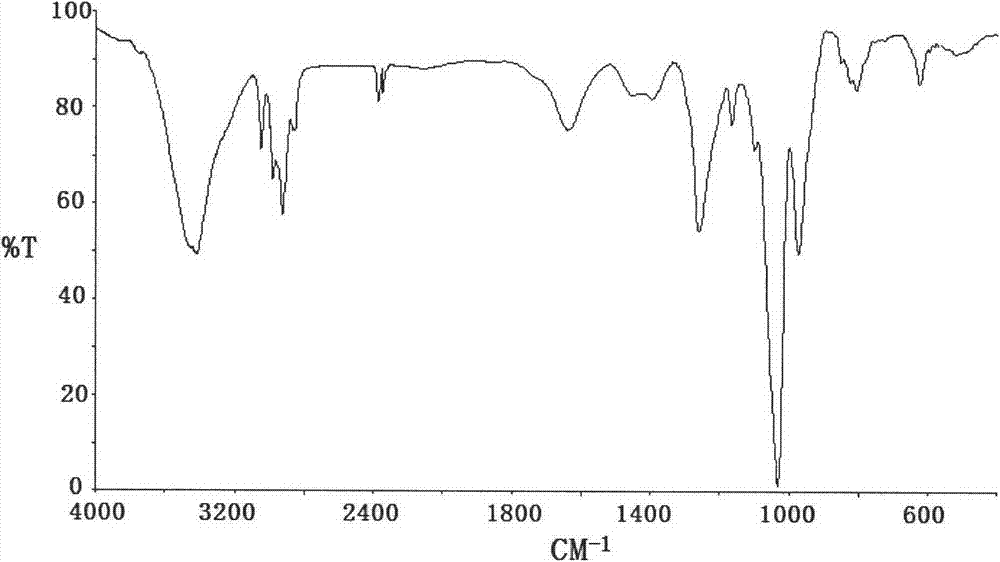

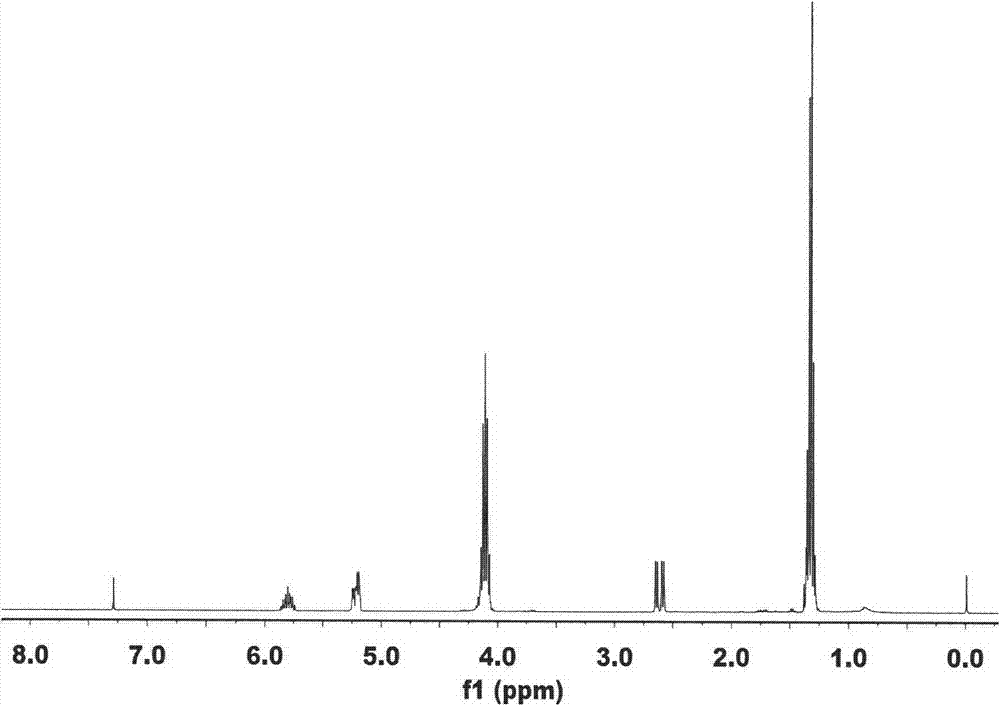

[0026] Embodiment 1 Set up the device of the 250mL four-neck flask equipped with agitator, thermometer, high-efficiency reflux condenser and ethyl chloride collector, replace the air in the device with nitrogen, add 150ml of chlorobenzene, 16.6g (0.1mol) Triethyl phosphite, 0.1g KI and 0.01g hydroquinone, raise the temperature to 130°C, within 5h, uniformly inject 9.2g (0.12mol) of allyl chloride with a micropump under the liquid surface. After the injection is completed, keep the reaction at 130°C for 4 hours, distill and recover the excess chloropropene, and then distill off the solvent under reduced pressure (for recycling) to obtain the product diethyl allyl phosphonate. Its yield is 74.7%, boiling point: 223°C, refractive index: n D 20 =1.4340, density (25°C): 1.035g / cm 3 .

Embodiment 2

[0027] Example 2 Set up a 250mL four-necked flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and an ethyl chloride collector, replace the air in the device with nitrogen, add 150ml of diethylene glycol dimethyl ether, 16.6 g (0.1mol) triethyl phosphite, 0.1g NaI and 0.01g hydroquinone, raise the temperature to 130°C, within 5h, uniformly inject 10.72g (0.14mol) allyl chloride with a micropump under the liquid surface. After the injection is completed, raise the temperature to 140°C, keep it warm for 4 hours, recover excess chloropropene by distillation, and then remove the solvent by distillation under reduced pressure (for recycling) to obtain the product diethyl allyl phosphonate. Its yield is 82.5%, boiling point: 223°C, refractive index: n D 20 =1.4340, density (25°C): 1.035g / cm 3 .

Embodiment 3

[0028] Embodiment 3 Set up the device of the 250mL four-neck flask equipped with agitator, thermometer, high-efficiency reflux condenser and ethyl chloride collector, replace the air in the device with nitrogen, add 100mlDMF, 16.6g (0.1mol) phosphorous acid Triethyl ester, 0.2g CuCl and 0.01g hydroquinone, raise the temperature to 130°C, within 6h, uniformly inject 12.25g (0.16mol) of chloropropene with a micropump under the liquid surface. After the injection is completed, raise the temperature to 150°C, keep the temperature for 5 hours, and recover excess chloropropene by distillation, and then remove the solvent by distillation under reduced pressure (recycling) to obtain the product diethyl allyl phosphonate. Its yield is 85.6%, boiling point: 223°C, refractive index: n D 20 =1.4340, density (25°C): 1.035g / cm3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com