Method and device for optimizing iron ore through gas-coal double-base direct reduction magnetic separation

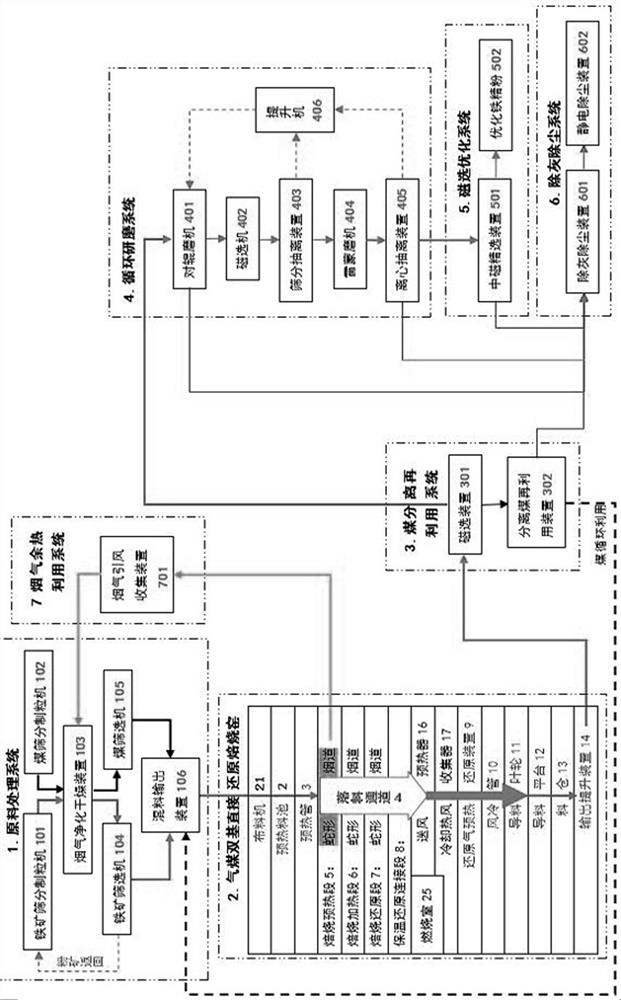

A gas-coal and iron ore technology, applied in the field of energy-saving and comprehensive utilization of direct reduction of mineral resources, can solve the problem that natural raw materials are difficult to meet the needs of large-scale production of direct reduction iron raw materials, the frustration of industrial production and application of gas-based shaft furnace technology, sorting and screening treatment Incomplete and other problems, achieve significant removal effect, improve quality structure and energy structure, and be easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

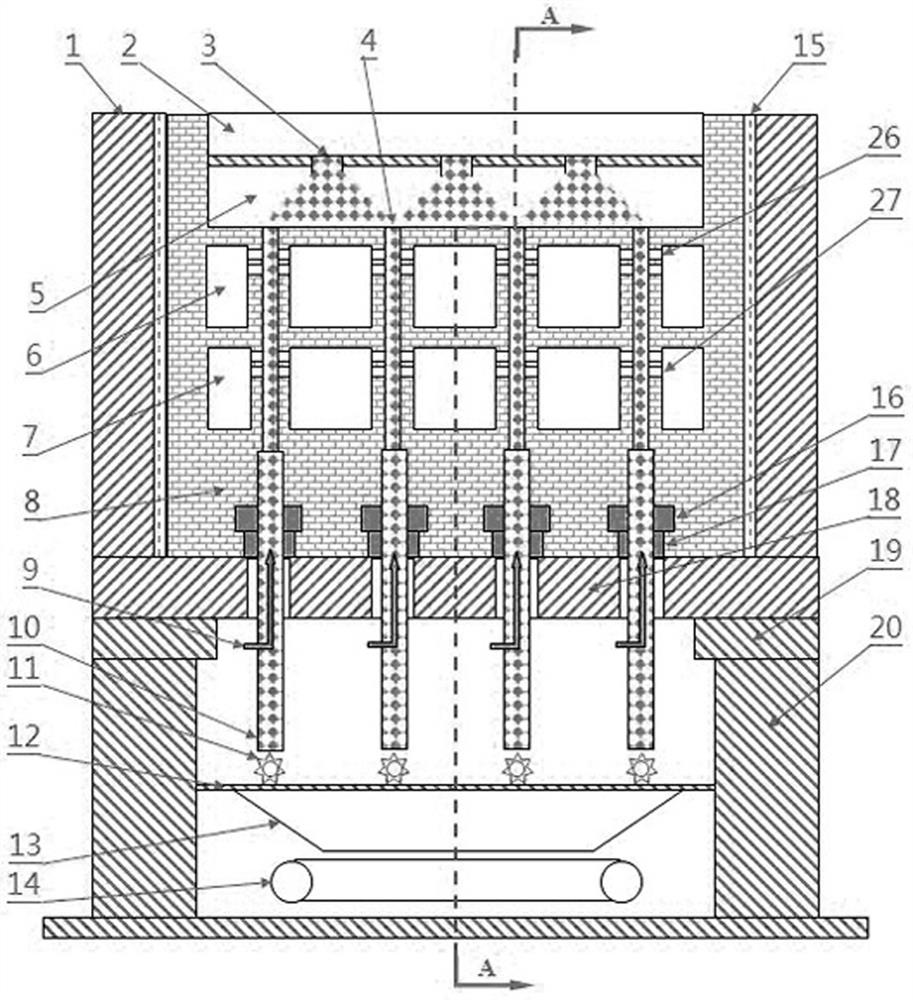

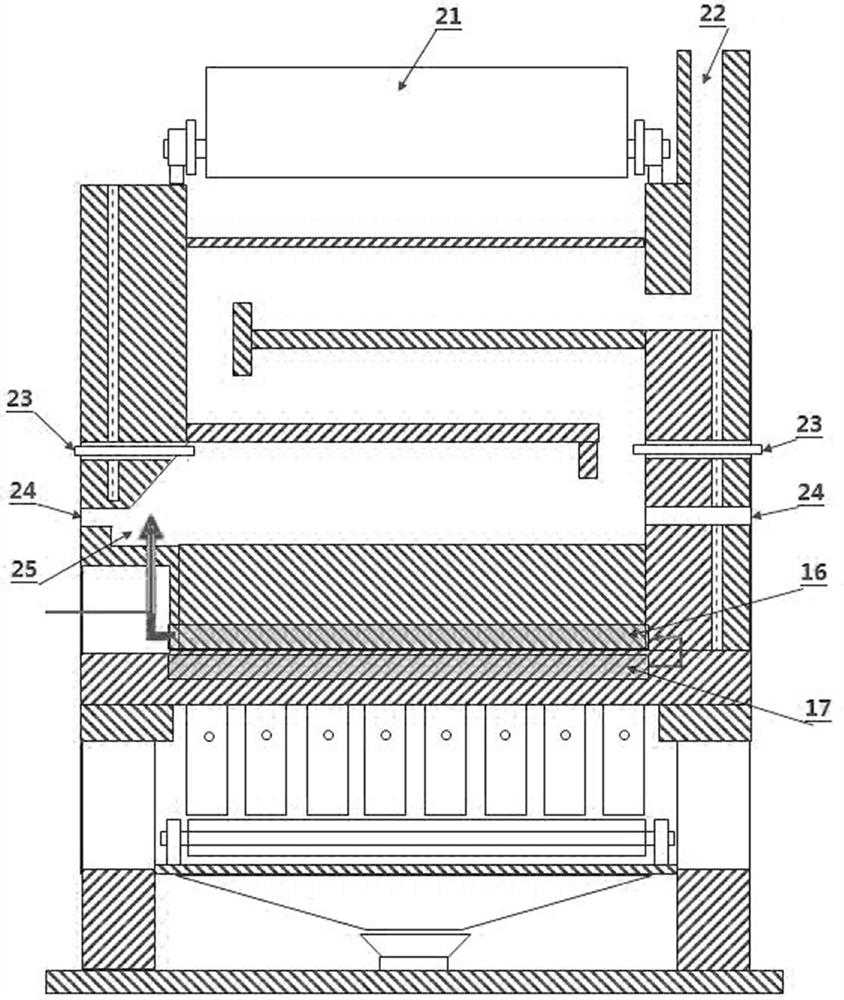

Method used

Image

Examples

Embodiment 1

[0104] A certain iron oxide ore contains Fe42.87% (weight percentage). Follow these steps:

[0105] ①Raw material treatment: The iron oxide ore Fe42.87% raw material and reducing agent coal were sieved, granulated, dried and screened to obtain iron oxide ore particles with a particle size of 3-40 mm and coal particles with a particle size of 5-10 mm. Mix 10mm coal particles at a ratio of 8%, and a particle size of 1-5mm, and then use coal particles at a ratio of 6% and 3-40mm iron oxide particles to obtain a mixed material, and the water content of the mixed material is less than 10%.

[0106] ②Gas-coal double-base direct reduction roasting: roast the mixture of 3-40mm iron oxide ore particles in the gas-coal double-base direct reduction roasting test kiln, the gas-base reduction gas pressure is controlled at 1000Pa higher than the marked pressure, and the reduction temperature in the reduction section The temperature is controlled at about 930°C, and the rotating speed of th...

Embodiment 2

[0112] An iron ore contains Fe48.63% (weight percentage). Follow these steps:

[0113] ①Raw material treatment: The iron oxide ore Fe48.63% raw material and reducing agent coal were sieved, granulated, dried and screened to obtain iron ore particles with a particle size of 3-40 mm and coal particles with a particle size of 5-10 mm. 8% of coal particles in millimeters, 1-5mm in particle size, and 6% of recycled coal particles in proportion to 3-40mm iron oxide particles are mixed to obtain a mixed material, and the weight percentage of the mixed material is less than 10%.

[0114] ②Gas-coal double-base direct reduction roasting: Roast 3-40 mm iron oxide ore pellet mixture in the gas-coal double-base direct reduction roasting test kiln. The reduction temperature is controlled at about 930°C, and the rotation speed of the material guide impeller is about 6 revolutions per hour, so as to obtain roasted reduced materials.

[0115] ③Coal separation and reuse: The obtained roasted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com