Wet-type dust removal device

A technology of wet dust removal and dust board, which is applied in the direction of combination device, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low water consumption, high dust removal rate, and small gas resistance, so as to save water resources and improve dust removal rate , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

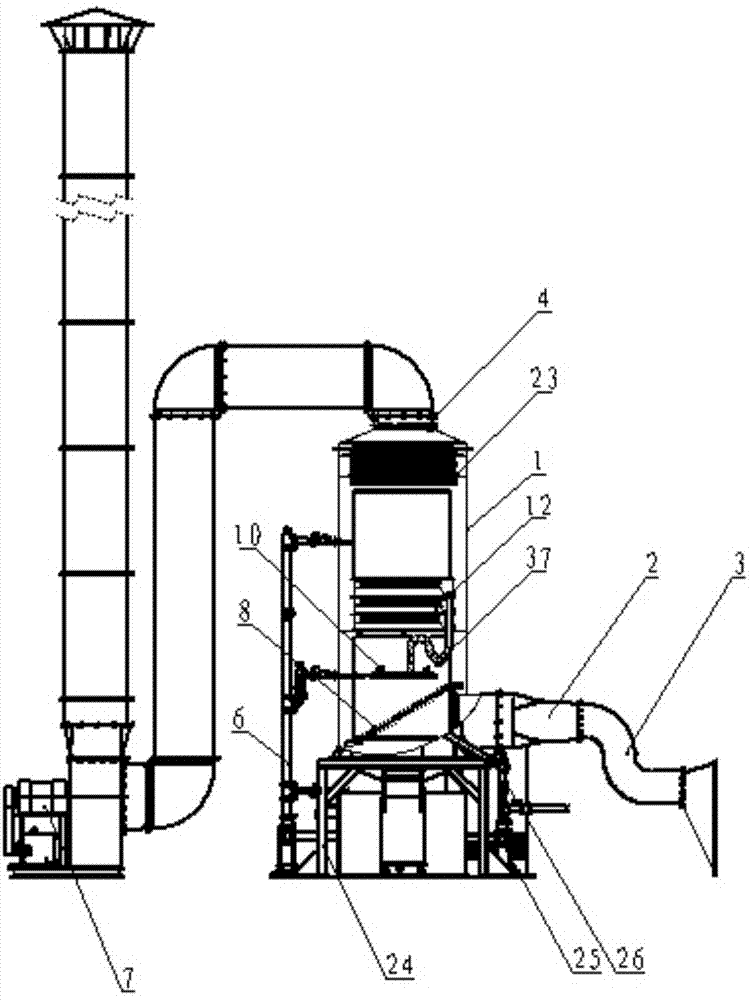

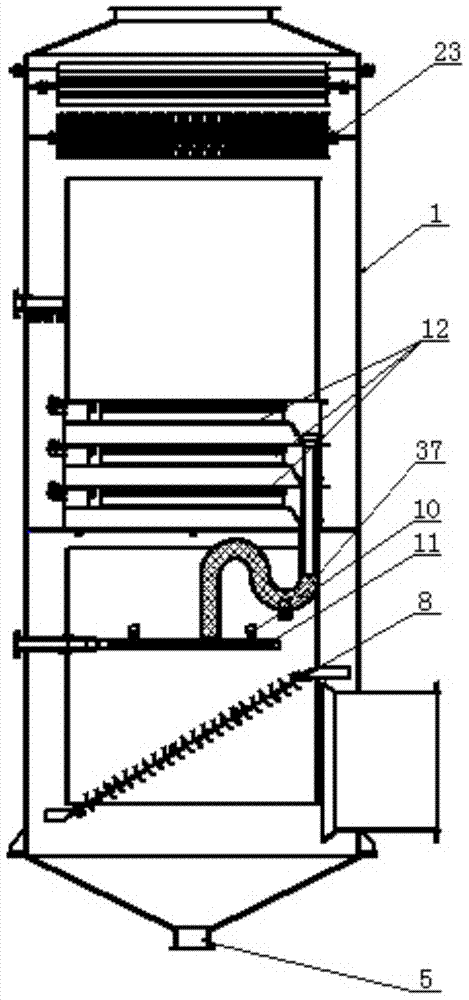

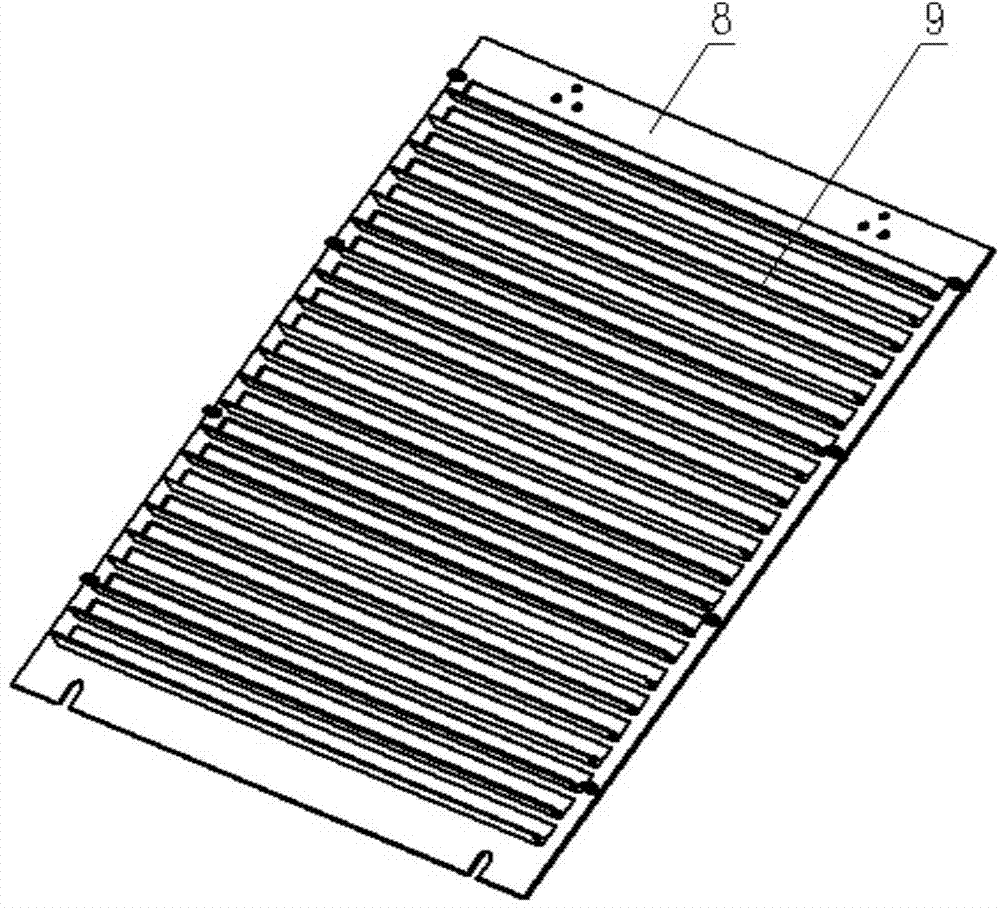

[0049] This embodiment is an integrated wet dust removal device for dust removal and sewage treatment, and its overall structure is as follows figure 1 As shown, it consists of two parts: dust removal system and sewage treatment system. Among them, the dust removal system such as figure 2 As shown, there is a circular tower body 1 with a height of 15m and an inner diameter of 5m. There is an air inlet at the lower part of the right side wall of the tower body 1, and the air inlet is connected with the air inlet pipe 3 through the Venturi tube 2. The dust-laden gas (flue gas) enters the tower from the intake pipe 3 through the Venturi pipe 2 under the suction of the induced draft fan 7, and flows from bottom to top, and the clean gas after dust removal passes through the exhaust pipe connected to the top of the tower body 4 into the atmosphere. The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com