Fluorine capturing fuel with enwrapped stone coal as main material and its production method

A technology for fuel and stone coal, applied in the field of combined fuel and its preparation method, can solve the problems of large differences in civil stove types, large differences in fluorine content and form, and deterioration of living environment quality, so as to increase the economic burden of farmers, The cost of raw materials is low, and the effect of easy to obtain materials on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

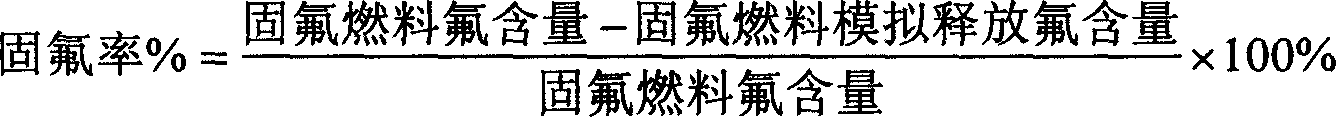

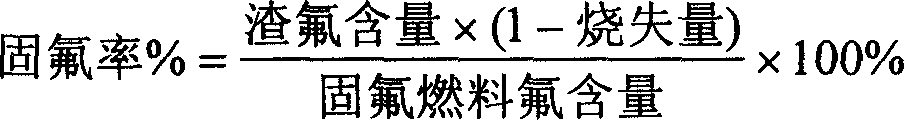

Embodiment 1

[0043] Weigh 83% of the southern Shaanxi stone coal and lay it flat on the cement floor or iron plate, evenly sprinkle 7% of anthracite powder, 6% of No. 1 slaked lime and 4% of clay on it, stir evenly, and sprinkle a small amount of water to make Anthracite coal powder, slaked lime and clay are evenly wrapped on the stone coal block and dried in the air. Select 16 local households with the same ground furnaces, of which 8 households burn the fluorine-fixed fuel treated by the above method, and 8 households burn untreated stone coal. Collect unburned coal and slag after combustion, measure the fluorine content of each household, and calculate the fluorine fixation rate to be 75.0% (see Table 1). Then collect the fluorine content of the air in the two groups of ground furnace rooms respectively, and the fluorine content of the air in the burning fluorine fuel is 0.04625±0.02878mg / m 3 , those who burn untreated stone coal 0.324±0.2591mg / m 3 , The average fluoride removal rate ...

Embodiment 2-17

[0051] Take stone coal block, anthracite powder, matured dolomite or lime and clay according to the proportion of each component in Table 5, stir evenly, sprinkle a small amount of water, make anthracite powder, matured dolomite or lime and The clay is evenly wrapped on the stone coal block and dried in the air. Take part of it and pulverize it, wherein the fluorine is measured by the above-mentioned method for measuring fluorine in fluorine-fixed fuel; part of it is measured by the above-mentioned method for measuring fluorine released by the above-mentioned fluorine-fixed fuel simulating the combustion temperature of a stone coal furnace.

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com