Process for treating and recovering dye industrial wastewater

A technology for producing wastewater and dyes, which is applied in the textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment and other directions, and can solve the problems of cumbersome steps in the wastewater treatment process, recovery of useful components, and high treatment costs. Achieve the effect of promoting clean production, reducing load and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

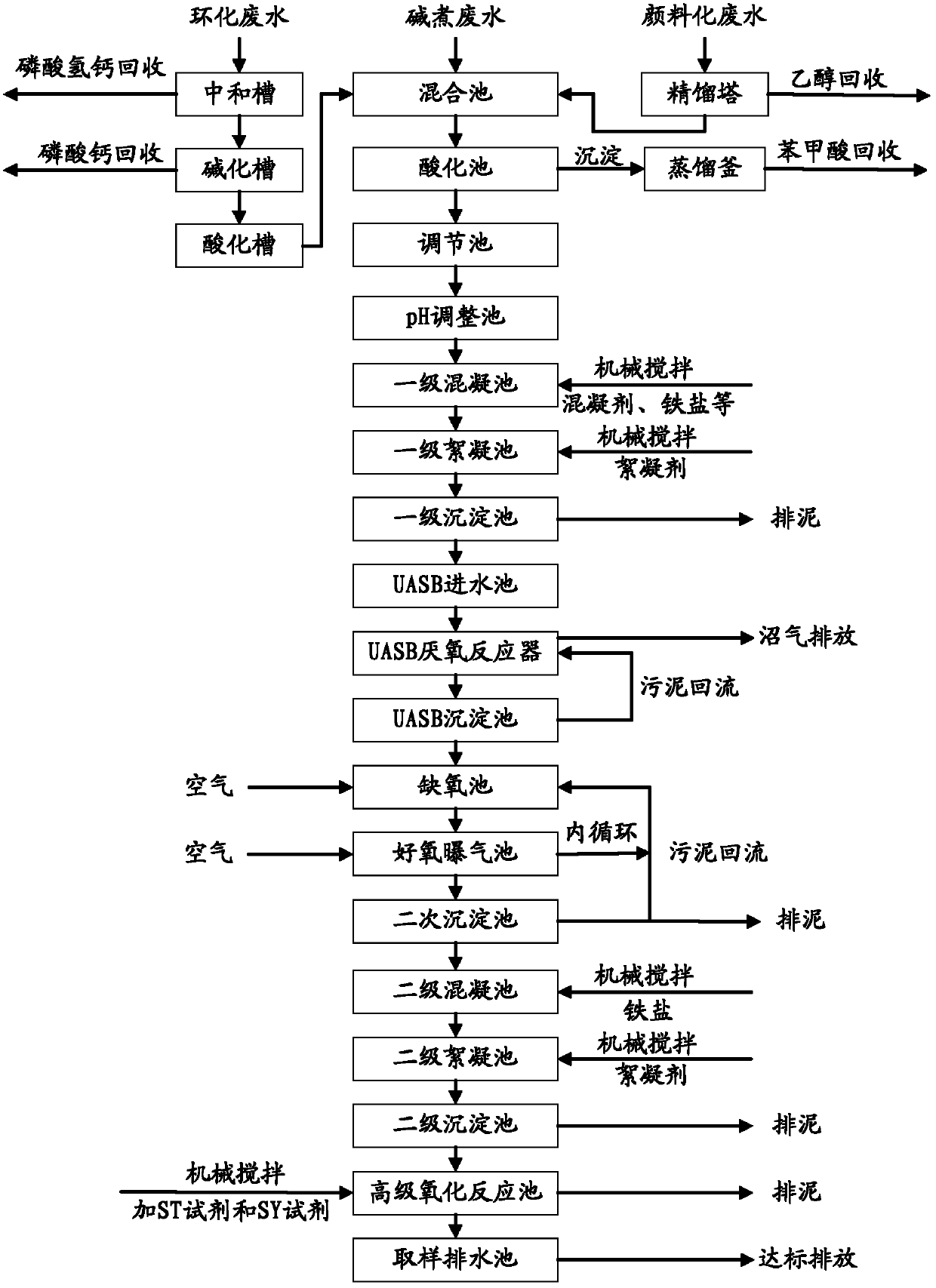

[0033] A pigment factory in Wenzhou, Zhejiang, produces 600t / d of wastewater per day, and the wastewater is treated and recycled according to the following process.

[0034] 1. Pigment wastewater recycling technology

[0035] (1) Regeneration of phosphate

[0036] Collect cyclization wastewater (high-concentration phosphorus-containing wastewater), put it into a neutralization tank equipped with lime solution (calcium hydroxide solution) for reaction, and when the pH value reaches 6, separate the generated solid calcium hydrogen phosphate; then Put the reacted cyclization wastewater into the alkalization tank, continue to add calcium hydroxide, and when the pH is 11, separate the generated solid calcium phosphate, at this time, the content of phosphorus in the cyclization wastewater is less than 1%; into the acidification tank, adding dilute sulfuric acid for neutralization; the treated cyclization wastewater enters the mixing tank.

[0037] (2) Recovery of ethanol

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com