Incoherence or weak caking coal deep processing method

A weakly caking coal and caking technology, applied in the field of coal chemical industry, can solve the problems of high investment, high operating cost, immature technology, etc., and achieve the effect of reducing pollution, reducing treatment cost and reducing environmental protection investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

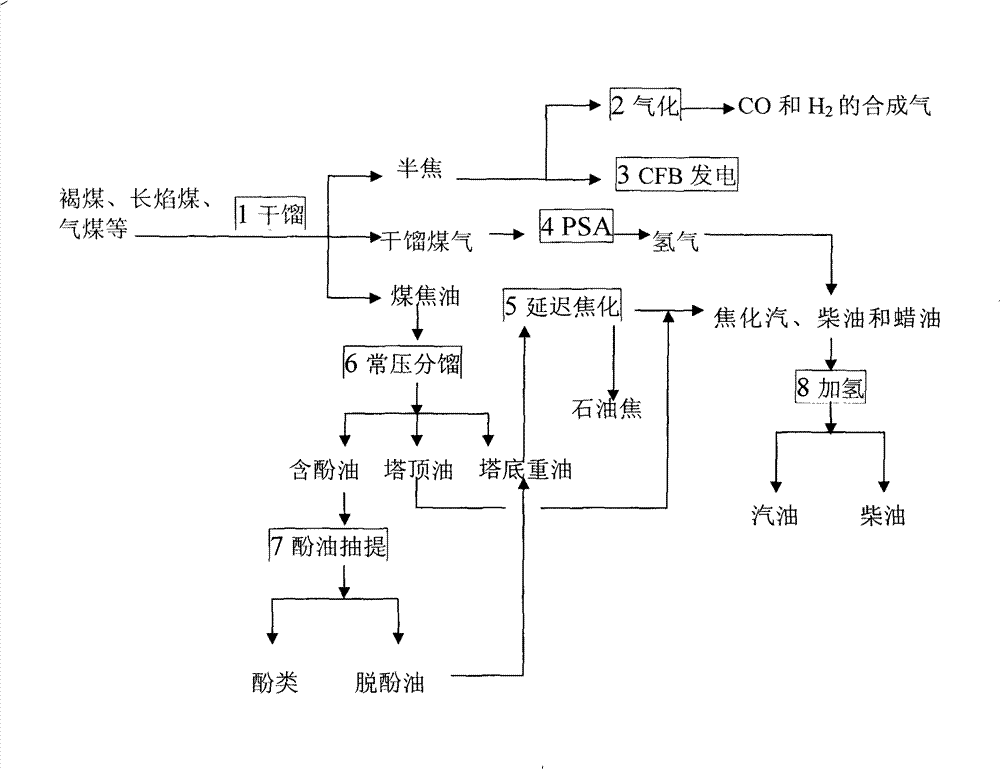

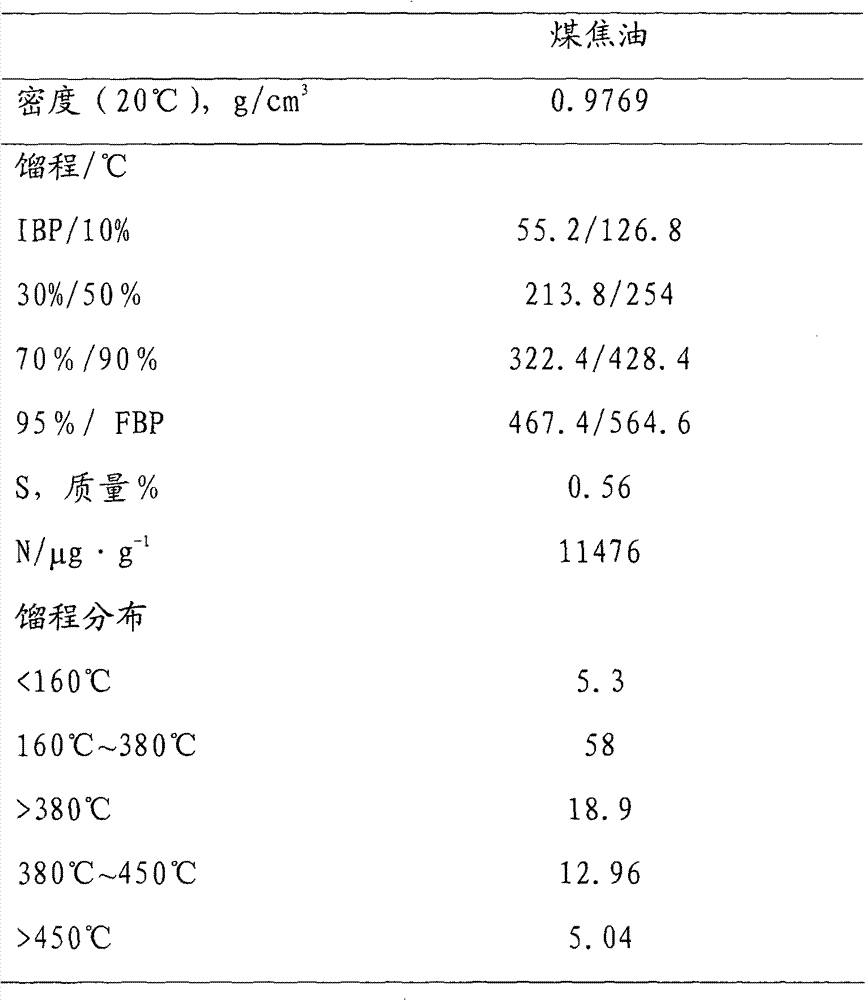

[0032] Nanning lignite is sent to medium-low temperature fluidized bed carbonization reactor 1 for carbonization reaction, the pressure is 0.1MPa, and the operating temperature is 500°C to generate carbonization gas, coal tar and semi-coke. The properties of carbonized coal tar are shown in Table 1. After the dry distillation gas is purified, it enters the PSA (Pressure Swing Adsorption) device 4, and passes through the adsorption bed layer made of zeolite molecular sieve. The operating pressure is 2MPa, and the hydrogen in it is extracted, and the carbon monoxide component in it is also combined with the medium change technology. The water reacts to generate hydrogen, which together with the hydrogen generated by coal dry distillation is used as feedstock for the coal tar hydrocracking unit 8 by using PSA technology. Dry distillation semi-coke is sent to the fluidized bed gas generator 2 to react with oxygen and water vapor to produce synthesis gas and coal ash. When the sem...

Embodiment 2

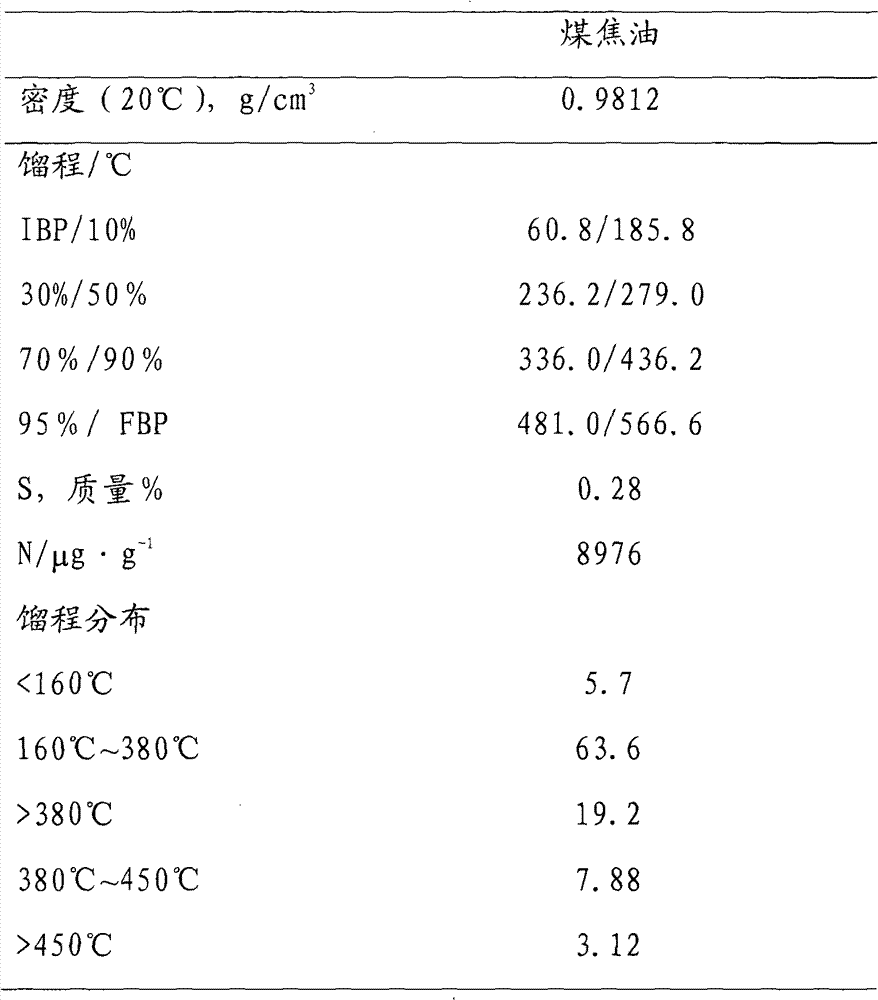

[0034] The Yilan coal is sent to medium-low temperature fluidized bed carbonization reactor 1 for carbonization reaction, the pressure is 0.12MPa, and the operating temperature is 600°C to generate carbonization gas, coal tar and semi-coke. The properties of carbonized coal tar are shown in Table 2. After the dry distillation gas is purified, it enters the PSA (Pressure Swing Adsorption) device 4, through the adsorption bed layer composed of silica gel, the operating pressure is 2.45MPa, and the hydrogen gas is extracted, and the carbon monoxide component is also recovered by using medium-range technology. The reaction with water produces hydrogen, which together with the hydrogen produced by coal dry distillation, is proposed as feedstock for the coal tar hydrogenation unit 8 by using PSA technology. The semi-coke is dry-distilled and sent to a CFB (circulating fluidized bed boiler) device 3 for power generation. The carbonized coal tar enters the atmospheric fractionation t...

Embodiment 3

[0036] The Ylang lignite is sent to medium-low temperature fluidized bed carbonization reactor 1 for carbonization reaction, the pressure is 0.18MPa, and the operating temperature is 650°C to generate carbonization gas, coal tar and semi-coke. The properties of carbonized coal tar are shown in Table 3. After the dry distillation gas is purified, it enters the PSA (Pressure Swing Adsorption) unit 4, and passes through the adsorption bed composed of CO special adsorbent, with an operating pressure of 1.2 MPa, to extract the hydrogen therein for the feed of the coal tar hydrogenation unit 8. Dry distillation semi-coke is sent to the fluidized bed gas generator 2 to react with oxygen and water vapor to produce synthesis gas and coal ash. When the semi-coke is gasified, the semi-coke reacts with oxygen and water vapor (the volume ratio of water vapor and oxygen is 5:1) to produce synthesis gas (carbon monoxide and hydrogen) and coal ash; the reaction pressure of the gas generator i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com