A kind of industrial preparation method of phosvitin phosphopeptide and yolk polypeptide

A phosvitin and phosphopeptide technology is applied in the field of industrialized preparation of phosvitin phosphopeptides and yolk polypeptides, and can solve the problems of unsuitability for industrialized large-scale production, low degree of denaturation of egg yolk powder, inability to comprehensively utilize egg yolk, and the like, To achieve the effect of improving the utilization value, increasing the added value of the product, and promoting the absorption of the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

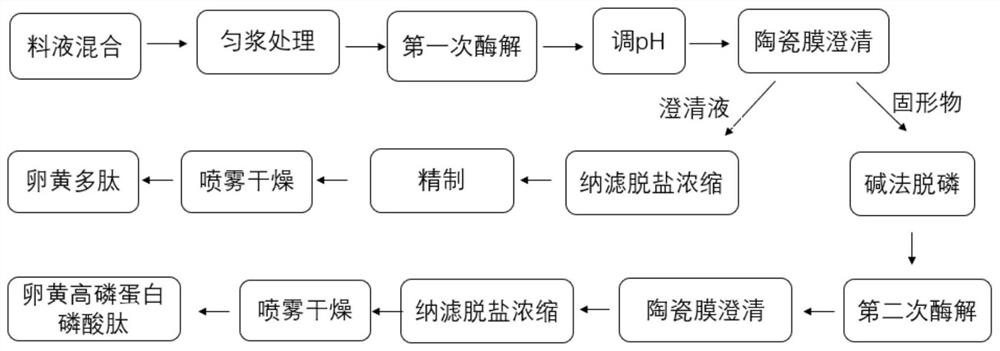

[0065] A method for industrially preparing phosvitin phosphopeptide and yolk polypeptide at the same time, comprising the steps of:

[0066] (1) Dissolving defatted egg yolk powder (containing 85% protein), controlling the ratio of solid to liquid to be 1:8 (w / v);

[0067] (2) adopt 3000rpm rotary disc type wet pulverization, pass through 100 mesh sieves then, obtain the homogenate of defatted egg yolk powder;

[0068] (3) Homogenate the obtained defatted egg yolk powder to adjust the pH=7.0, carry out enzymolysis with neutral protease, the addition amount is 2000U / g, stirring the enzymolysis time is 2.5h, after the enzymolysis, adjust the pH to 4.2, stir at 30rpm for 2min, Use a 100nm ceramic membrane to filter and separate at 0.1MPa at a temperature of 30°C to obtain a yolk polypeptide clarified liquid and a phosvitin precipitate;

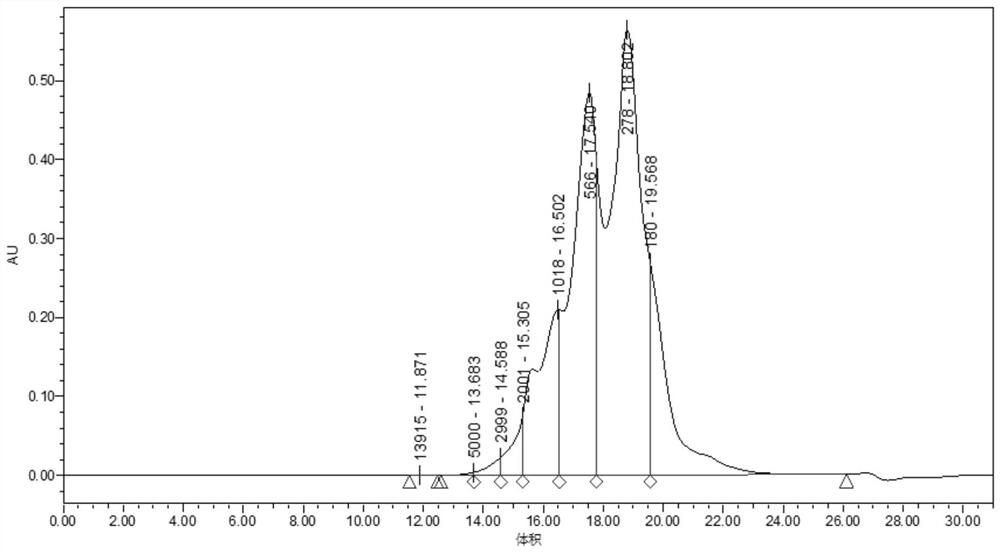

[0069] (4) desalting the egg yolk polypeptide clarified liquid obtained in step (3) through a nanofiltration membrane with a molecular weight o...

Embodiment 2

[0078] A method for industrially preparing phosvitin phosphopeptide and yolk polypeptide at the same time, comprising the steps of:

[0079] (1) Dissolving defatted egg yolk powder (containing 65% protein), controlling the ratio of solid to liquid to be 1:10 (w / v);

[0080] (2) Adopt 3000rpm rotary disc type wet pulverization to pass through a 300 mesh sieve to obtain a homogenate of defatted egg yolk powder;

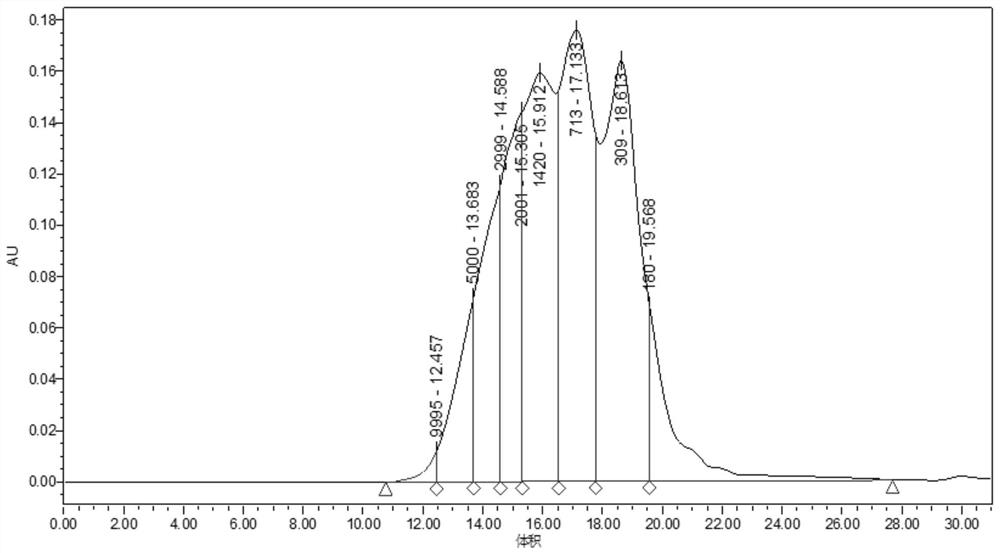

[0081] (3) Homogenate the obtained defatted egg yolk powder to adjust the pH to 7.0, use neutral protease for enzymolysis, add 3000U / g, stir for 3 hours for enzymolysis, adjust the pH to 4.2 after enzymolysis, stir at 50rpm for 2min, and use 500nm The ceramic membrane was filtered and clarified at 0.3MPa and 50°C, and clarified and separated to obtain yolk polypeptide clarified liquid and phosvitin precipitate;

[0082] (4) desalting the egg yolk polypeptide clarified liquid obtained in step (3) through a nanofiltration membrane with a molecular weight of 300, adding 3...

Embodiment 3

[0097] A method for industrially preparing phosvitin phosphopeptide and yolk polypeptide at the same time, comprising the steps of:

[0098] (1) Dissolving defatted egg yolk powder (containing 75% protein), controlling the ratio of solid to liquid to be 1:9 (w / v);

[0099] (2) adopt 3000rpm rotary disc type wet pulverization to pass through a 200-mesh sieve to obtain a homogenate of defatted egg yolk powder;

[0100] (3) The resulting defatted egg yolk powder was homogenized to adjust pH=7.0, and the enzymolysis was carried out with neutral protease. The 200nm ceramic membrane is filtered and clarified at 0.2MPa and 60°C to clarify the separated yolk polypeptide clarified liquid and phosvitin precipitate;

[0101] (4) desalting the egg yolk polypeptide clarified liquid obtained in step (3) through a nanofiltration membrane with a molecular weight of 300, adding 3 times the volume of pure water for desalination, to obtain a egg yolk polypeptide concentrate (solid content is 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com