Patents

Literature

115results about "Refining with two or more solvents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

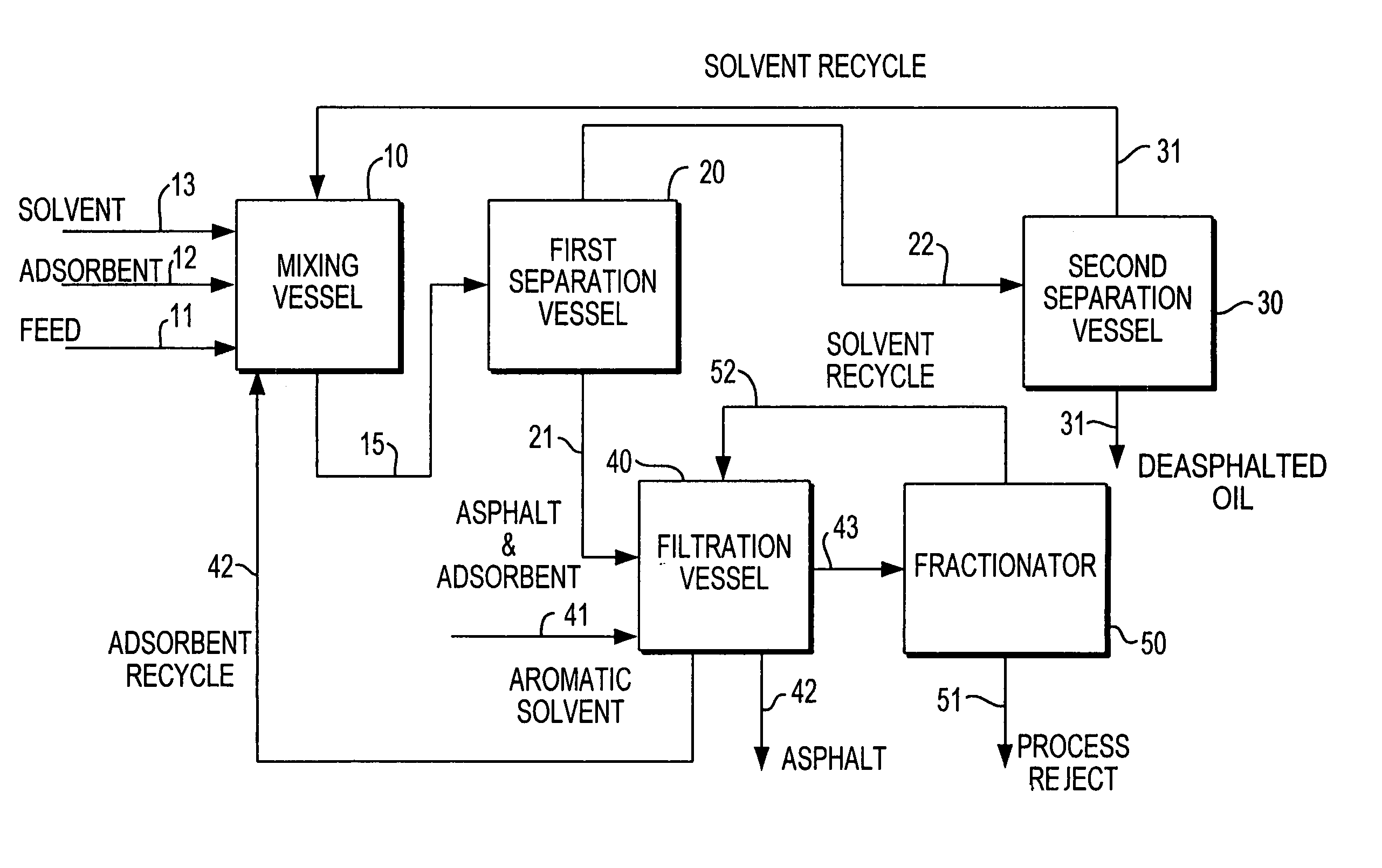

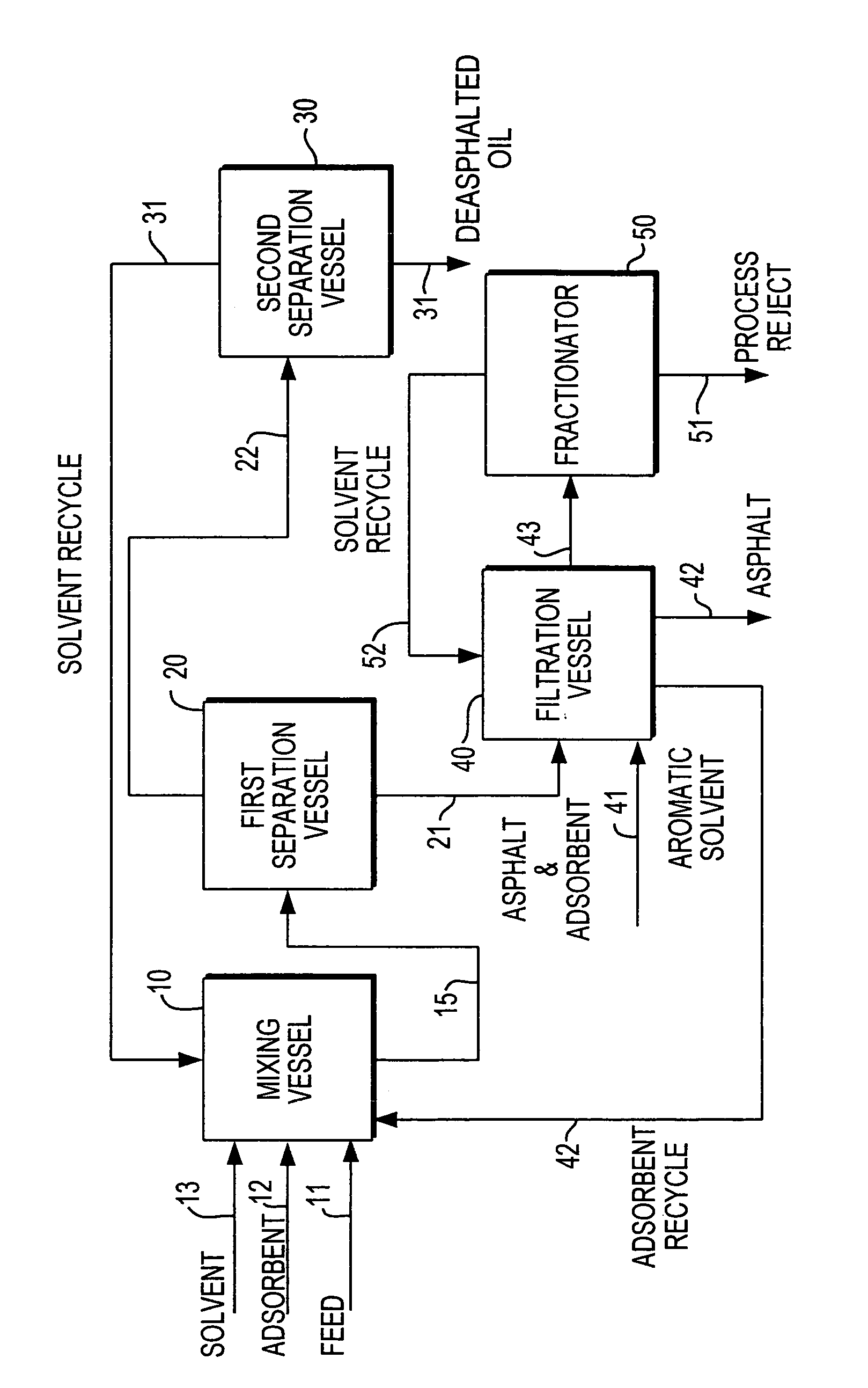

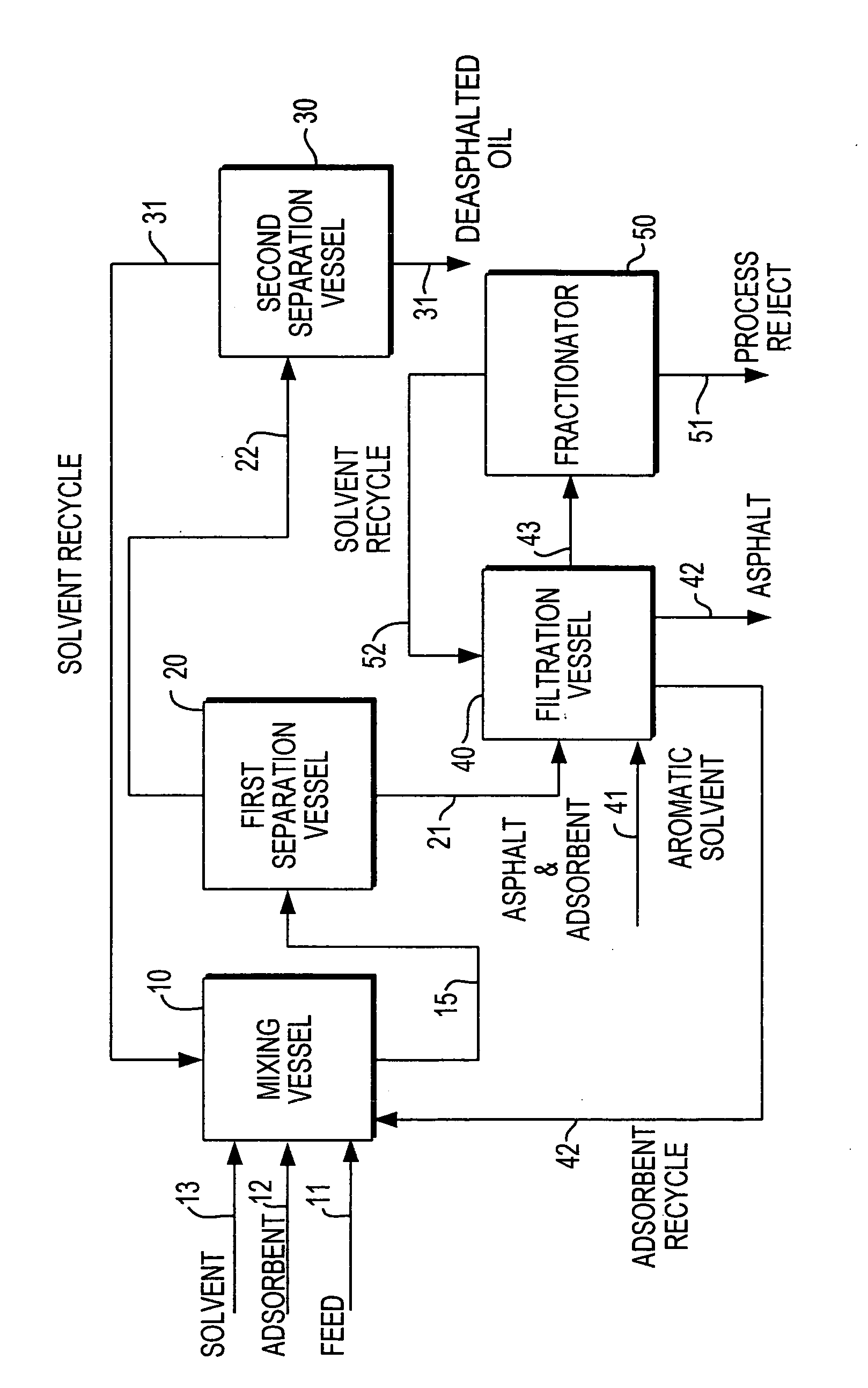

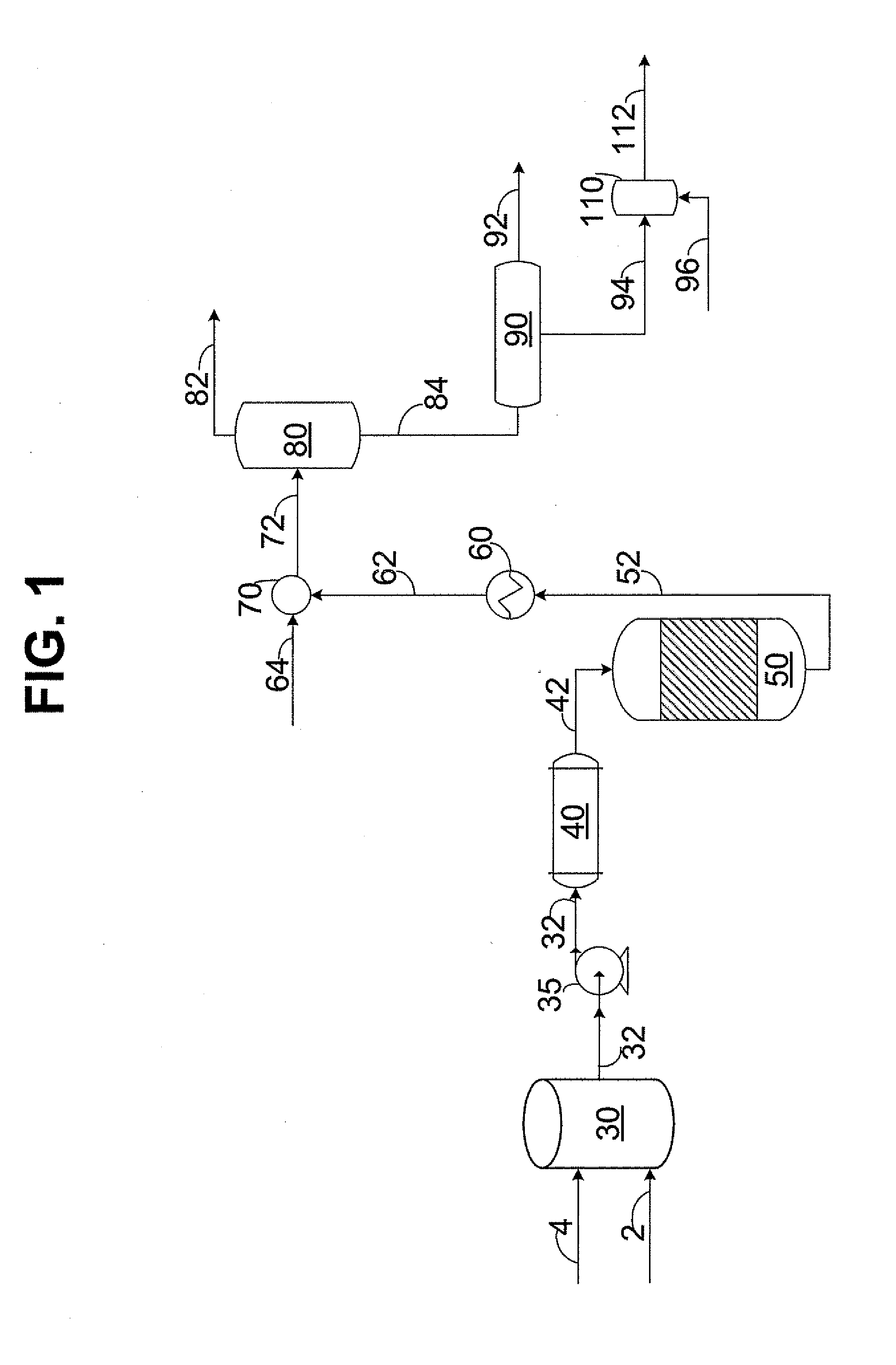

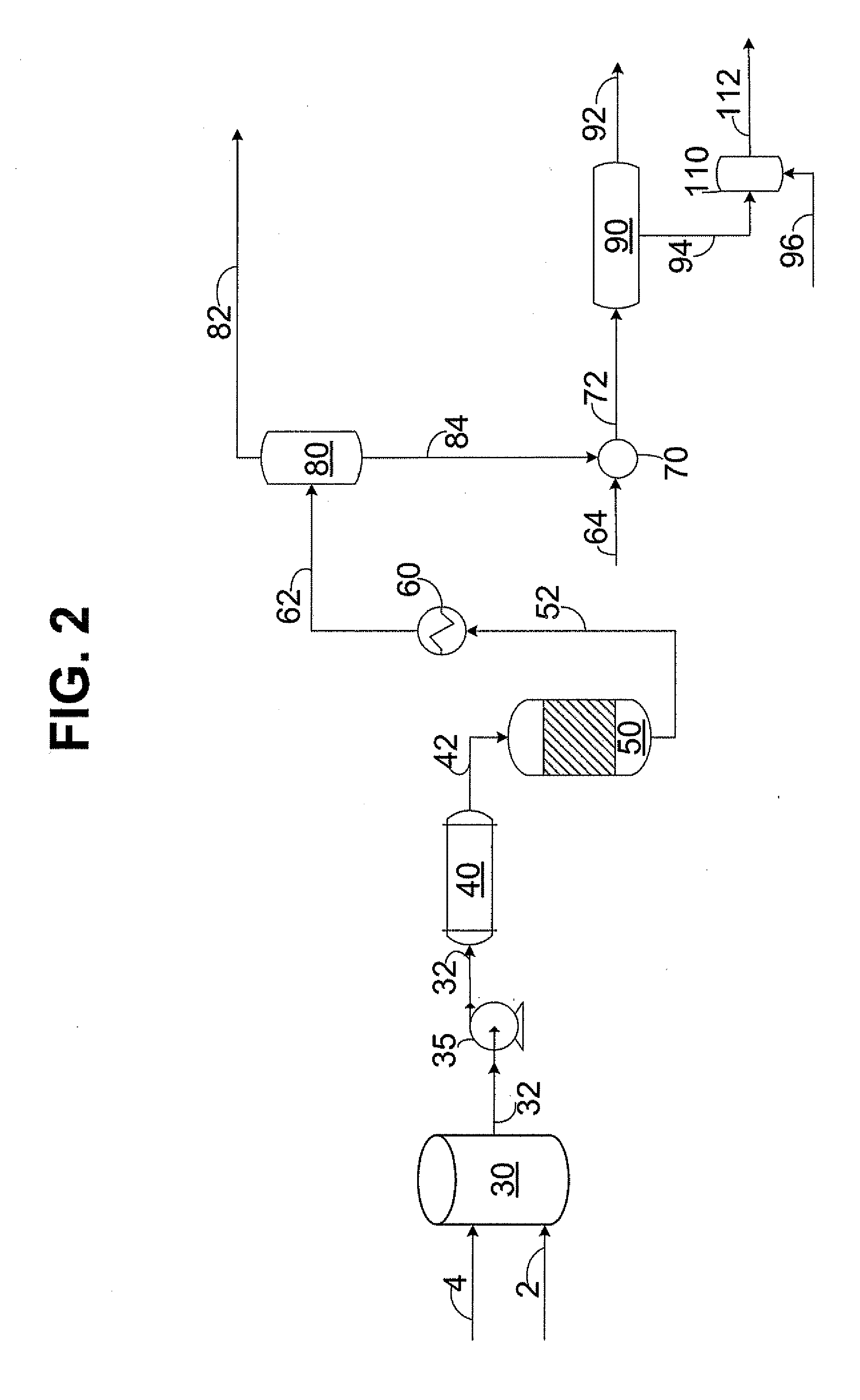

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS7566394B2Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

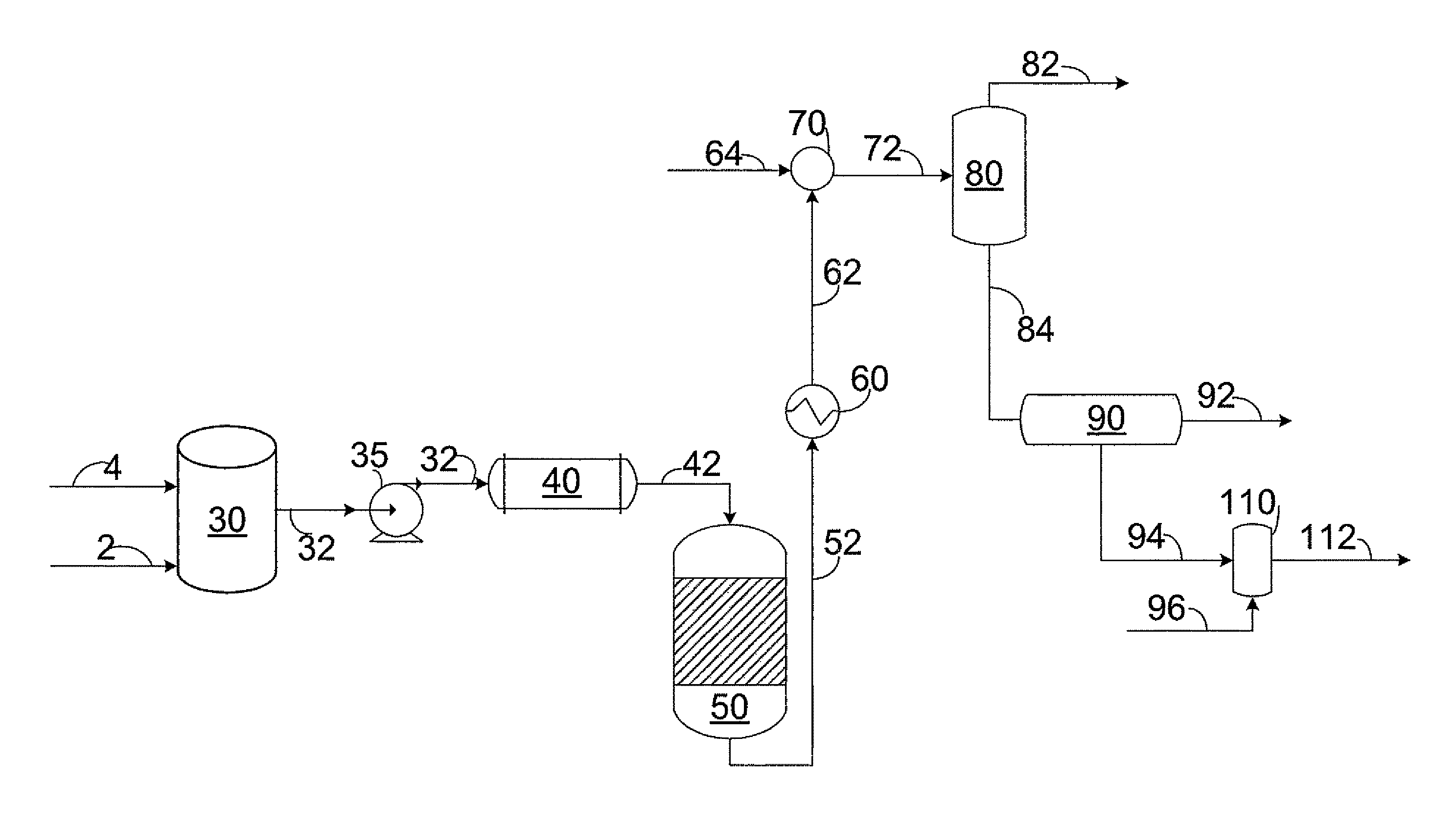

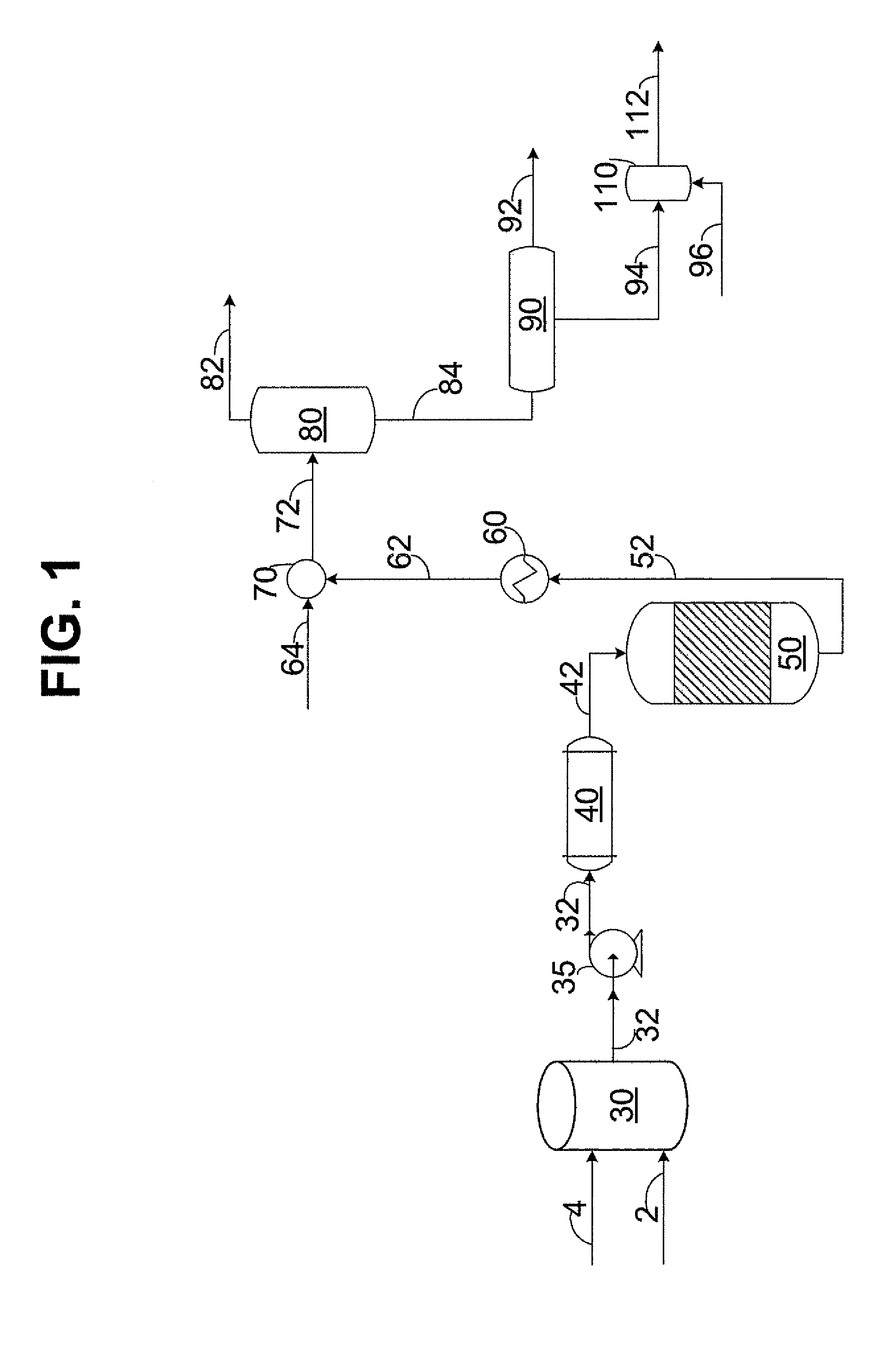

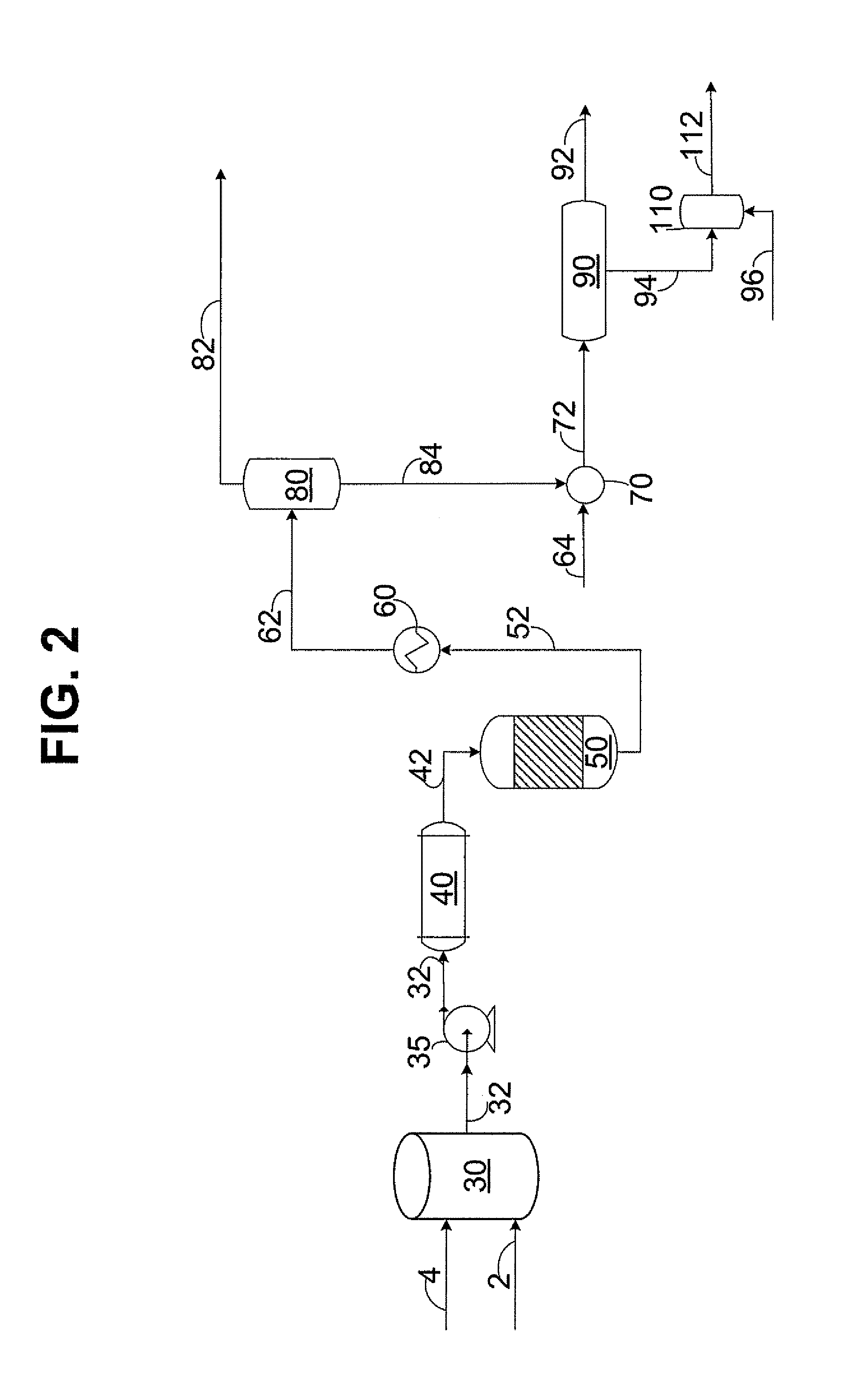

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS20080093260A1Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

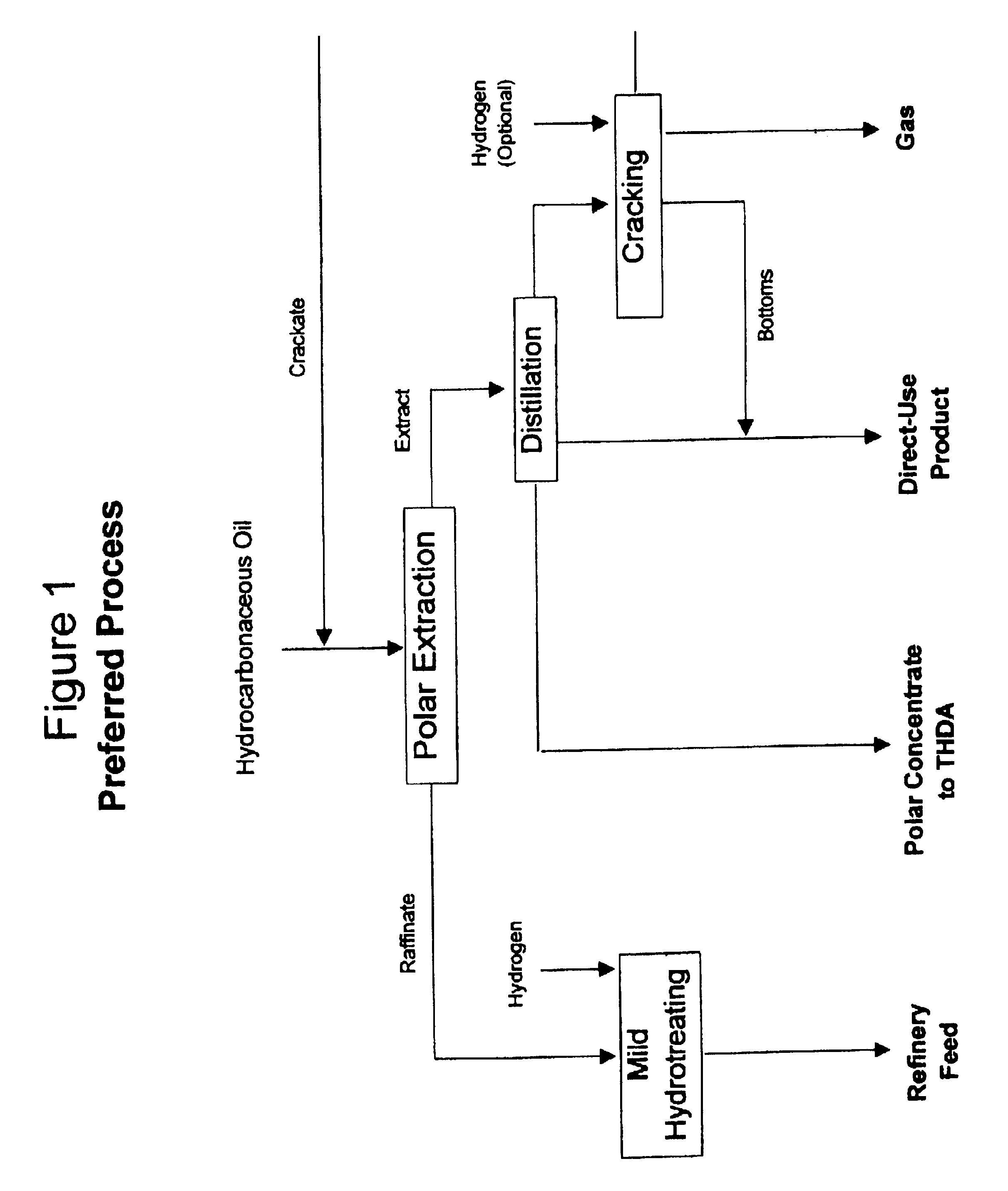

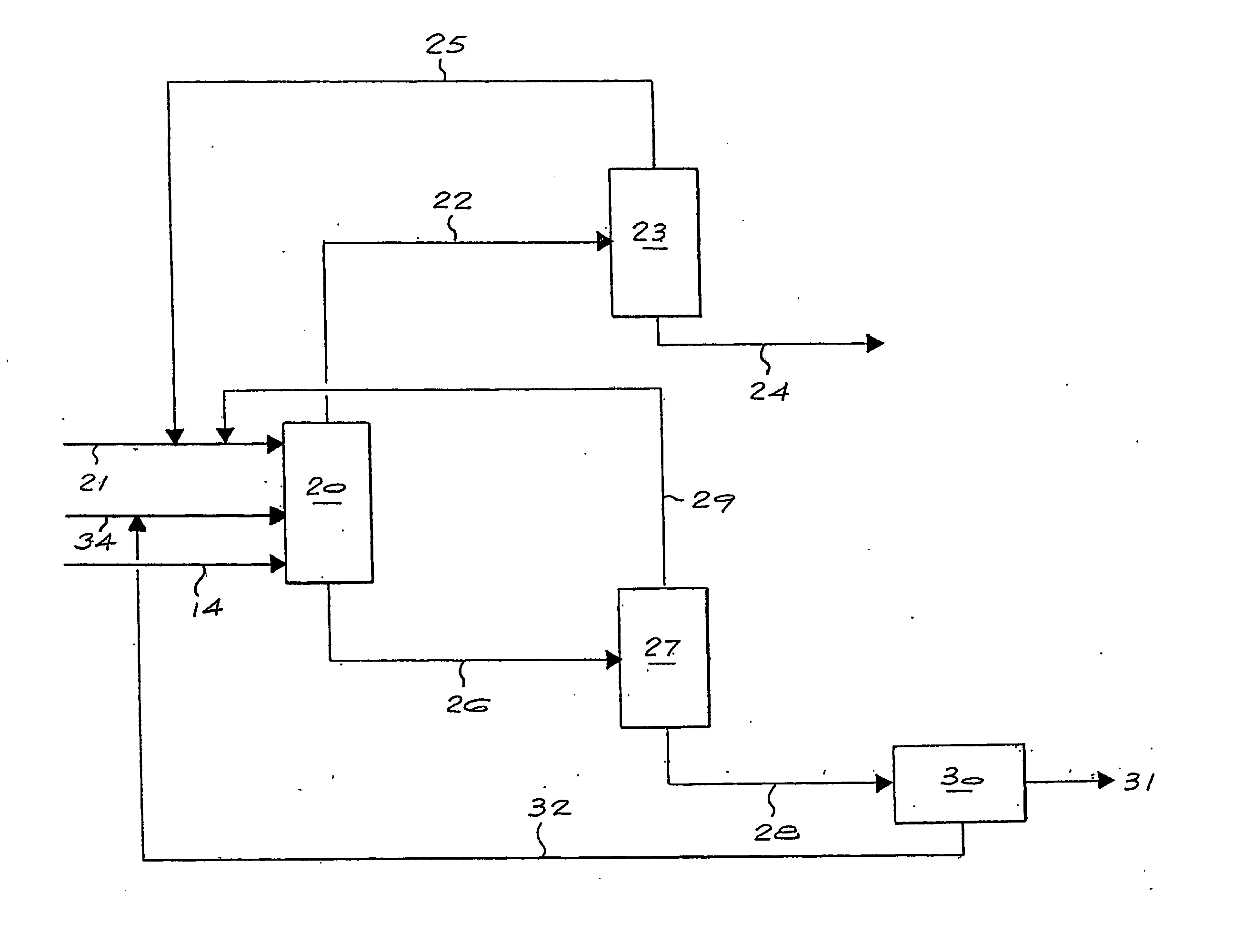

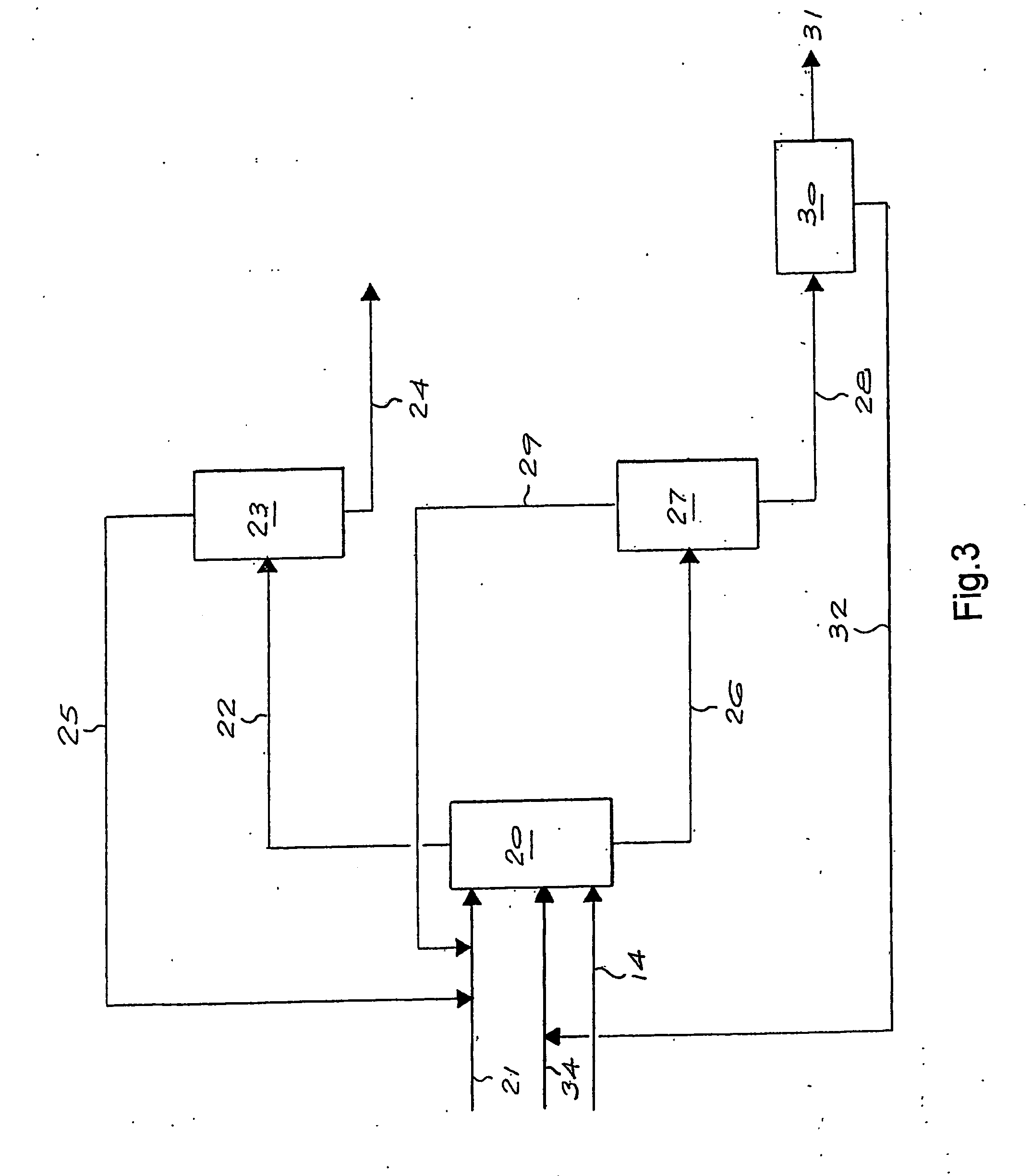

Process for enhancing the value of hydrocabonaceous natural recources

InactiveUS6875341B1Little and valueReduce total process throughputRefining with acid-containing liquidsHydrocarbonsSolubilitySolvent free

Owner:JWBA

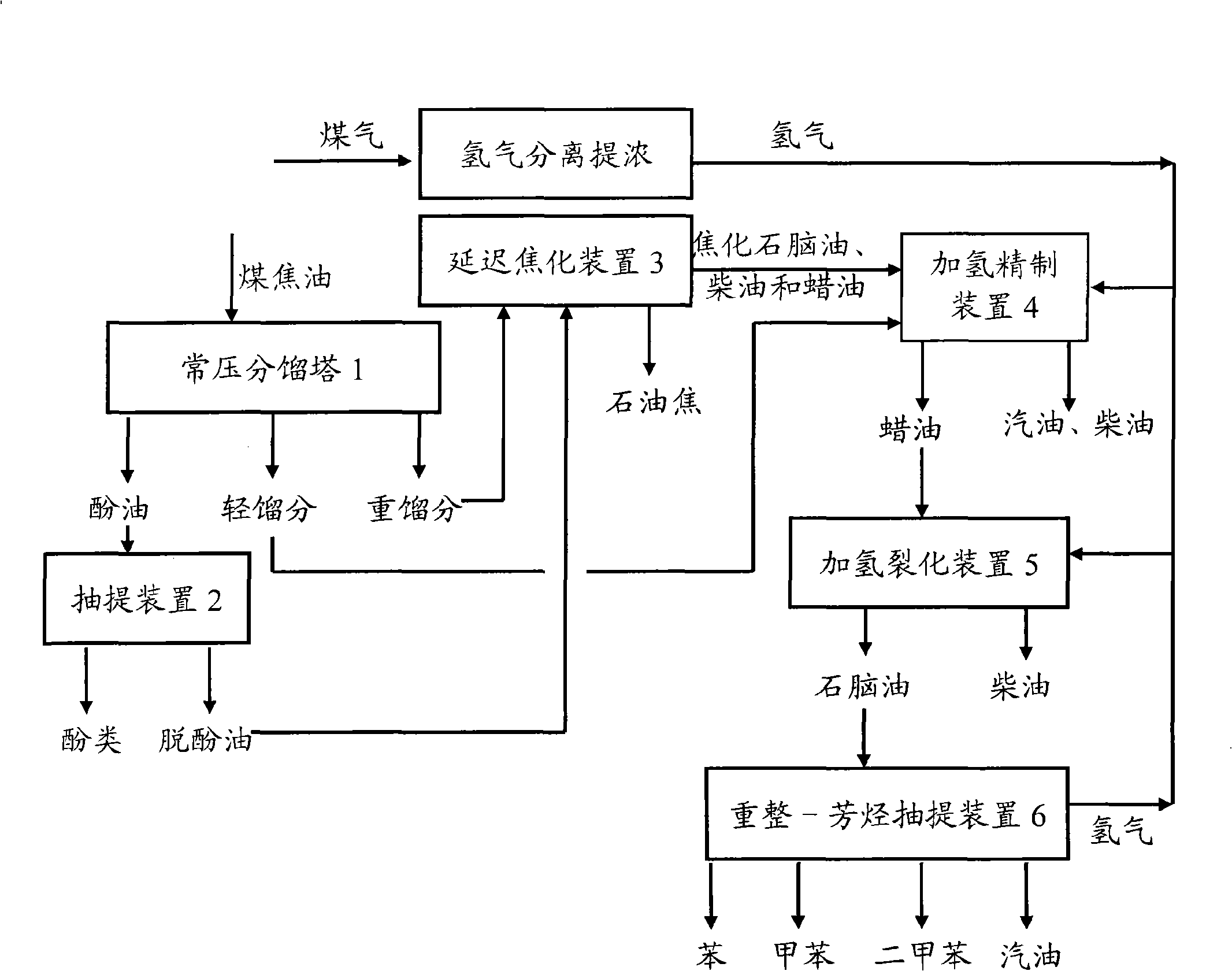

Medium and low temperature coal tar deep processing method

InactiveCN101538482AImprove performanceEfficient use ofThermal non-catalytic crackingCatalytic naphtha reformingCatalytic reformingFractionation

The invention discloses a medium and low temperature coal tar deep processing method. Medium and low temperature coke material is pretreated and fractionated to obtain light fraction, carbolic oil and heavy fraction, dephenolization treatment is carried out on the carbolic oil to obtain phenols product and dephenolized oil, the dephenolized oil and the above heavy fraction carry out pyrogenetic reaction jointly to obtain various carbonized products, wherein carbonized naphtha, at least one of carbonized diesel oil and carbonized wax oil is mixed with the light fraction obtained by material fractionation to carry out hydrofining and hydrocracking reaction, hydrogenated naphtha obtained by hydrocracking carries out catalytic reforming-aromatics extraction to obtain benzene, toluol, xylene, solvent oil and other products. Compared with the prior art, gasoline fraction and diesel oil fraction obtained by the inventive method are clean and stable in properties. In addition, the invention can produce a plurality of chemical products with high added value, truly realizes the effective utilization of medium and low temperature coal tar, and greatly improves the service life of devices.

Owner:胜帮科技股份有限公司

Removal of sulfur compounds from petroleum stream

ActiveUS20110315600A1Reduce the amount requiredIncreasing API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyThiolLow nitrogen

A process for upgrading an oil stream by mixing the oil stream with a water stream and subjecting it to conditions that are at or above the supercritical temperature and pressure of water. The process further includes cooling and a subsequent alkaline extraction step. The resulting thiols and hydrogen sulfide gas can be isolated from the product stream, resulting in an upgraded oil stream that is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the oil stream.

Owner:SAUDI ARABIAN OIL CO

Process for separating aromatics by extractive distillation and a composite solvent used therein

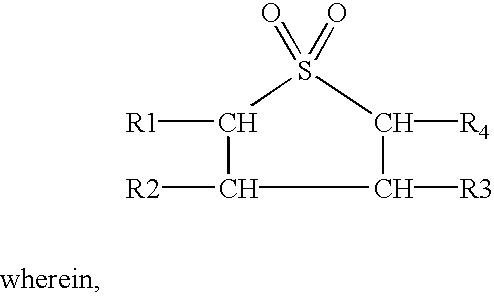

InactiveUS7078580B2Improve solubilityWide boiling rangeDistillation purification/separationHydrocarbonsSulfolaneAlkalinity

This application relates to a composite solvent for separating aromatics by extractive distillation, comprising a main solvent, a solutizer and a modifier. Said solutizer is selected from any one or mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the content of which is 3–39 wt %, and the number of carbon atoms of the lowest aromatic in the solutizer should be greater than that of the highest aromatic in the aromatics to be separated. When the solutizer is selected from any one of C8–C11 aromatics, the composite solvent contains 0.01–10.0 wt % of the modifier; when the solutizer is selected from mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the composite solvent contains 0–10.0 wt % of the modifier. Said main solvent and modifier are independently selected from sulfolane derivatives, N-formyl morpholine, and N-methyl pyrrolidone, provided that the acidity and basicity of the modifier are opposite to those of the main solvent. When the composite solvent is used to recover aromatics by extractive distillation, it is possible to moderate the operation conditions of solvent recovery, increase the yield of aromatics, and make the separated aromatics to be neutral.

Owner:CHINA PETROCHEMICAL CORP +1

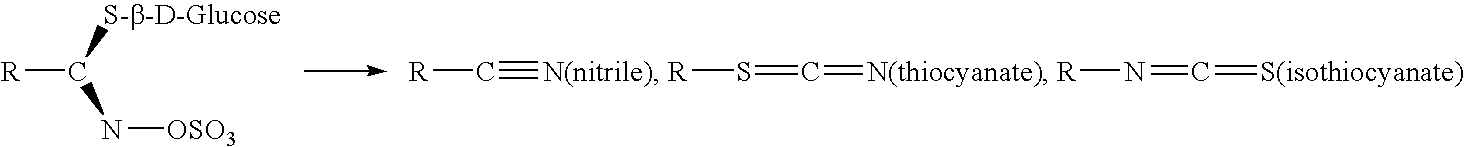

ITFM extraction of oil seeds

InactiveUS7156981B2Superior, high purity, bright proteinsIncrease in absorbable proteinHydrocarbon distillationEssential-oils/perfumesProtein insertionProtein isolate

A process for the producing edible protein-containing meal for human and animal consumption and high quality food grade oils from oil seed using iodotrifluoromathane as the solvent is shown. The meal has a significantly improved level of dietary available (absorbable) protein. The process involves the preparation of protein isolates by a procedure which is conducted at room temperature, thus decreases protein degradation and denaturing which is caused by elevated temperatures. The process also provides for extraction of substantially all oils and fats, which interfere with the formation of the protein micelle, from the protein meal providing a cleaner, purer product with high levels of absorbable protein. Such protein isolates can then be used as such or added to formulated foods in order to increase the total protein content of that food. The protein produced and the oils recovered have compositions which are also unique and unobtainable by prior processing methods.

Owner:BIO EXTRACTION INC

Reactive Extraction of Sulfur Compounds from Hydrocarbon Streams

InactiveUS20070227950A1Hydrocarbon purification/separationLiquid hydrocarbon mixture recoveryAlkaline earth metalHypochlorite

A process to substantially reduce the sulfur content of a liquid hydrocarbon stream by contacting the hydrocarbon stream with an aqueous stream containing a mixture of one or more extraction agents selected from hypochlorites, cyanurates and alkali metal and alkaline earth metal hydroxides, optionally in the presence of a catalyst, to remove sulfur compounds.

Owner:SAUDI ARABIAN OIL CO

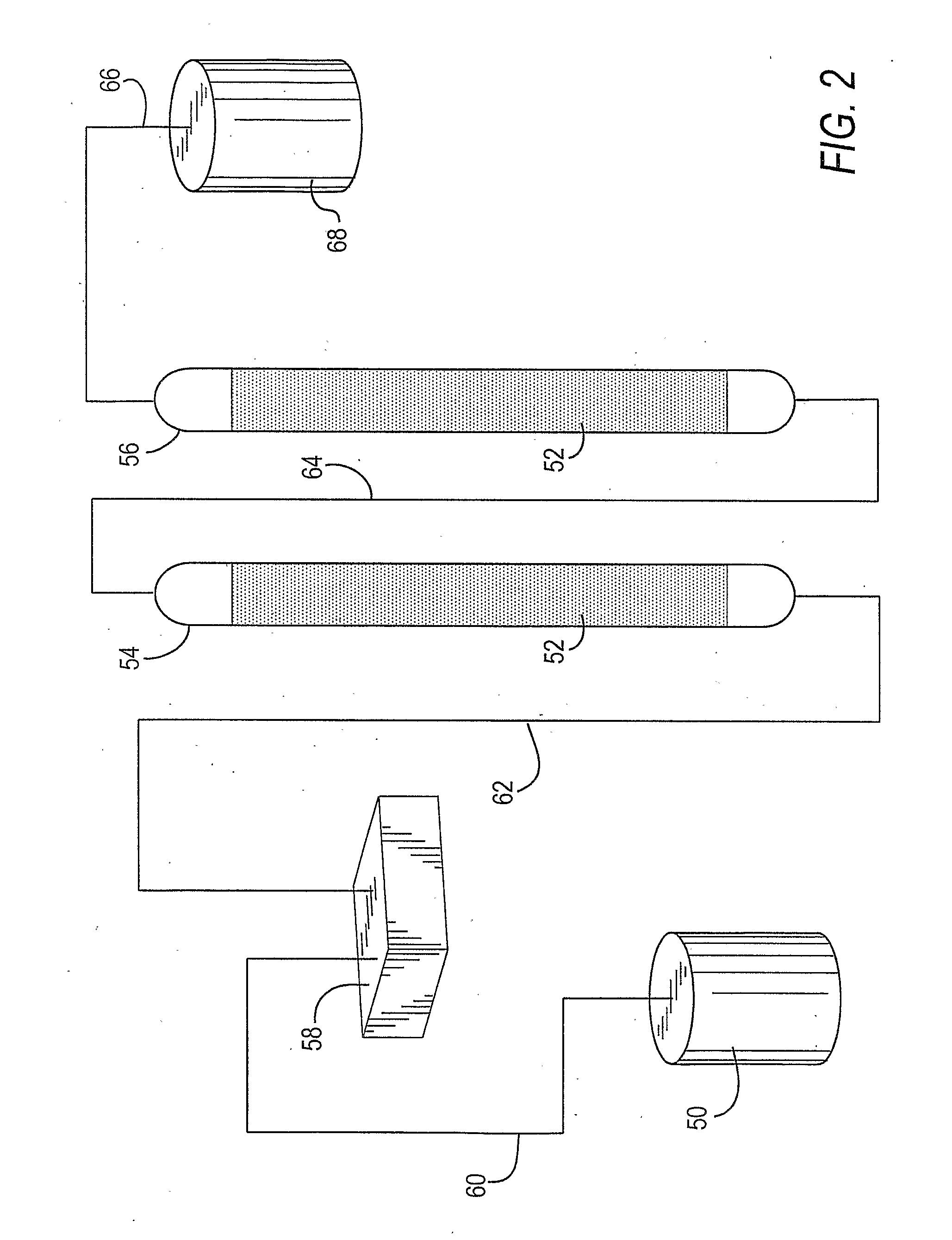

Metal impurity and high molecular weight components removal of biomass derived biocrude

This invention relates to a process for production of transportation fuels from biomass. More particularly, this invention relates to a process for using solvent to remove metal impurities and high molecular weight components from biomass derived biocrude to prevent potential catalyst poisoning and catalyst bed plugging in biocrude-to-transportation fuel upgrading process.

Owner:PHILLIPS 66 CO

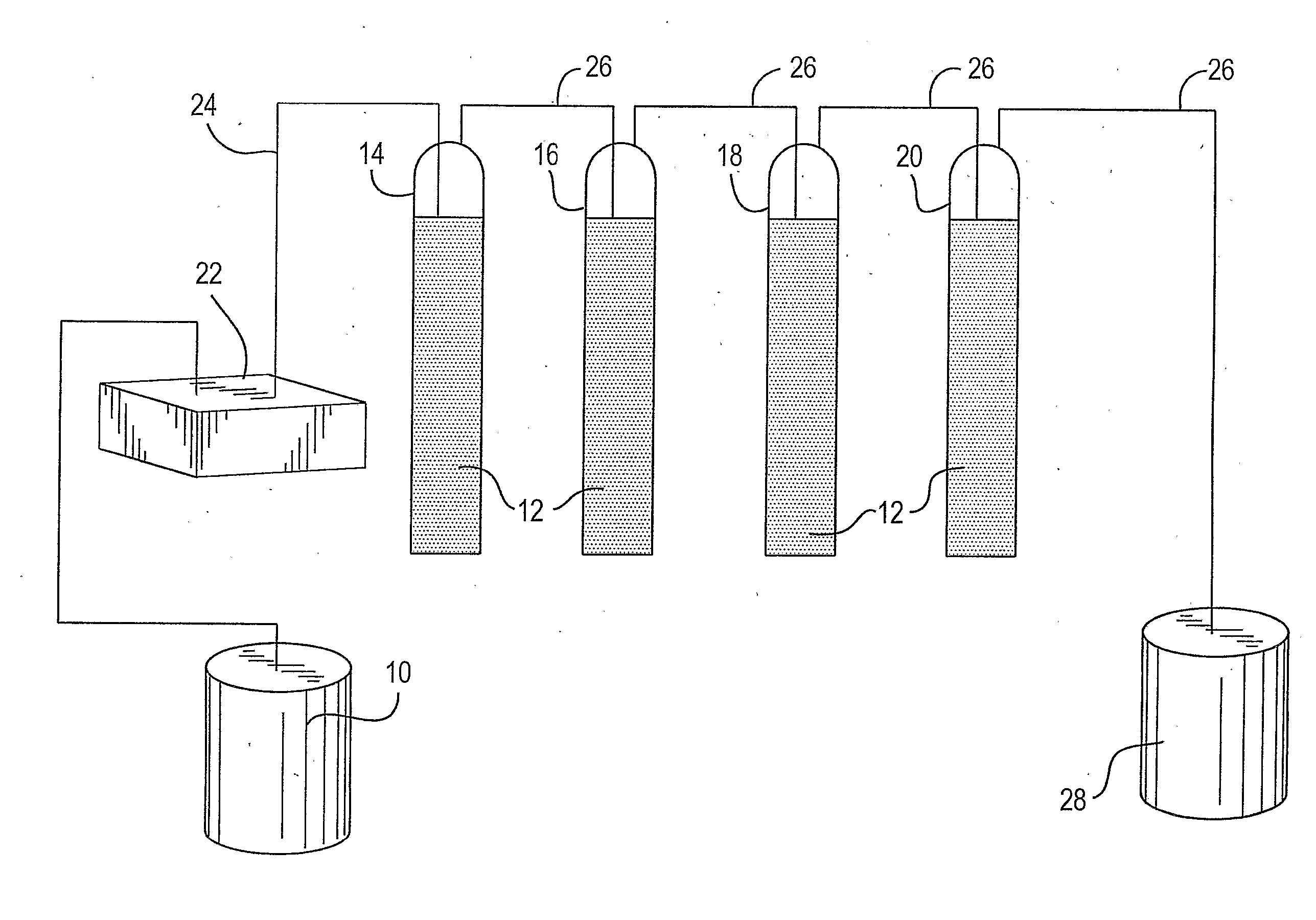

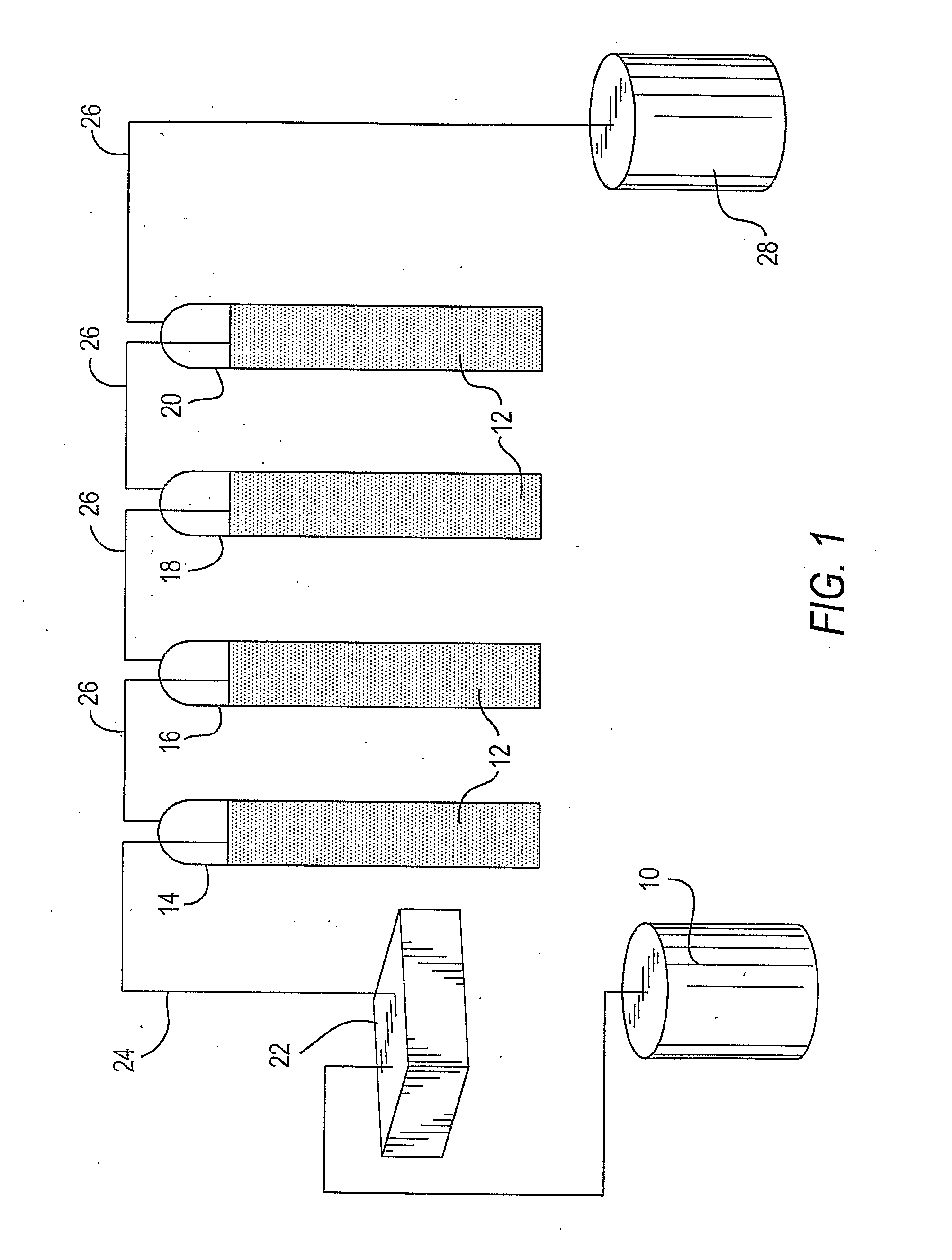

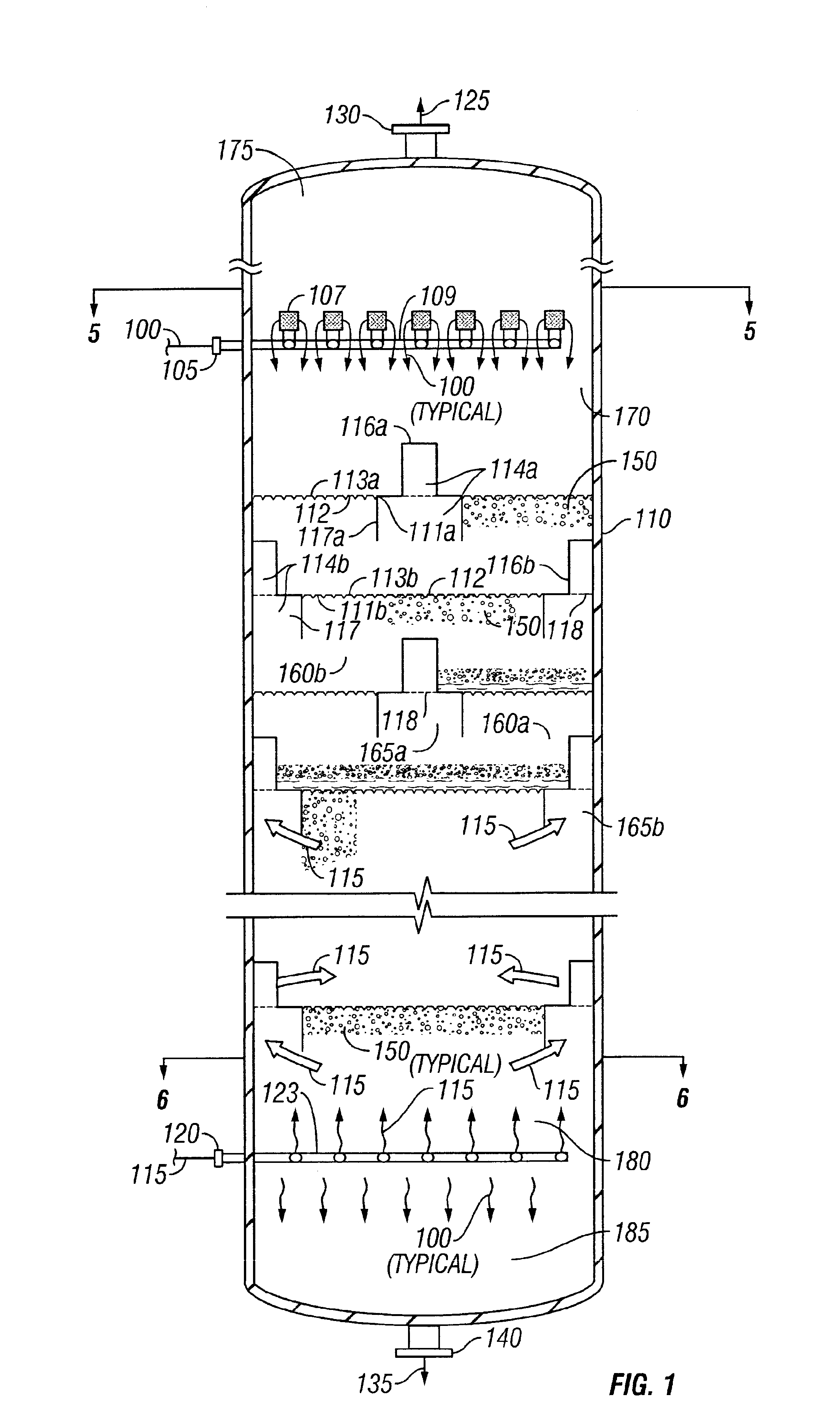

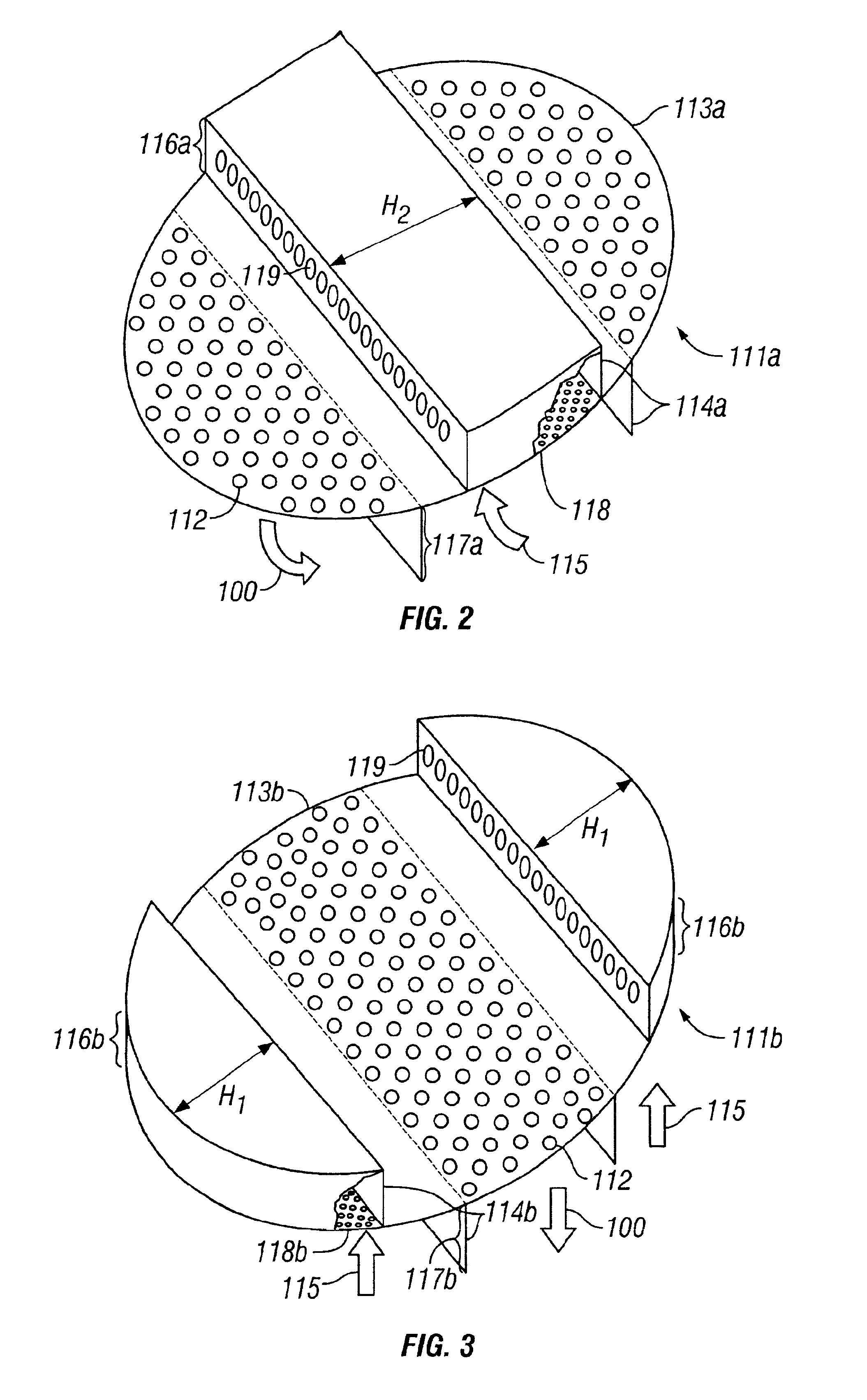

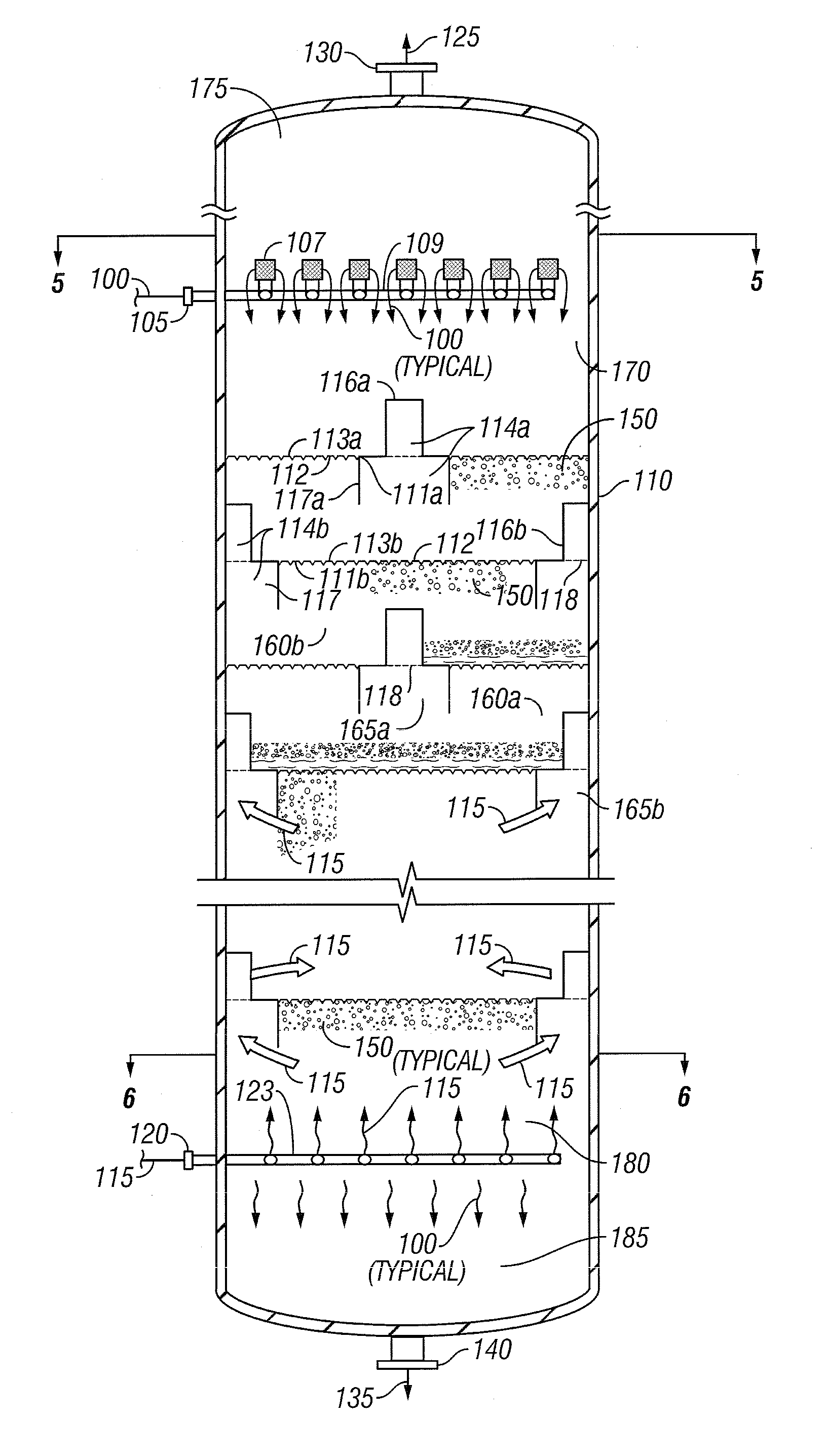

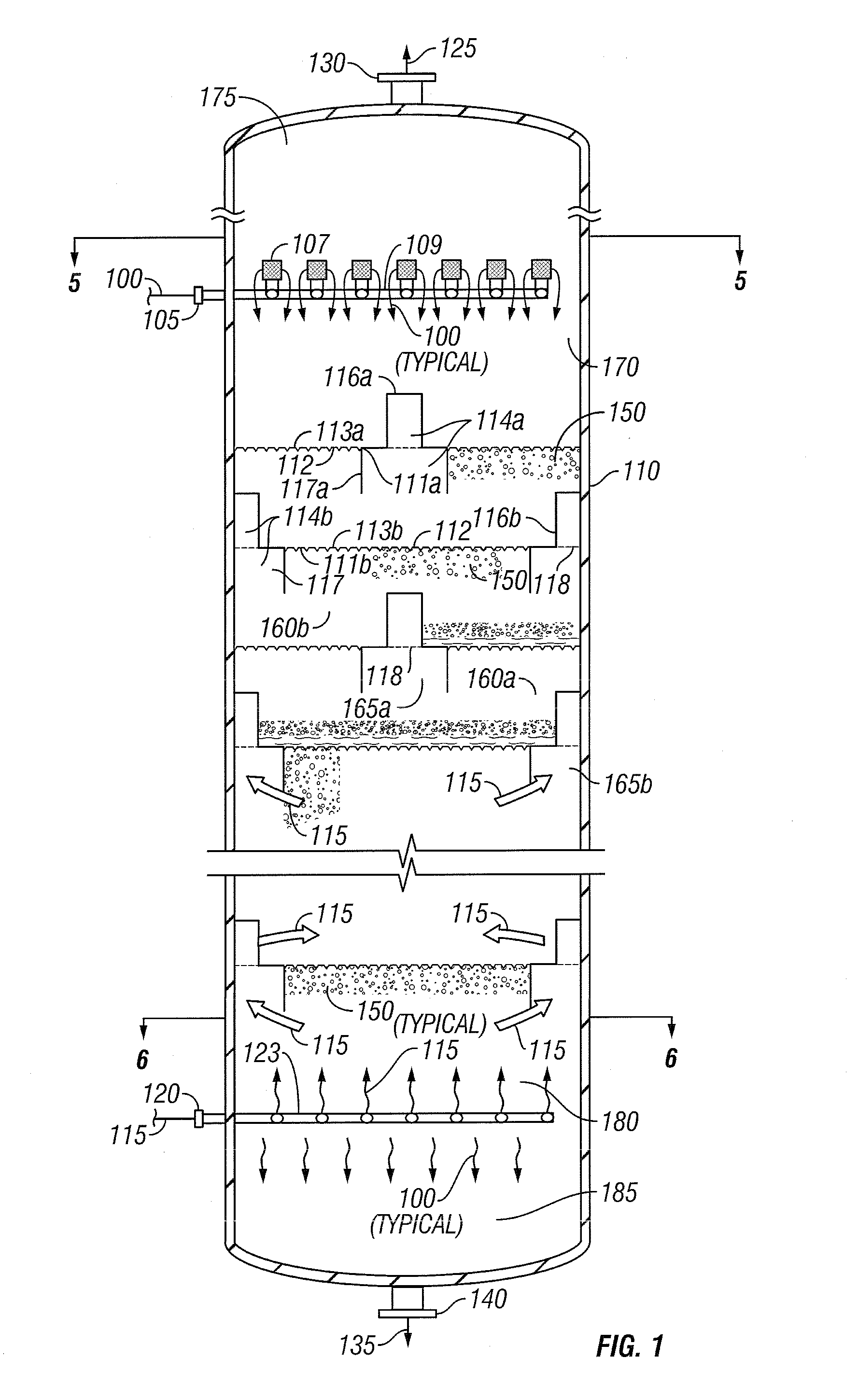

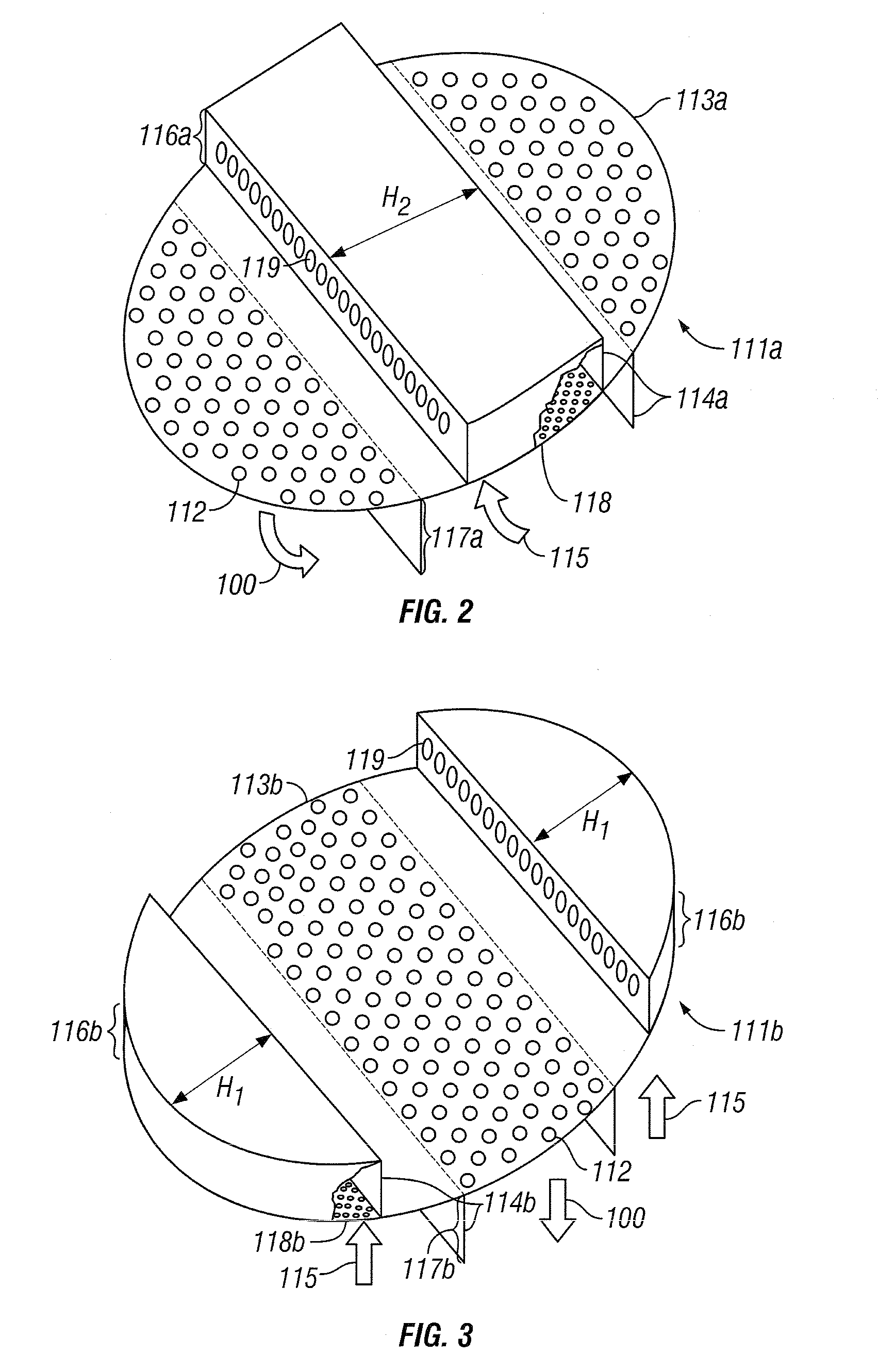

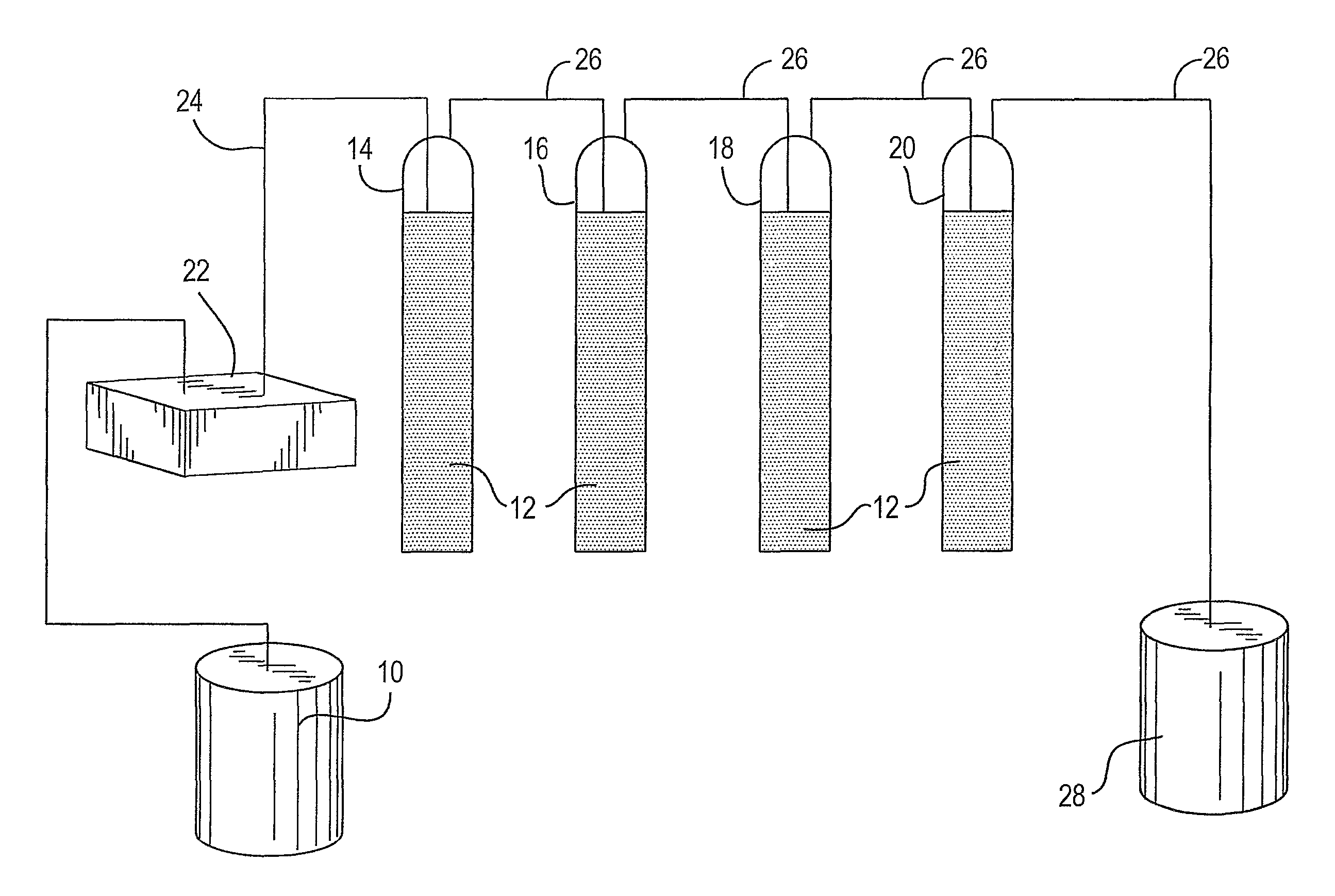

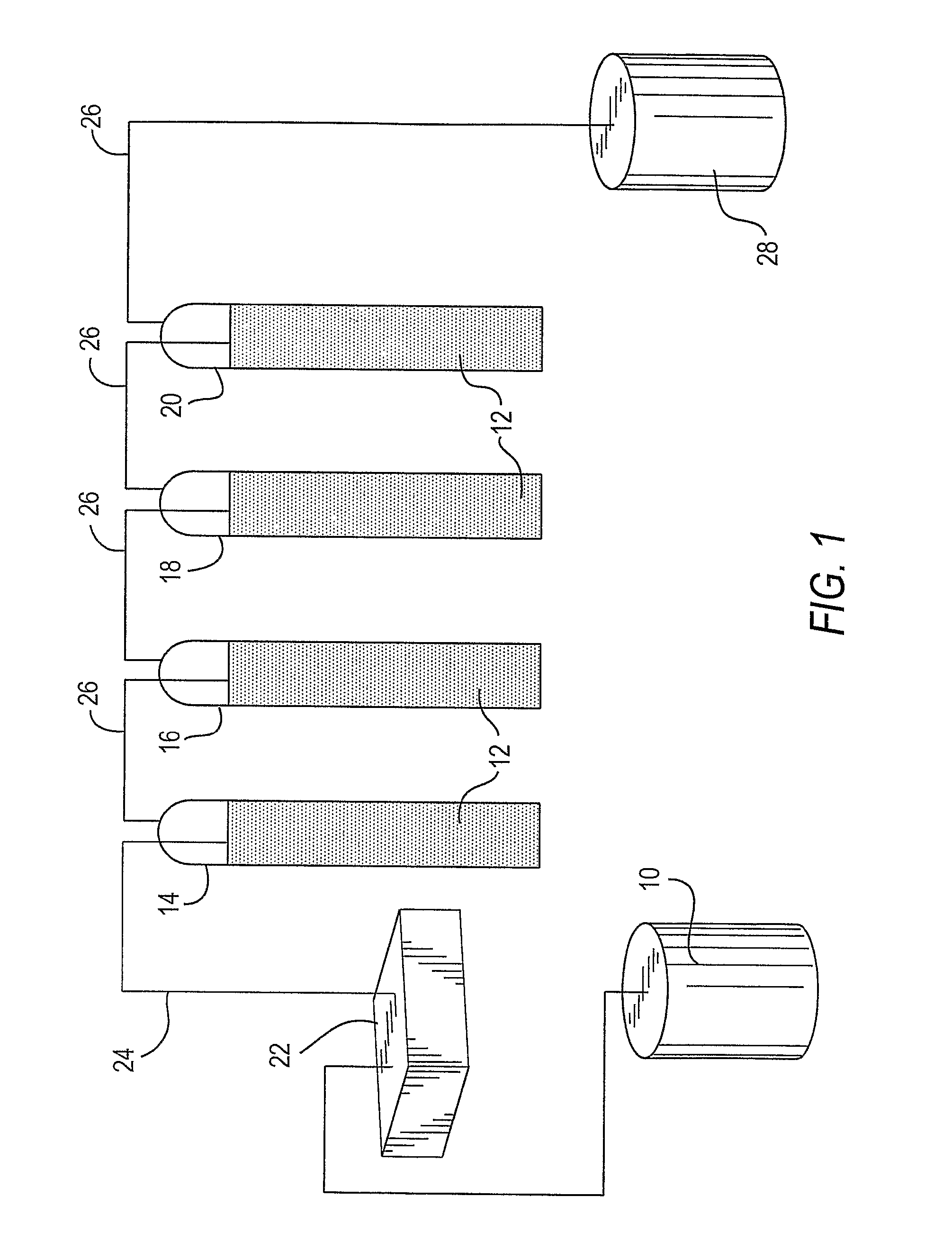

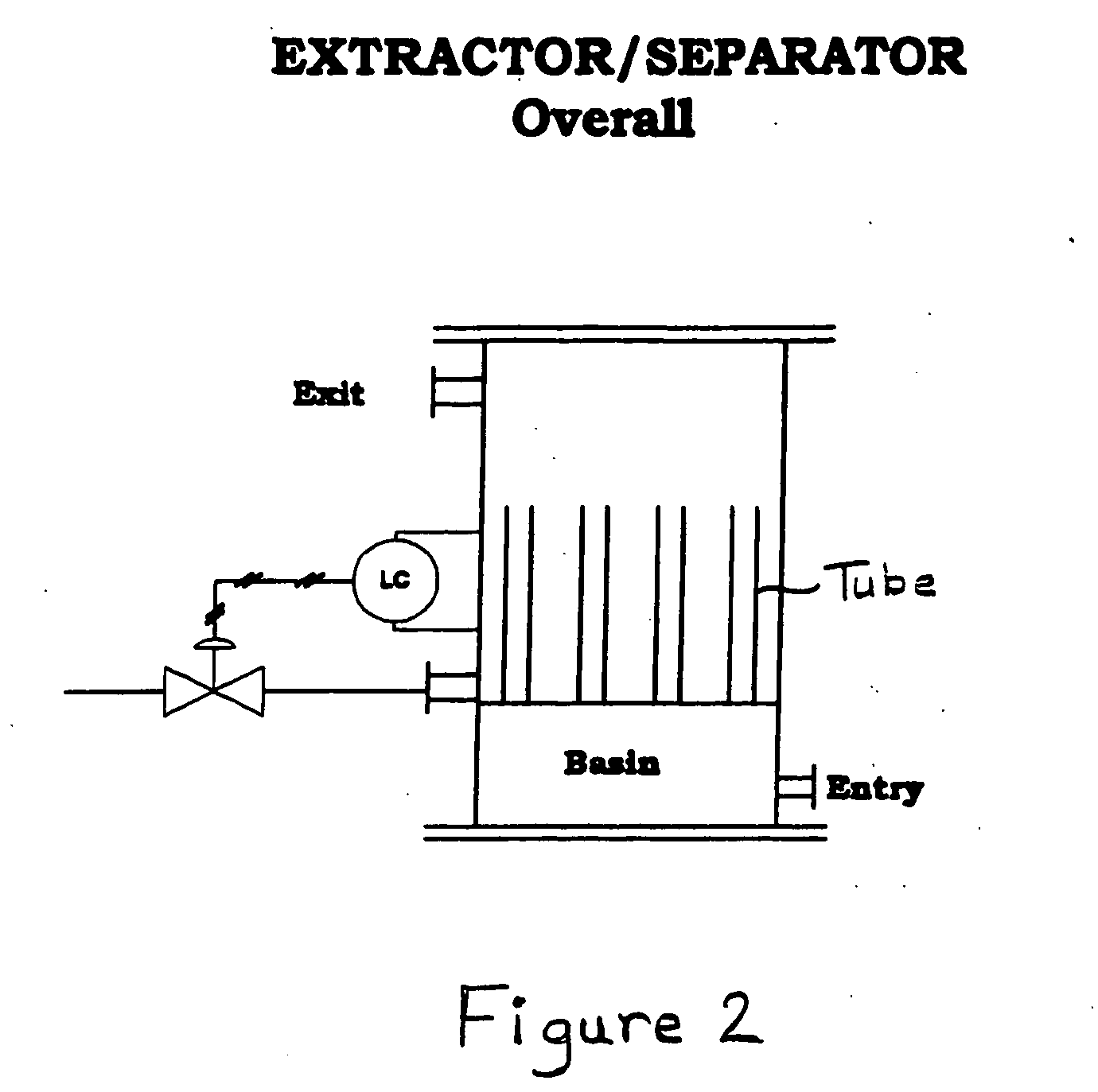

Liquid-liquid extraction apparatus and method

InactiveUS6962661B2Reduce loss ratePromote recoveryWorking-up pitch/asphalt/bitumen by selective extractionSedimentation separationEngineeringLiquid phase

Method and apparatus for contacting two liquid phases for liquid-liquid extraction in a vertical extraction vessel. A relatively heavier liquid phase, descending the extraction vessel at a relatively low volumetric flow rate, is dispersed into a continuous phase comprising a relatively lighter liquid rising through the extraction vessel at a relatively high flow rate. Sieve trays are provided with adjustable active areas and overlapping manways for personnel access.

Owner:KELLOGG BROWN & ROOT INC

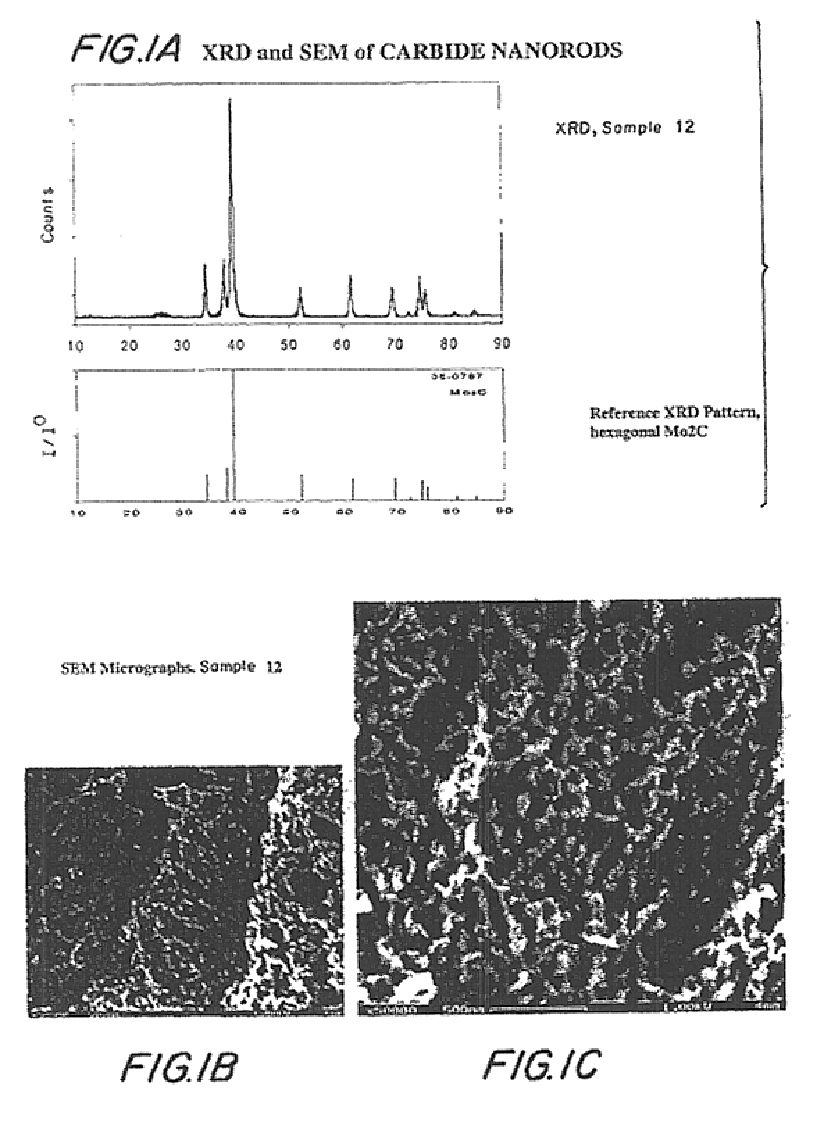

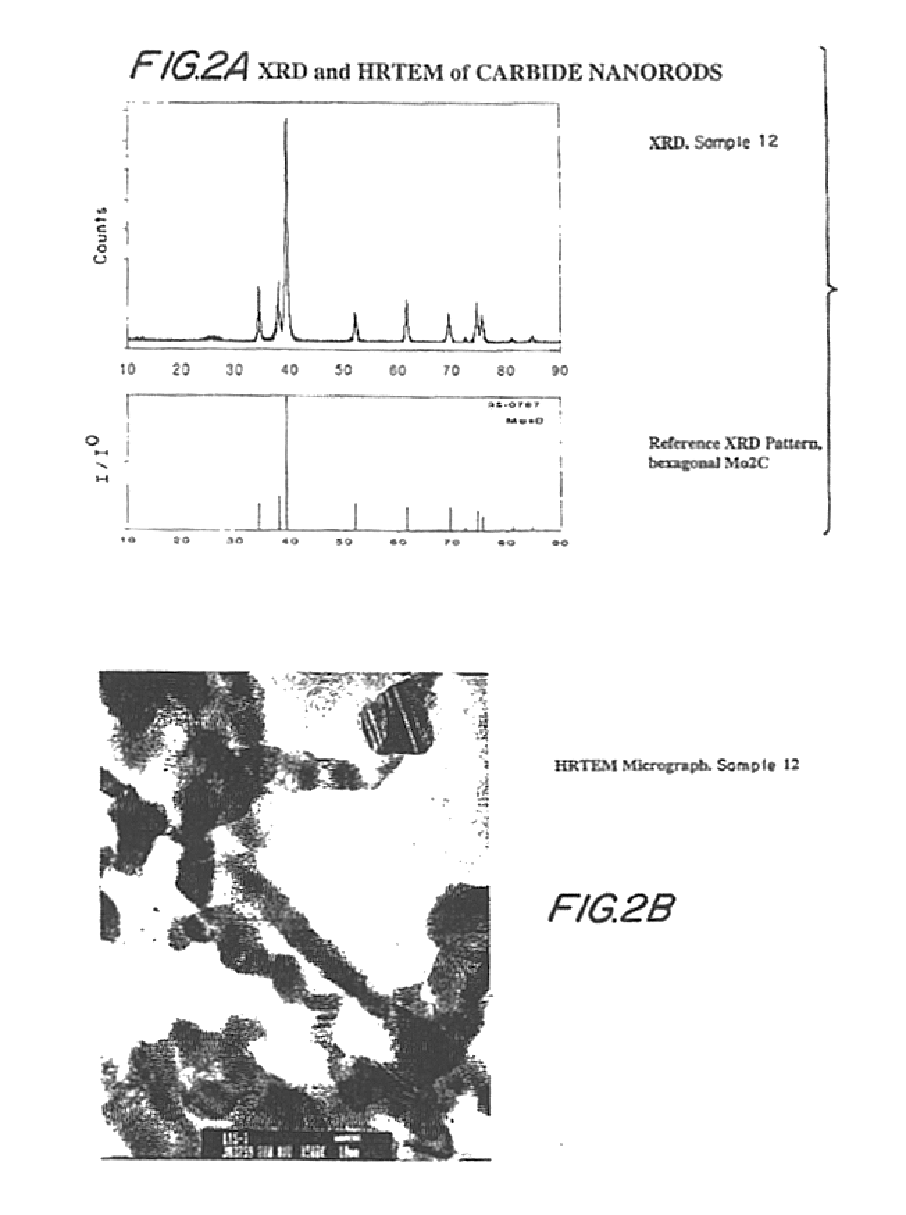

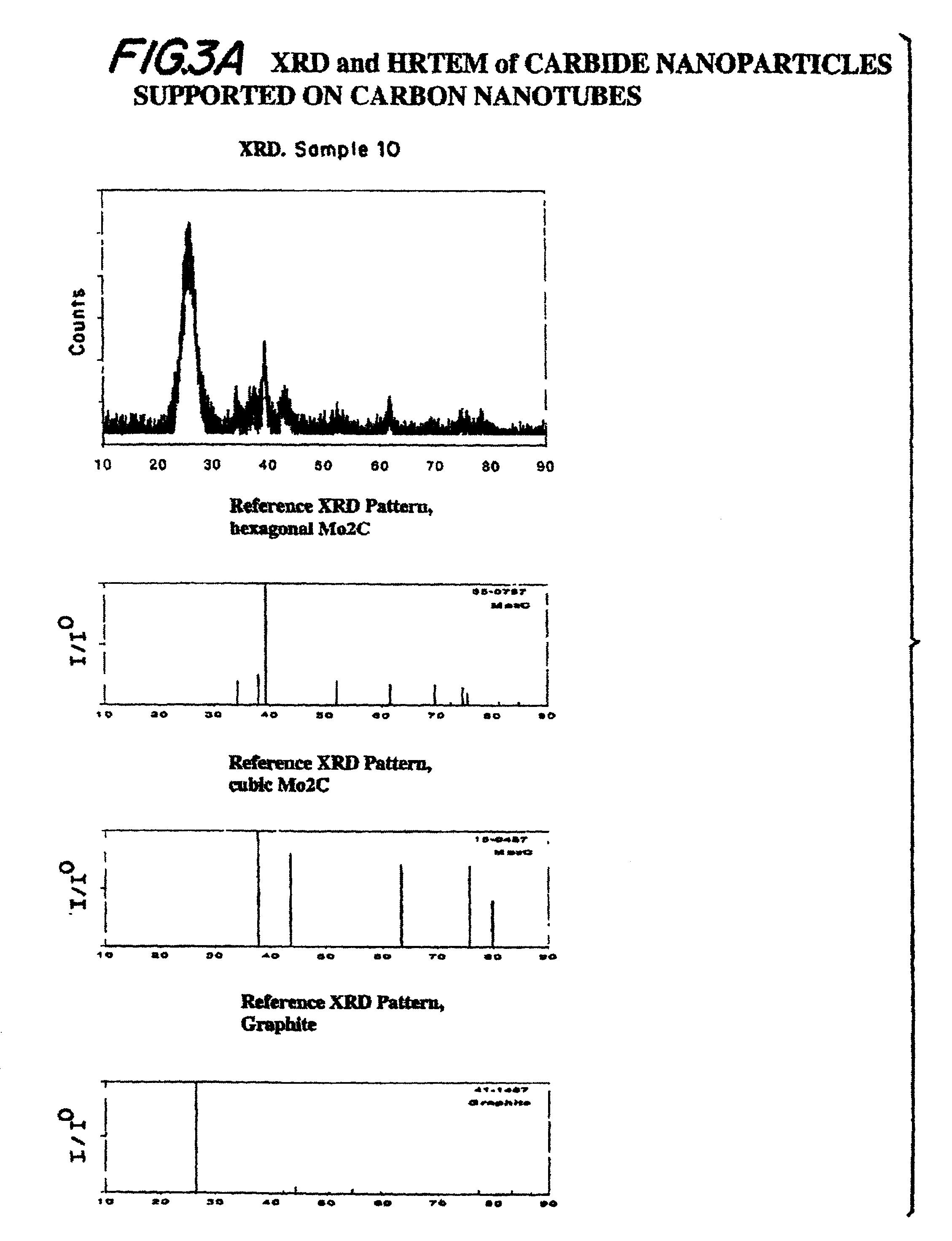

Method of using carbide and/or oxycarbide containing compositions

InactiveUS6809229B2Improve economyHigh purityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

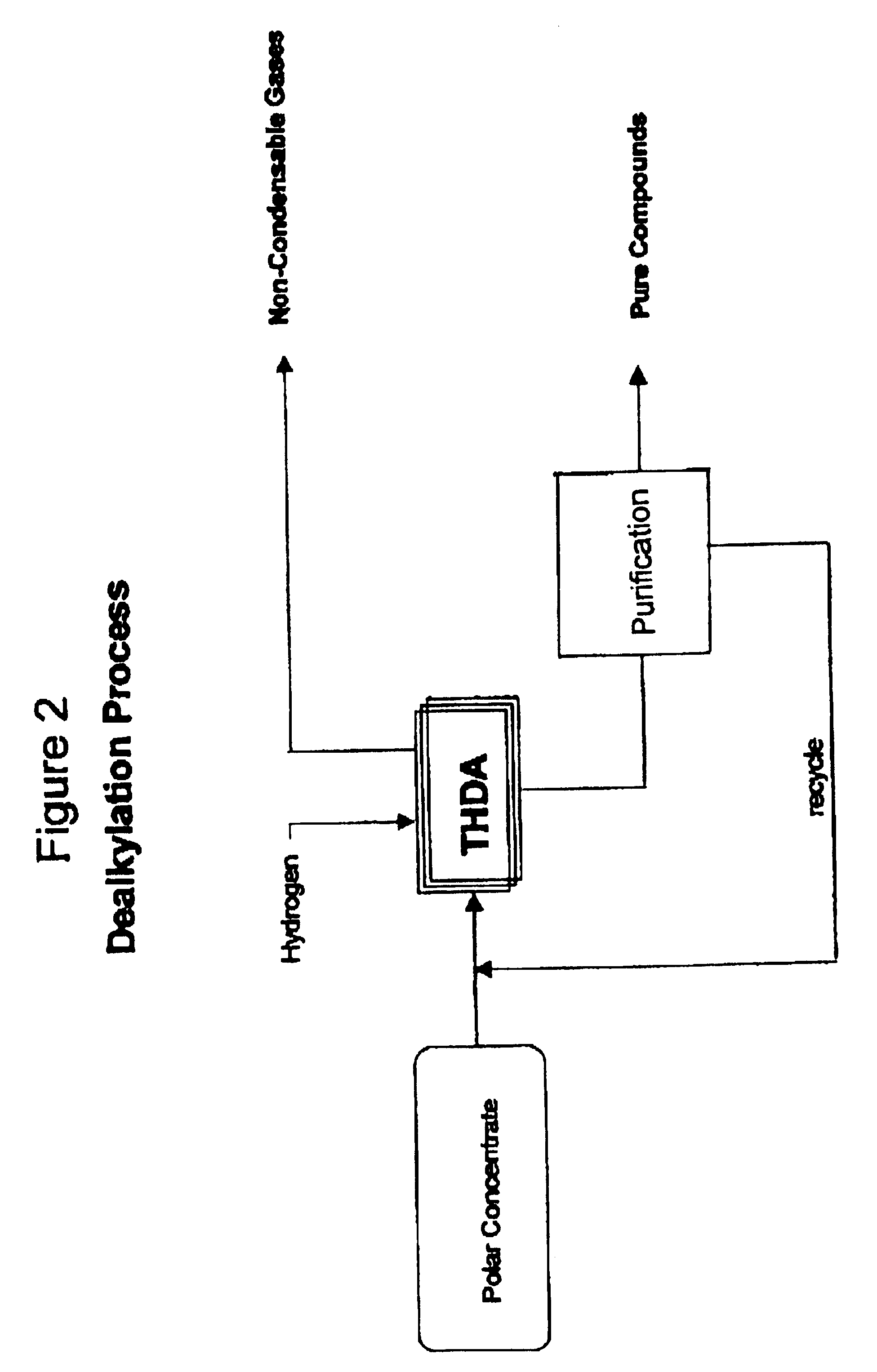

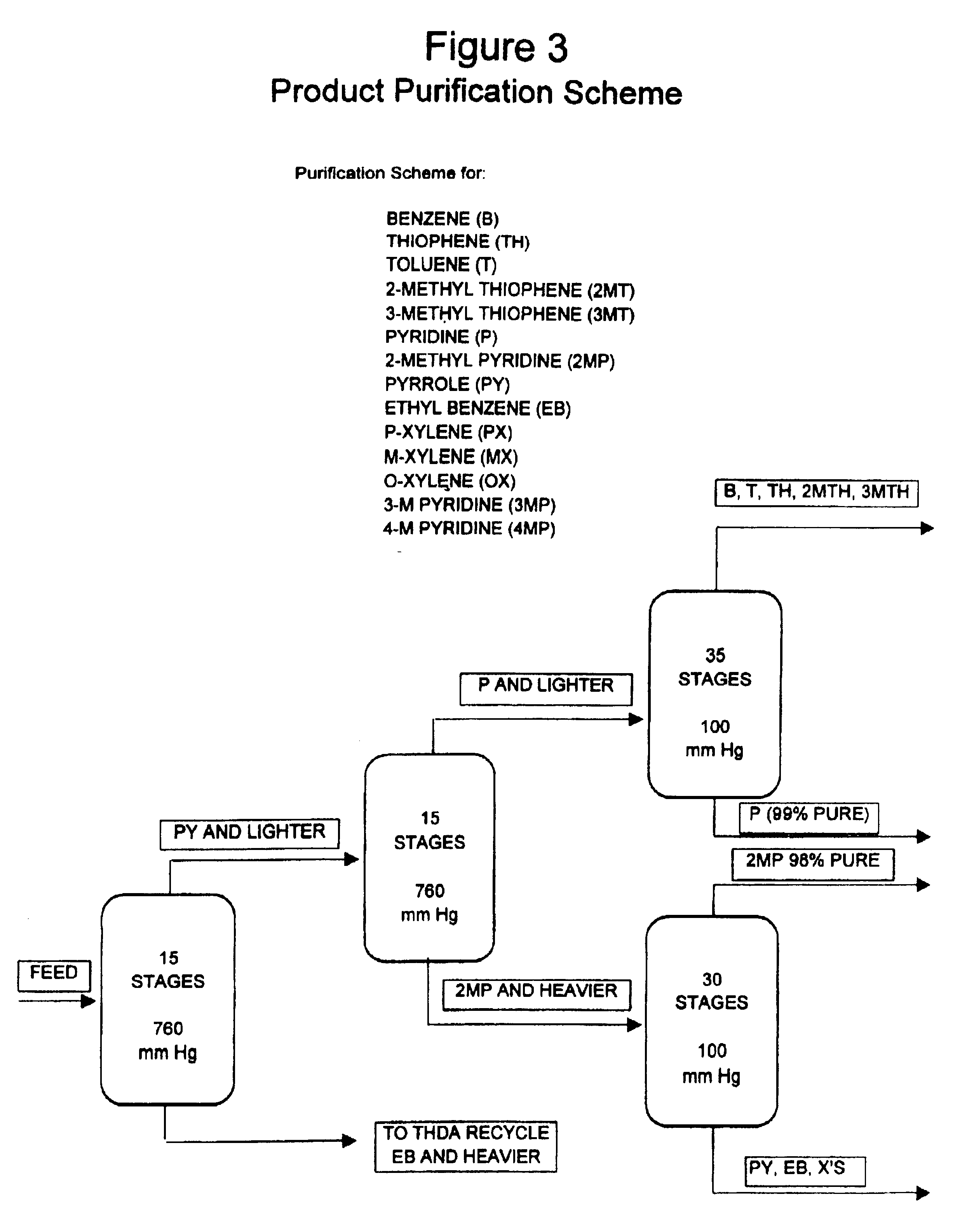

Process for extraction of aromatics from petroleum streams

InactiveUS20040182750A1Lower cost of capitalReduce operating costsTreatment with plural serial refining stagesRefining with two or more solventsDistillates petroleumNaphtha

Owner:COUNCIL OF SCI & IND RES

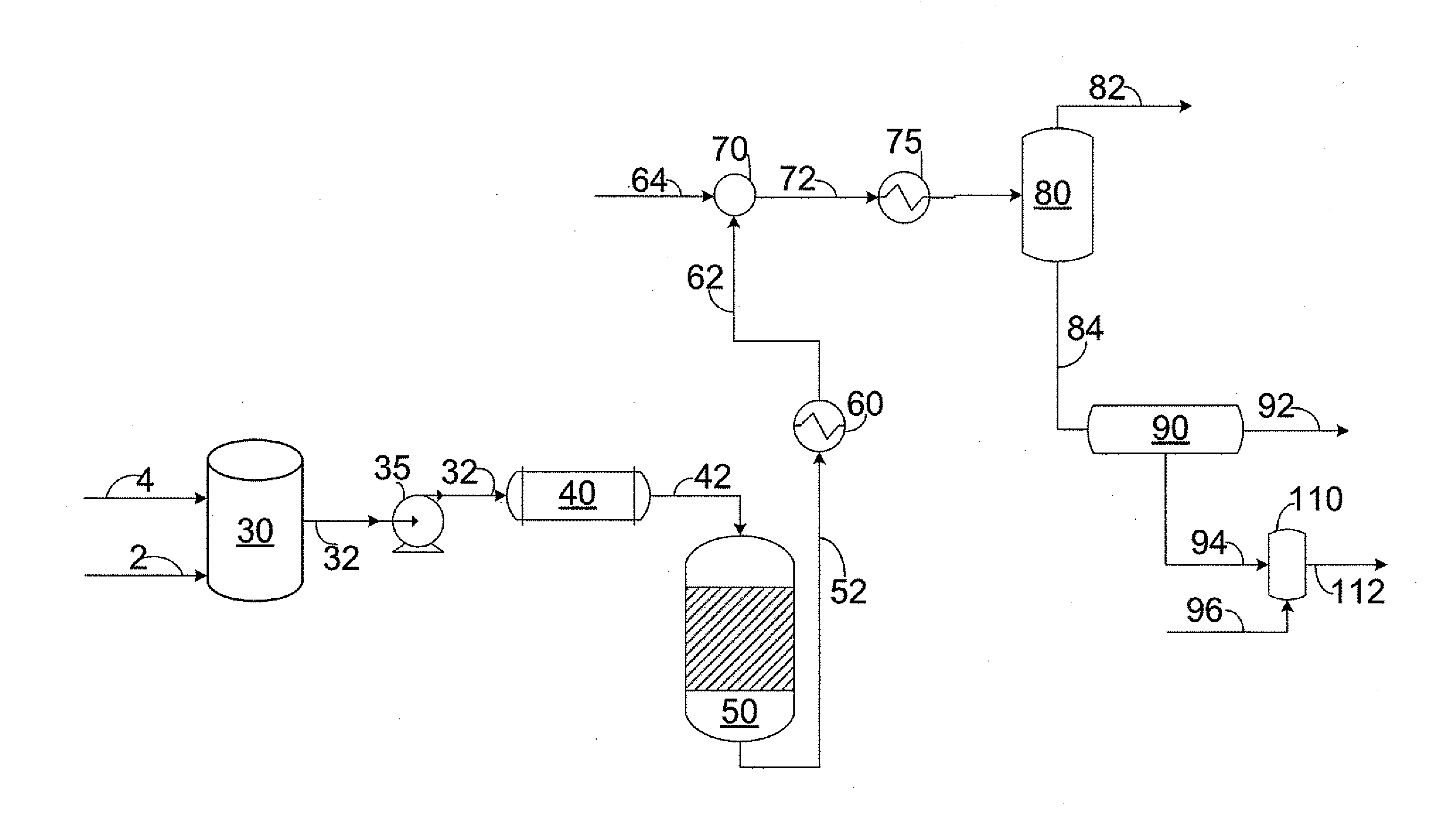

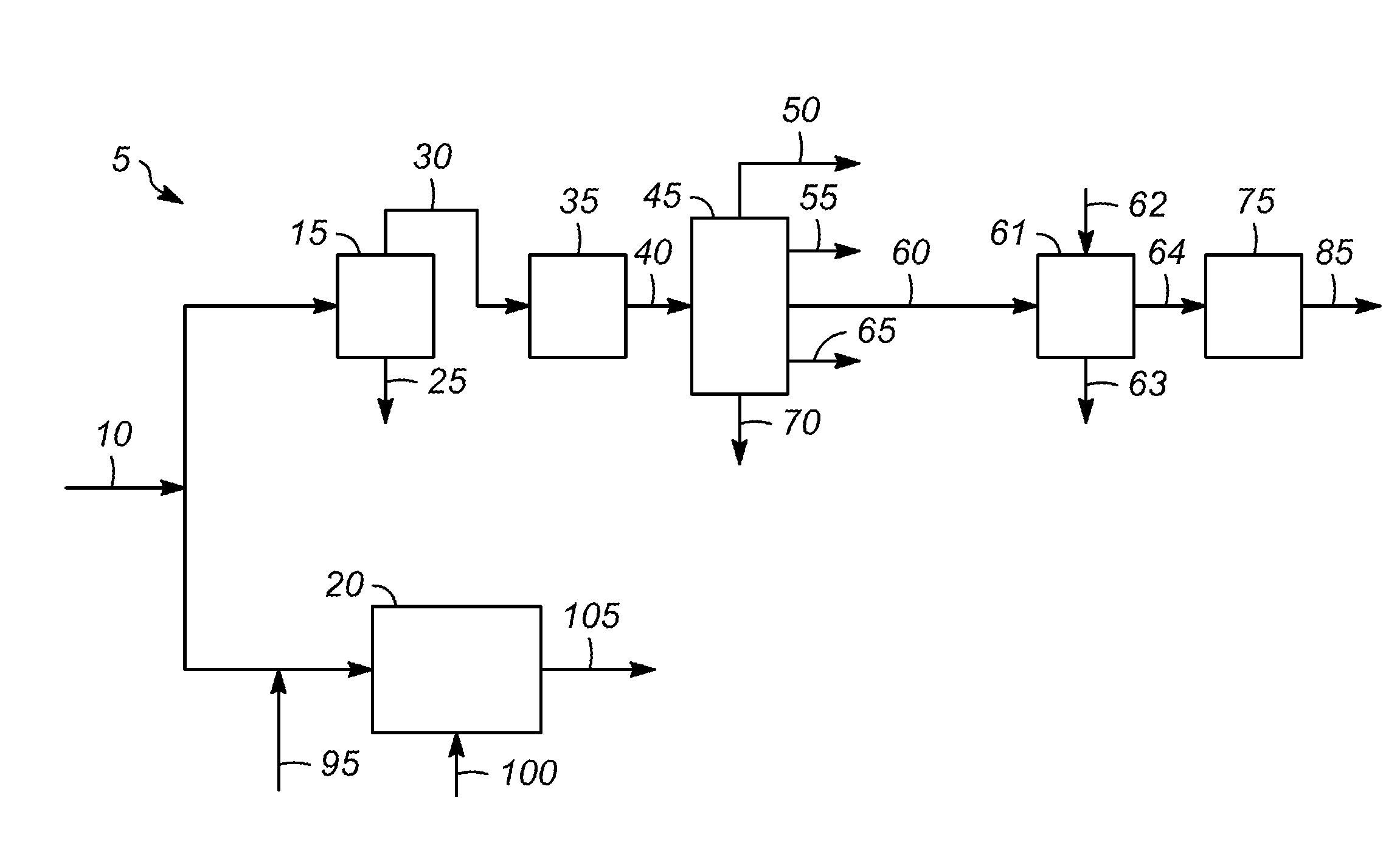

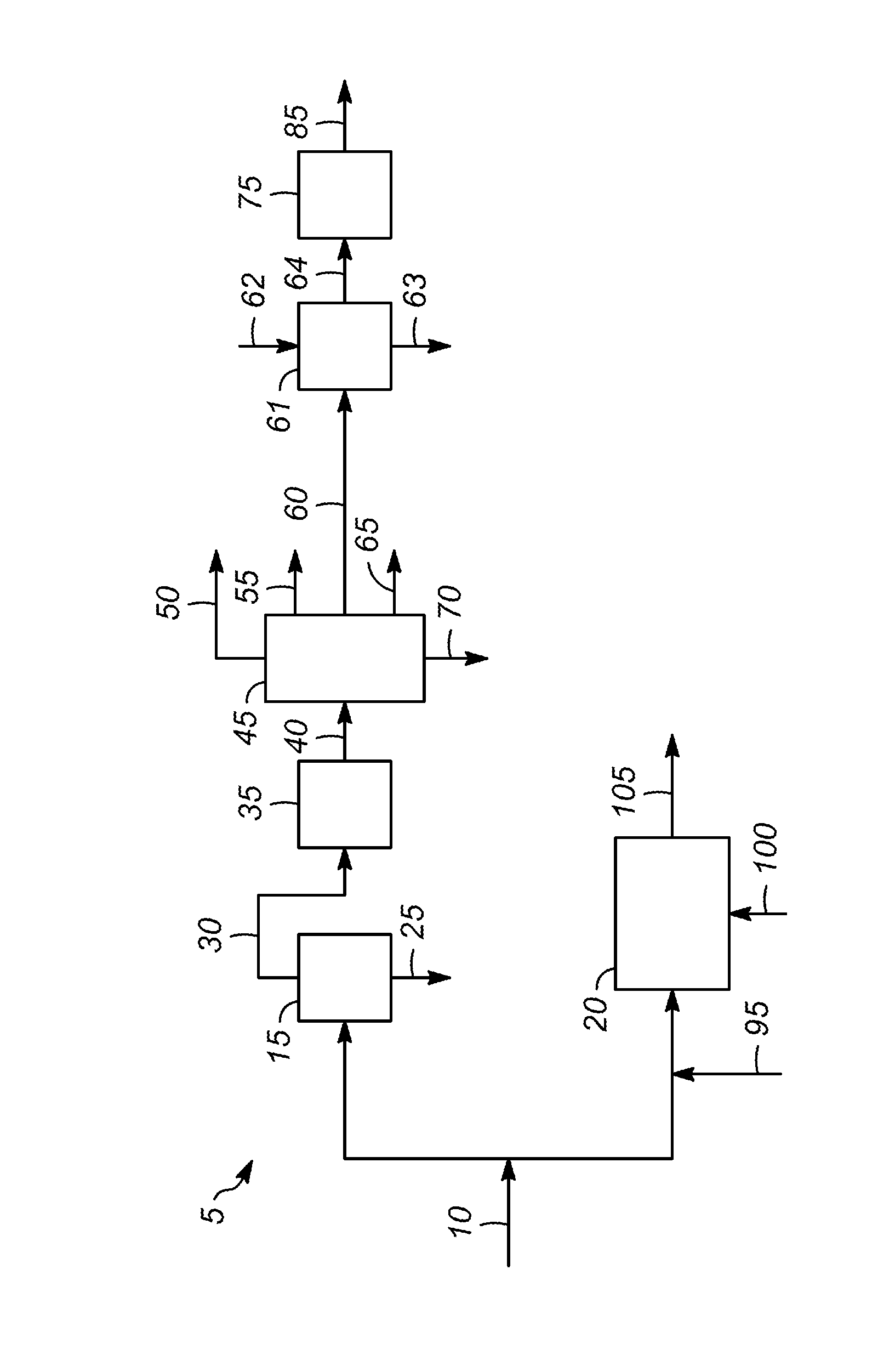

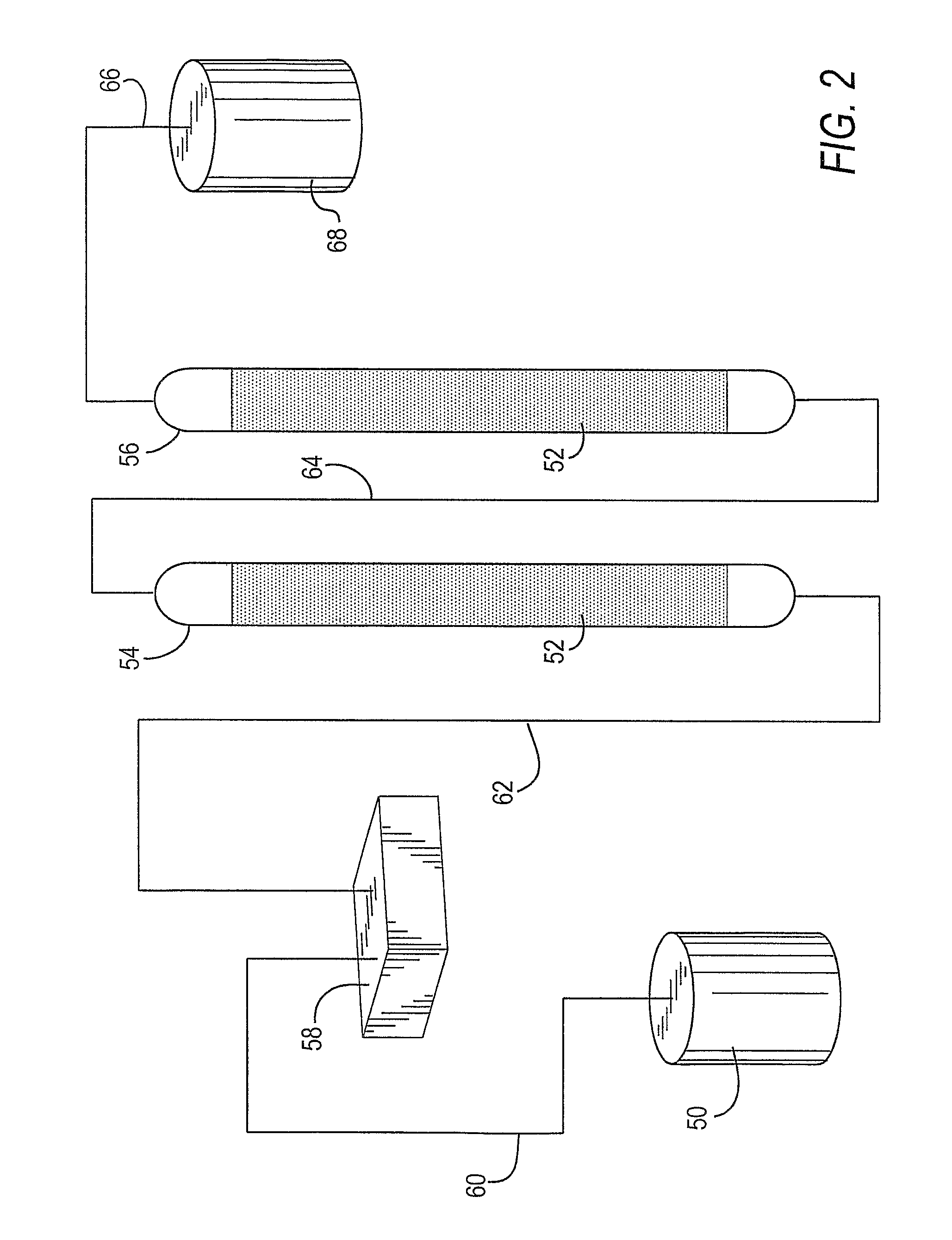

Process and system for recovery of asphaltene by-product in paraffinic froth treatment operations

ActiveUS20100096297A1Improved quality and cleanlinessIncrease heightWorking-up pitch/asphalt/bitumen by selective extractionTreatment with plural serial refining stagesParaffin waxThree stage

A process for treating bitumen froth with paraffinic solvent is provided which uses three stages of separation. Froth and a first solvent are directed to a first stage at a solvent / bitumen ratio for precipitating few or substantially no asphaltenes. A first stage underflow is directed to a second stage and a first stage overflow is directed to a third stage. A second stage underflow is directed to waste tailings and the second stage overflow joins the first stage overflow. A third stage underflow is recovered as an asphaltene by-product and a third stage overflow is recovered as a diluted bitumen product. At least a second solvent is added to one or both of the second or third stages for controlling a fraction of asphaltenes in the third stage underflow. Asphaltene loss to waste tailings is minimized and asphaltenes are now recovered as asphaltene by-product.

Owner:CANADIAN NATURAL RESOURCES

Removal of sulfur compounds from petroleum stream

ActiveUS9005432B2Reduce the amount requiredIncrease gravityThermal non-catalytic crackingMolecular sieve catalystsThiolLow nitrogen

A process for upgrading an oil stream by mixing the oil stream with a water stream and subjecting it to conditions that are at or above the supercritical temperature and pressure of water. The process further includes cooling and a subsequent alkaline extraction step. The resulting thiols and hydrogen sulfide gas can be isolated from the product stream, resulting in an upgraded oil stream that is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the oil stream.

Owner:SAUDI ARABIAN OIL CO

Liquid-liquid extraction apparatus and method

ActiveUS20050045558A1Reduce loss ratePromote recoveryWorking-up pitch/asphalt/bitumen by selective extractionLiquid displacementEngineeringLiquid phase

Method and apparatus for contacting two liquid phases for liquid-liquid extraction in a vertical extraction vessel. A relatively heavier liquid phase, descending the extraction vessel at a relatively low volumetric flow rate, is dispersed into a continuous phase comprising a relatively lighter liquid rising through the extraction vessel at a relatively high flow rate. Sieve trays are provided with adjustable active areas and overlapping manways for personnel access.

Owner:KELLOGG BROWN & ROOT INC

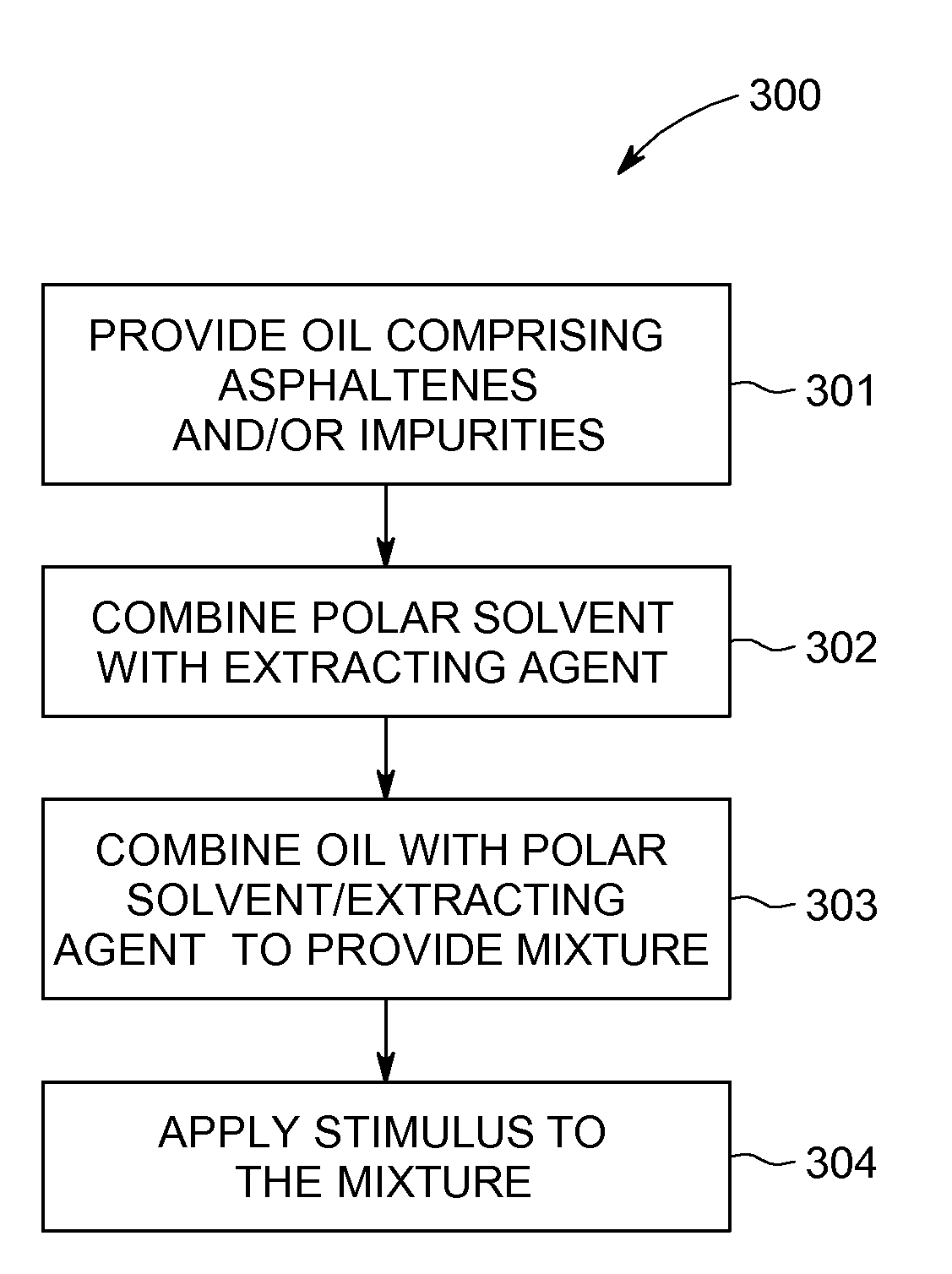

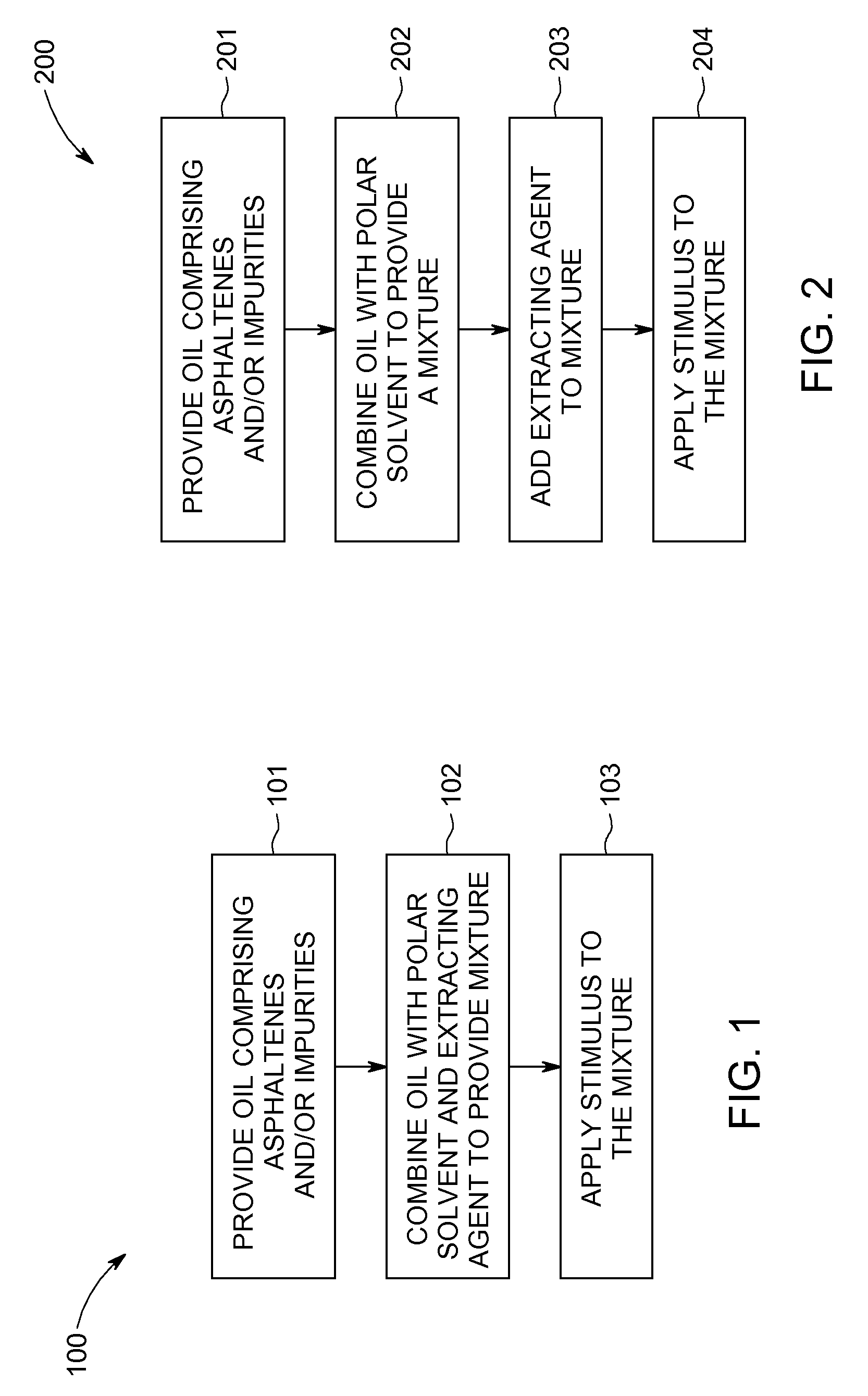

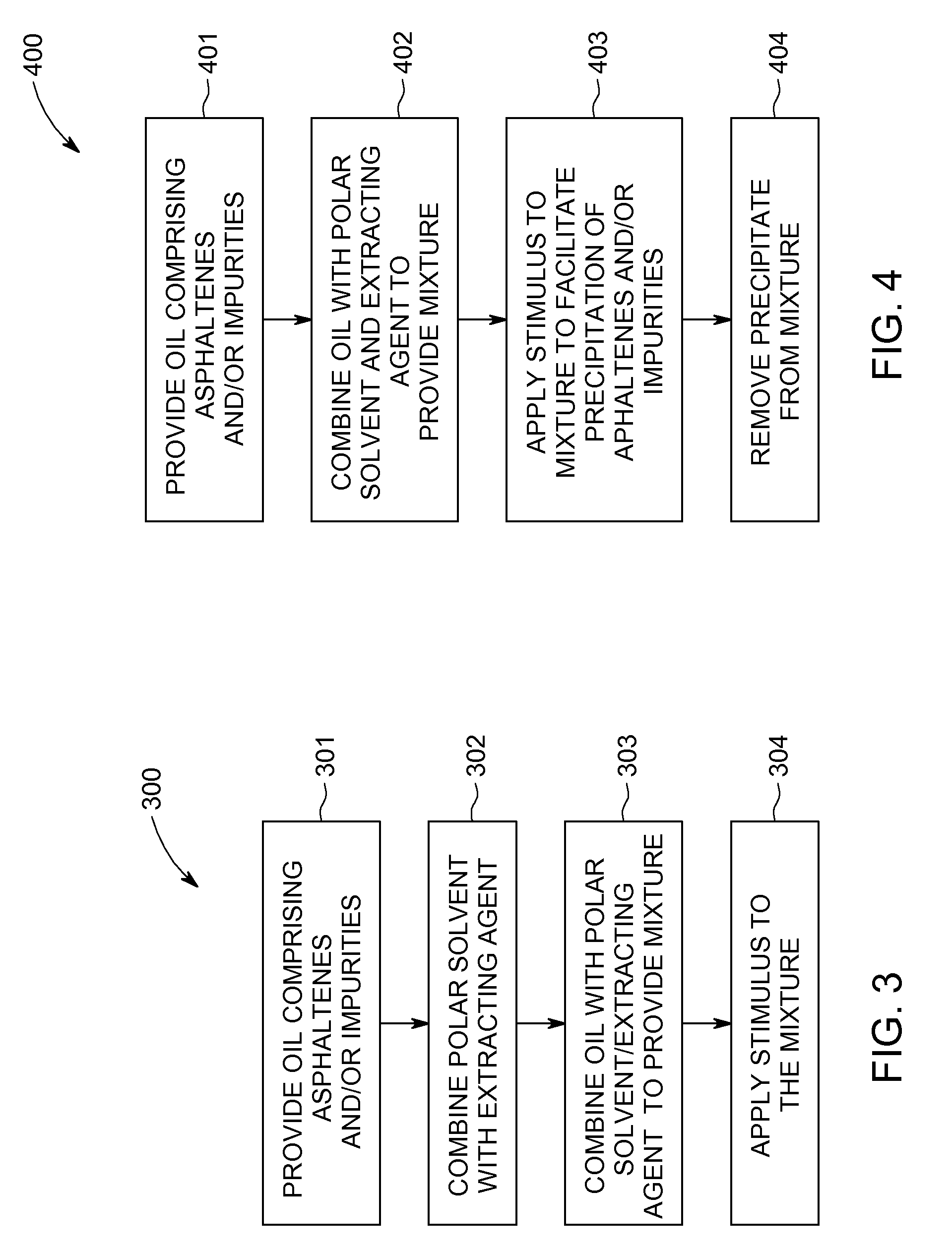

Method for deasphalting and extracting hydrocarbon oils

ActiveUS8658030B2Refining with metalsWorking-up pitch/asphalt/bitumen by selective extractionSolventAsphaltene

Provided herein are processes for deasphalting and extracting a hydrocarbon oil. The processes comprise providing an oil comprising asphaltenes and / or other impurities, combining the oil with a polar solvent an extracting agent to provide a mixture, and applying a stimulus to the mixture so that at least a portion of any asphaltenes and / or impurities in the oil precipitate out of the oil.

Owner:GENERAL ELECTRIC CO

Method and system for reclaiming waste hydrocarbon from tailings using solvent sequencing

InactiveUS8454821B2Working-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionParaffin waxEmulsion

Owner:EXXONMOBIL UPSTREAM RES CO

Demetalization method of oil products

InactiveCN101381620ANo emissionsHigh demetallization rateRefining with two or more solventsTO-18Ultrasound - action

The invention discloses a demetallization method for oil products. The method comprises the following steps: 1) the weighed oil products are pre-heated up to the temperature of between 50 and 70 DEG C so as to ensure that the oil products are in flowing state; 2) a demetallization agent and water are added in the oil products, completely mixed and subjected to ultrasonic wave action for 10 to 18 minutes; and 3) the mixed liquid after the ultrasonic treatment is kept stand at a temperature of between 60 and 90 DEG C for one hour, and is subjected to oil-water separation. In the method, the demetallization agent is added in the oil products for the demetallization reaction, and the ultrasonic wave action is used to strengthen the demetallization reaction, the metalloporphyrin and the non-porphyrin oil soluble compositions in the oil products are converted into hydrophilic compositions which are subjected to the oil-water separation, so that metal in the oil products is removed. The method can effectively remove the metal in the oil products without rigorous reaction conditions such as high temperature, high pressure and the like, so that the method has the advantages of mild operating condition, low investment and operational cost, low energy consumption, no pollutant emission, simple process, easy operation, high metal removing ratio and obvious metal removing effect.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Incoherence or weak caking coal deep processing method

InactiveCN101538473ASave investment in environmental protectionReduce processing costsTreatment with hydrotreatment processesSpecial form destructive distillationWater vaporCarbonization

The invention discloses an incoherence or weak caking coal deep processing method. Firstly, coking coal is fed into a carbonization reactor to carry out carbonization reaction, thus generating coal gas, carbocoal and coal tar; hydrogen in the coal gas is extracted out by pressure swing absorption; the carbocoal is fed into a coal gas generator and reacts with oxygen and water vapour to generate synthesis gas and coal ash; or the carbocoal is fed into a circulating fluid bed boiler to carry out generating; the coal tar enters a normal pressure fractionating tower to obtain creosoted oil, oil at the top of the tower and heavy oil at the bottom of the tower; wherein the creosoted oil is extracted to obtain crude phenol product and dephenolized oil, the dephenolized oil and heavy oil at the bottom of the tower enter a delayed coking device to carry out thermal cracking reaction. Through the optimization design of the flow, the invention realizes the deep processing of incoherence or weak caking coal such as ignite, long flame coal, gas coal and the like, and effectively improves the utilization factor of the materials.

Owner:胜帮科技股份有限公司

Process for removing a contaminant from coal tar

InactiveUS20150136660A1Lower Level RequirementsRefining with metalsTreatment with plural serial stages onlyPolycyclic aromatic hydrocarbonSorbent

A process for removing at least one contaminant from coal tar is described. The process involves extraction with an extraction agent or adsorption with an adsorbent. The extraction agent includes at least one of amphiphilic block copolymers, inclusion complexes of poly(methyl methacrylate) and polycyclic aromatic hydrocarbons, cyclodextrins, functionalized cyclodextrins, and cyclodextrin-functionalized polymers, and the adsorbent includes exfoliated graphite oxide, thermally exfoliated graphite oxide or intercalated graphite compounds.

Owner:UOP LLC

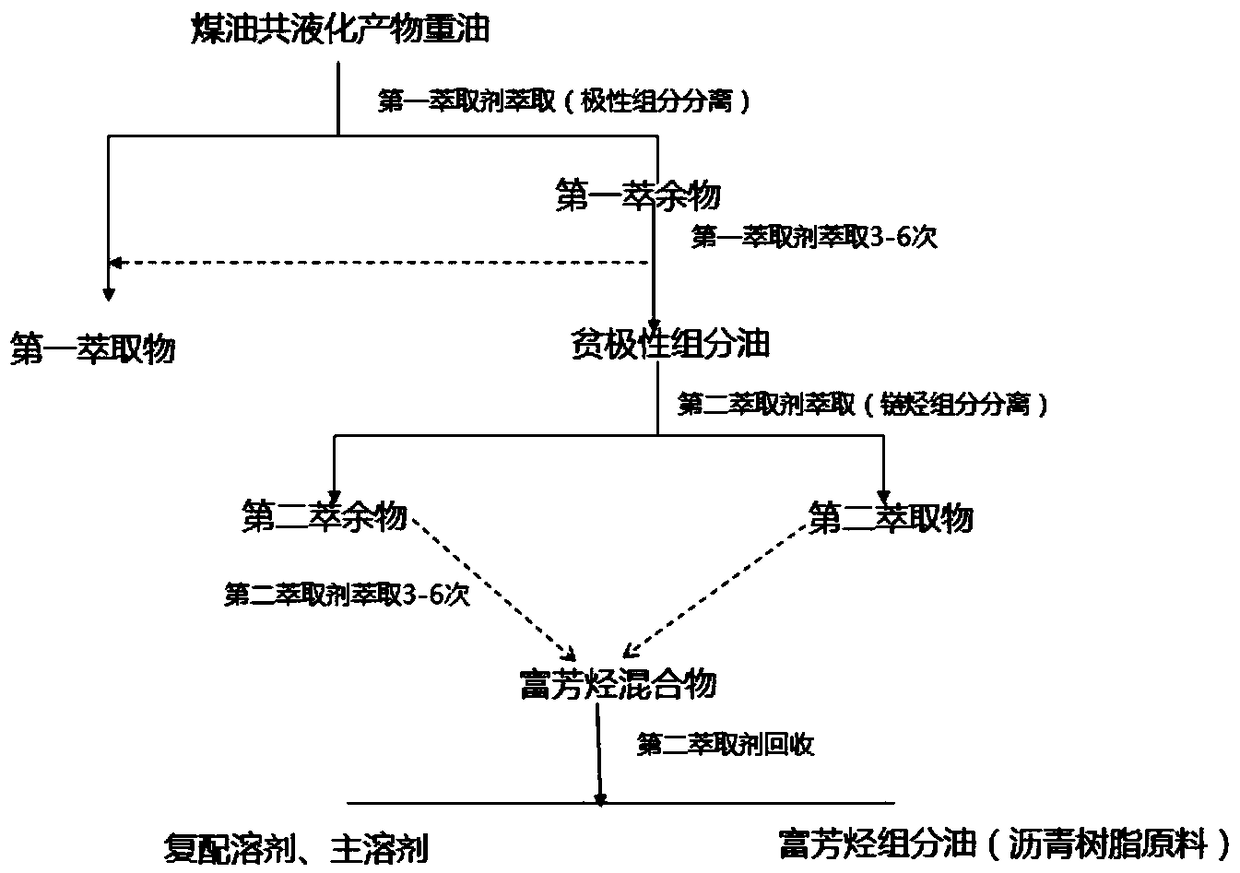

Method for preparing raw material for asphalt resin by using kerosene co-liquefaction product heavy oil

The invention relates to a method for preparing a raw material for asphalt resin by using kerosene co-liquefaction product heavy oil. The method comprises the steps of firstly separating a polar component in a the heavy oil with a first extracting agent to obtain a poor polarity component oil; separating a non-aromatic component in the poor polarity component oil with a second extracting agent toobtain an aromatic-rich mixture, and recycling the second extracting agent in the obtained mixture to obtain a remaining material aromatic-rich component oil, namely, the raw material for preparing the asphalt resin. According to the method provided by the invention, the aromatic component with higher purity is obtained by removing the polar component and chain hydrocarbon component in the kerosene co-liquefaction product oil. The separation method provided by the invention is simple to operate and high in separation efficiency; furthermore, the needed extracting agents are wide in source, better in heat stability and low in price and toxicity, so that the method is suitable for large-scale application.

Owner:SHAANXI YANCHANG PETROLEUM GRP

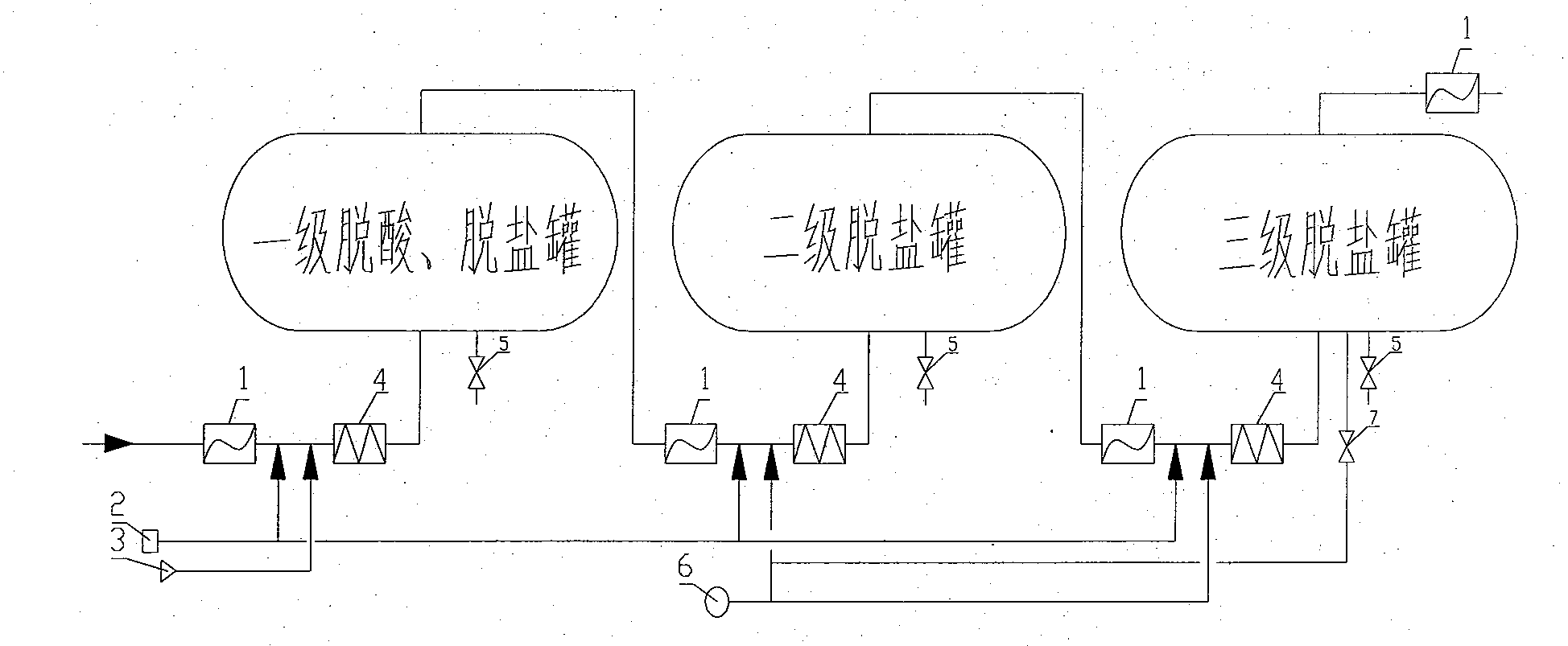

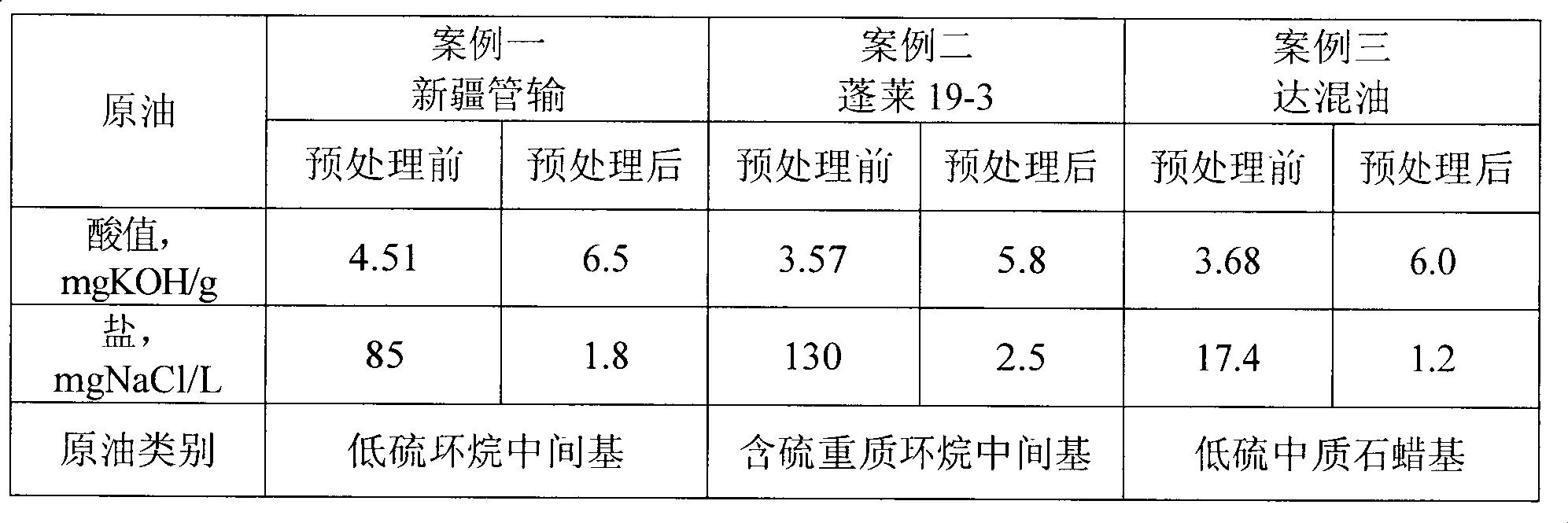

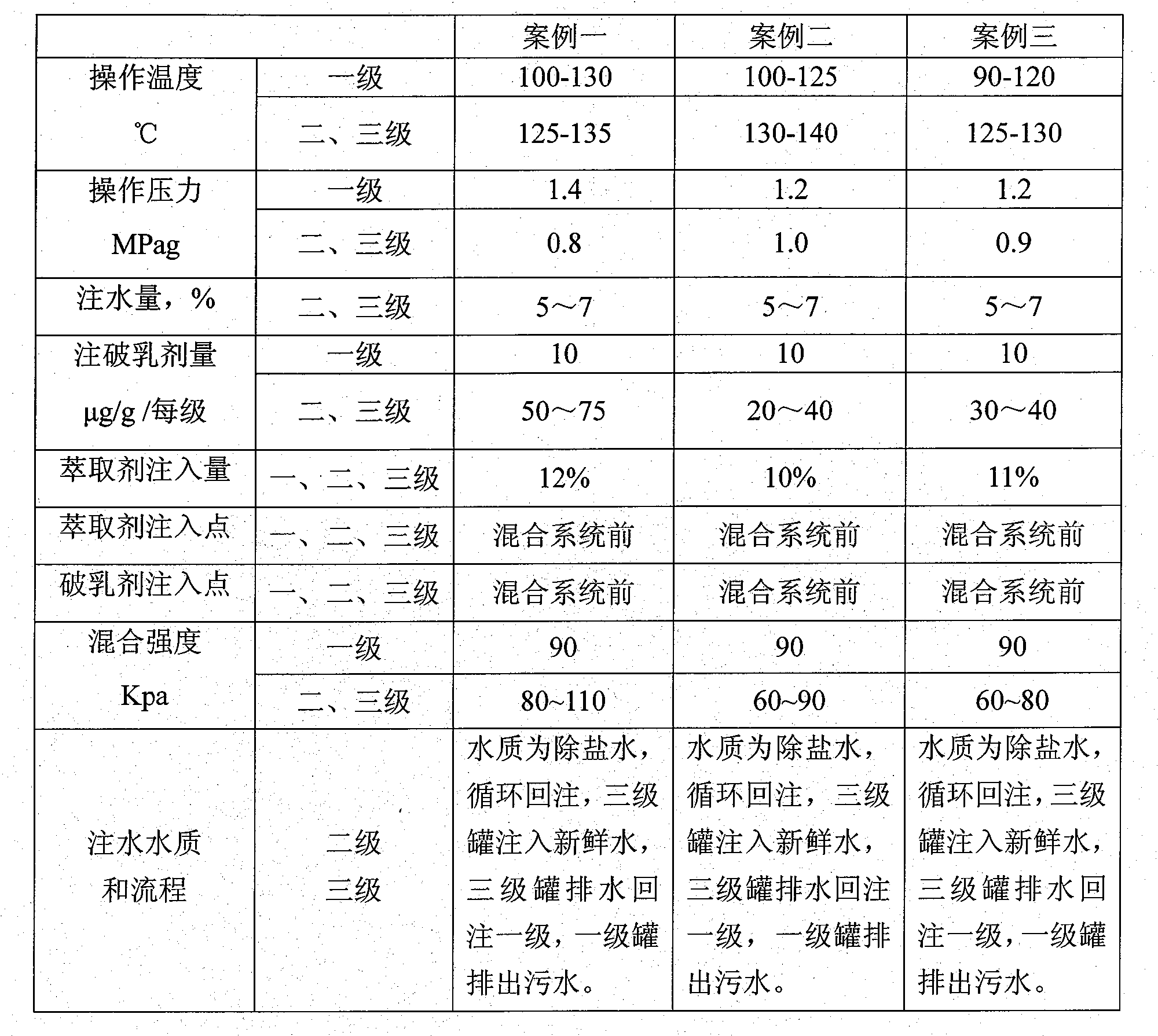

Pre-treatment process method of high acid crude oil

ActiveCN103805227AAvoid corrosionSimple processDewatering/demulsification with electric/magnetic meansRefining with two or more solventsDemulsifierDesalination

The invention relates to a pre-treatment process method of high acid crude oil. The method comprises the following steps that high acid crude oil is treated by coupling deacidification and electro-desalting processes by combining chemical extraction and electro-desalting; a first level tank is taken as a deacidification and electro-desalting tank; a demulsifier and an extractant are injected before a crude oil electro-desalting static mixer; after being fully mixing with crude oil, the mixture enters into the first level desalting tank; generated naphthenate and salt-containing sewage in the crude oil are dissolved in the extractant; treated deacidified oil enters into second and third level desalting tanks after being mixed with the demulsifier and water through the static mixer for desalination and dehydration; treated crude oil enters into a subsequent heat exchange unit; after a period time of operation of an electro-desalting system, impurities such as mud in raw material oil are flushed by a non-stop back purge device to discharge mud-containing sewage out of the tank; an extract phase is acidified to separate out naphthenic acid which is further extracted and purified by light dydrocarbon, and the extractant is purified and recovered and recycled.

Owner:长江三星能源科技股份有限公司

Reactive extraction of sulfur compounds from hydrocarbon streams

Owner:SAUDI ARABIAN OIL CO

Extraction of oxygenates from a hydrocarbon stream

ActiveUS20060258894A1Promote recoveryHydrocarbonsExtraction purification/separationOrganic solventOxygenate

This invention relates to a commercially viable process for extracting oxygenates from a hydrocarbon stream, typically a fraction of the condensation product of a Fischer-Tropsch reaction, while preserving the olefin content of the condensation product. The oxygenate extraction process is a liquid-liquid extraction process that takes place in an extraction column using a polar organic solvent, such as methanol, and water as the solvent, wherein the polar organic solvent and water are added separately to the extraction column.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

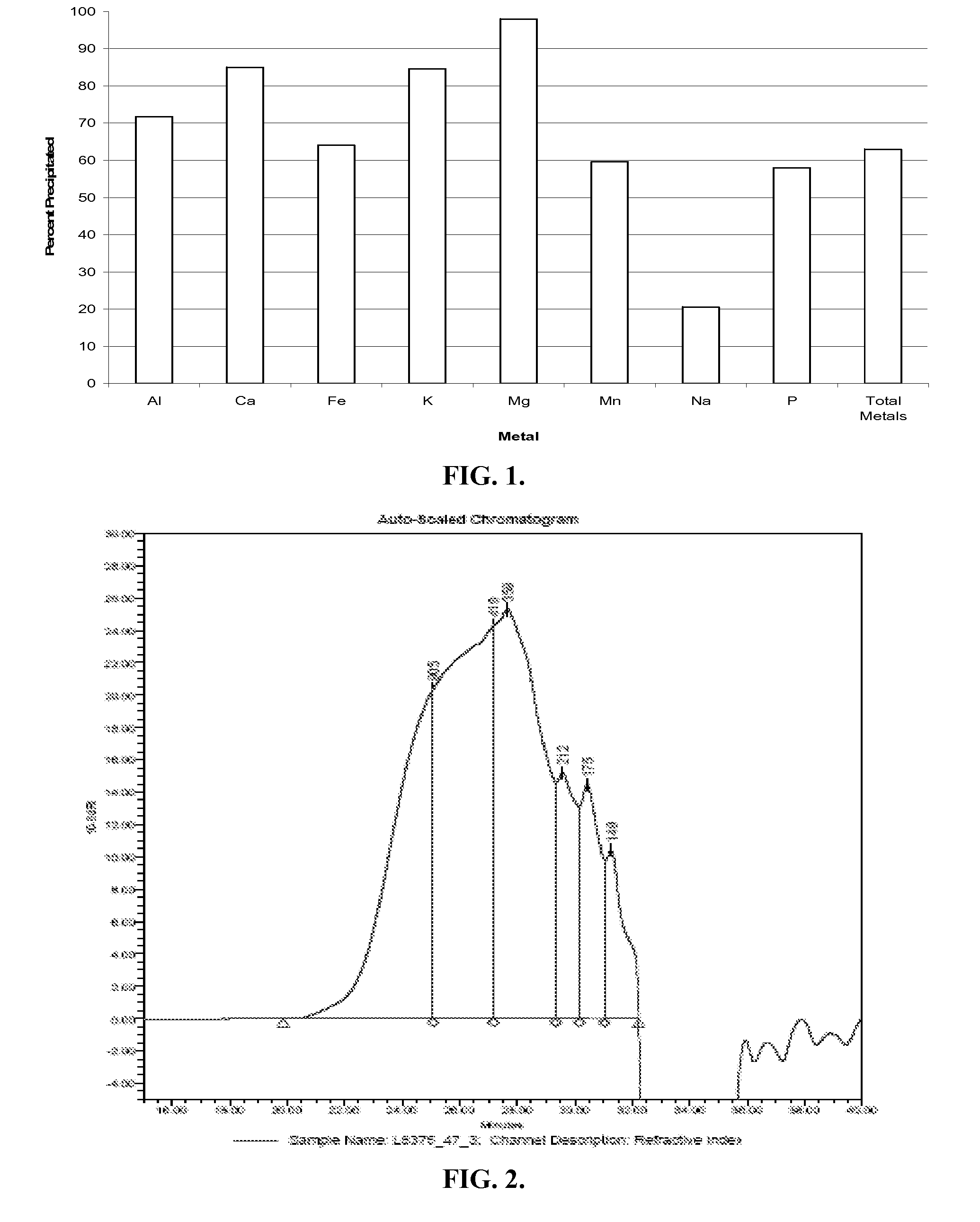

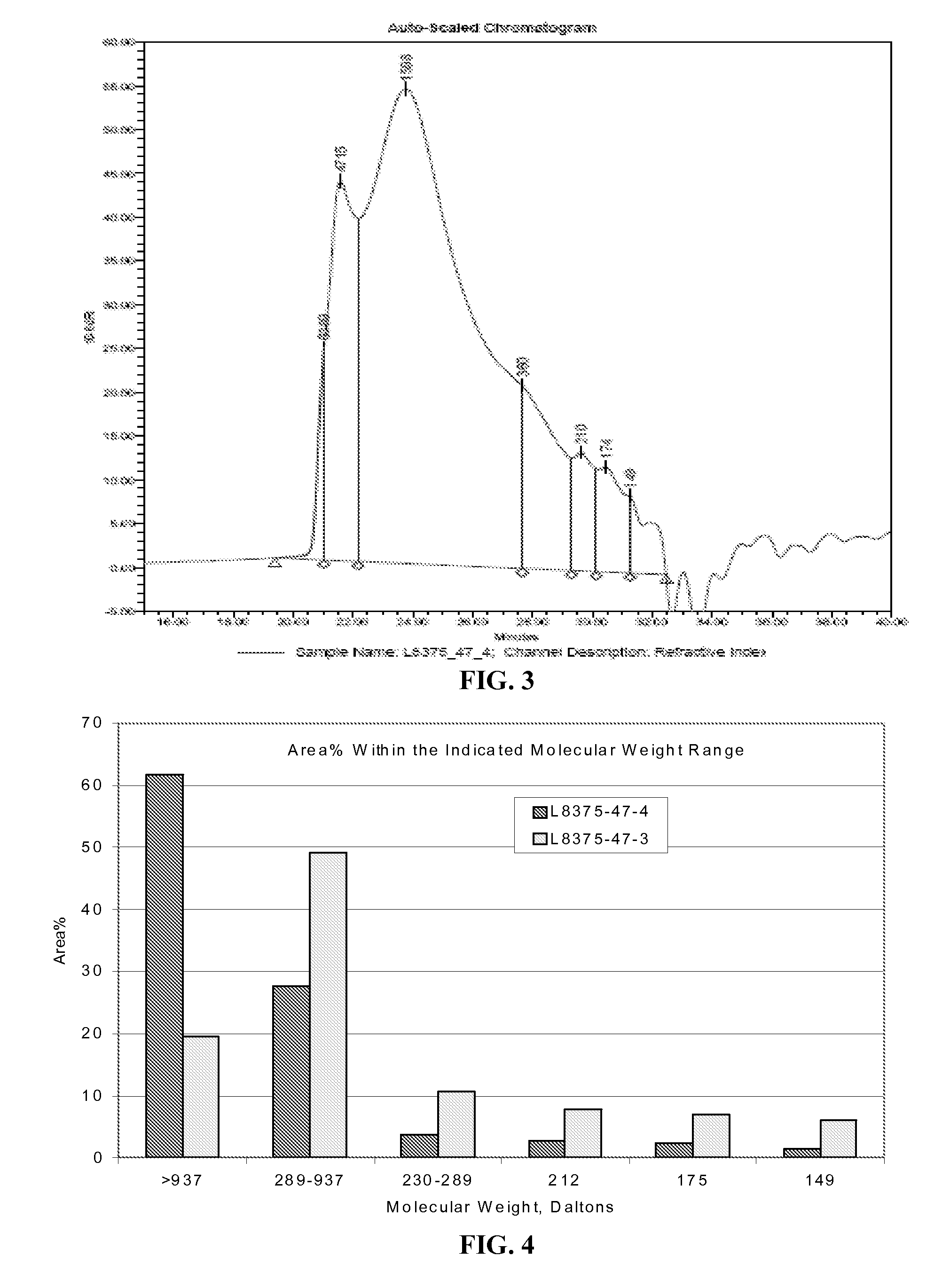

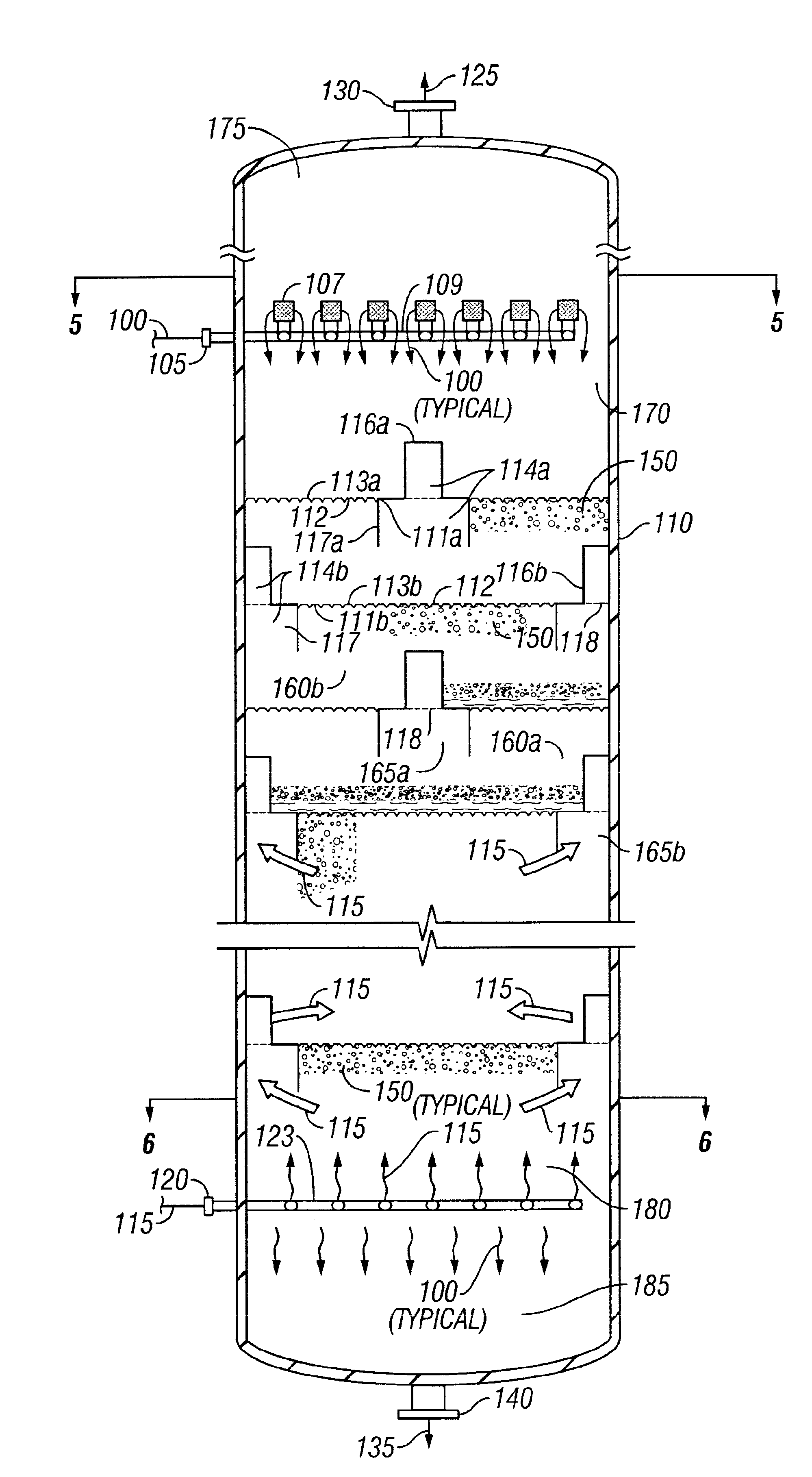

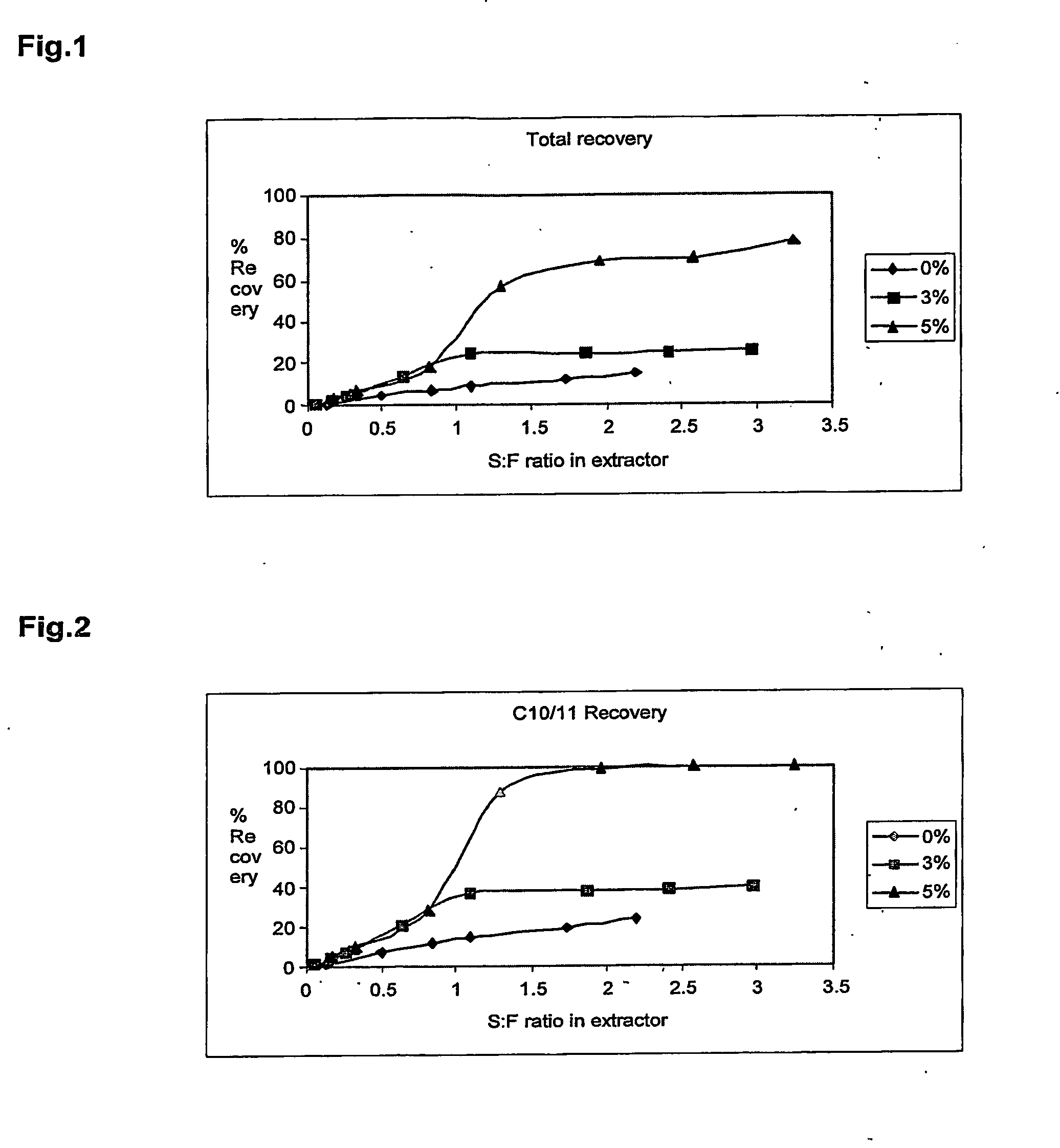

Extraction of aromatics from hydrocarbon oil using n-methyl 2-pyrrolidone and co-solvent

InactiveUS20100243533A1High yieldFlexibility in extractionRefining with two or more solvents2-PyrrolidoneRefractive index

The present invention provides a process for extraction of aromatic material from hydrocarbon oil by using a solvent mixture comprising N-Methyl-2-Pyrrolidone (NMP), at least one co-solvent and optionally water, to obtain a raffinate. The process of the present invention lowers operating cost as the cost of the co-solvent employed is lower than that of neat NMP. Another feature of the present invention is that it produces the same quality raffinate as those of neat NMP-water measured by the refractive index but produces higher yield of raffinate at same feed to solvent mixture ratio.

Owner:INDIAN OIL CORPORATION

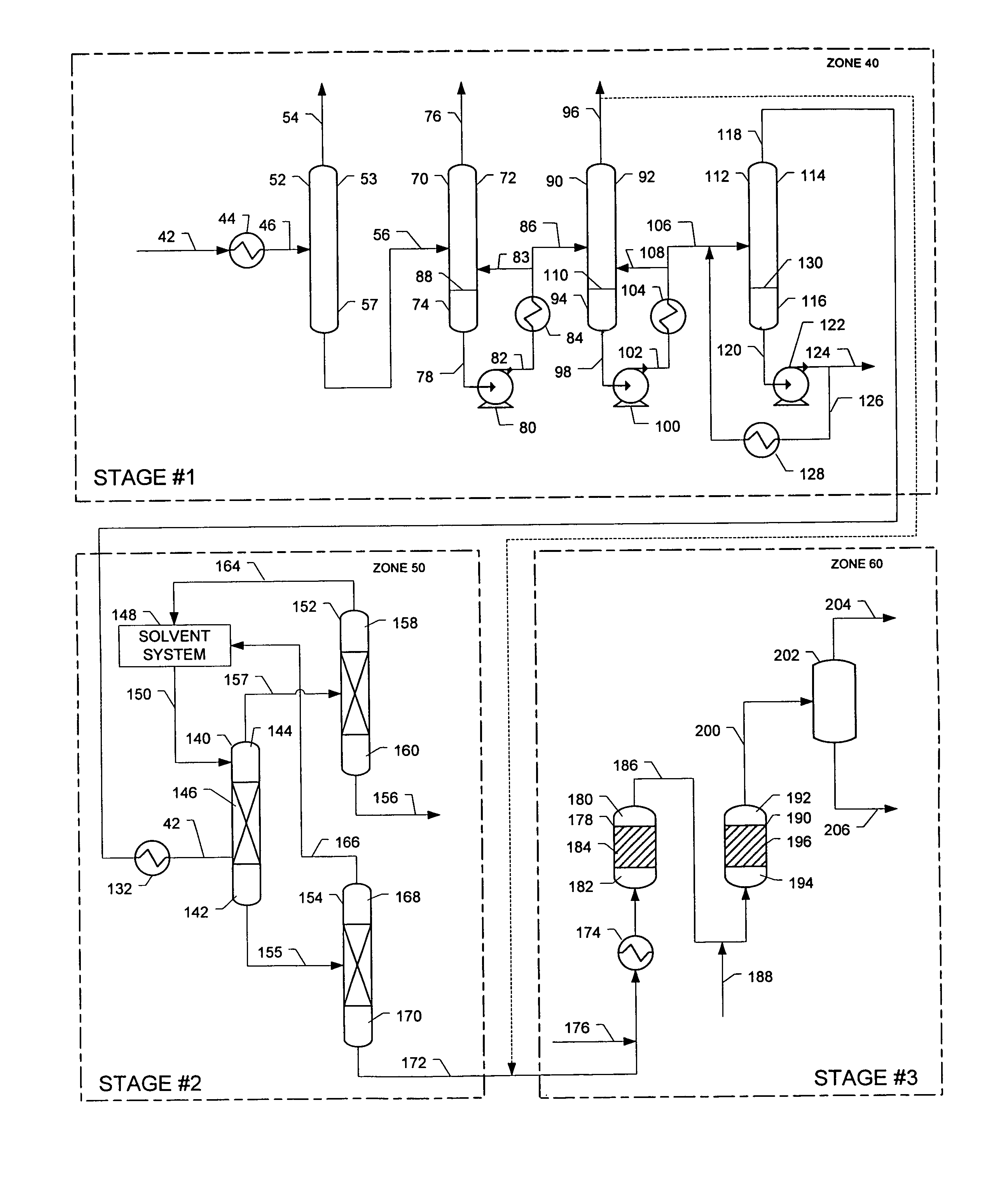

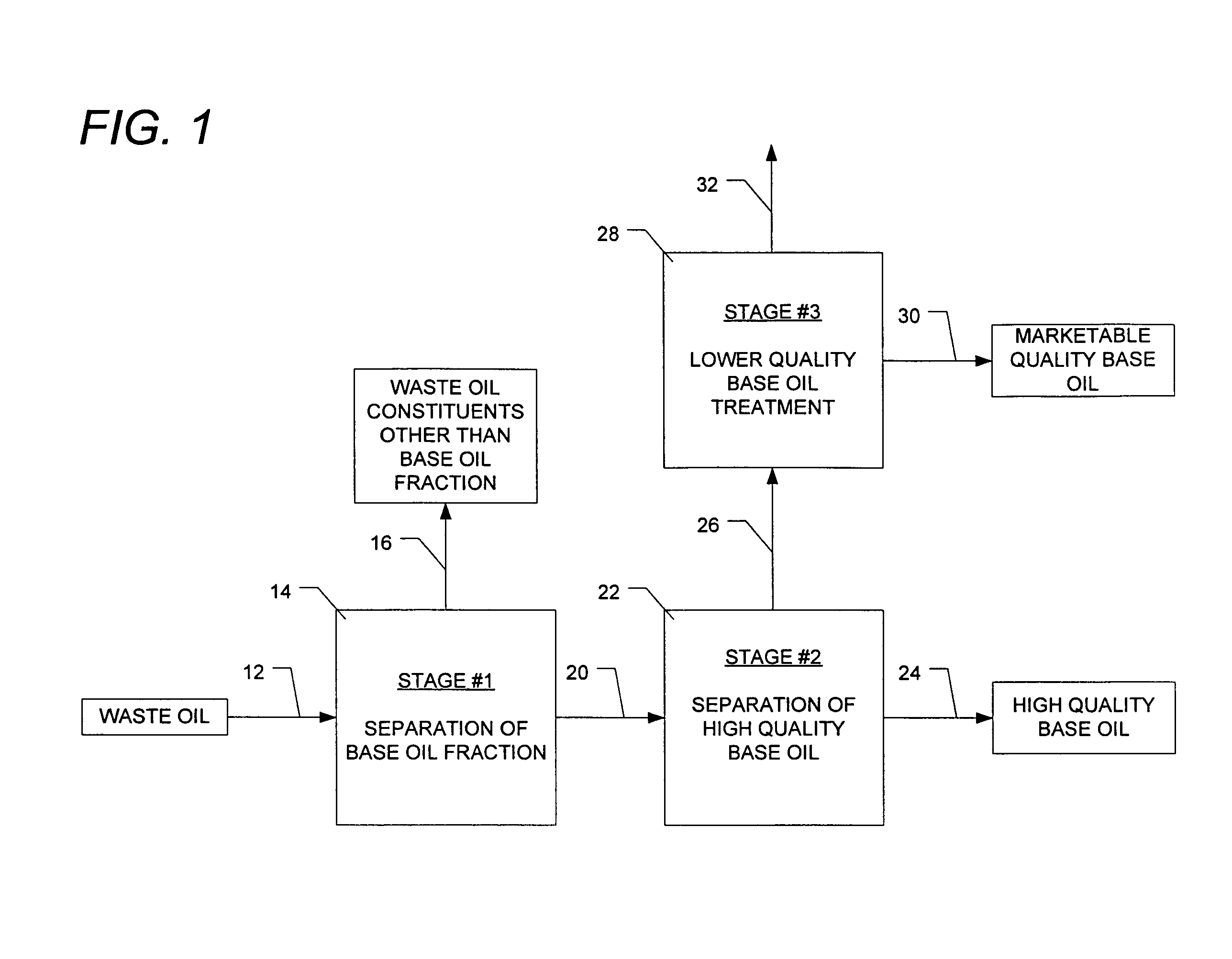

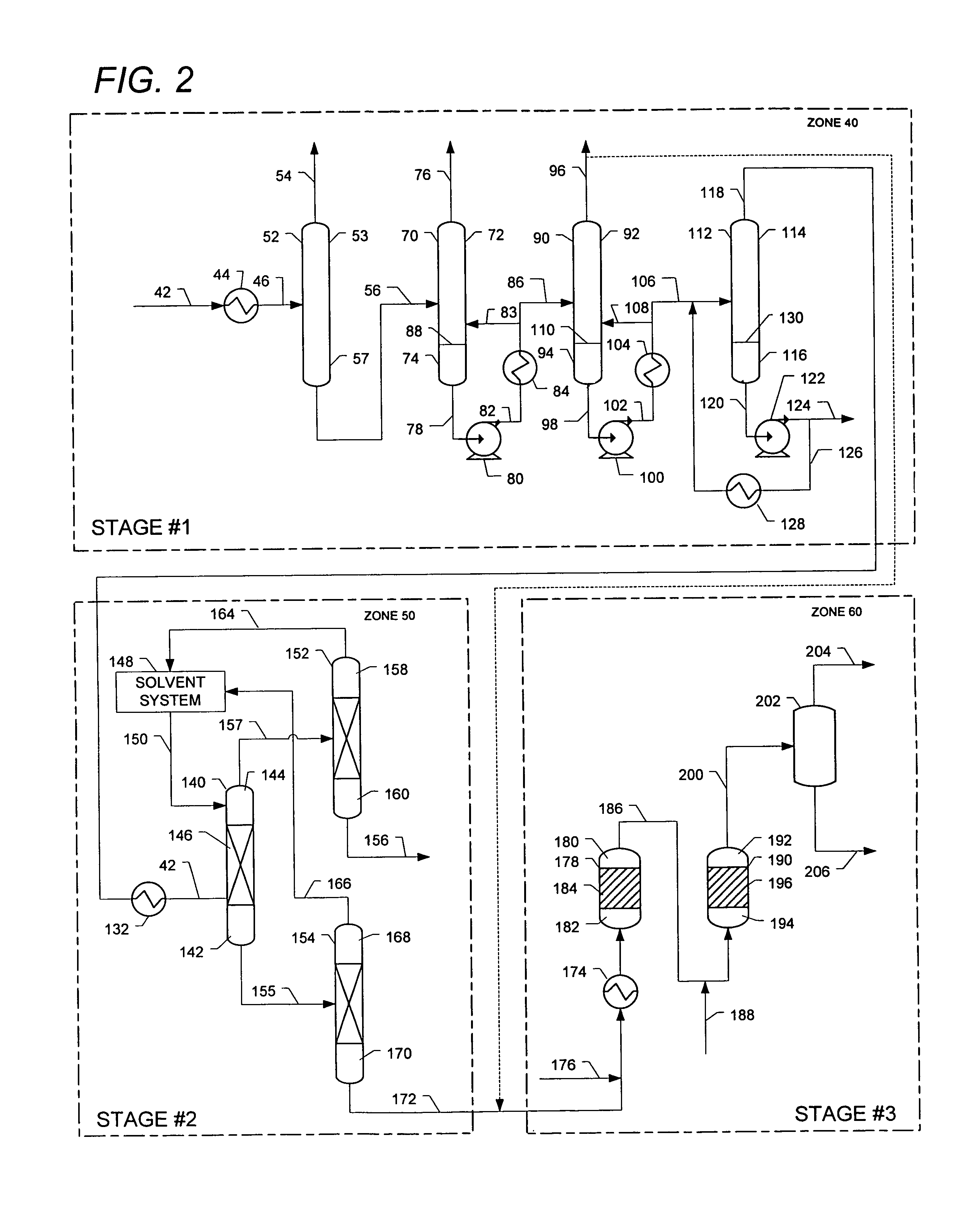

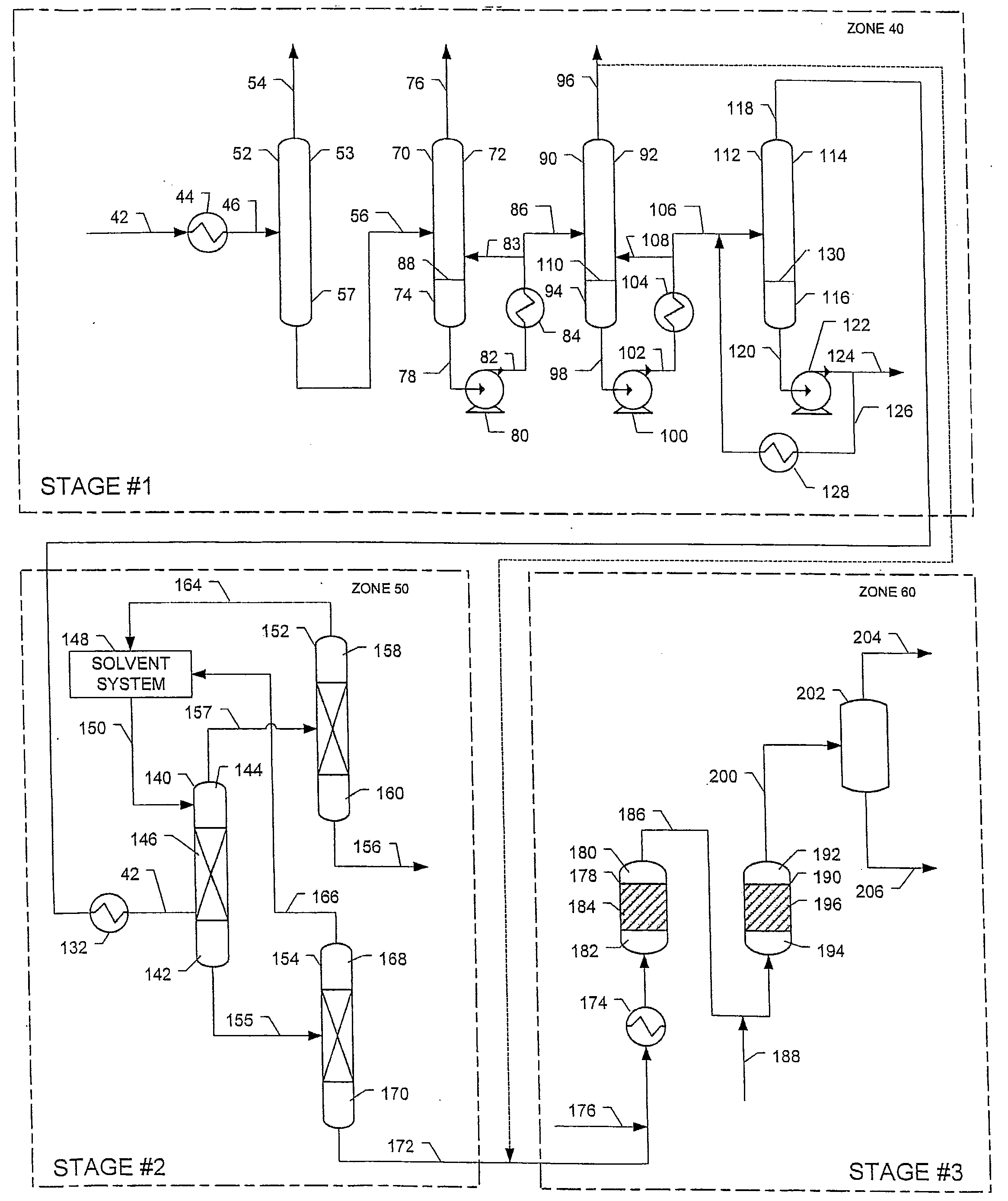

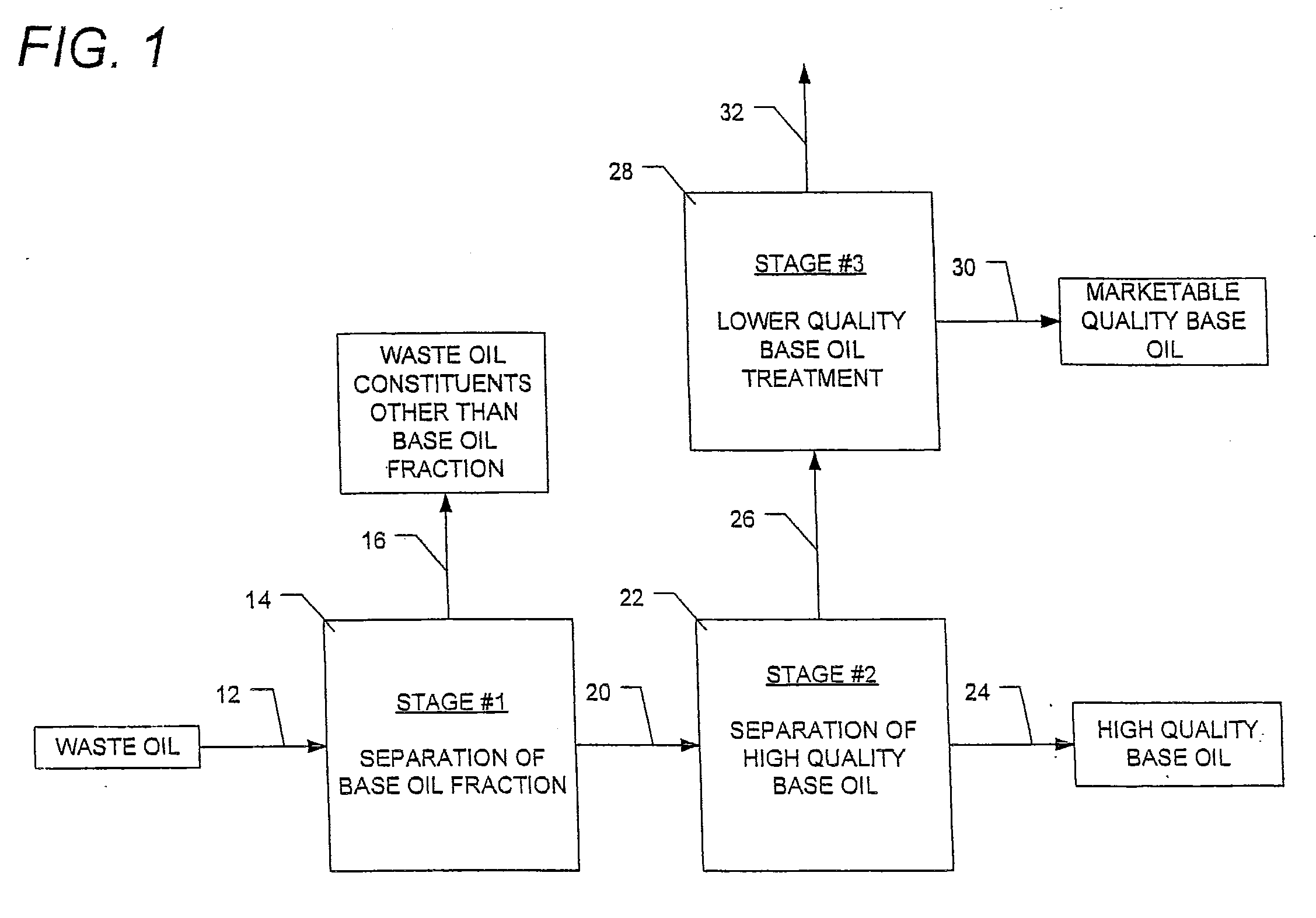

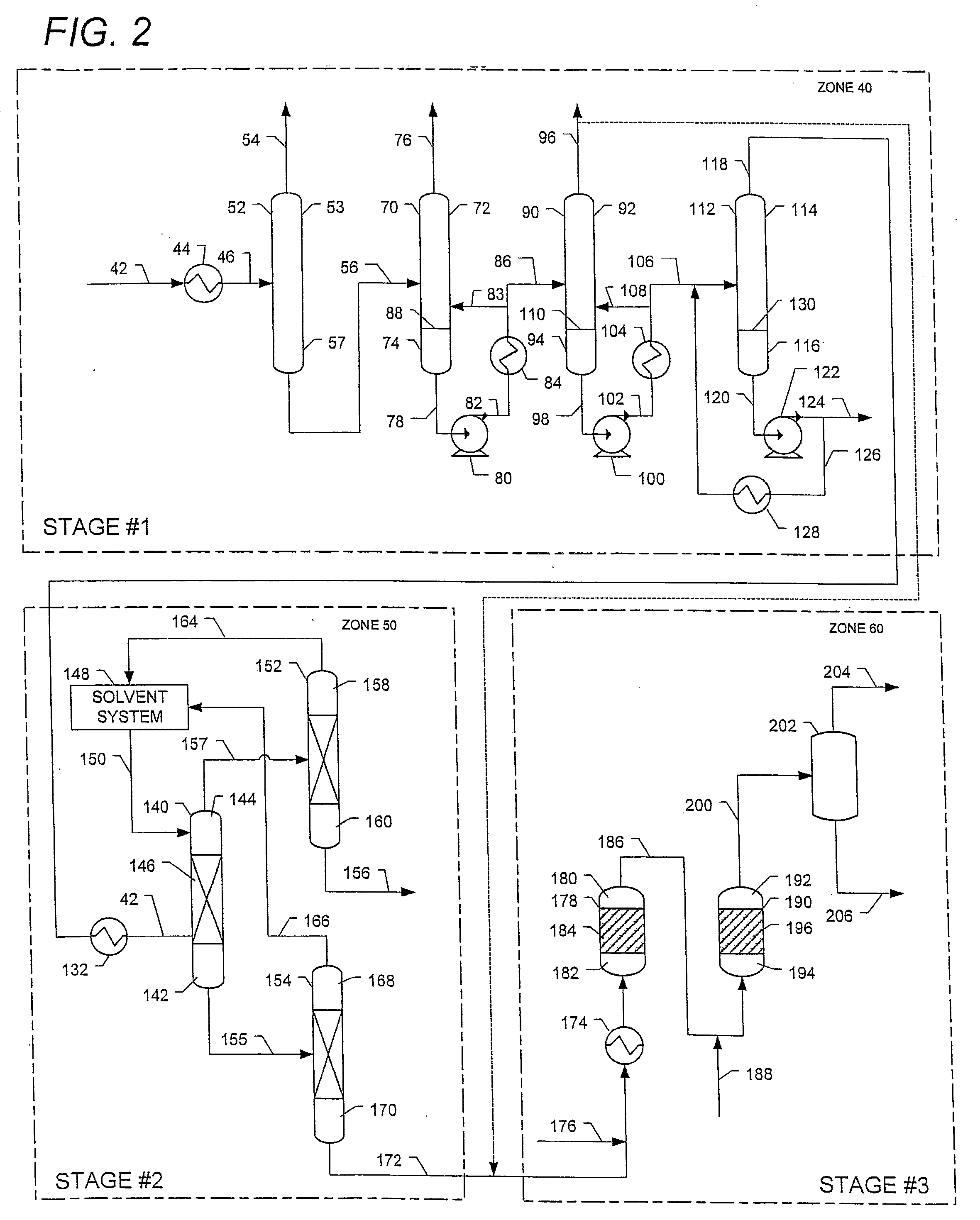

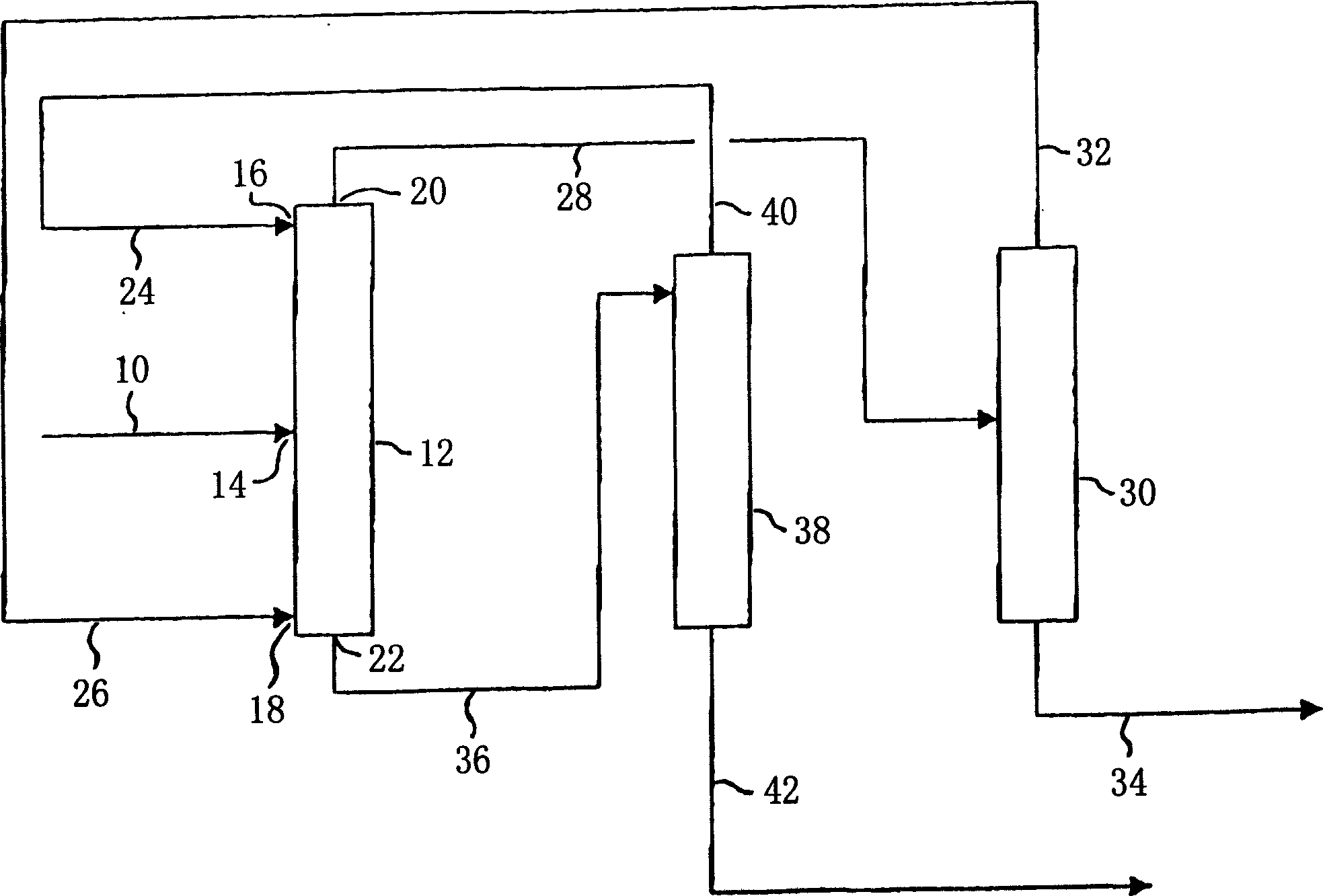

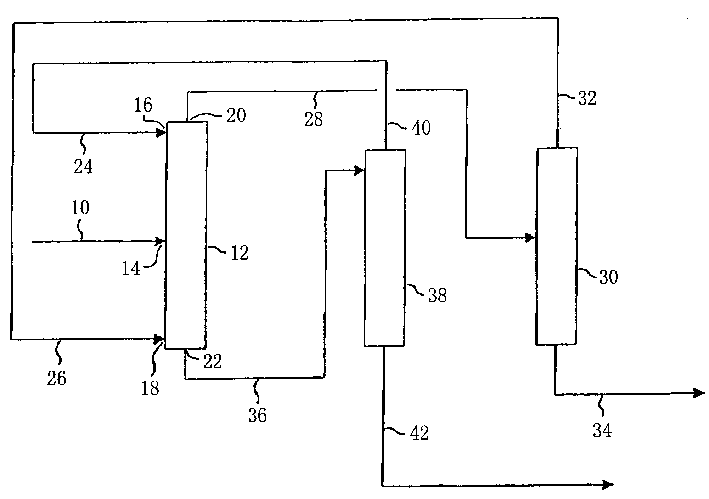

Method for producing base lubricating oil from waste oil

ActiveUS8366912B1Efficient productionQuality improvementThermal non-catalytic crackingHydrocarbon distillation control/regulationWaste oilProduct base

A method for recovering base oil from waste lubricating oil by separating base oil range constituents from a waste lubricating oil mixture, thereafter separating higher quality base oil constituents and lower quality base oil constituents from the base oil recovered from the waste lubricating oil mixture and thereafter treating the lower quality base oil constituents to produce marketable base oil. The total base oil produced from a waste lubricating oil mixture by this process is greater than the quantity producible by previous processes using only base oil separation from the waste lubricating oil mixture or processes which use only treatment of the base oil recovered from the waste lubricating oil mixture to produce the product base oil.

Owner:GEN III OIL CORPORATION

Method for producing base lubricating oil from waste oil

InactiveUS20090223862A1Efficient productionQuality improvementThermal non-catalytic crackingHydrocarbon distillation control/regulationProduct baseWaste oil

A method for recovering base oil from waste lubricating oil by separating base oil range constituents from a waste lubricating oil mixture, thereafter separating higher quality base oil constituents and lower quality base oil constituents from the base oil recovered from the waste lubricating oil mixture and thereafter treating the lower quality base oil constituents to produce marketable base oil. The total base oil produced from a waste lubricating oil mixture by this process is greater than the quantity producible by previous processes using only base oil separation from the waste lubricating oil mixture or processes which use only treatment of the base oil recovered from the waste lubricating oil mixture to produce the product base oil.

Owner:VEROLUBE

Separation of oxygenates from a hydrocarbon stream

InactiveCN1468292ATreatment with plural serial refining stagesRefining with two or more solventsAlkaneAlcohol

This invention relates to a method for separating olefins and paraffins from oxygenates in a liquid hydrocarbon stream containing a high proportion of olefins, paraffins and oxygenates (mainly alcohols). Typically, the hydrocarbon stream is obtained from a Fischer-Tropsch process. The organic counter-solvent has a boiling point which is less than the boiling point of the most volatile alcohol in the hydrocarbon stream. A raffinate from the liquid-liquid extractor is passed to a distillation column. A bottoms product from the distillation column comprises olefins and paraffins, and the overhead product comprising solvents is recycled. An extract from the liquid-liquid extractor is sent to a stripping column, where a bottoms product containing pure alcohol is obtained. The overhead product containing counter-solvent is recycled.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

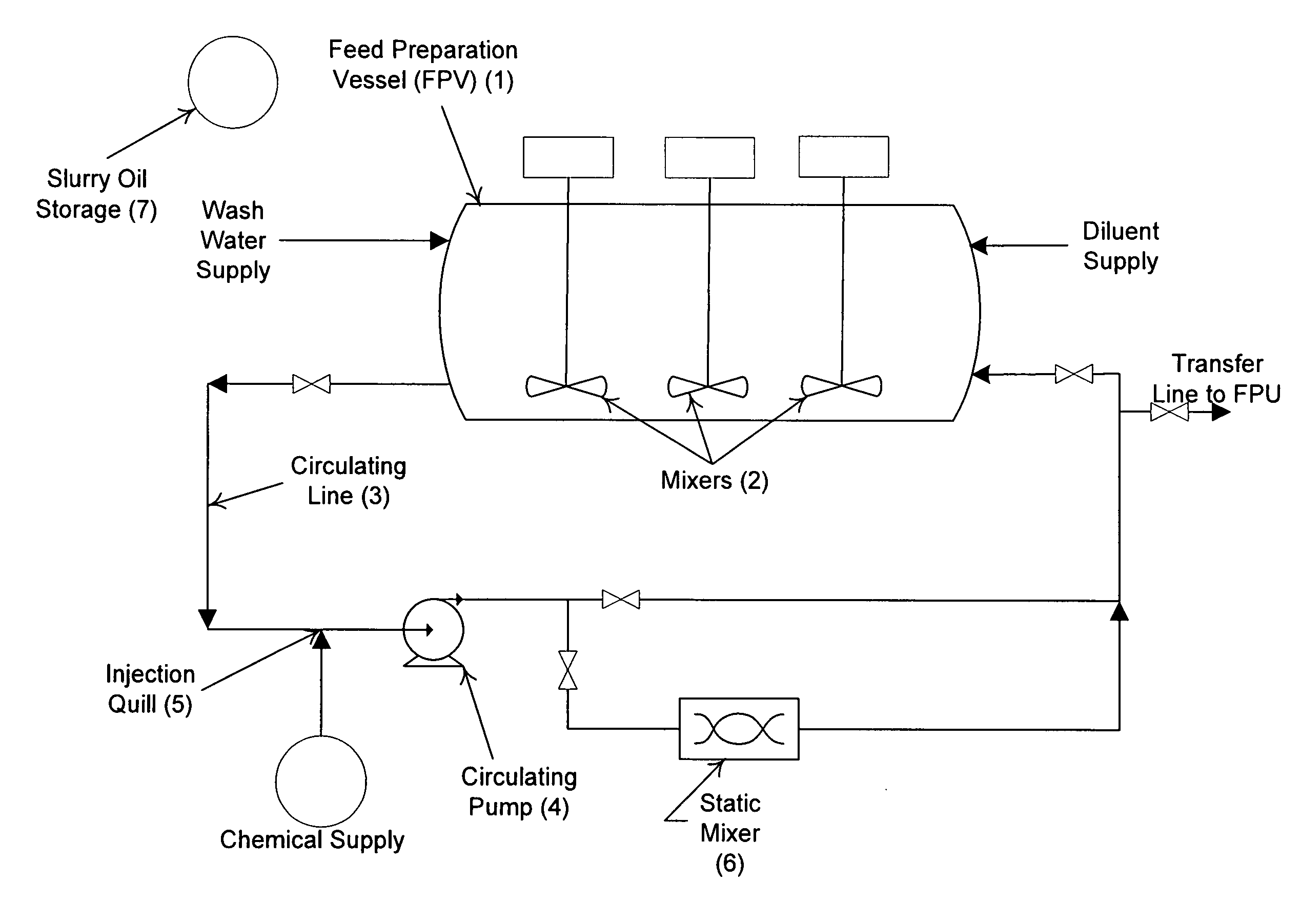

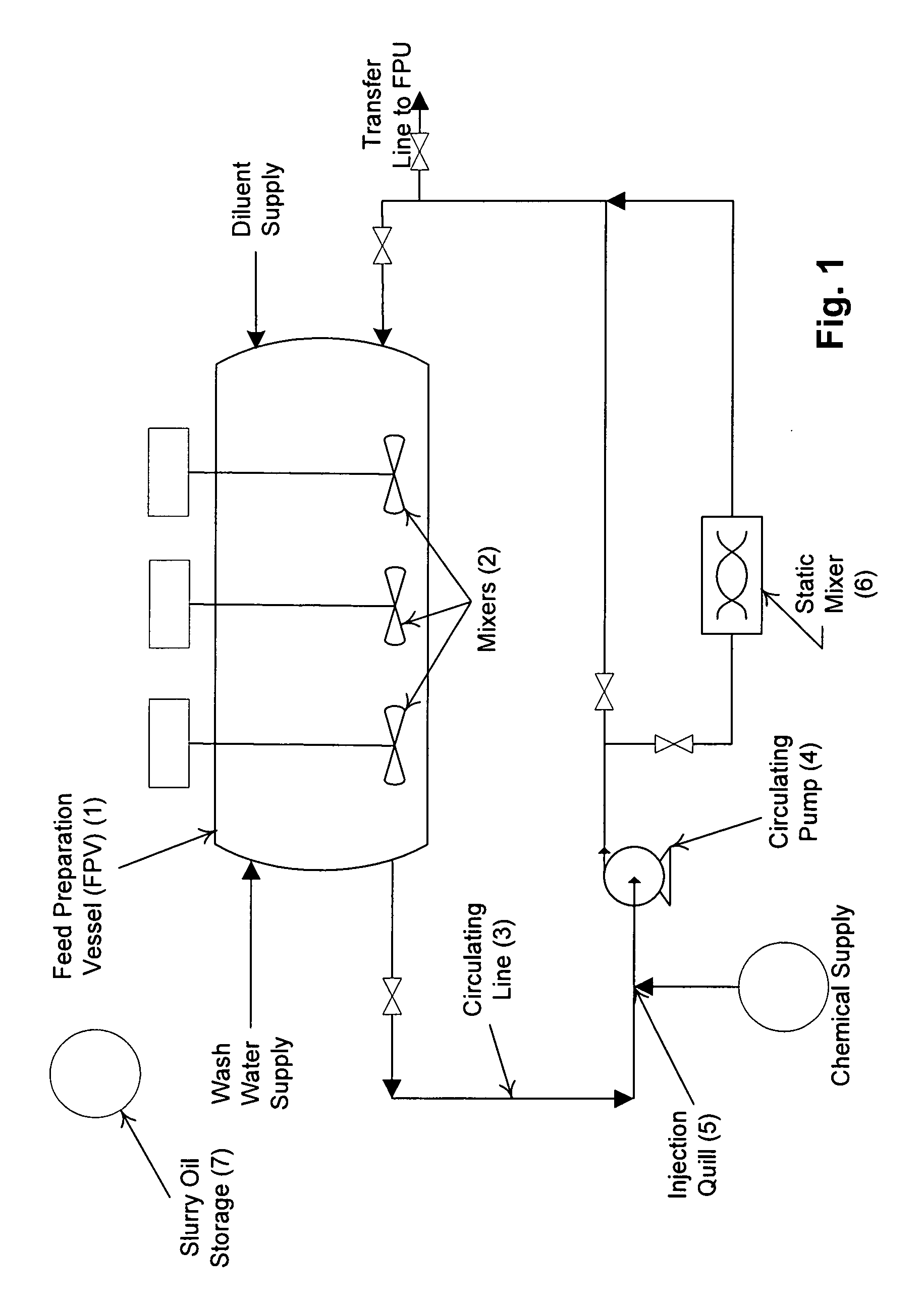

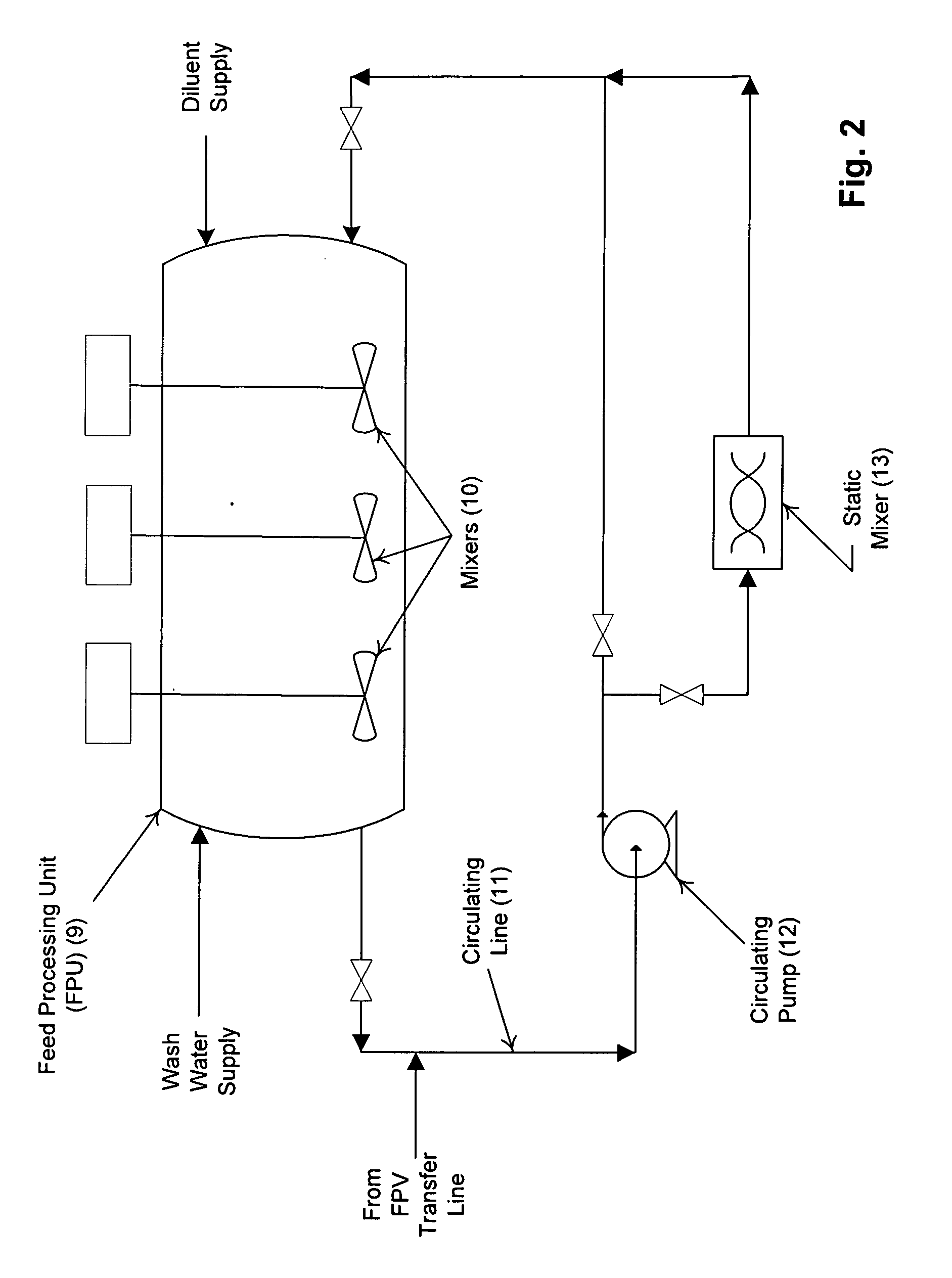

FCC-CFE CAT FINE EXTRACTION: METHOD AND SYSTEM FOR EXTRACTING CATALYST FINES FROM SLURRY OIL CAT FINE BOTTOMS (SOCFBs) INTO AN AQUEOUS LAYER

A method for separating hydrocarbons from Slurry Oil Cat' Fine Bottoms (SOCFBs) comprising the steps of removing SOCFBs from a slurry oil storage tank and combining the SOCFBs with diluent and water in a Feed Preparation Vessel (FPV) and transferring the SOCFB and water emulsion to a Feed Processing Unit (FPU) in which the SCDM settles into a hydrocarbon layer, an emulsion layer and a water layer containing catalyst particles.

Owner:WEBER LARRY J

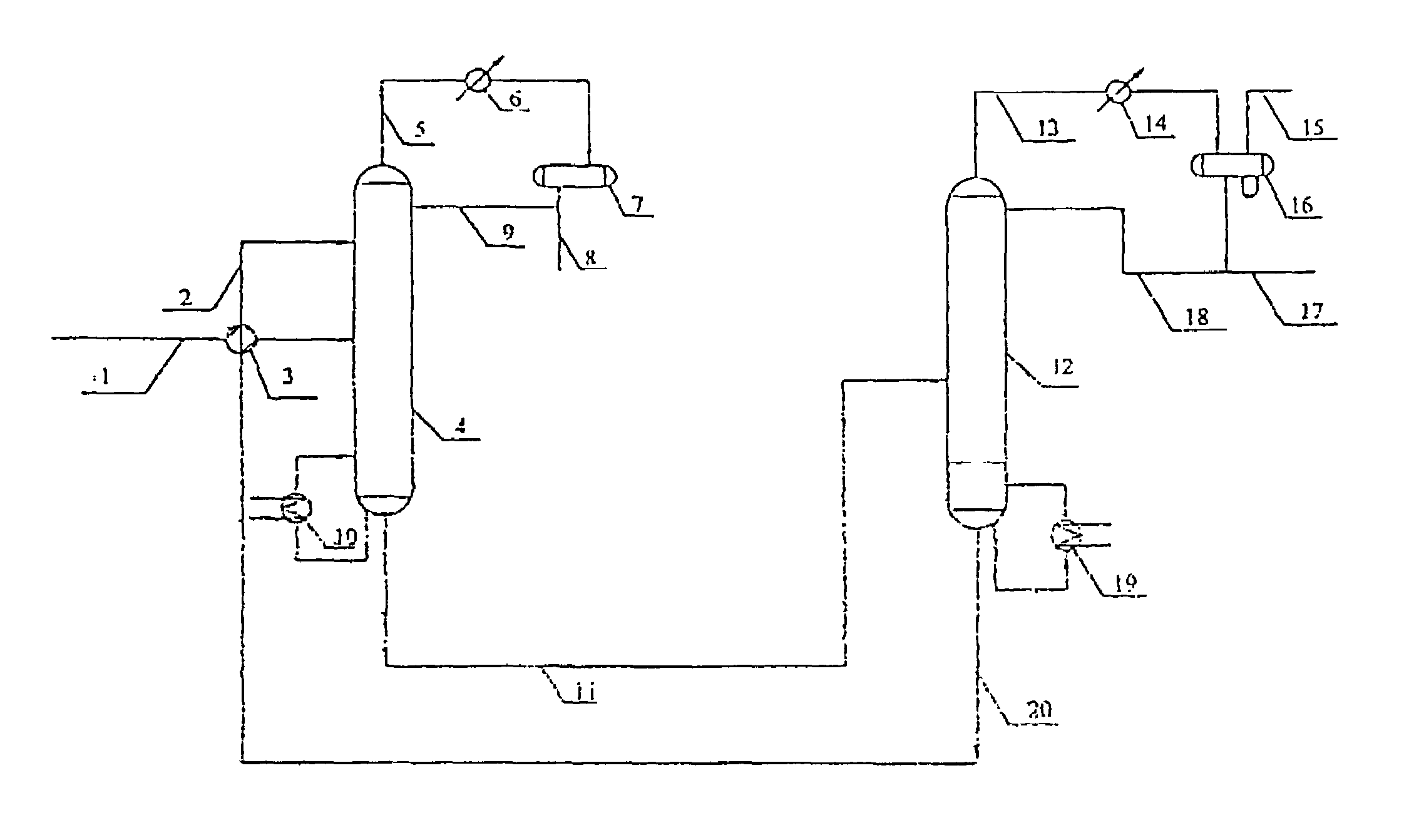

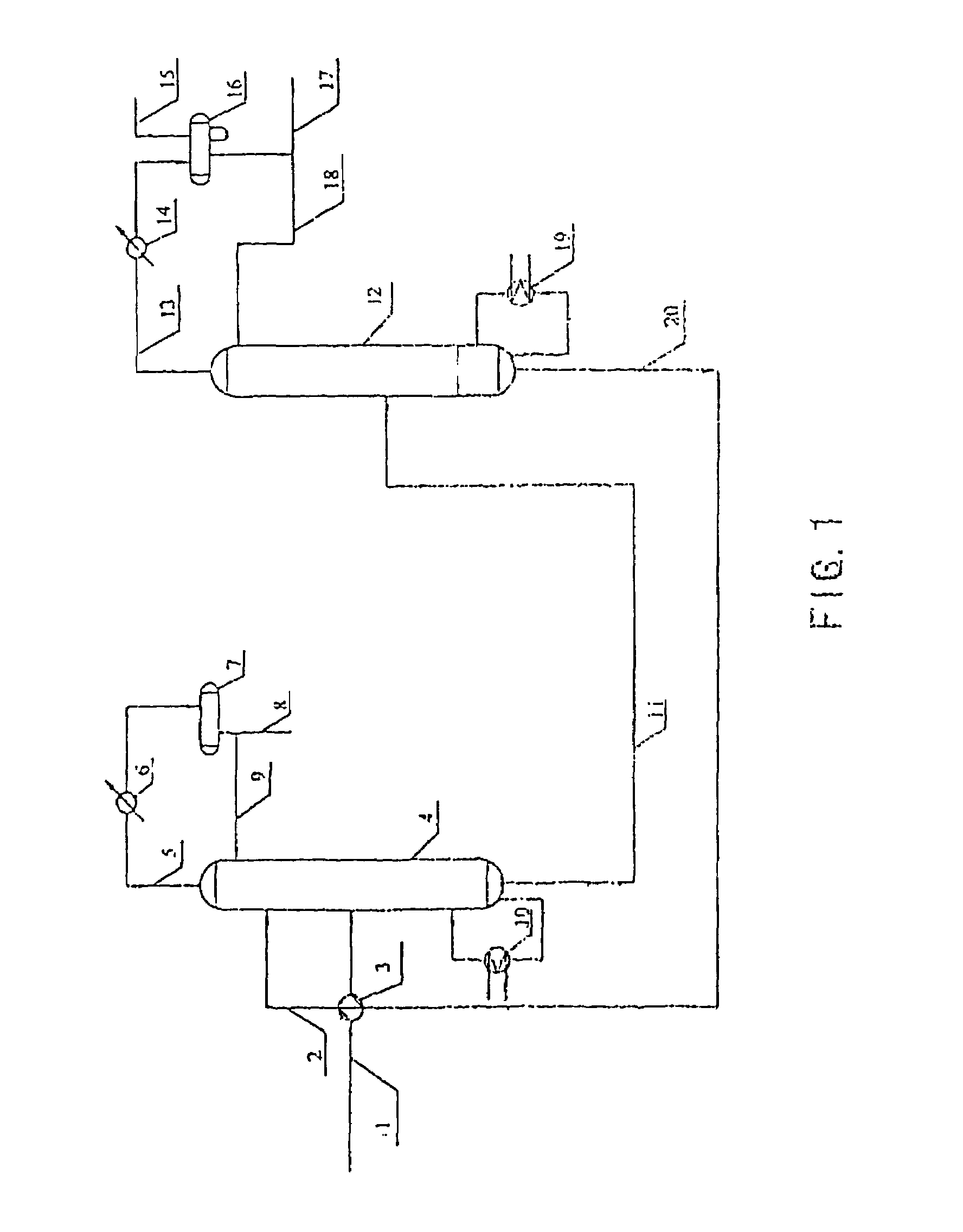

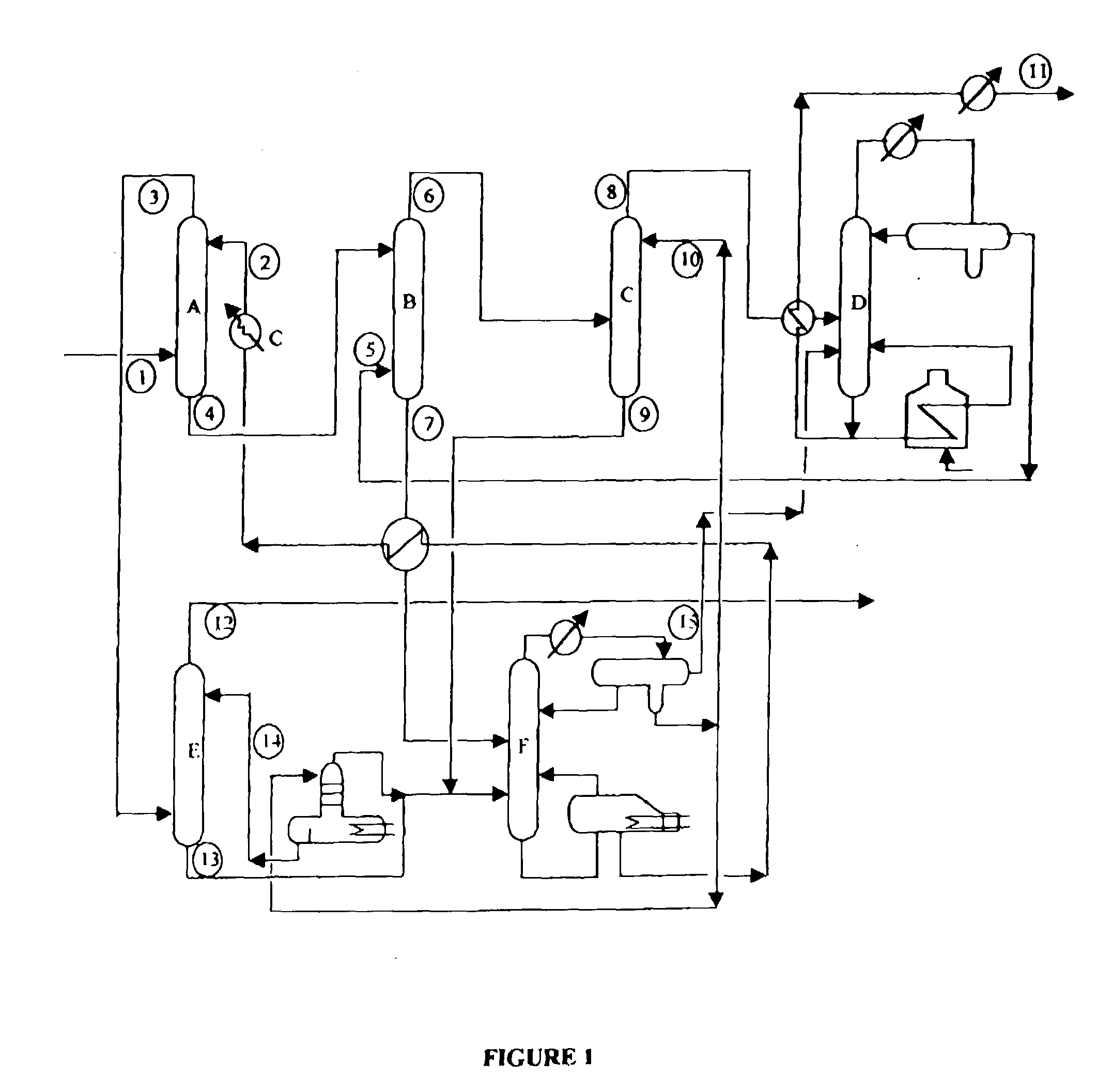

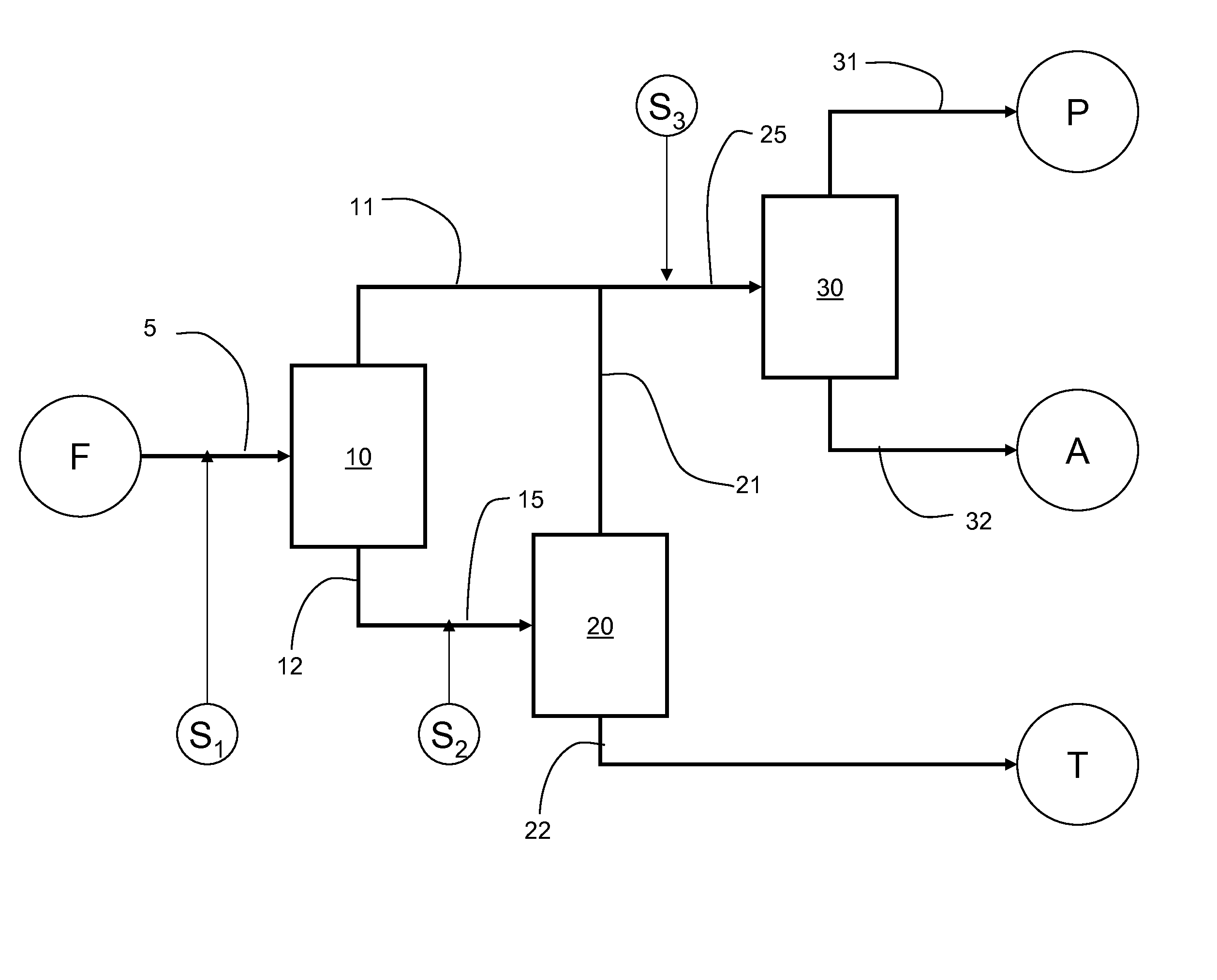

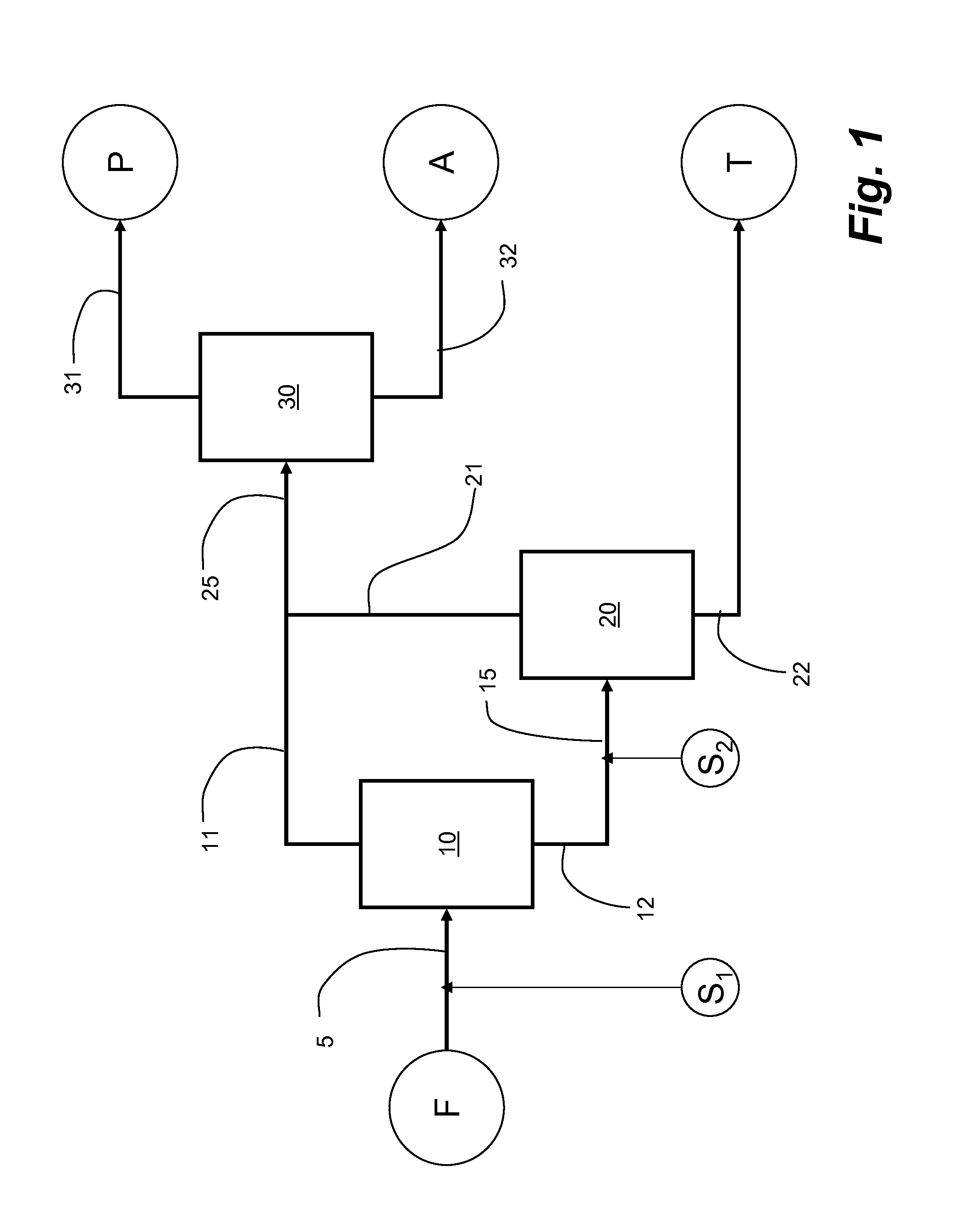

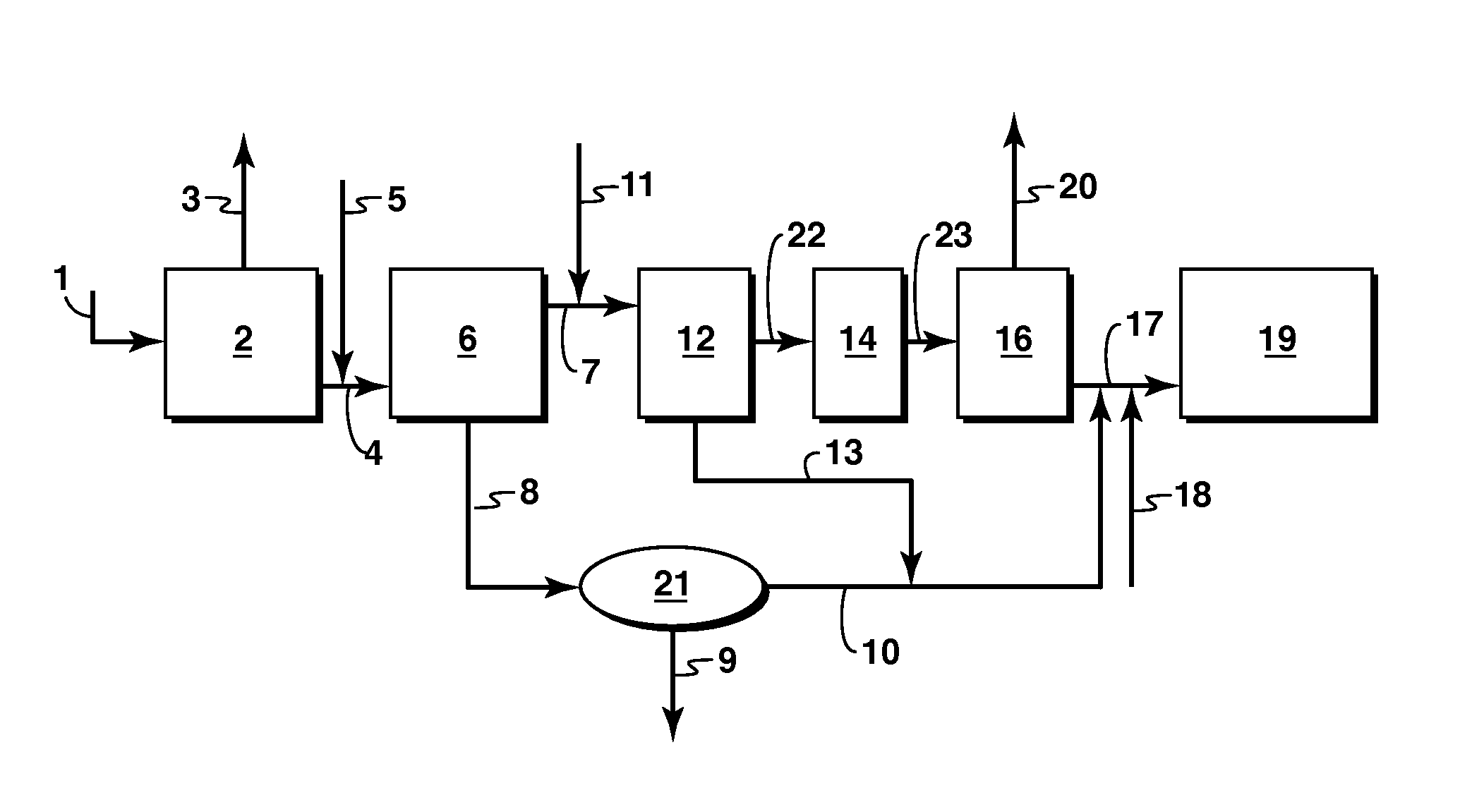

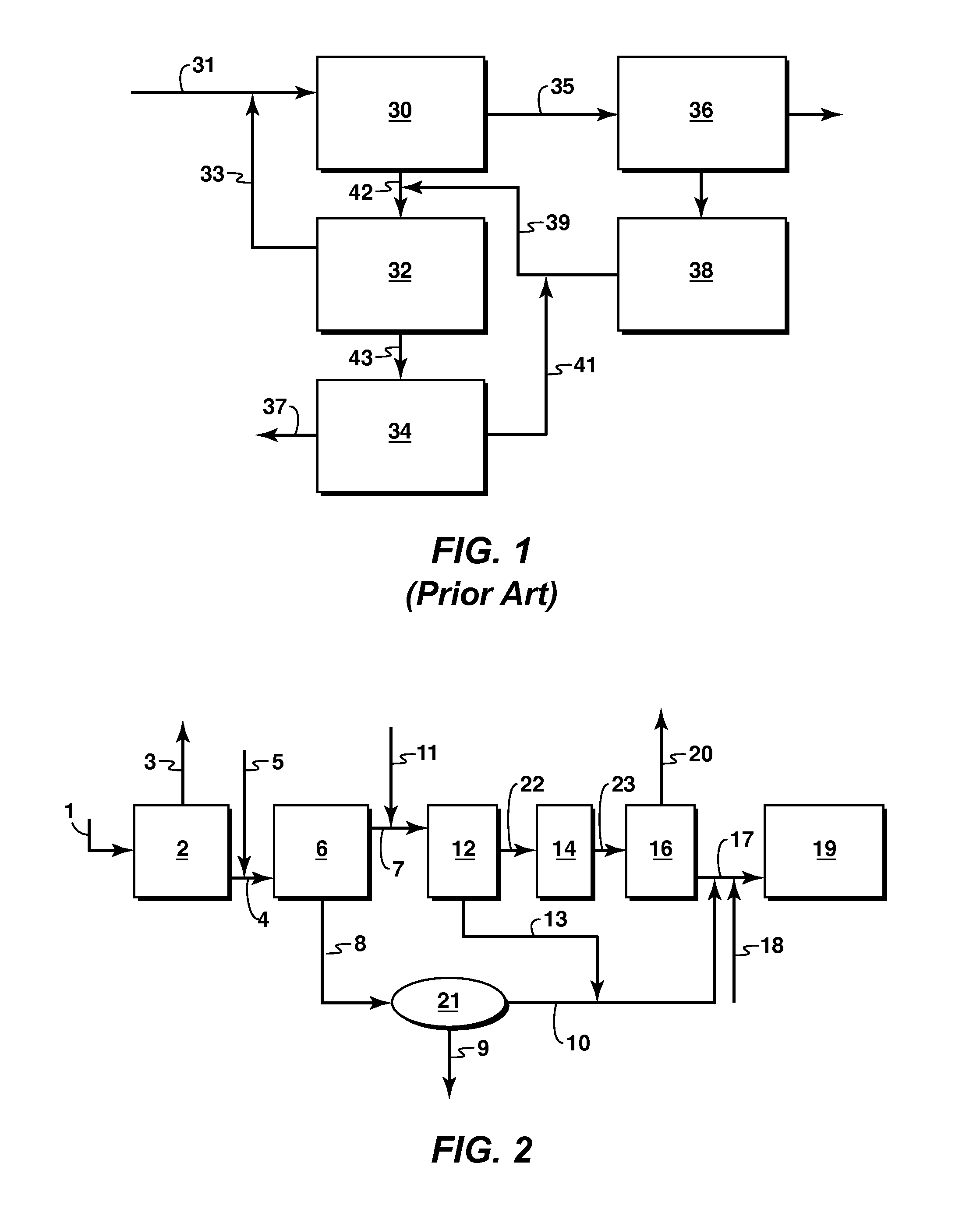

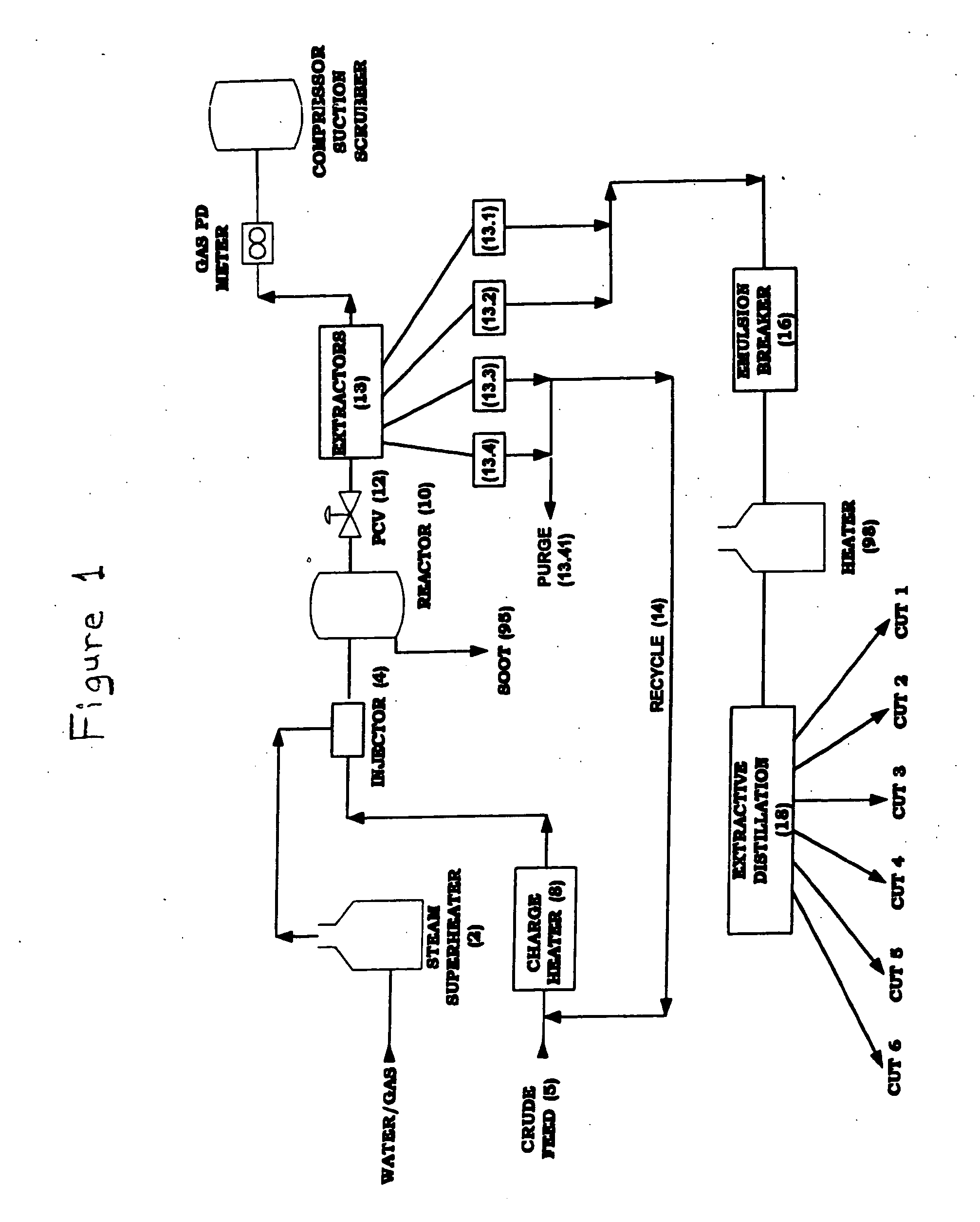

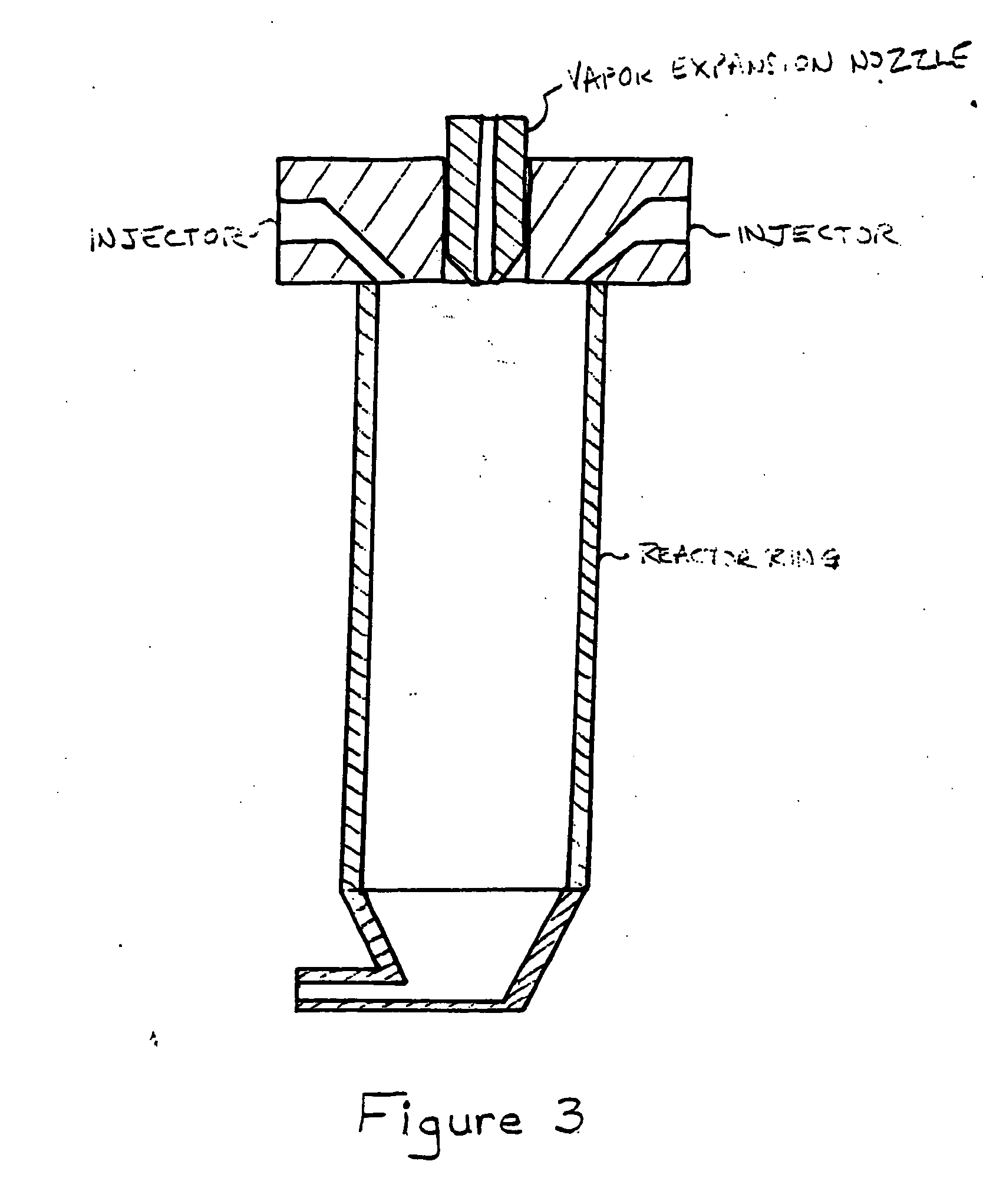

Deep conversion combining the demetallization and the conversion of crudes, residues or heavy oils into light liquids with pure or impure oxygenated compounds

InactiveUS20050211602A1Thermal non-catalytic crackingDewatering/demulsification with mechanical meansSuperheaterFuel oil

A process for the conversion of hydrocarbons that are solid or have a high boiling temperature and may be laden with metals, sulfur or sediments, into liquids (gasolines, gas oil, fuels) with the help of a jet of gas pity superheated between 600 and 800° C. The process comprises preheating a feed 5 in a heater 8 to a temperature below the selected temperature of a reactor 10. This feed is injected by injectors 4 into the empty reactor 10 (i.e., without catalyst.) The feed is treated with a jet of gas or superheated stem from superheater 2 to activate the feed. The activated products in the feed are allowed to stabilize at the selected temperature and at a selected pressure in the reactor and are then run through a series of extractors 13 to separate heavy and light hydrocarbons and to demetallize the feed. Useful products appearing in the form of water / hydrocarbon emulsions are generally demulsified in emulsion breaker 16 to form water laden with different impurities. The light phase containing the final hydrocarbons is heated in heater 98 and is separated into cuts of conventional products, according to the demand for refining by an extractor 18 similar to 13.

Owner:WESCO ENERGY

Popular searches

Dispersed particle separation Adsorption purification/separation Distillation separation Tar working-up by solvent extraction Refining by solvent de-asphalting Hydrocarbon oils refining control/regulation Refining with aqueous alkaline solutions Chemical modification purification/separation Extractive distillation Azeotropic/extractive distillation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com