Separation of oxygenates from a hydrocarbon stream

A technology for hydrocarbon streams and oxidation, which is applied in the direction of refining hydrocarbon oil, petroleum industry, refining with two or more solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

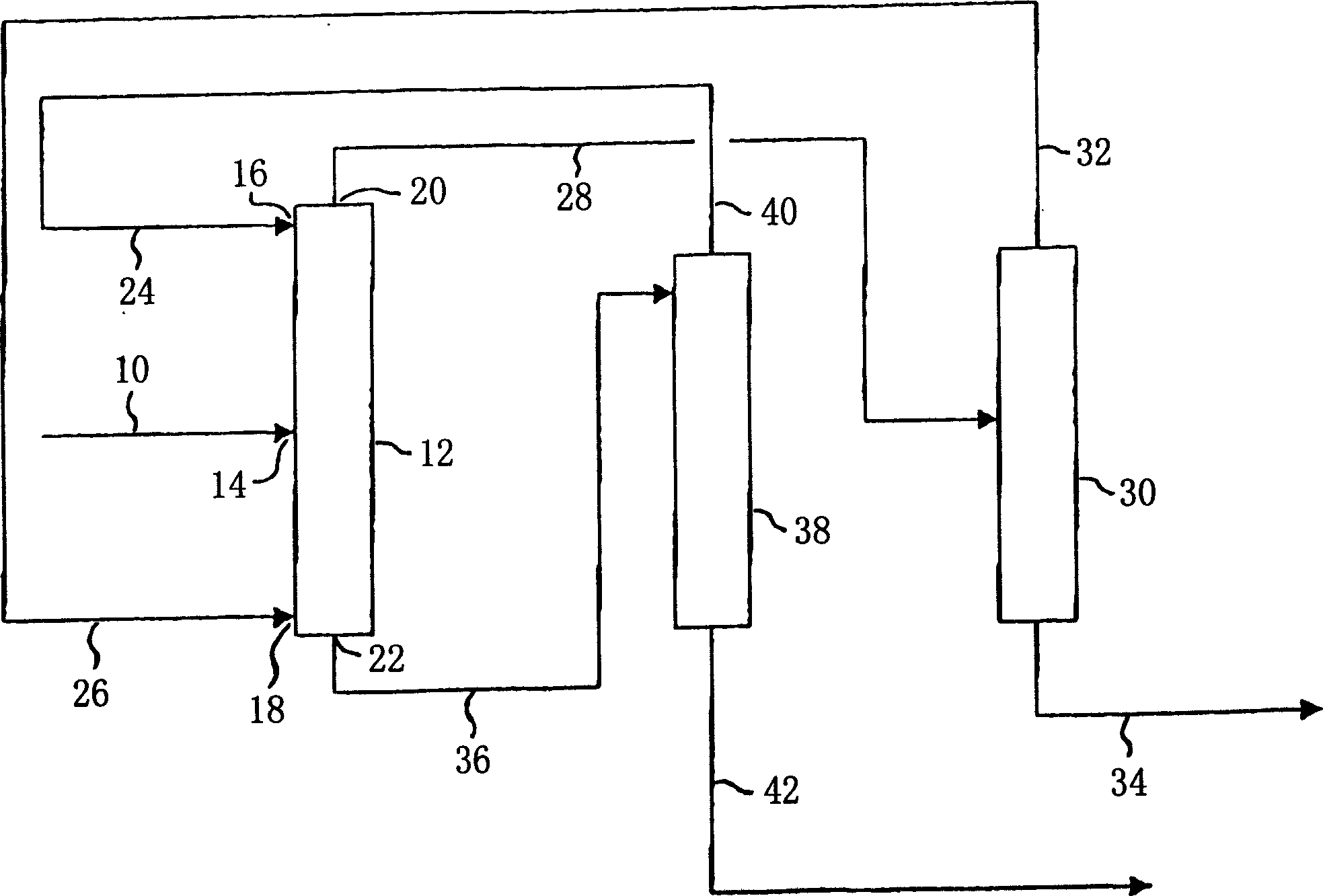

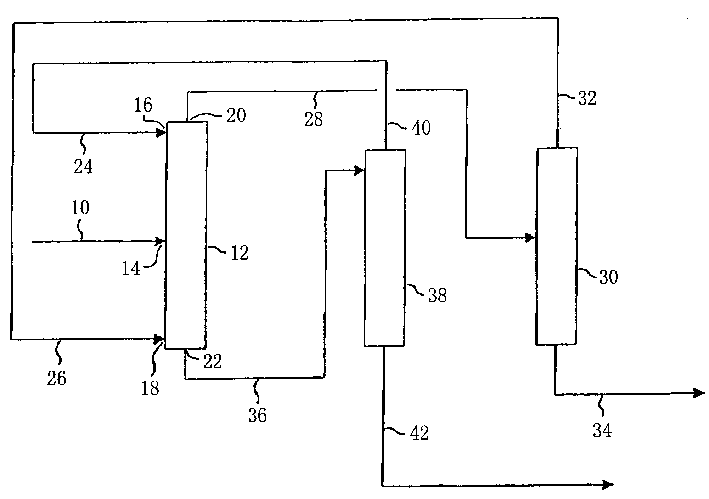

Image

Examples

Embodiment

[0035] A 3-meter-high vertical rotating disk extraction column, which is a multi-stage contact device, was operated under liquid-liquid extraction conditions. Supply points are installed at the top, bottom and middle of the extraction tower to feed separately. The solvent consisted of acetonitrile with 18% water. The solvent enters the extraction column from the top feed point at a flow rate of 2 kg / h. The stripping solvent was 1-octene (comonomer grade). The stripping solvent was introduced into the extraction column at a rate of 1 kg / h from the bottom feed point at a height of 2 m. The Fischer-Tropsch reaction was carried out in a slurry bed reactor using iron / manganese / zinc catalysts at a pressure of 45 bar and a reaction temperature of 230°C, with the resulting condensate as feed. The extraction operation was carried out at an operating temperature of 45°C. The solvent forms the continuous phase and the interface is at the top of the extraction column. For the particu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com