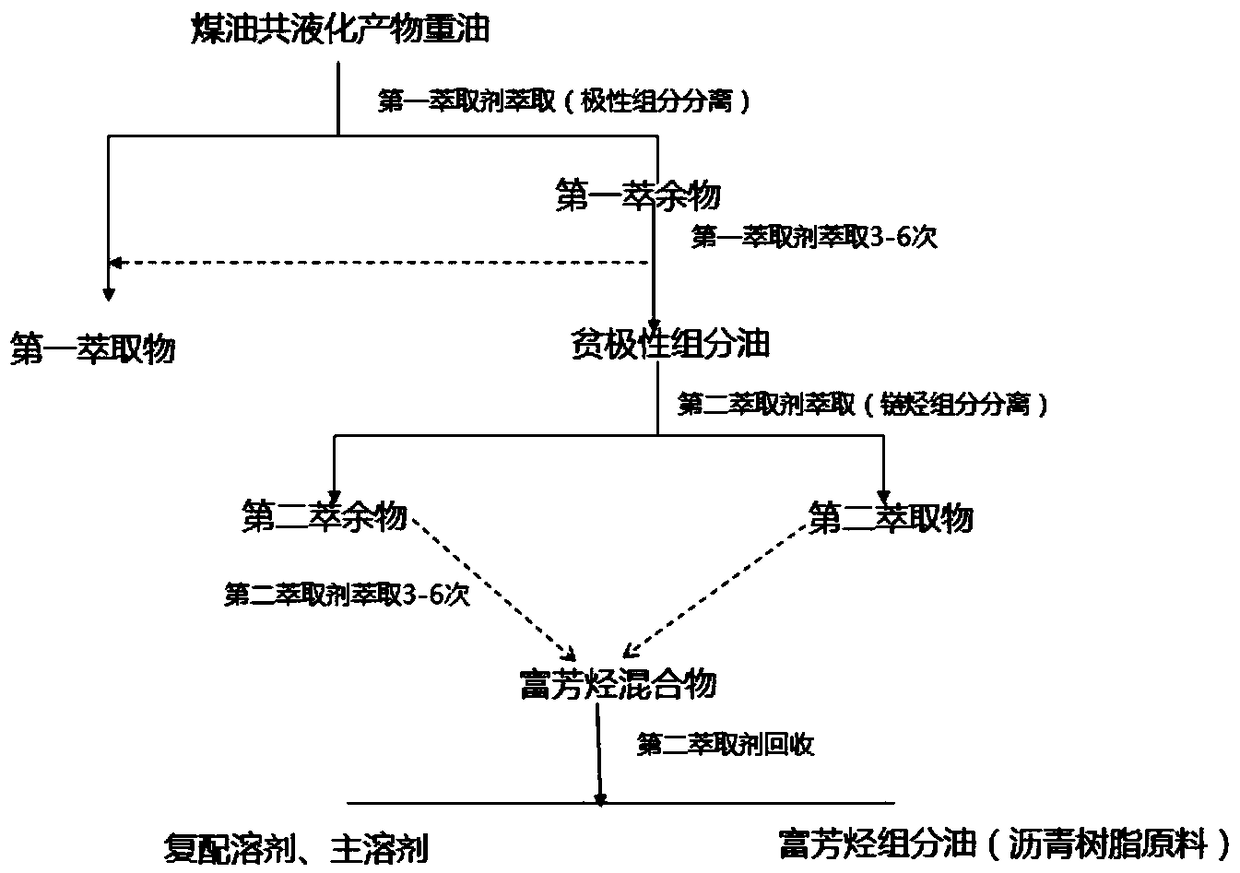

Method for preparing raw material for asphalt resin by using kerosene co-liquefaction product heavy oil

A technology of asphalt resin and co-liquefaction, which can be used in refining with two or more solvents, petroleum industry, refining hydrocarbon oil, etc. It can solve the problems of low purity of aromatics, low economic benefits, incomplete separation, etc., and achieve separation efficiency. High, good thermal stability, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 100g of kerosene co-refining product heavy oil and put it into a methanol amine solvent containing 7 times the volume, sonicate at 35°C for 20 minutes, rest for 30 minutes, and filter; use methanol to extract the obtained first raffinate for 6 Once, a polar component-poor oil is obtained.

[0026] (2) Extract the first raffinate with 7 times the volume of N,N-dimethylacetamide containing 15% volume of methanol, sonicate at 35°C for 20 minutes, rest for 30 minutes, and filter; use 15% volume of methanol The obtained second raffinate was extracted 6 times with N,N-dimethylacetamide to obtain a second extract rich in aromatic components.

[0027] (3) The methanol solvent was recovered by distillation under the conditions of 40°C and 0.05Mpa, and the N,N-dimethylacetamide was recovered under the conditions of 85°C and 0.1MPa to obtain 72.5g of aromatic-rich component oil, whose composition is shown in Table 1 shown.

Embodiment 2

[0029] (1) Weigh 100 g of coal liquefied oil and put it into a formamide solvent containing 10 times its volume, ultrasonicate for 25 minutes at 42 ° C, rest for 45 minutes, and filter; use methanol to extract the first raffinate obtained 4 times to obtain Polar-poor oil.

[0030] (2) Extract the first raffinate with 10 times the volume of N,N-dimethylacetamide in 10% methanol by volume, sonicate at 10°C for 25 minutes, let stand for 45 minutes, and filter; , and extracting the second raffinate with N-dimethylacetamide 4 times to obtain a second extract rich in aromatics components.

[0031] (3) The methanol solvent was recovered by distillation under the conditions of 50°C and 0.04Mpa; N,N-dimethylacetamide was recovered under the conditions of 100°C and 0.08MPa to obtain 71.9g of aromatic-rich component oil, whose composition is shown in Table 1 shown.

Embodiment 3

[0033] (1) Weigh 100 g of coal liquefied oil and put it into a formamide solvent containing 12 times its volume, sonicate at 50°C for 30 minutes, rest for 60 minutes, and filter; use methanol to extract the first raffinate obtained 3 times to obtain Polar-poor oil.

[0034] (2) Extract the first raffinate with 12 times the volume of N,N-dimethylacetamide in 25% methanol by volume, sonicate at 25°C for 30 min, rest for 60 min, and filter; , N-dimethylacetamide extracted 3 times the obtained first raffinate to a second extract rich in aromatics components.

[0035] (3) The methanol solvent was recovered by distillation under the conditions of 60°C and 0.03Mpa; N,N-dimethylacetamide was recovered under the conditions of 110°C and 0.07MPa to obtain 72.3g of aromatic-rich component oil, whose properties are shown in Table 1 shown.

[0036]Refer to the "NB / SH / T 0509-2010" standard method to determine the group composition of the raw oil (kerosene co-refinery product oil) and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com