Pre-treatment process method of high acid crude oil

A technology of high-acid crude oil and process method, which is applied in the direction of refining with two or more solvents, dehydration/demulsification with electricity/magnetism, etc. It can solve the problems of high-acid crude oil density and high viscosity, and achieve less alkali consumption , The agent-oil ratio is small, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

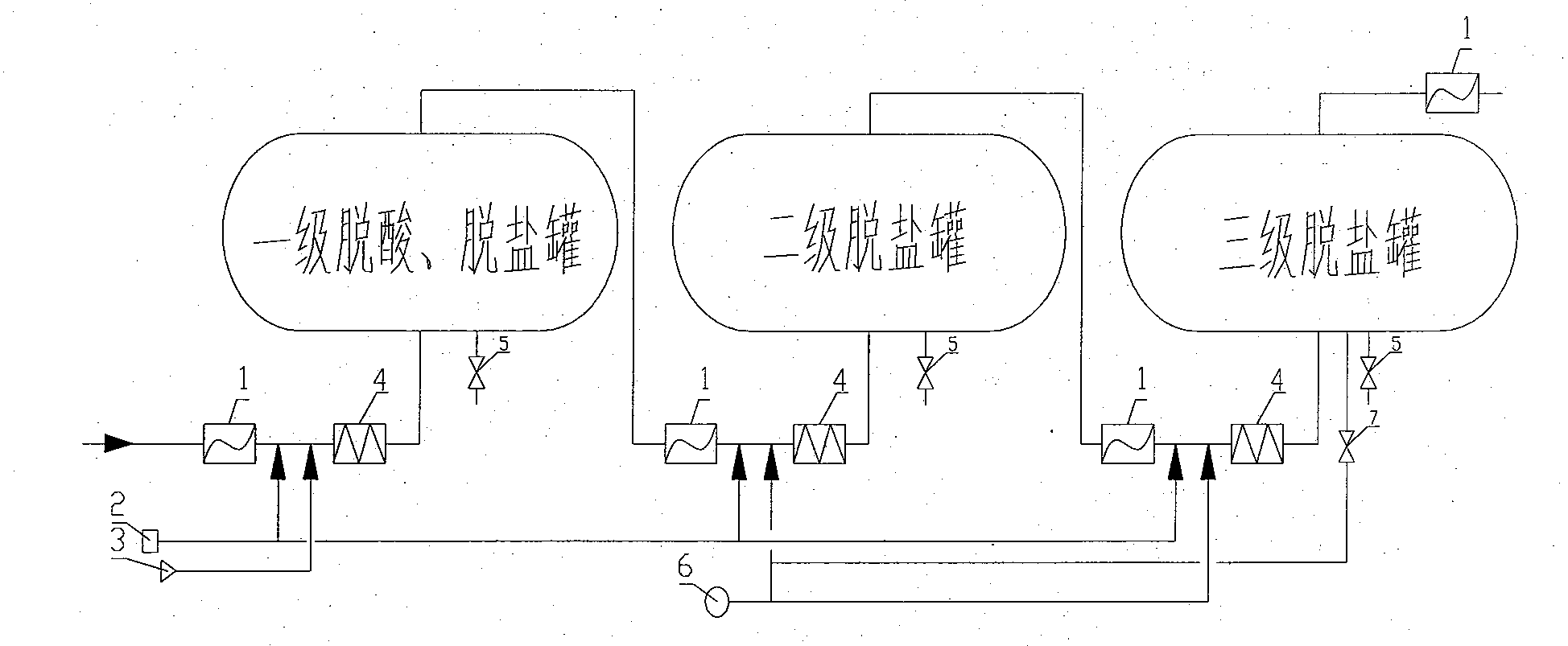

Image

Examples

specific Embodiment

[0029] The present invention is described in detail by using the implementation case of a high-acid crude oil pretreatment process in this patent application, but the scope of the present invention is not limited.

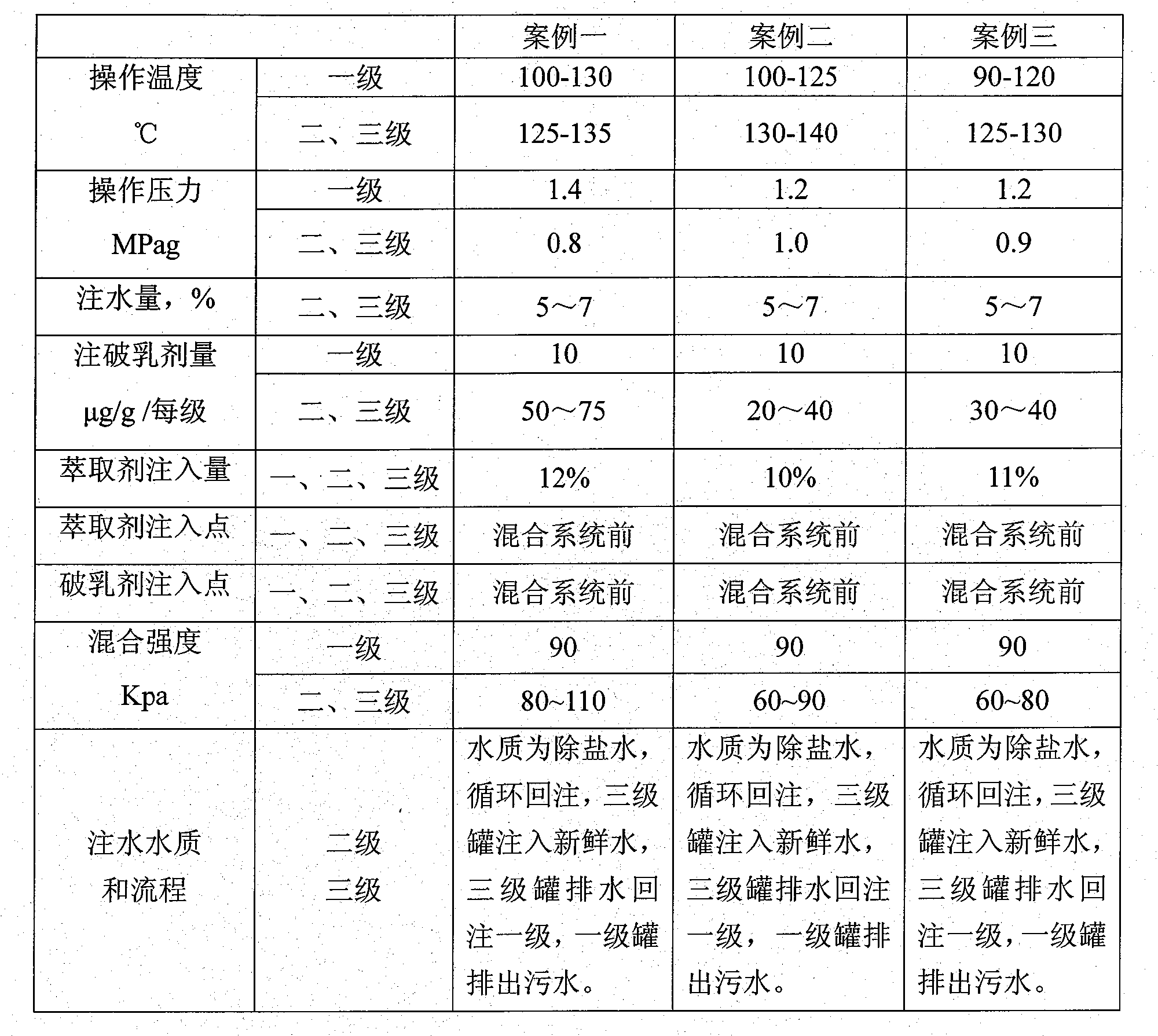

[0030] The composition of extractant is ethanol 5%, ethylene glycol 85%, glycerol 7%, sodium hydroxide 3%, test process operating conditions are shown in Table 1, and adopting process technology pretreatment effect of the present invention is shown in Table 2.

[0031] Table 1 Operating conditions of high-acid crude oil pretreatment

[0032]

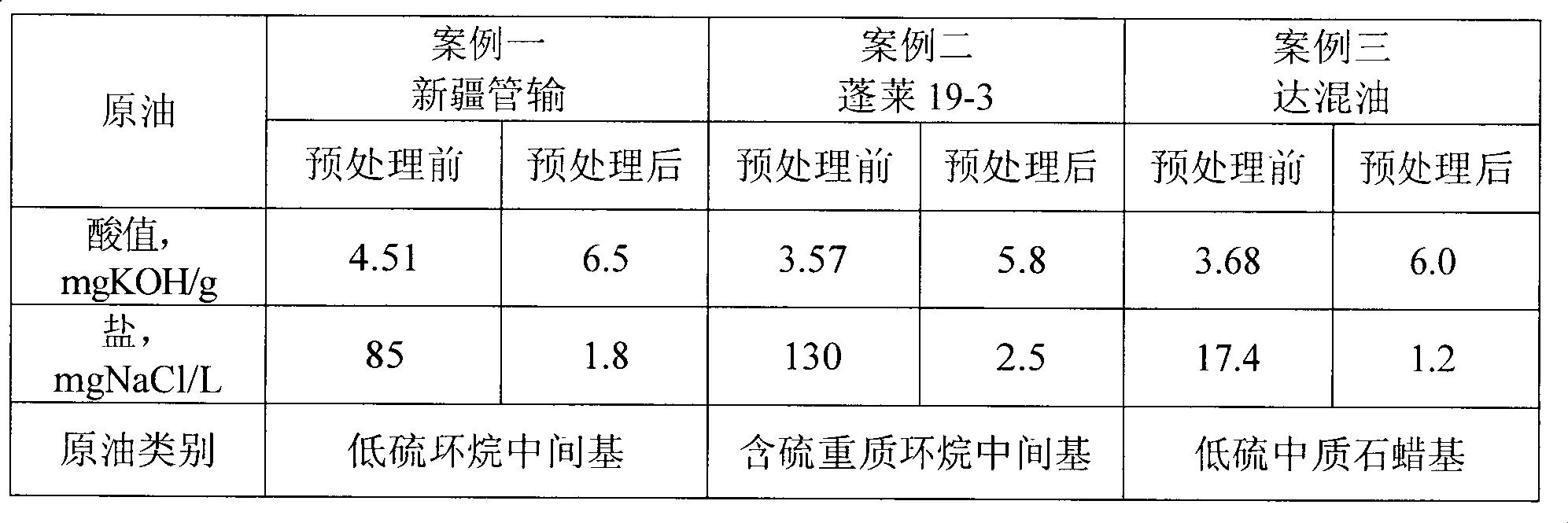

[0033] Table 2 Properties of crude oil before and after pretreatment

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com