Patents

Literature

106results about How to "Moderate reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

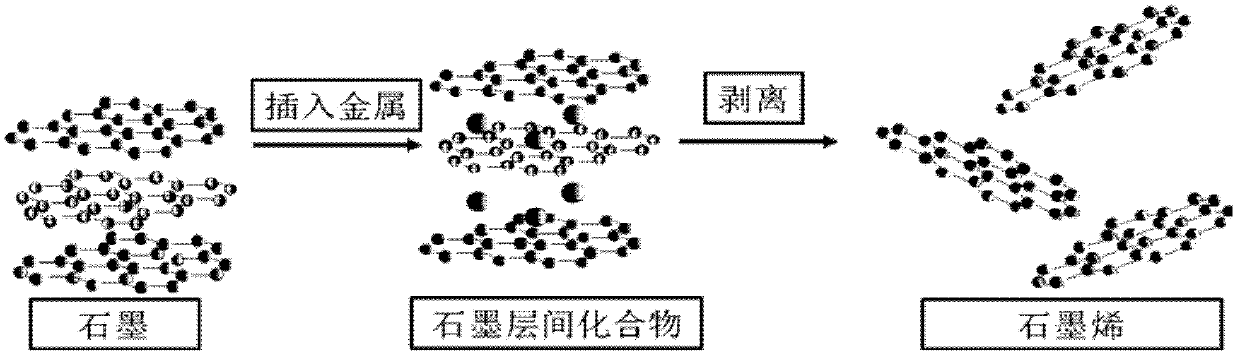

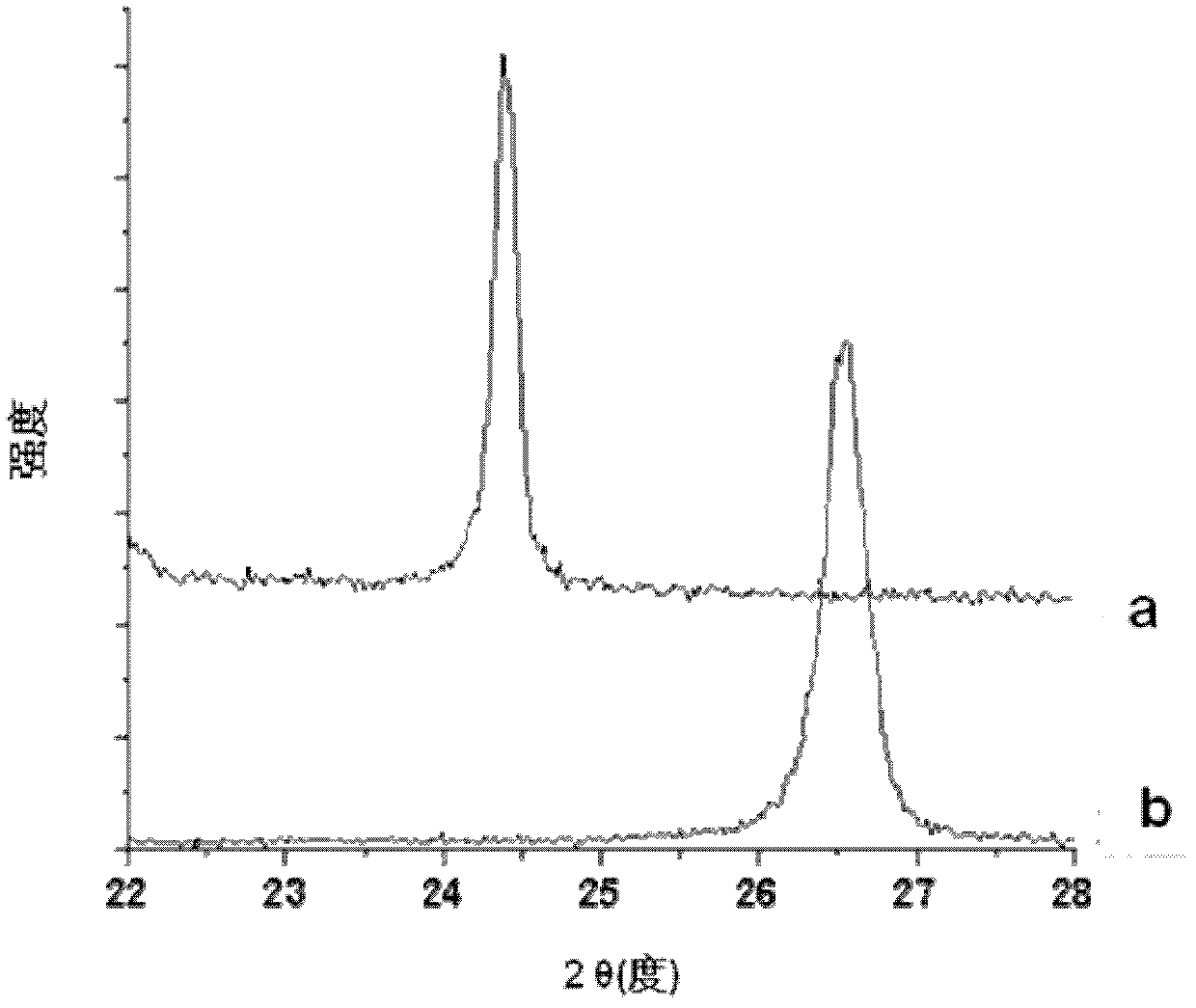

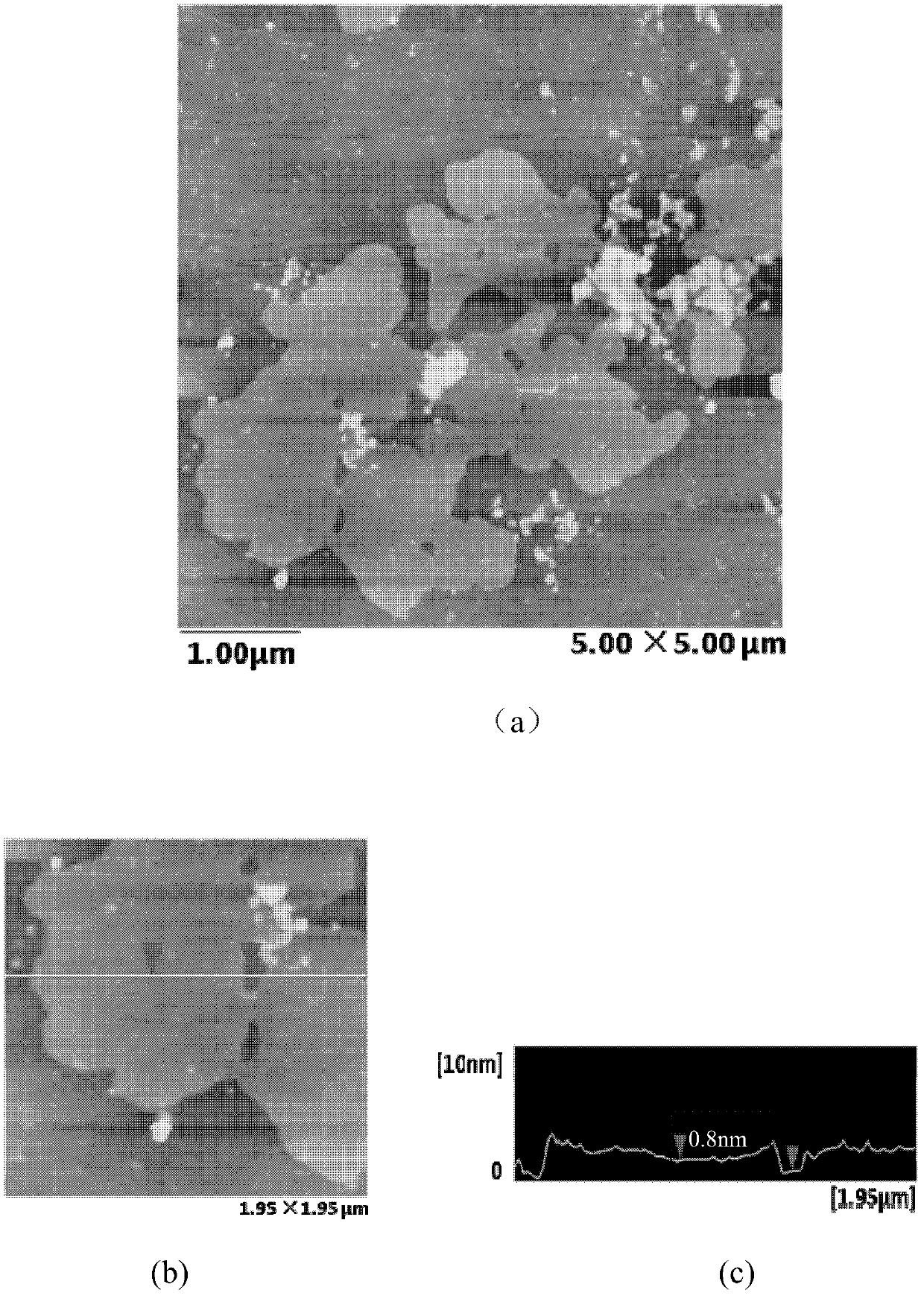

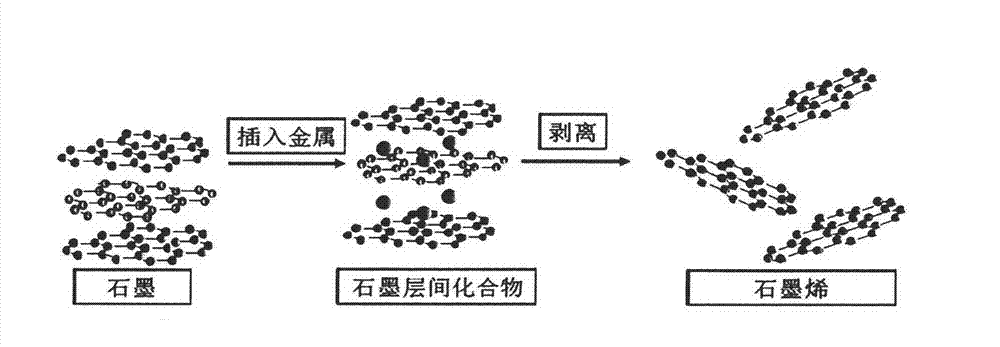

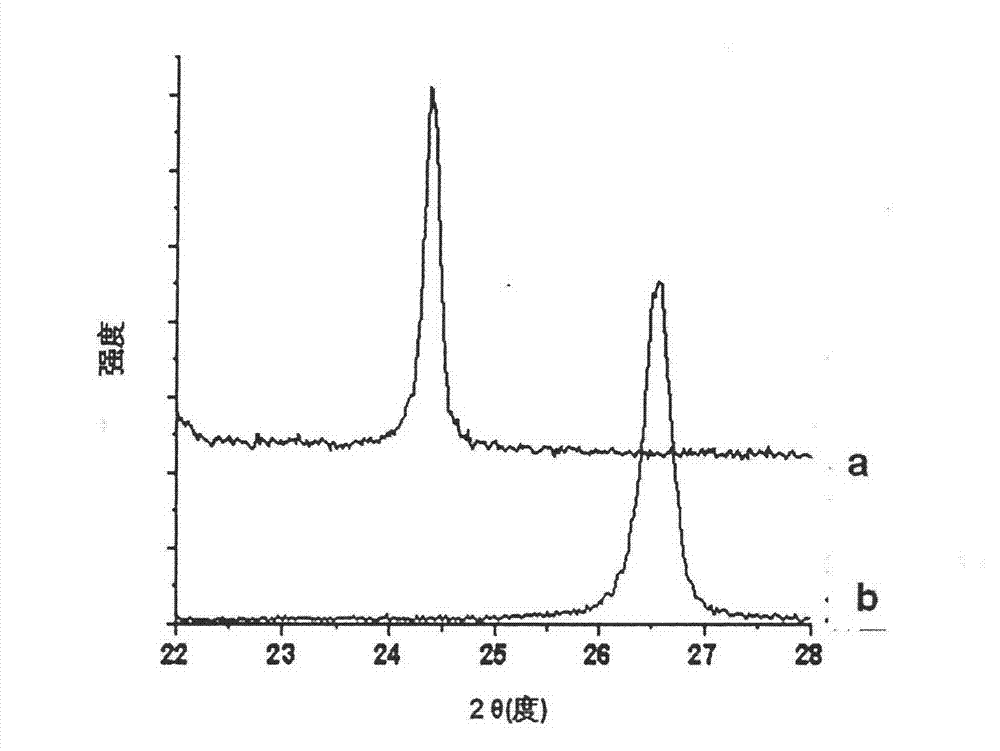

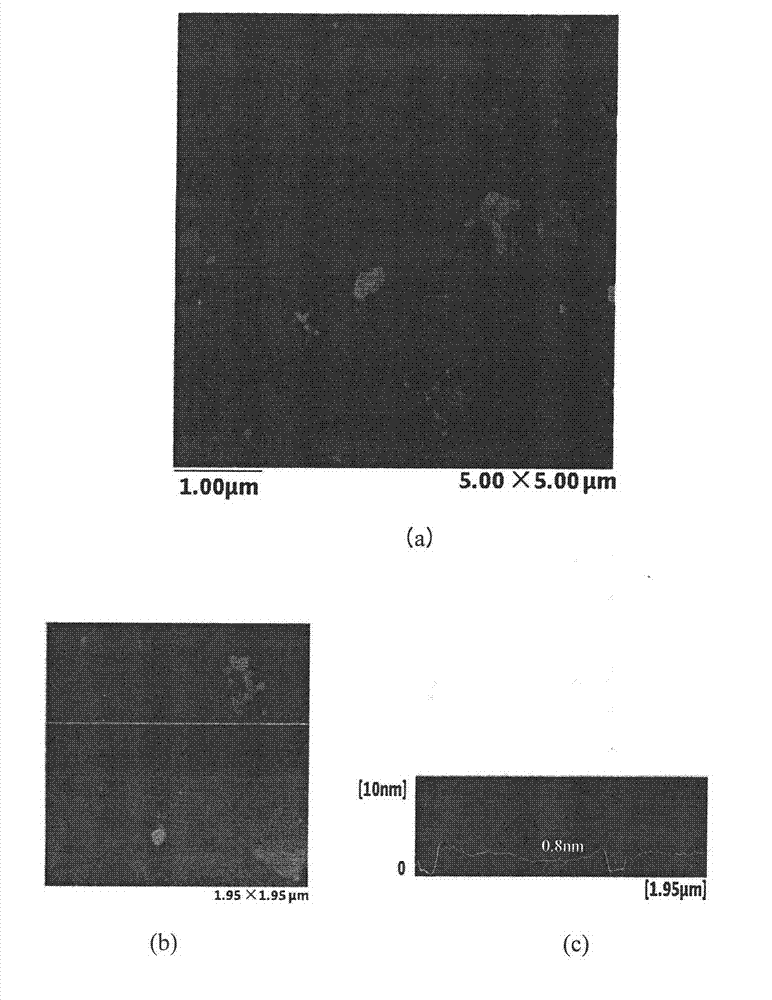

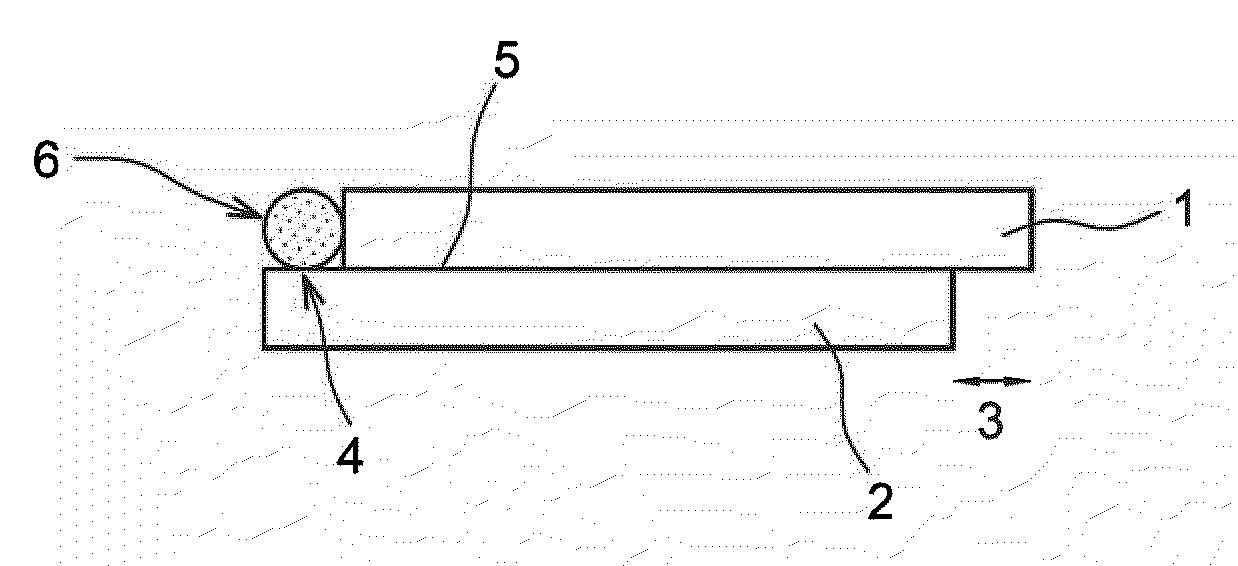

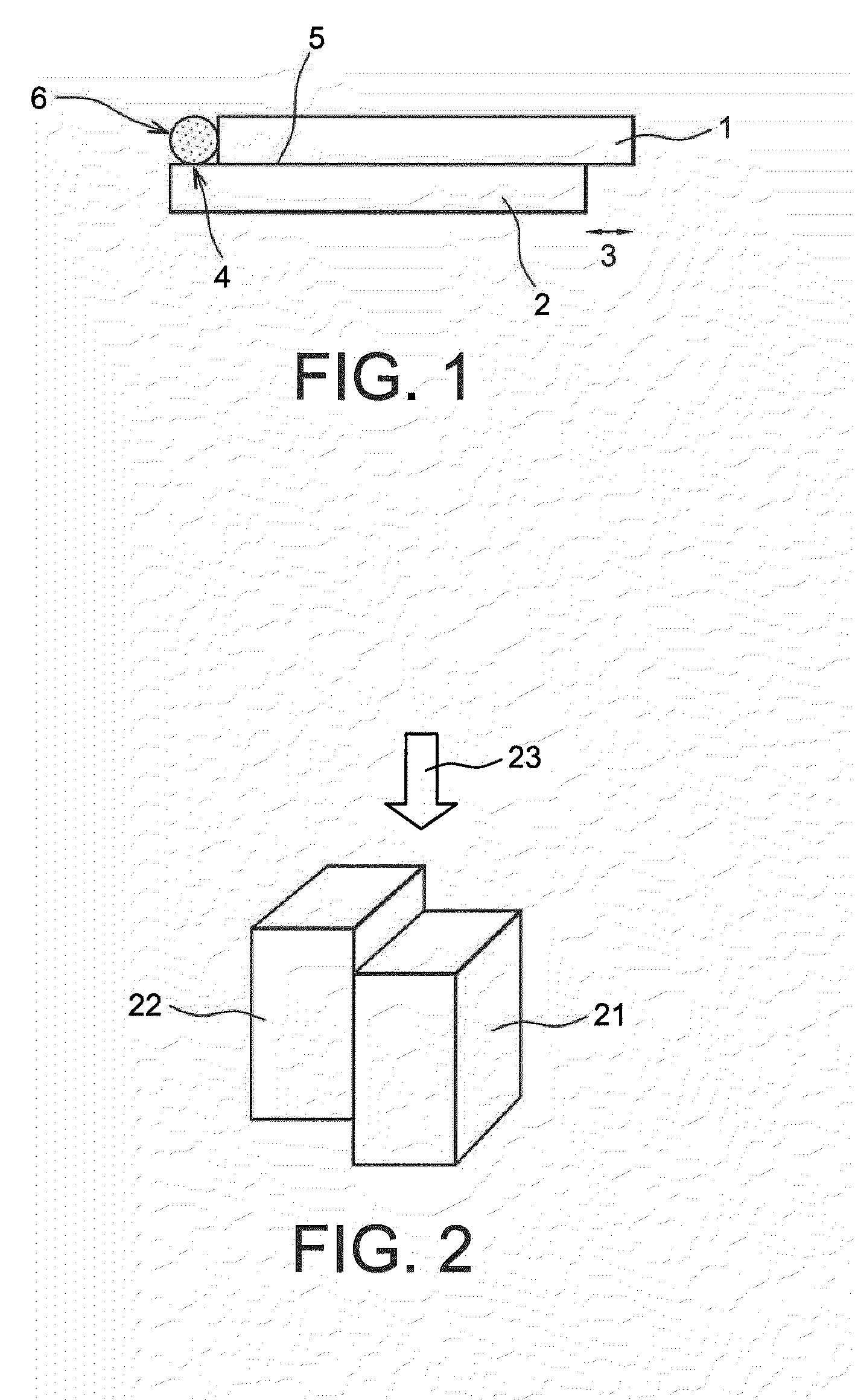

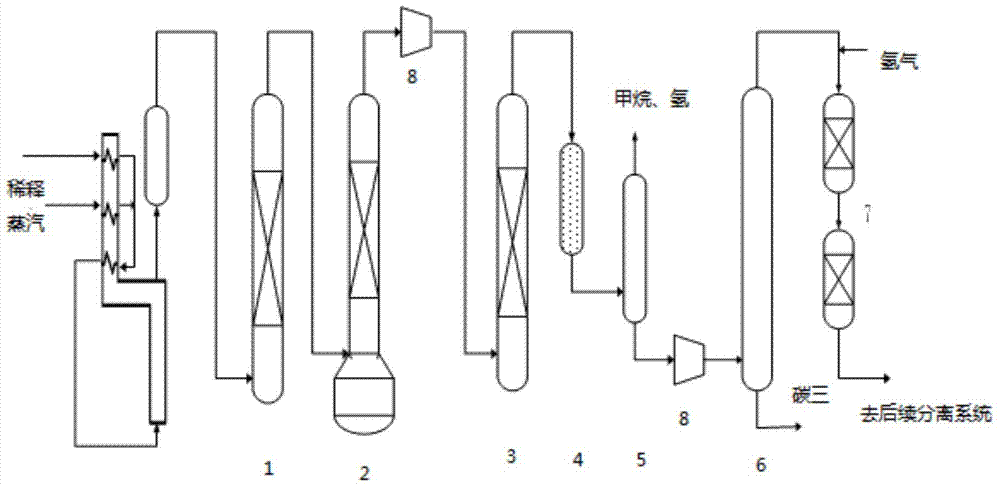

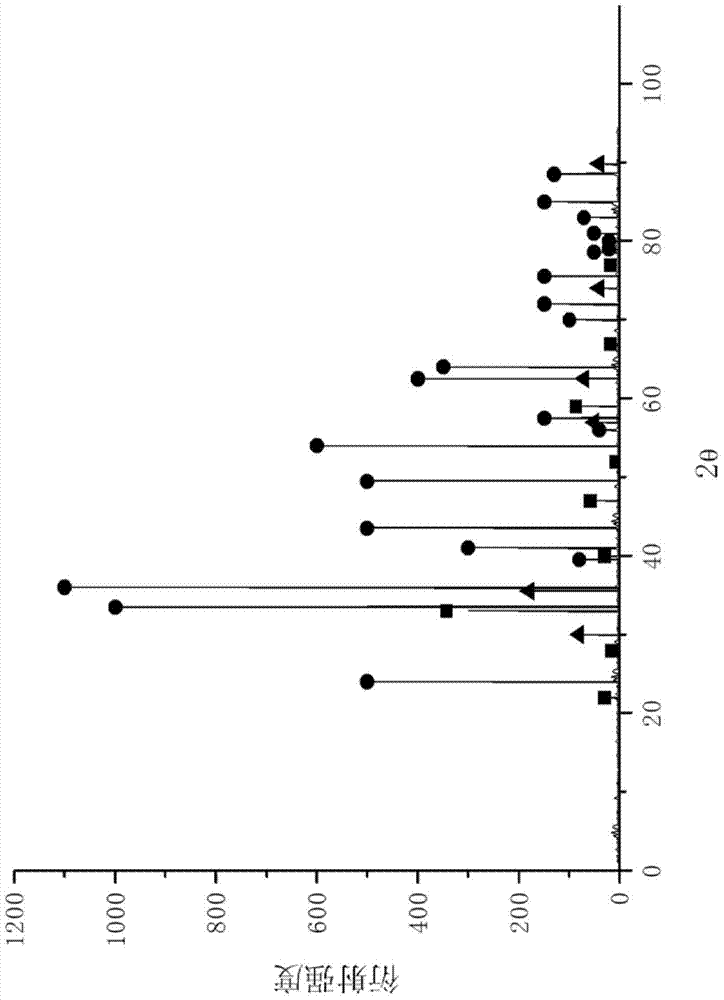

Preparation method of graphene and graphene prepared by same

The invention relates to a preparation method of graphene and graphene prepared by the method, and is characterized in that the method adopts graphite as a raw material; a graphite intercalation compound is prepared by intercalating metal between graphite layers; and then graphene is prepared by peeling the graphite intercalation compound. The graphene prepared by the method has a length and a width of 5-15000 nm, and a thickness of 0.3-15 nm. The advantages of the invention are that: the raw material source is wide; the cost is low; the preparation method is simple; the product performance is stable and controllable; and the method is suitable for industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Graphene preparation method, and graphene prepared through using method

InactiveCN102815694AWide variety of sourcesLow costGrapheneNanotechnologyCvd grapheneGraphite intercalation compound

The invention relates to a graphene preparation method, and graphene prepared through using the method. The preparation method is characterized in that a metal is intercalated into layers of graphite which is a raw material to prepare a graphite intercalation compound, and the graphite intercalation compound is peeled to prepare the graphene. The length, the width and the thickness of the graphene prepared through using the method are 5-15000nm, 5-15000nm and 0.3-15nm respectively. The method has the advantages of wide raw material source, low cost, simplicity, stable controllability of the graphene performances, and suitableness for industrialized production.

Owner:EAST CHINA UNIV OF SCI & TECH

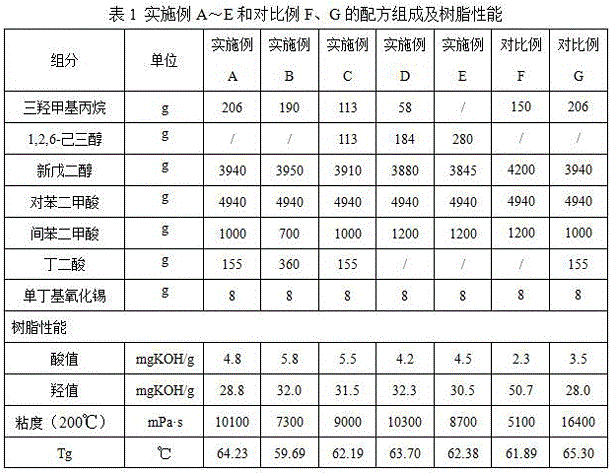

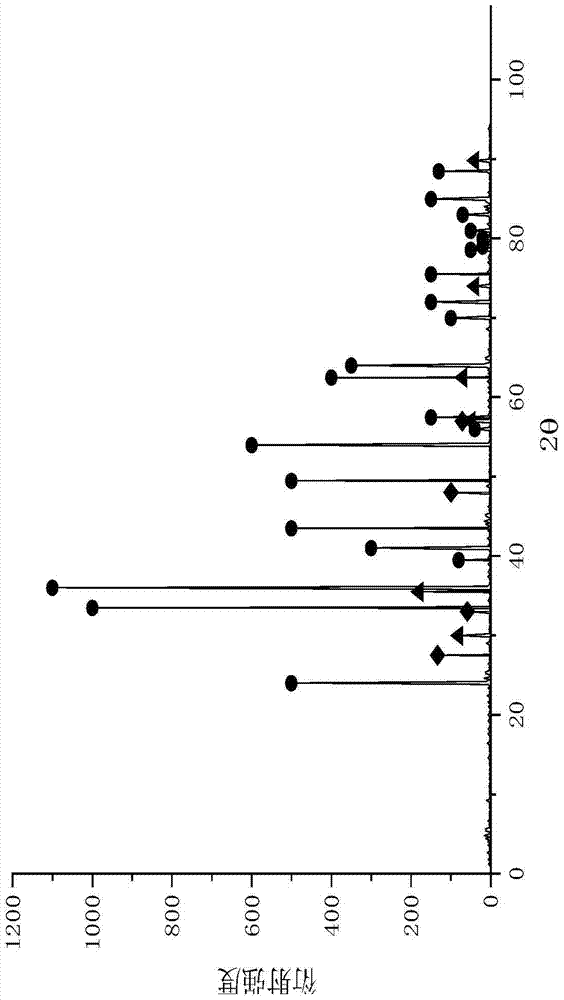

Preparation method of polyester resin for mixing type powdery coating

InactiveCN1962717AReduce melt viscosityUniform molecular weightPowdery paintsPolyester coatingsPolymer sciencePolymer resin

Owner:GUANGZHOU QINGTIAN INDAL

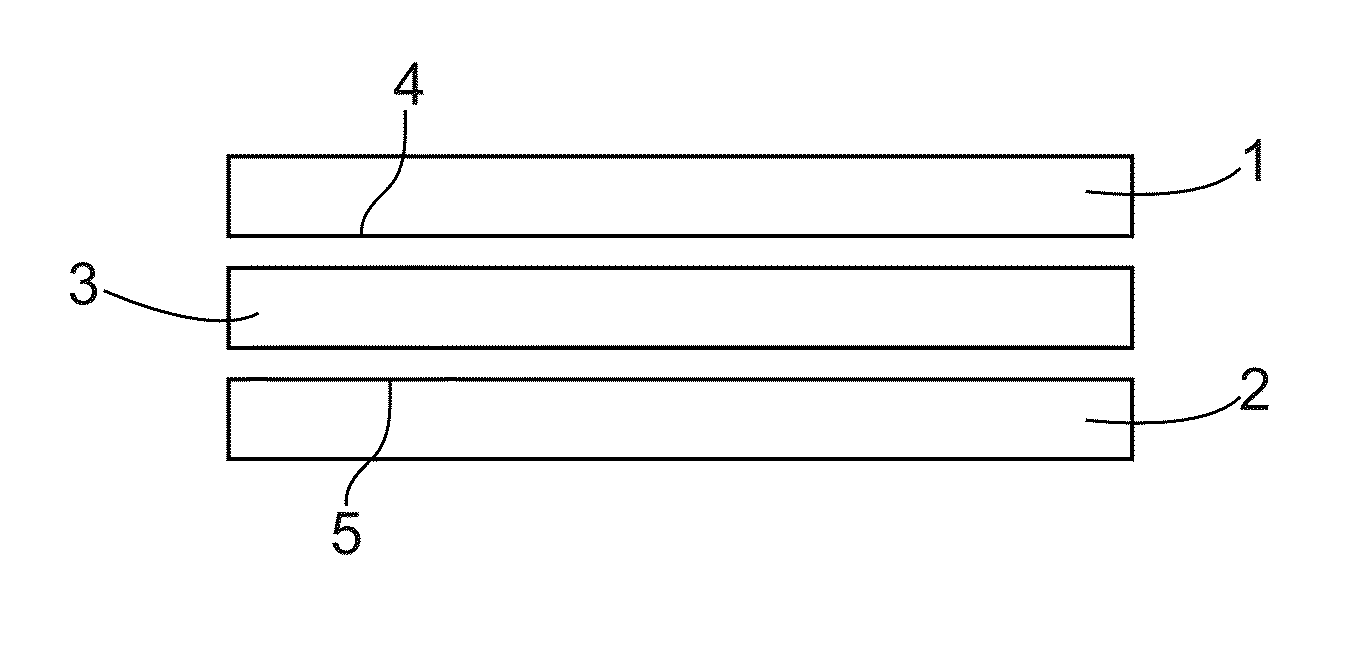

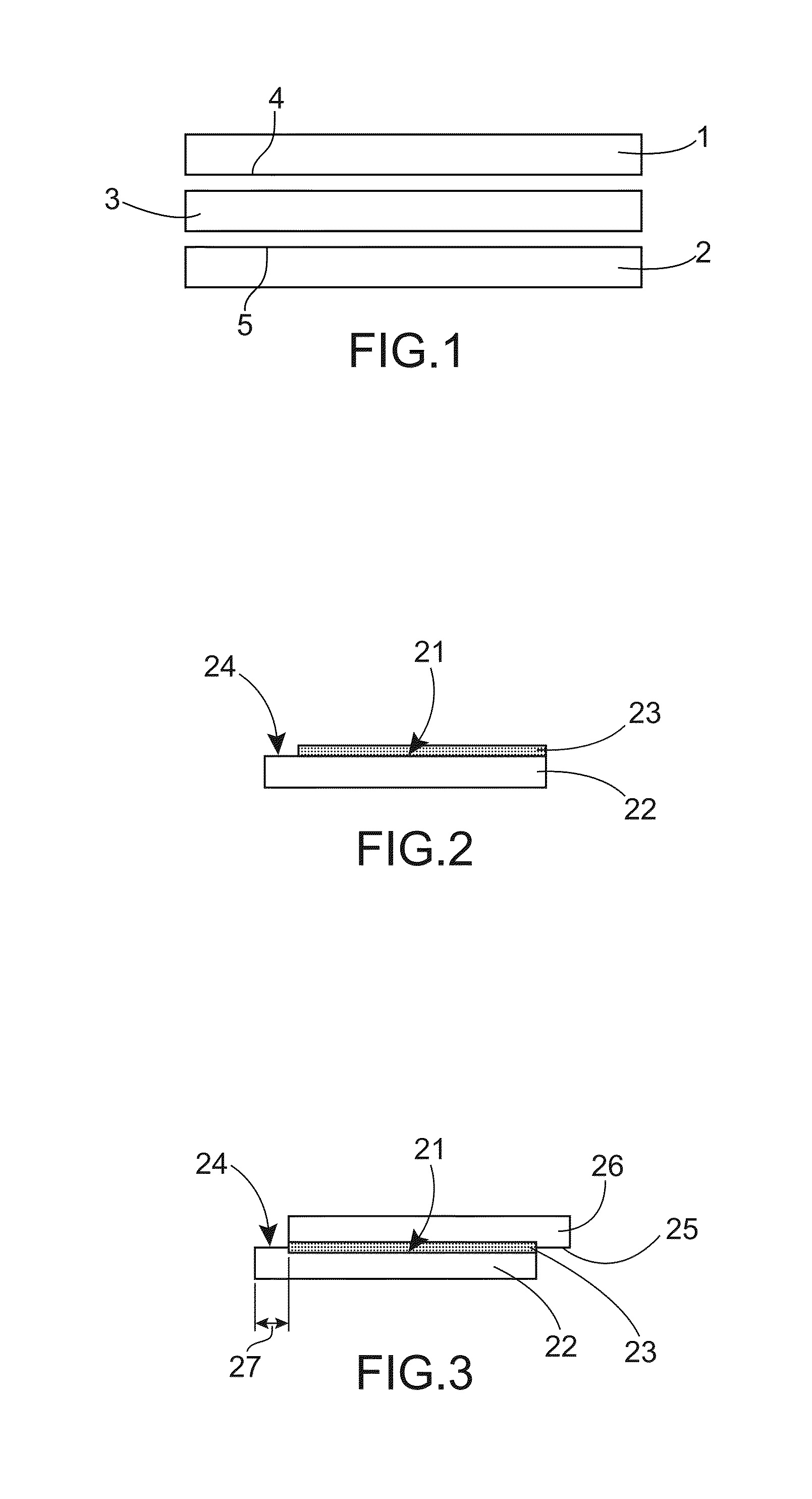

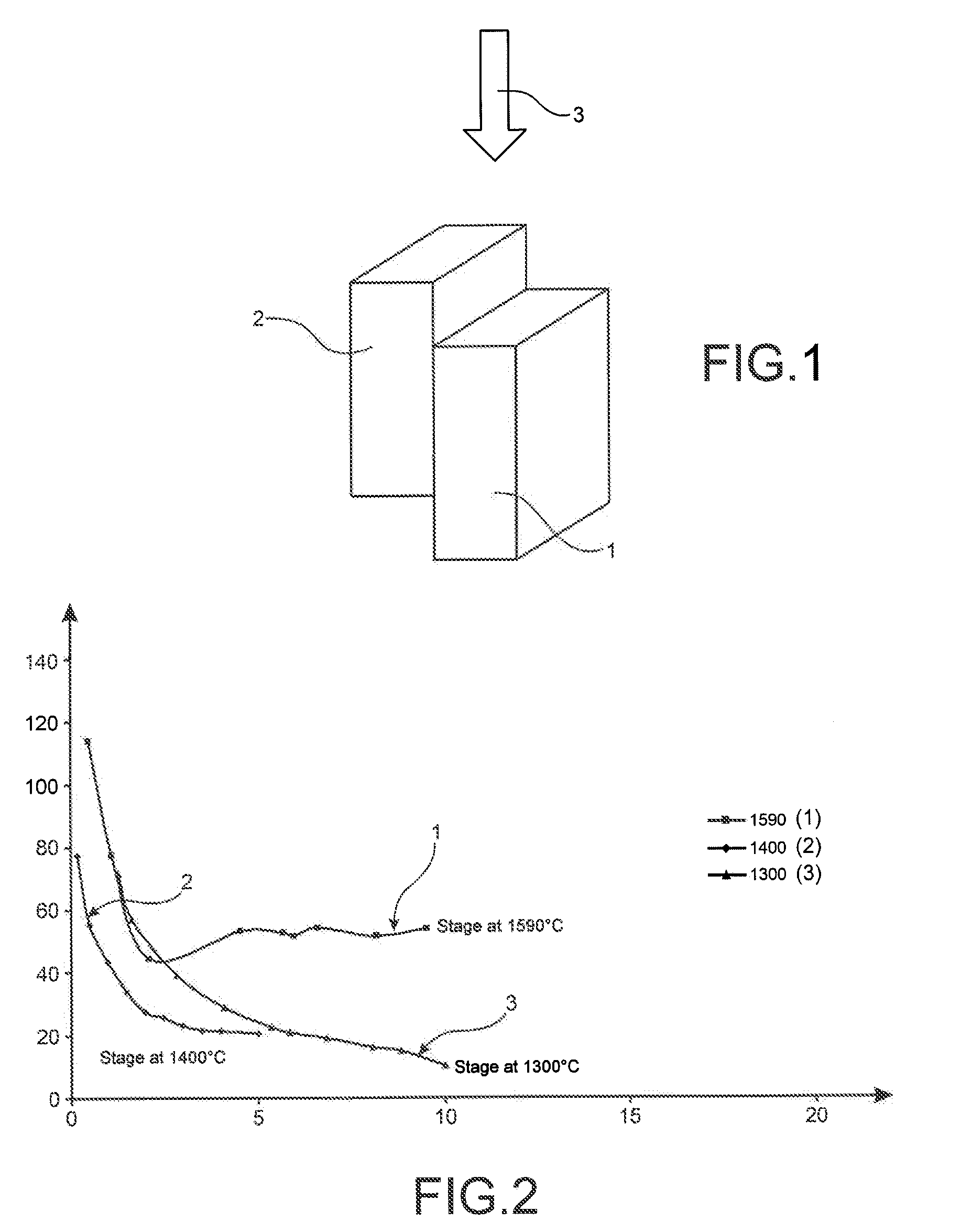

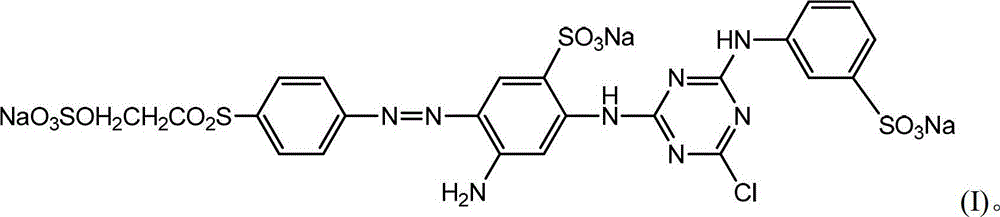

Process for the Moderately Refractory Assembling of Articles Made of SiC-Based Materials by Non-Reactive Brazing, Brazing Compositions, and Joint and Assembly Obtained by this Process

InactiveUS20100075160A1Low costImprove surface wettabilityLayered productsWelding/cutting media/materialsYttriumBrazing

Process for the assembly of at least two articles made of silicon carbide-based materials by moderately refractory non-reactive brazing, in which the articles are placed in contact with a non-reactive brazing composition, and the assembly formed by the articles and the brazing composition is heated to a brazing temperature that is sufficient to melt the brazing composition in order to form a refractory joint, in which the non-reactive brazing composition is a binary alloy formed, as mass percentages, from 56% to 70% silicon and 44% to 30% yttrium.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for regenerating polyol by using waste polyurethane

The invention discloses a method for regenerating polyol by using waste polyurethane. In the method, fragments of polyurethane waste, an alcoholysis agent, a catalyst, an antioxidant and a treating agent are used as raw materials; and the method comprises the following reaction steps: (1) adding the alcoholysis agent in a reaction kettle, heating up to 200-220 DEG C under the protection of nitrogen, and adding the catalyst and antioxidant; (2) adding the fragments of polyurethane waste, and preserving the temperature for 1-5 hours; and (3) cooling to 80-150 DEG C, adding the treating agent, preserving the temperature for 1-3 hours to obtain a polyol liquid homogeneous phase mixture, wherein the fragments of polyurethane waste are added at least twice in the step (2). The method disclosed by the invention has high alcoholysis rate; the product has low viscosity, moderate reactivity and easiness for use; and the prepared polyurethane product has excellent performance.

Owner:希肤科技(上海)有限公司

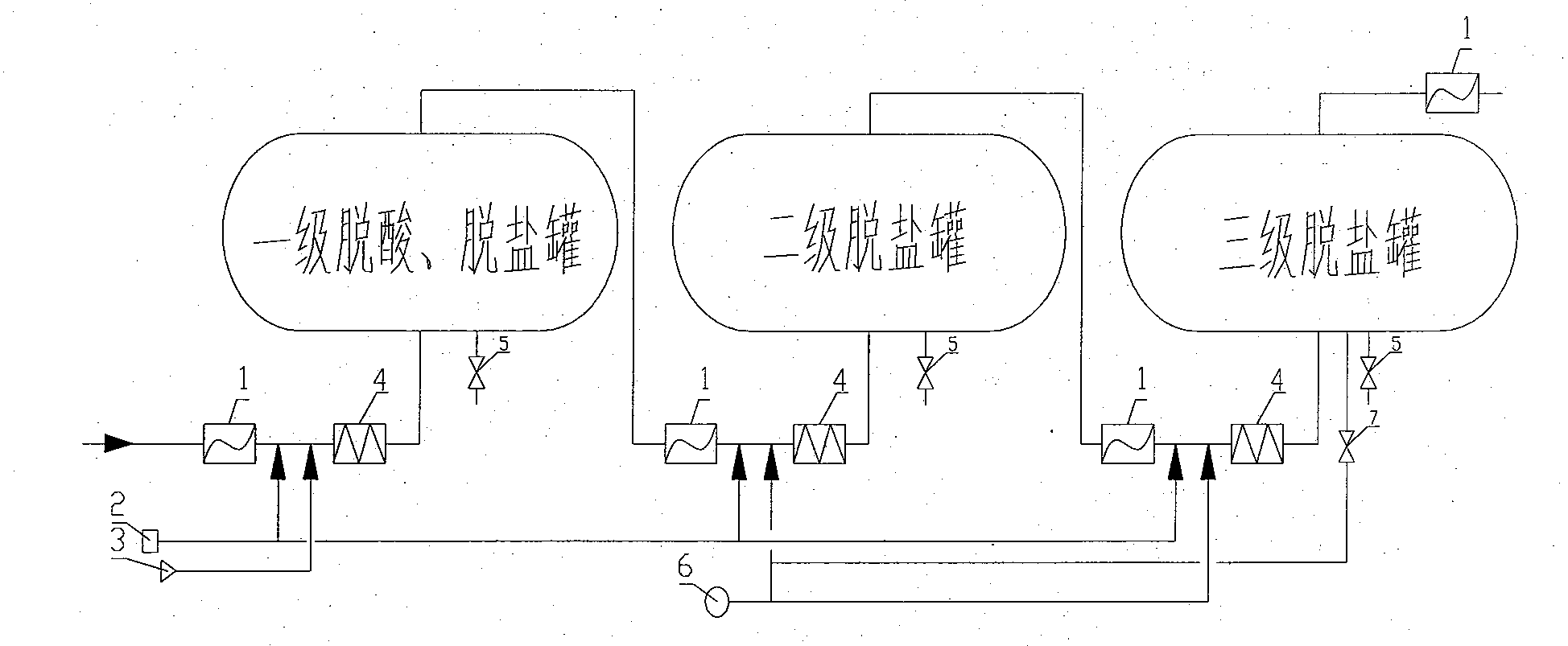

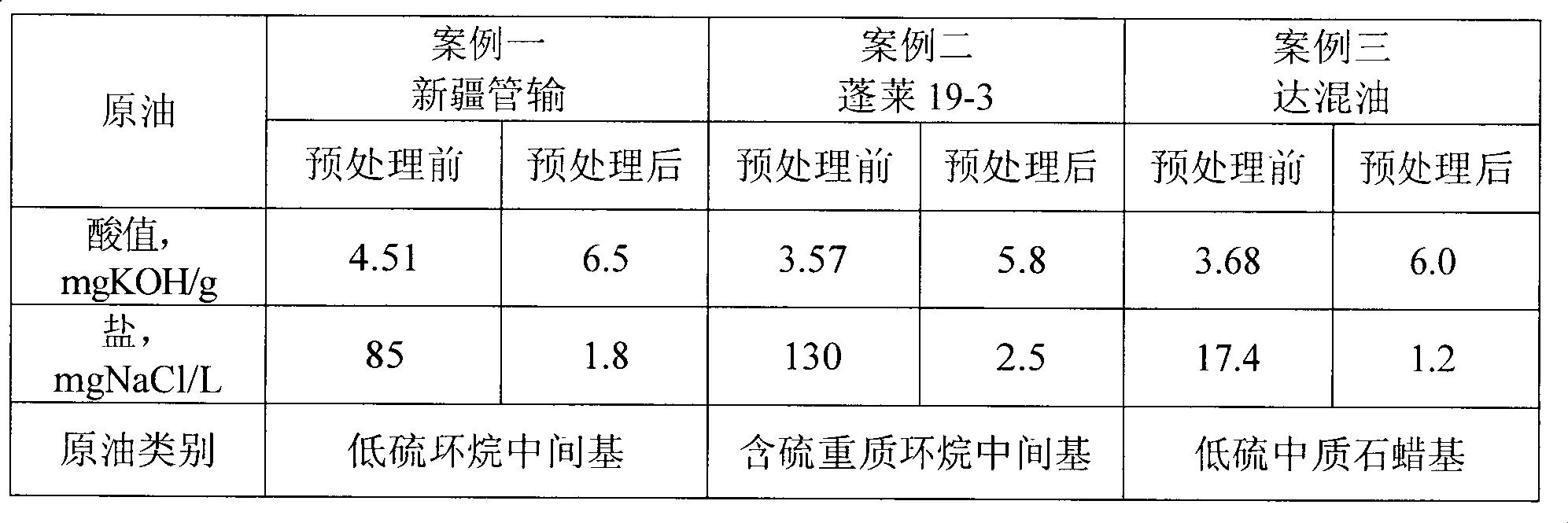

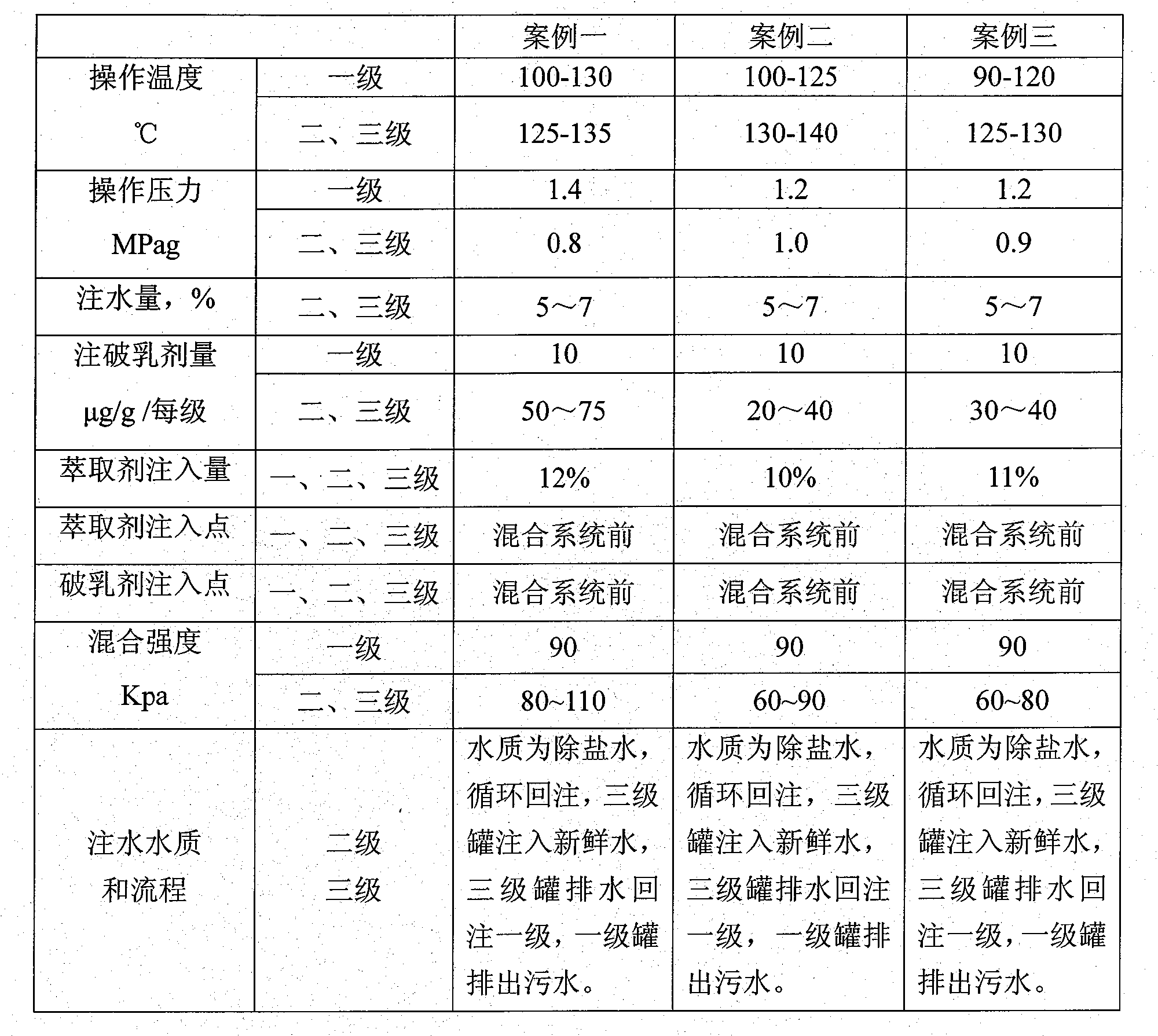

Pre-treatment process method of high acid crude oil

ActiveCN103805227AAvoid corrosionSimple processDewatering/demulsification with electric/magnetic meansRefining with two or more solventsDemulsifierDesalination

The invention relates to a pre-treatment process method of high acid crude oil. The method comprises the following steps that high acid crude oil is treated by coupling deacidification and electro-desalting processes by combining chemical extraction and electro-desalting; a first level tank is taken as a deacidification and electro-desalting tank; a demulsifier and an extractant are injected before a crude oil electro-desalting static mixer; after being fully mixing with crude oil, the mixture enters into the first level desalting tank; generated naphthenate and salt-containing sewage in the crude oil are dissolved in the extractant; treated deacidified oil enters into second and third level desalting tanks after being mixed with the demulsifier and water through the static mixer for desalination and dehydration; treated crude oil enters into a subsequent heat exchange unit; after a period time of operation of an electro-desalting system, impurities such as mud in raw material oil are flushed by a non-stop back purge device to discharge mud-containing sewage out of the tank; an extract phase is acidified to separate out naphthenic acid which is further extracted and purified by light dydrocarbon, and the extractant is purified and recovered and recycled.

Owner:长江三星能源科技股份有限公司

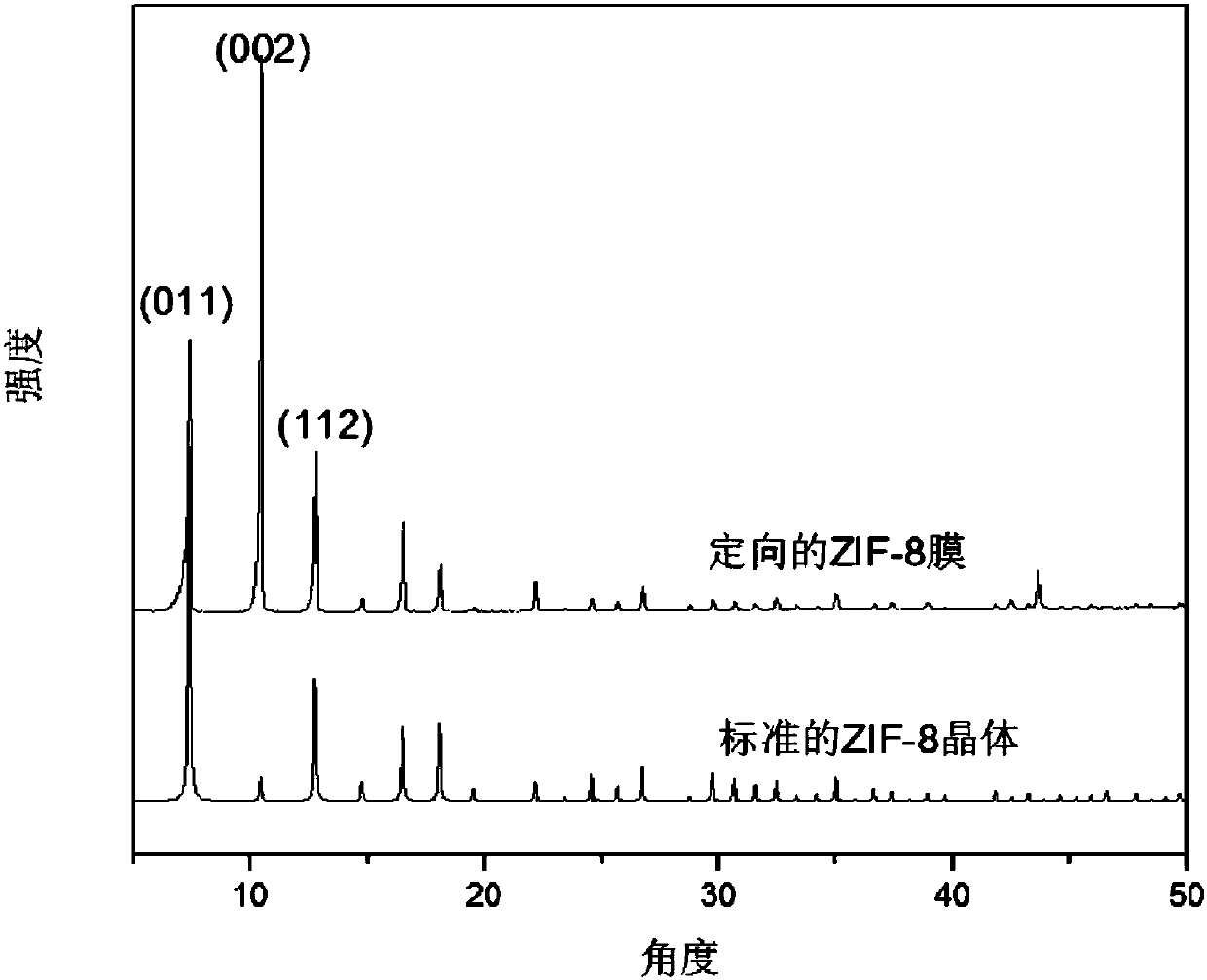

Method for preparing metal organic framework film having specific orientation by using template method

PendingCN107602474AModerate reactivityImprove versatilityMaterial nanotechnologyOrganic chemistryElectricityReaction rate

The present invention discloses a method for preparing a metal organic framework film having specific orientation by using a template method. According to the method, a one-dimensional nano-rod template is modified on a substrate through an electrodeposition method, and a metal organic framework film having specific orientation is prepared at the one-dimensional nano-rod template through a solvothermal one-pot method. According to the present invention, the method can provide good versatility for a variety of substrates; the one-dimensional nano-rod template introduced by the electrodepositionmethod has the advantages of moderate chemical stability and moderate reaction activity, such that the reaction rate is substantially accelerated, the operation process is simplified, and the production efficiency is substantially improved; various substrates are the commercialized materials, and are cheap and are easy to obtain; and the metal organic framework film having the specific orientation is directly synthesized through the solvothermal one-pot method, such that the repeatability is high, and the method is suitable for the large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

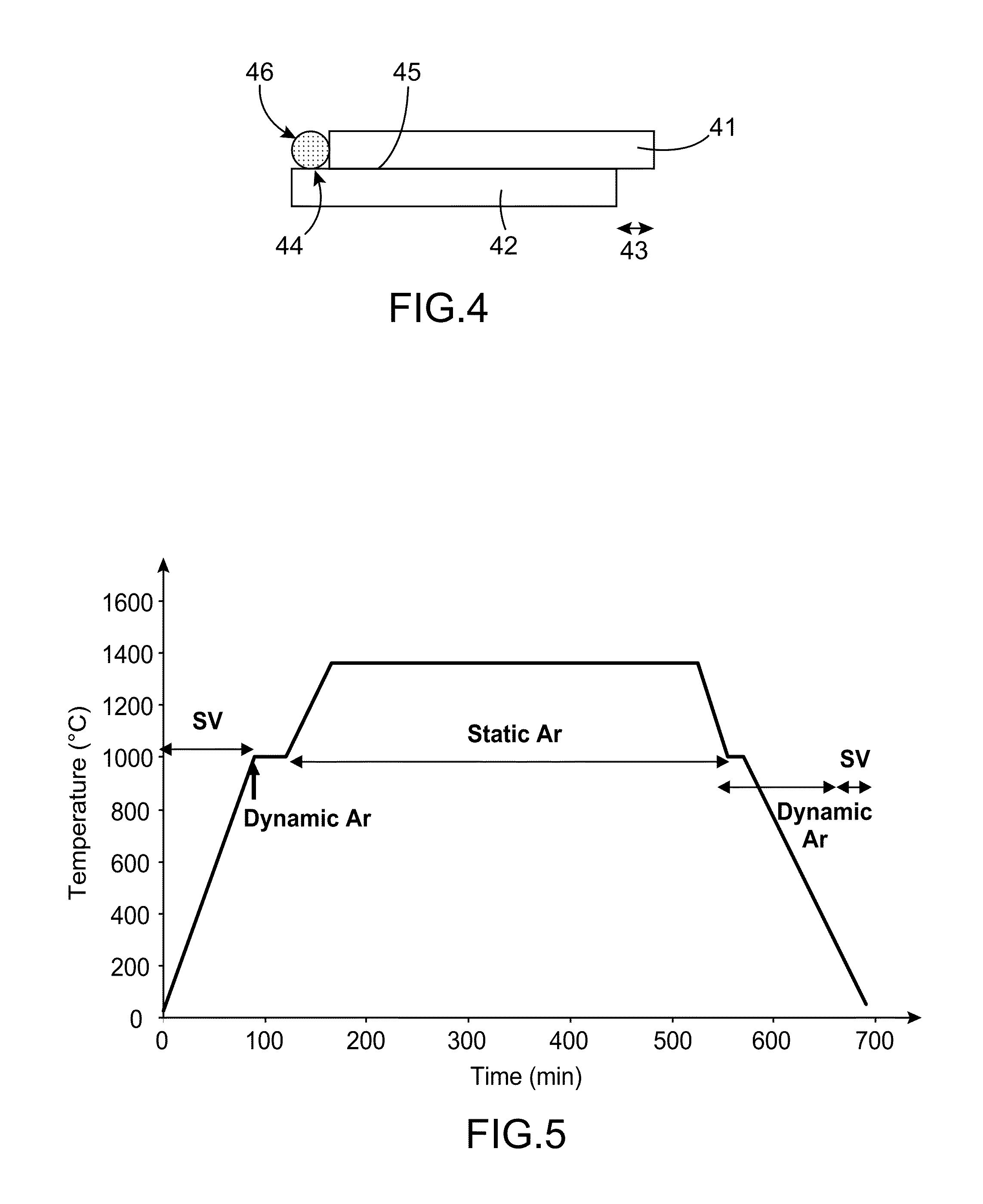

Method for assembling parts made of sic materials by means of non-reactive brazing in an oxidizing atmosphere, brazing compositions, and gasket and assembly obtained by said method

ActiveUS20140328615A1Moderate reactivityEnhanced couplingLaminationLamination apparatusCarbide siliconSILICONE DIOXIDE

A method is described for assembling at least two parts made of silicon carbide based materials by non-reactive brazing in an oxidizing atmosphere, each of the parts comprising a surface to be assembled, wherein the parts are placed in contact with a non-reactive brazing composition, the assembly formed by the parts and the brazing composition is heated to a brazing temperature sufficient for completely or at least partially melting the brazing composition, or rendering the brazing composition viscous, and the parts and the brazing composition are cooled so as to form, after cooling the latter to ambient temperature, a moderately refractory joint. The non-reactive brazing composition is a composition A consisting of silica (SiO2), alumina (Al2O3), and calcium oxide (CaO), or a composition B consisting of alumina (Al2O3), calcium oxide (CaO), and magnesium oxide (MgO), and, before heating the assembly formed by the parts and the brazing composition to the brazing temperature, a supply of silicon in a non-oxidized form is carried out on the surfaces to be assembled of the parts to be assembled, and / or on the surface layers comprising the surfaces to be assembled of the parts to be assembled, and / or in the brazing composition.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

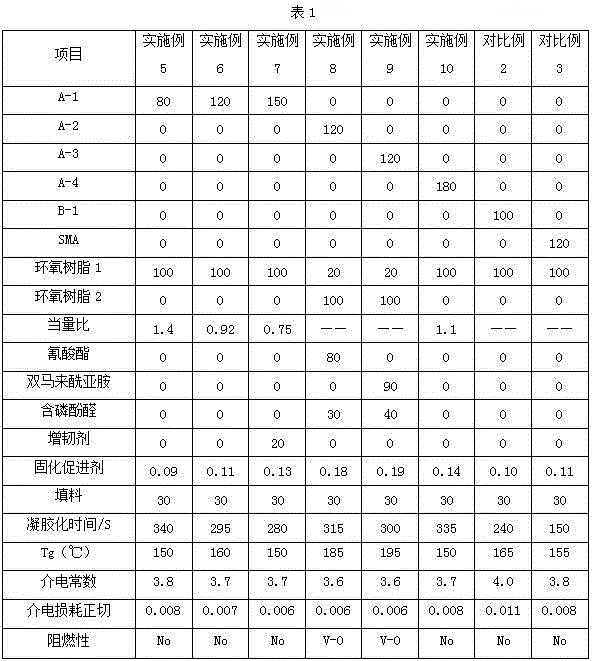

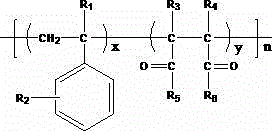

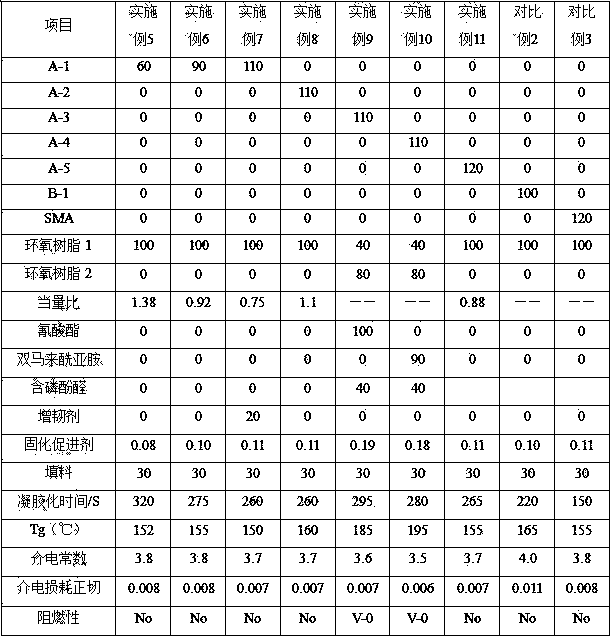

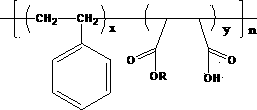

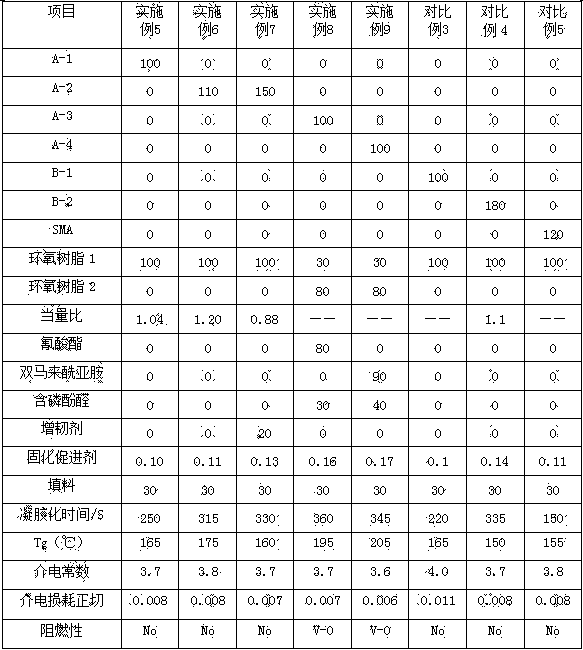

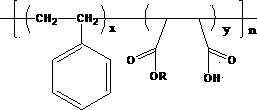

Modified styrene-maleic anhydride copolymer and thermosetting resin composition

ActiveCN104151473AExcellent dielectric propertiesExcellent process controllabilitySynthetic resin layered productsEpoxyDielectric loss

The invention provides a modified styrene-maleic anhydride copolymer which adopts the structural formula shown in the specification. The invention also provides a thermosetting resin composition including both the modified styrene-maleic anhydride copolymer and epoxy resin, and the composition is relatively low in dielectric constant and low in dielectric loss tangent and has excellent heat resistance, processing technology and storage performance. The invention further provides a prepreg and a laminate which are prepared from the thermosetting resin composition and both can be used as printed circuit substrate materials, PCBs and the like.

Owner:SHENGYI TECH SUZHOU

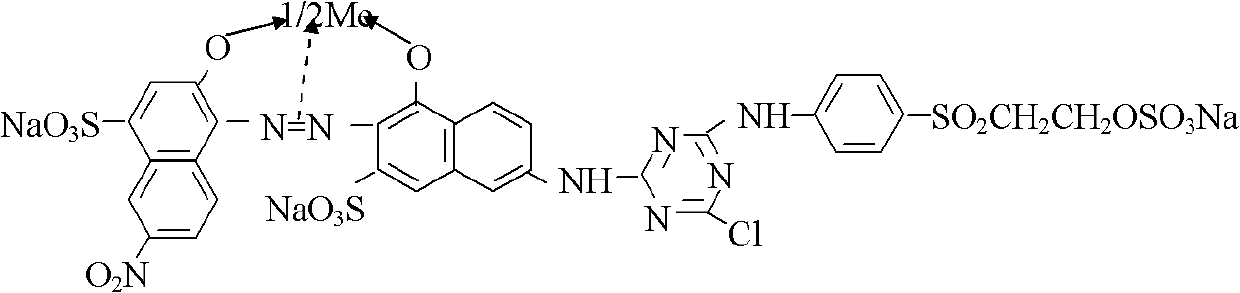

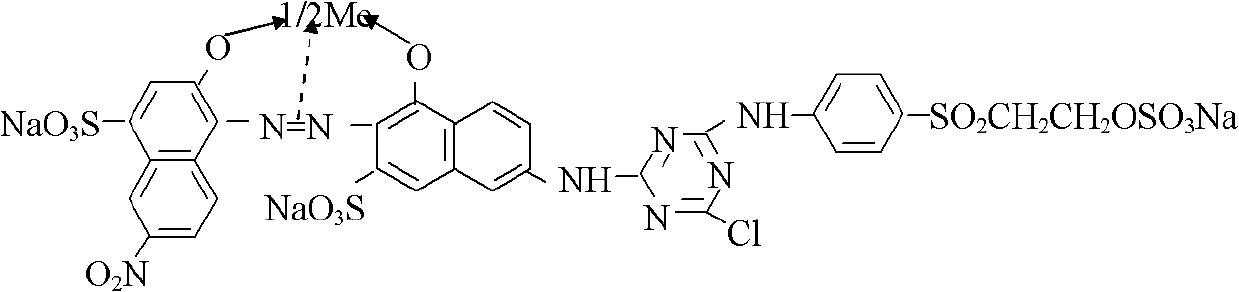

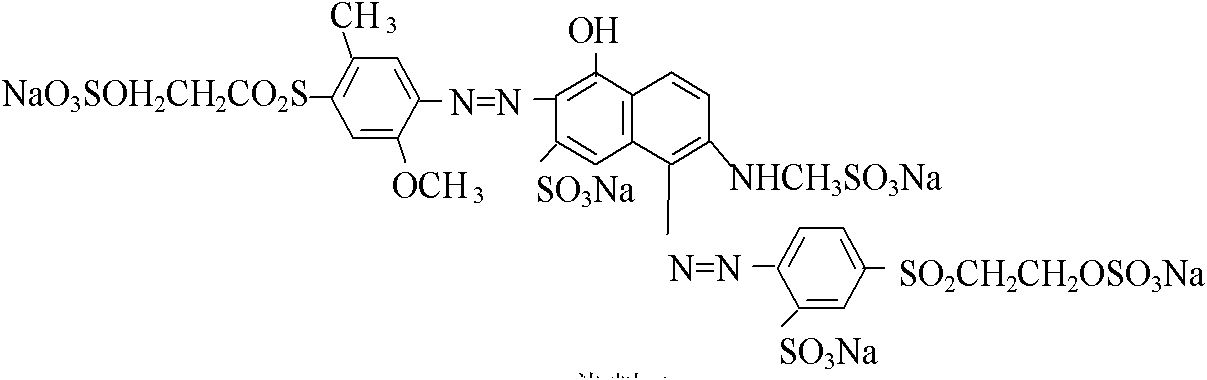

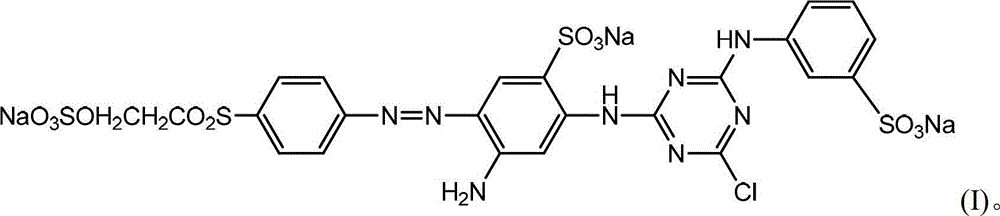

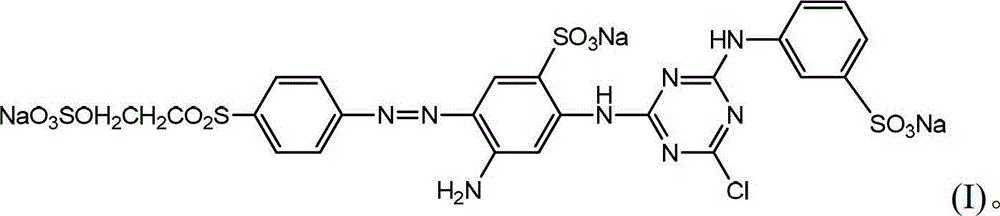

Composite reactive grey for printing and dyeing and clean production process thereof

The invention discloses a composite reactive grey for printing and dyeing and a clean production process thereof. The composite reactive grey consists of active ingredients, namely a chromium grey dye component, a cobalt grey dye component and C.I. reactive black 5 with the structure shown in the specifications in a weight ratio of (10-20):(55-80):(5-10); and the dye has the characteristics of high solubility, particularly low temperature solubility, high fastness to light and chlorine, mild reactivity, low substantivity and high chromatic light controllability. The replacement of a reductivegrey dye under the common conditions can be met; printing and dyeing cost is reduced; printing and dyeing processes are simplified; energy conservation and emission reduction are realized; three-waste emission in dye production is reduced; and clean production is achieved.

Owner:无锡润新染料有限公司

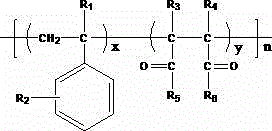

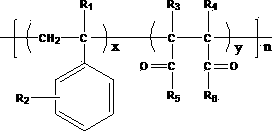

Terpolymer and thermosetting resin composition thereof

ActiveCN104211847AExcellent dielectric propertiesExcellent process controllabilitySynthetic resin layered productsCircuit susbtrate materialsEpoxyHeat resistance

The invention provides a terpolymer containing structural units represented by a general formula (I), a general formula (II) and a general formula (III). The invention also provides a thermosetting resin composition containing the terpolymer and epoxy resin. The composition has low dielectric constant, low dielectric loss tangent, and excellent heat resistance, processing manufacturability and storage performance. The invention also provides a prepreg and a laminate prepared from the thermosetting resin composition, and the thermosetting resin composition can be used in printed circuit substrate material and printed circuit board.

Owner:SHENGYI TECH SUZHOU

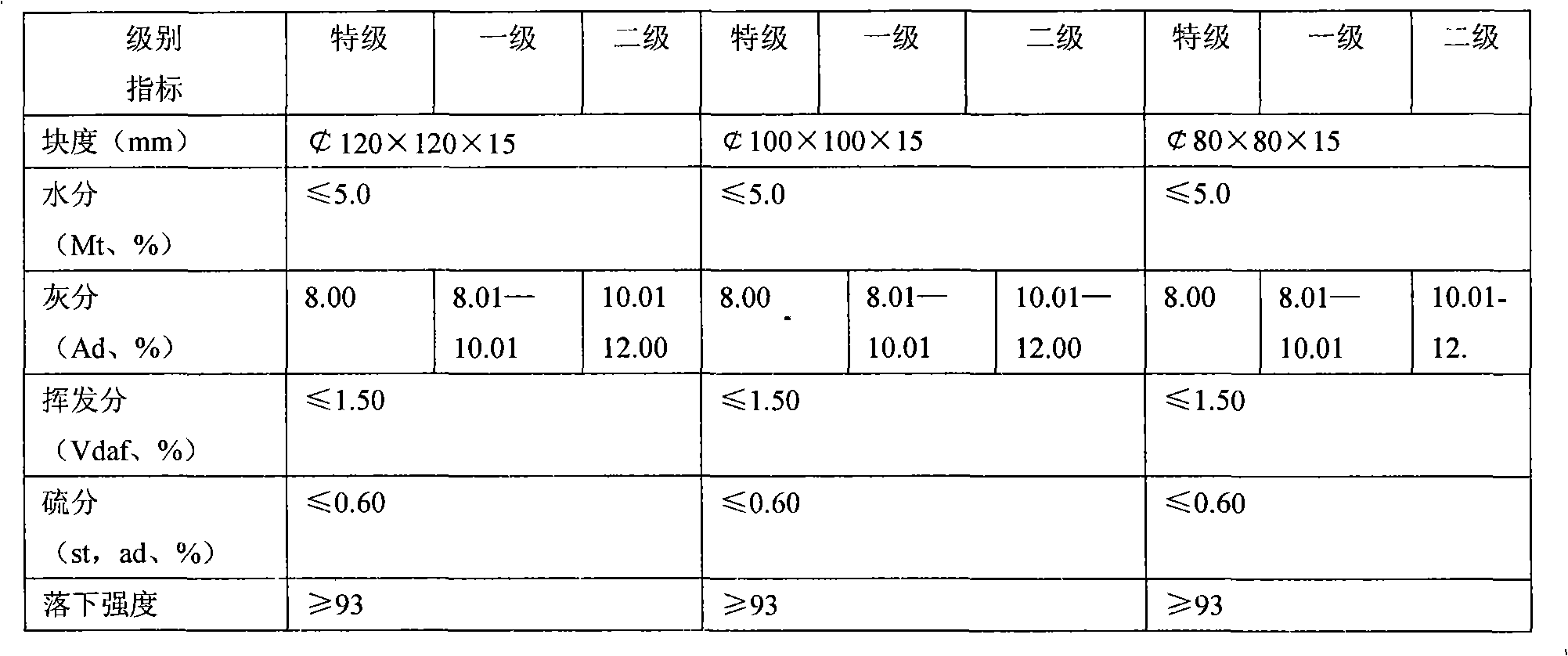

Anthracite carbon casting formed coke

InactiveCN101280203ARealize protection and meet emission standardsHigh carbon contentSpecial form destructive distillationFoundryHigh carbon

Disclosed is anthracite carbon foundry formed coke which solves the disadvantages of uneven granularity, insufficient oxygen-adding, high broken rate and environment pollution found in the formed coke in the prior art; the anthracite carbon foundry formed coke is characterized in that the anthracite or non-coking coal is used to produce the anthracite carbon foundry formed coke; the steps include that the raw coal is conveyed to the factory, crushed and grinded to powder; the binder is added to the grinded powder and the mixture is stirred under the cooling condition, and then stirred evenly after being heated; the mixture is conveyed to the pressing machine for the extruding formation; the formed material is conveyed to the carbonization chamber and then is processed with dry distillation and carbonization under the conditions of air-isolation and the temperature ranging from 950 DEG C-1050 DEG C; finally, the formed material is cooled and the finished product is outputted to be stored in the storehouse for sale; the process of comprehensive utilization of the coke-oven gas generated in the carbonization chamber is set for the lime joint production; the process of dust removal and desulfurization is set for the flue gas and SO2 in the exhausted gas; based on the special binder formula and the special product structure and compared with the traditional coking method, the anthracite carbon foundry formed coke has the advantages of high carbon content, high calorific value, low ash content and sulfur content, crush resistance, abrasion resistance, good intensity, moderate reactivity, high intensity after reaction, good cold and heat intensity, reasonable and simple structure, small investment, low expense and specially being applicable to the coking and the mechanical casting industries.

Owner:YANGQUAN YANGMEI FORMED COKE TECH DEV CENT

One-component non-ionic polyurethane water dispersion

The present invention discloses a one-component non-ionic polyurethane water dispersion, which comprises the following raw materials by weight: an organic polyisocyanate, a polyether polyol, polyethylene glycol monomethyl ether, a chain extender, and water, wherein a molar ratio of the isocyanate group in the organic polyisocyanate to the active hydrogen in the polyether polyol is 1.2-1.5, the use amount of the polyethylene glycol monomethyl ether is 14-21 wt% of the total amount of the organic polyisocyanate, the polyether polyol and the polyethylene glycol monomethyl ether, the functionality of the isocyanate group in the organic polyisocyanate is more than 2, the polyether polyol is one or two selected from polyether diols, the molecular weight of the polyether polyol is 400-8000, the chain extender is an active hydrogen compound, and the chain extending coefficient is 0.80-0.95. According to the present invention, the one-component non-ionic polyurethane water dispersion has characteristics of no organic solvent, good water dispersion property, and good stability.

Owner:CHINA PETROCHEMICAL CORP

Method of producing substituted benzaldehydes with catalytic amounts of acid

InactiveUS6080892AHigh yieldReduce needOrganic compound preparationPreparation by carbon monoxide reactionAluminium chlorideBenzene

This invention relates to a process for preparing specific substituted benzaldehydes through the reaction of substituted benzenes with carbon monoxide and aluminum chloride at a relatively low pressure, at a low temperature, and in the presence of at most a catalytic amount of acid (preferably aqueous HCl) and a solvent. The resultant substituted benzaldehydes are useful as precursors to the formation of a number of different compounds, such as dyestuffs, flavorings, fragrances, nucleating agents, polymer additives, and the like. The inventive method provides a very cost-effective and safe procedure for producing such substituted benzaldehydes at very high yields.

Owner:MILLIKEN & CO

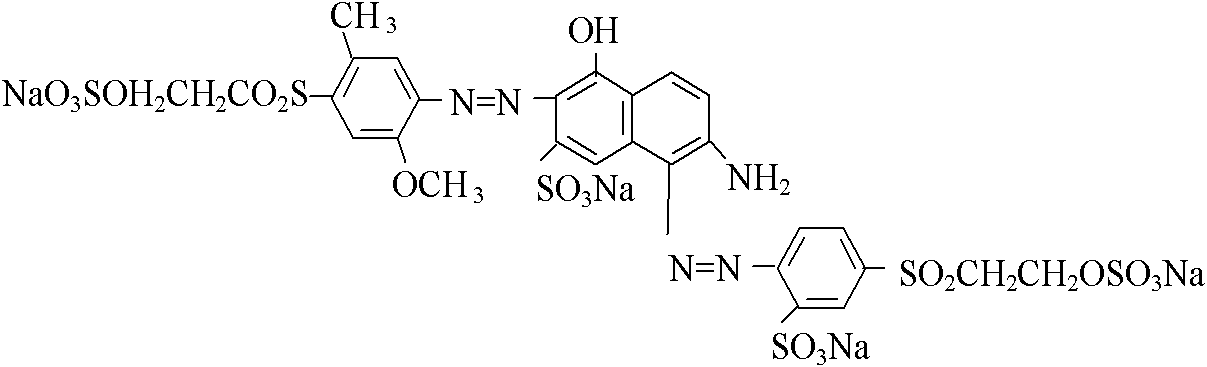

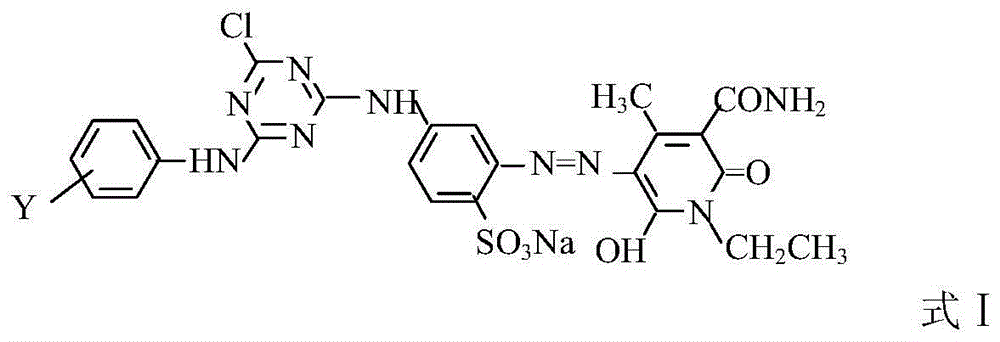

Novel composite active cardinal dye and manufacturing method thereof

ActiveCN102344693AReduce direct effectModerate reactivityOrganic dyesDyeing processSolubilityControllability

The invention discloses a novel composite active cardinal dye and a manufacturing method thereof. The composite active cardinal dye mainly comprises structural components shown in formula I, formula II and formula III, wherein the weight ratio of the structural components shown in formula I, formula II and formula III is (30-40): (30-40): (5-25). The dye disclosed by the invention can be used fordip dyeing, continuous pad dyeing and printing processes at 50-60 DEG C, and can be also used for cold pad batch dyeing; the dye has good color tone controllability, good dyeing build-up properties, high product solubility and good color fastness to chlorinated water; and the product performance of the dye is superior to that of the traditional active cardinal dye. Formula I, formula II and formula III are shown in the specification.

Owner:无锡润新染料有限公司

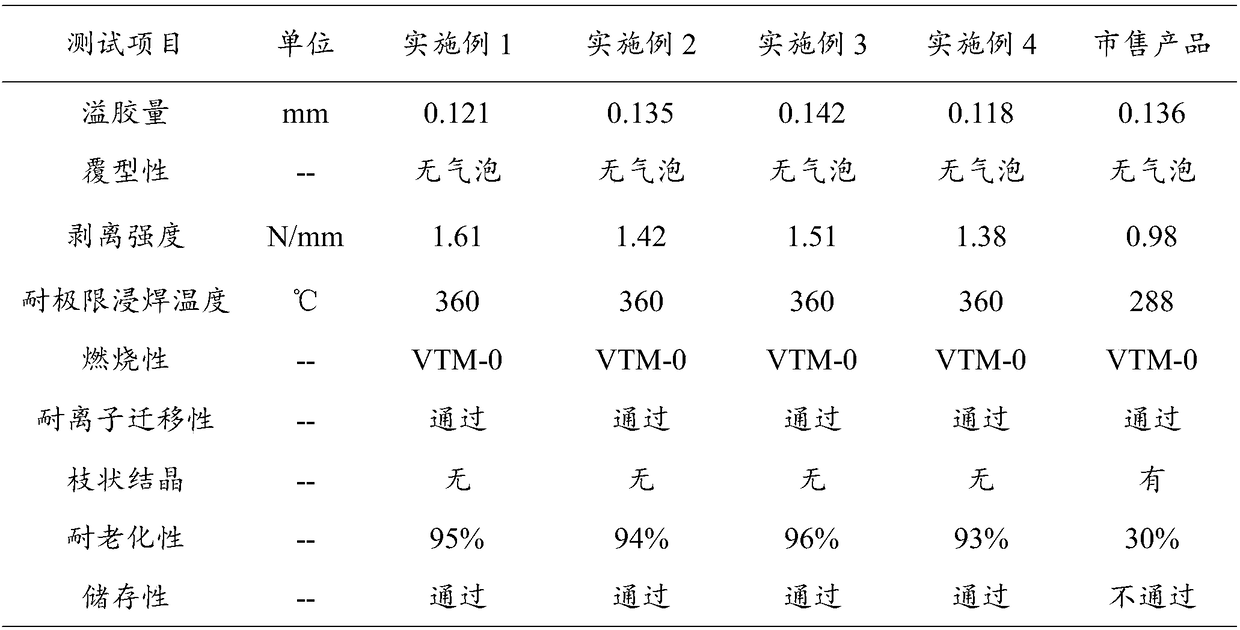

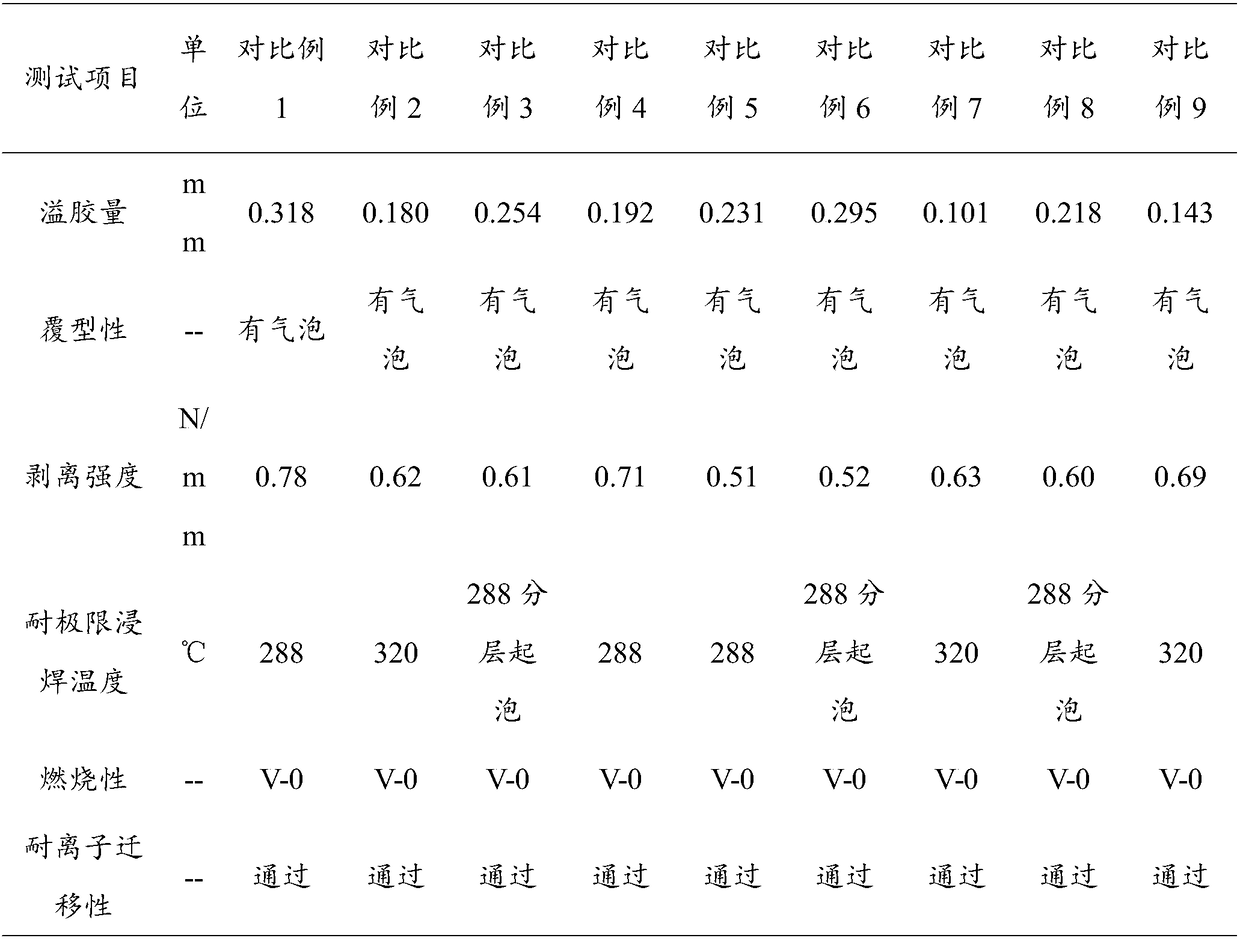

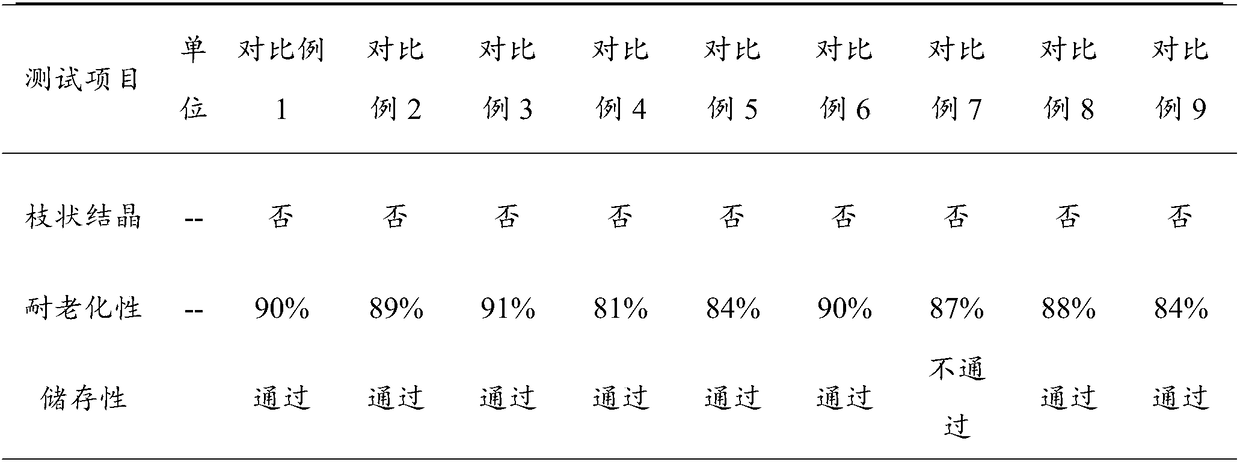

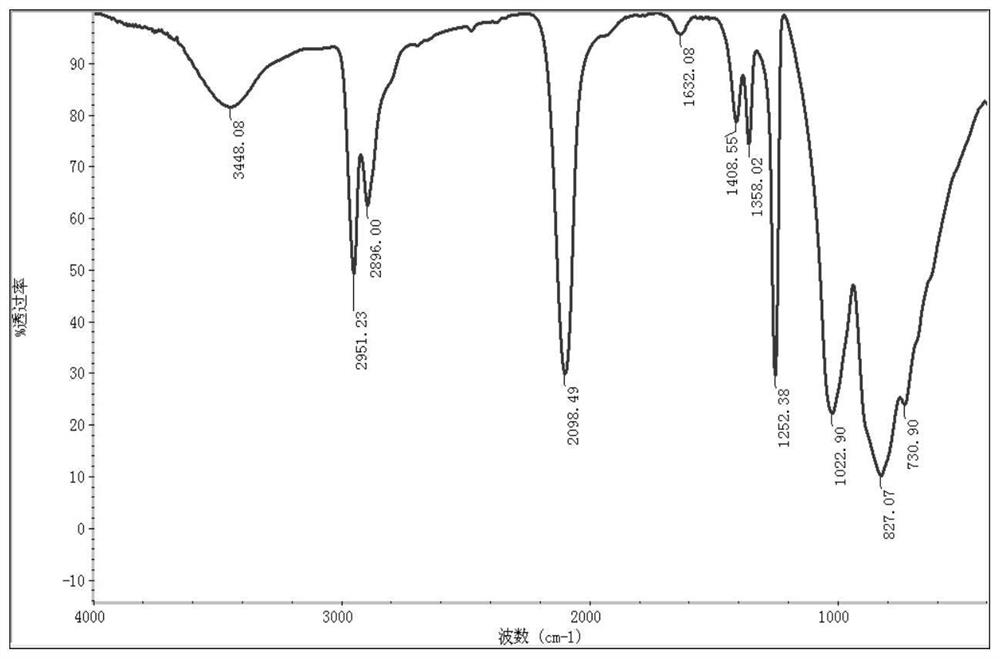

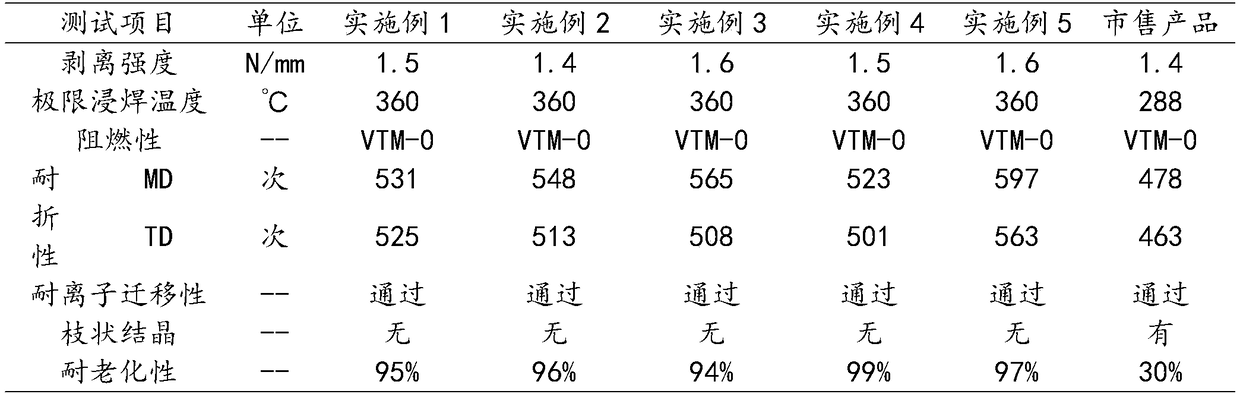

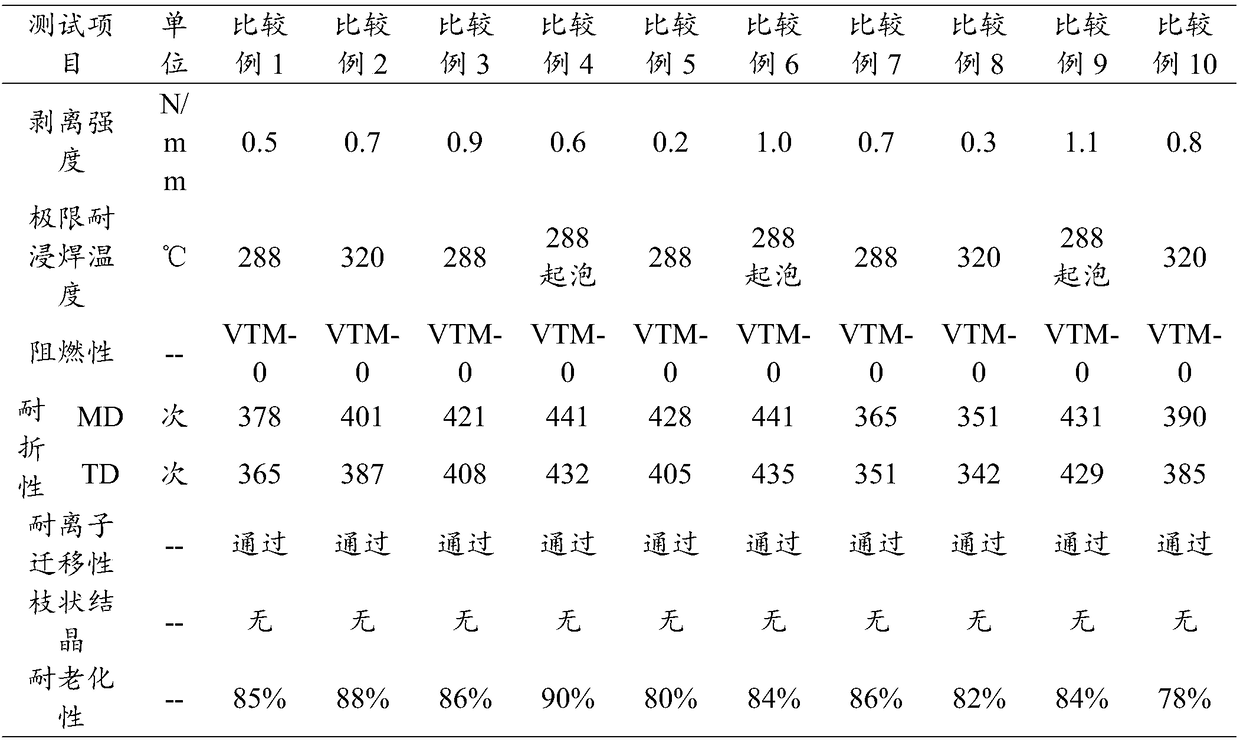

Halogen-free resin composition and coverage film used for flexible printed circuit board and prepared from same

ActiveCN108864924AImprove heat resistanceEffective control of flow behaviorFireproof paintsPolyurea/polyurethane coatingsPolymer scienceOrganic solvent

The invention discloses a halogen-free resin composition. The halogen-free resin composition comprises the following components in parts by weight dispersed in an organic solvent: 10 to 20 parts of phosphorus-containing epoxy resin, 10 to 15 parts of multi-functional epoxy resin, 35 to 50 parts of polyurethane and polyamide segmented copolymer, 10 to 20 parts of MQ resin, 5 to 10 parts of amine curing agent, and 5 to 15 parts of phosphorus-containing flame retardant. The invention also discloses a coverage film used for a flexible printed circuit board and prepared from same. The coverage filmhas excellent flexibility and low ion content, can avoid the branched crystal when in ion migration resistant test, has good insulation performance, and also has excellent stripping strength, heat resistance, size stability, chemical resistance, storage performance and processing performance, and the flame-retardant performance can reach grade UL94 VTM-0.

Owner:湖北恒驰电子科技有限公司

Process for the Moderately Refractory Assembling of Articles Made of SiC-Based Materials by Non-Reactive Brazing in an Oxidizing Atmosphere, Brazing Compositions, and Joint and Assembly Obtained by this Process

ActiveUS20100055498A1Moderate reactivityReduce financial costsLaminationLamination apparatusRefractoryComposition B

Process for the moderately refractory assembly of at least two articles made of silicon carbide-based materials by non-reactive brazing in an oxidizing atmosphere, in which the articles are placed in contact with a non-reactive brazing composition and the assembly formed by the articles and the brazing composition is heated in an oxidizing atmosphere at a brazing temperature sufficient to melt the brazing composition so as to form a moderately refractory joint, wherein the non-reactive brazing composition is a composition A composed of silica (SiO2), alumina (Al2O3) and calcium oxide (CaO), or alternatively a composition B composed of alumina (Al2O3), calcium oxide (Cao) and magnesium oxide (MgO).Brazing suspension, paste comprising a powder of said brazing composition and an organic binder.Refractory joint and assembly.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

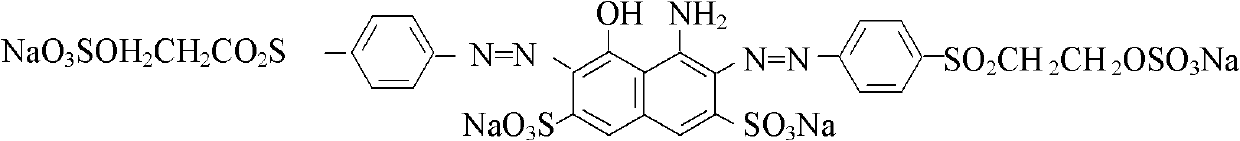

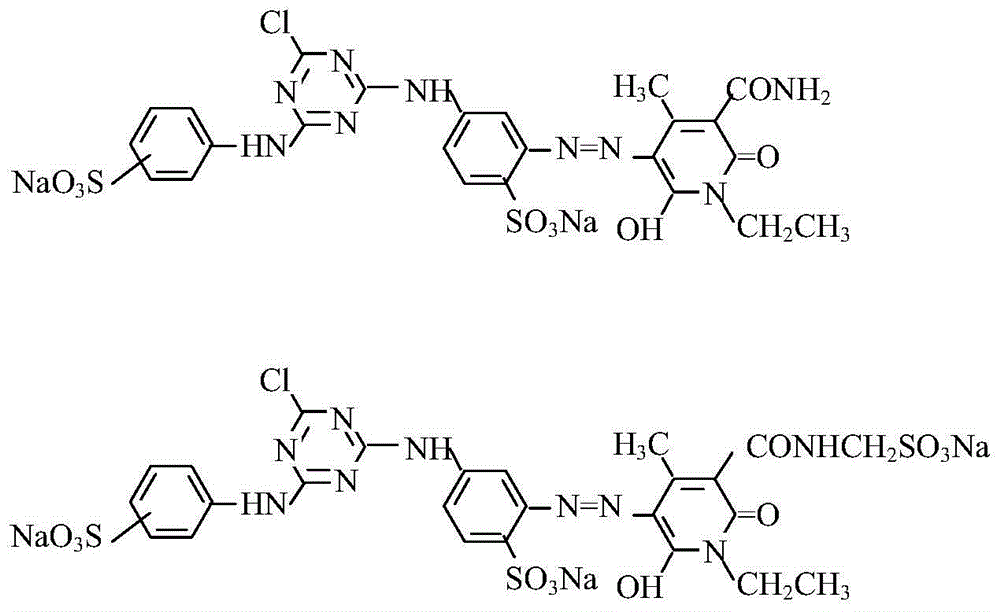

Reactive golden yellow dye and composite reactive brown dye

InactiveCN102911524AImprove metamerismImprove thermal discolorationReactive dyesSolubilityReactive orange

The invention relates to a reactive golden yellow dye and a composite reactive brown dye. The reactive golden yellow dye is shown in a formula (I), while the composite reactive brown dye is prepared be compounding the reactive golden yellow dye shown in formula (I), C.I reactive orange 107, reactive dark blue M-R, C.I reactive blue 203, reactive dark red and reactive red SHE according to the mass ratio of (30-55): (5-12): (5-15): (5-15): (5-15): (5-15). The dyes can be used for dip dyeing, continuous pad dyeing, cold batching and shortened wet steaming processes, are low in directness, moderate in reactivity and high in product solubility, and have 1 / 1 dyeing depth, grade 5 of fastness to light, grade 4-5 of fastness to soaping, grade 4-5 of fastness to perspiration, grade 4 of fastness to chlorine water, grade 4-5 of fastness to dry rubbing, grade 4 of fastness to wet rubbing and grade 4 of fastness to ironing, and particularly, the phenomena of metamerism of redness and thermosensitive discoloration of a lamp A are improved obviously.

Owner:无锡润新染料有限公司

Preparation method of 2-methyl-4-acetoxy-2-butenal with high yield

ActiveCN110734374AReduce productionImprove stabilityOrganic compound preparationCarboxylic acid esters preparationPtru catalystIsomerization

The invention provides a preparation method of 2-methyl-4-acetoxy-2-butenal (I) with high yield. The preparation method comprises the steps: with 2,5-dihydrofuran (II) and synthesis gas as raw materials, carrying out hydroformylation reaction under the action of a catalyst to prepare 3-formyl tetrahydrofuran (III); then carrying out a reaction with an acetylation reagent under the action of a catalyst to prepare 2-formyl-4-acetoxy-1-butene (IV); and carrying out double bond isomerization under the action of a catalyst to obtain 2-methyl-4-acetoxy-2-butenal (I). The method has the advantages ofcheap and accessible raw materials and low cost; the process flow is short, the reaction is easy to realize, the operation is safe, simple and convenient, the wastewater yield is low, and the green and environment-friendly effects are achieved; the method has the advantages of stable reaction intermediate product, proper reaction activity, high reaction selectivity, fewer side reactions and highyield, and is suitable for industrial production.

Owner:XINFA PHARMA

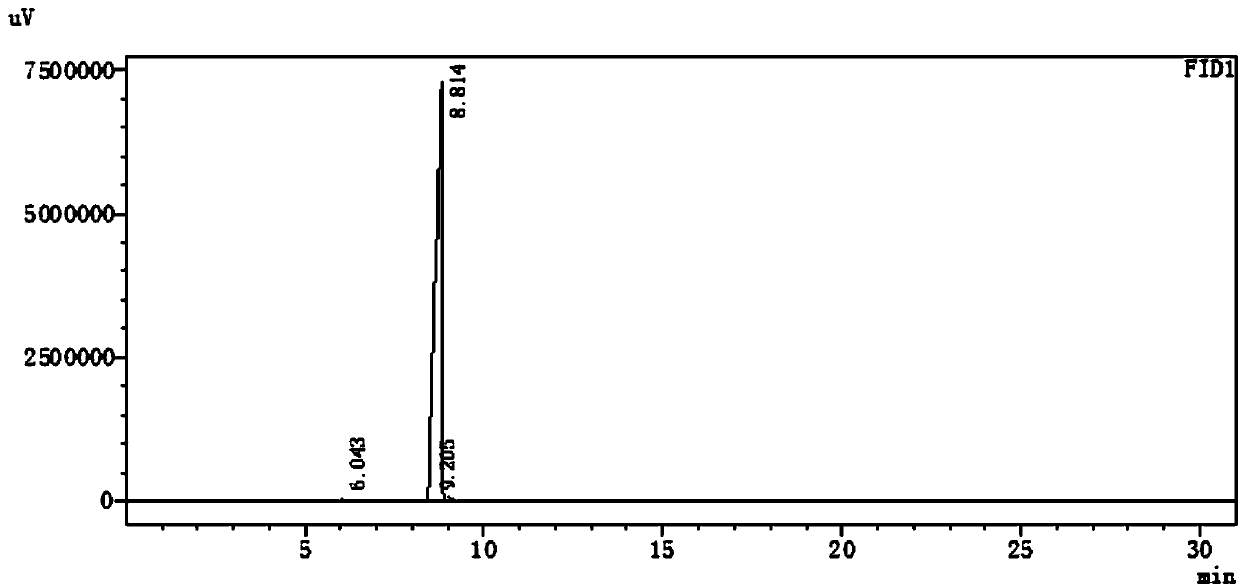

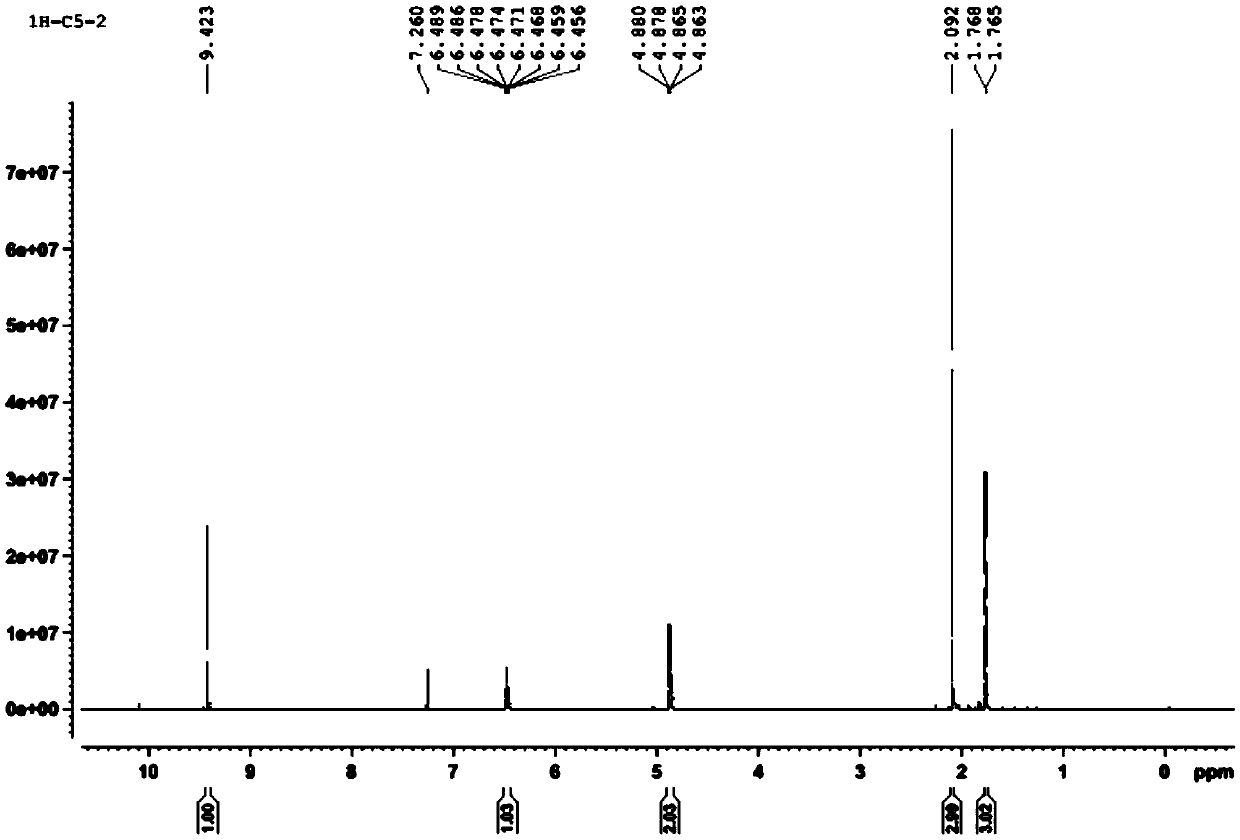

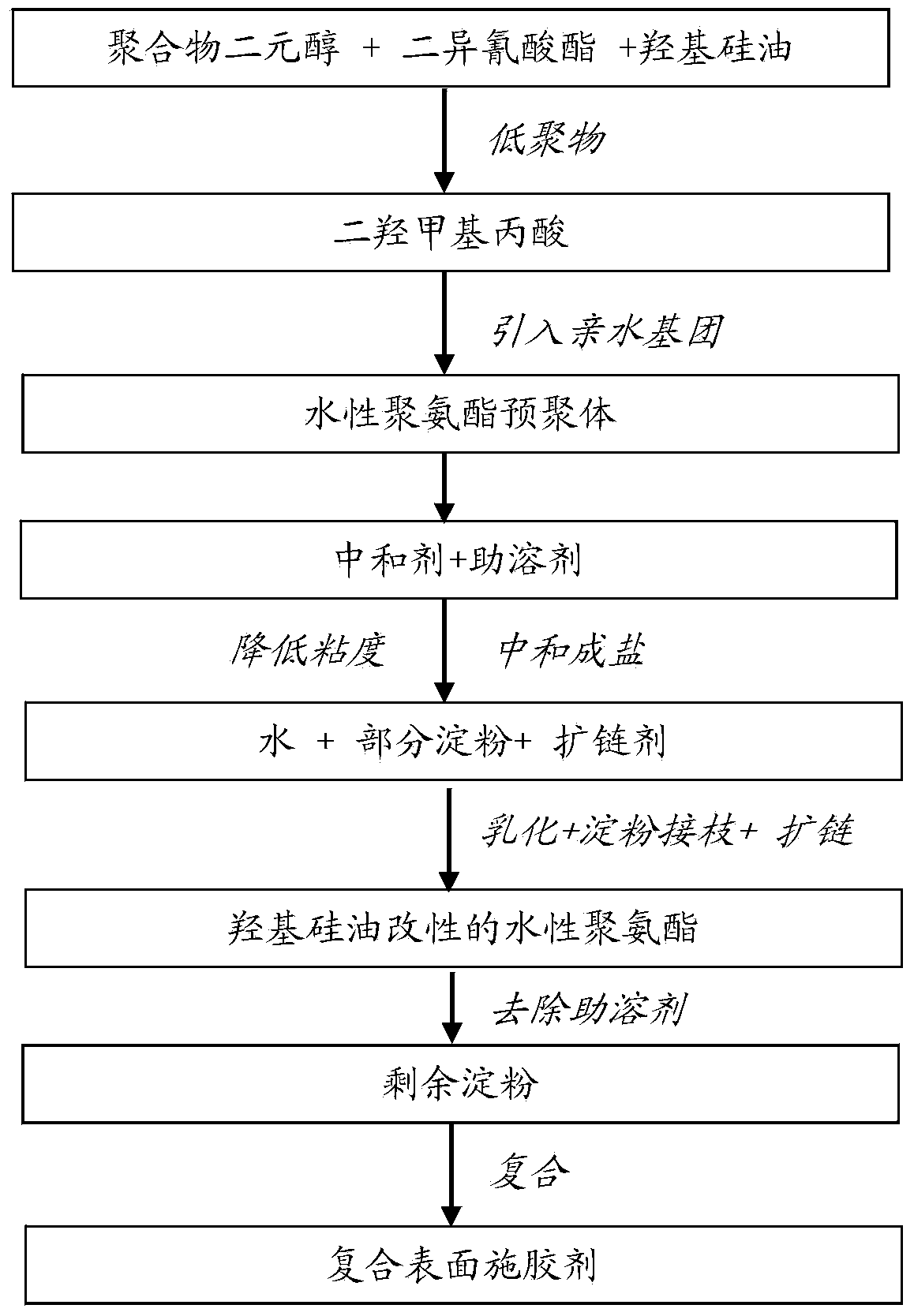

Preparation method of paper compound surface sizing agent

InactiveCN103711035ASmooth responseEasy to prepareWater-repelling agents additionPaper coatingPrepolymerSolvent

The invention discloses a preparation method of a paper compound surface sizing agent and provides a preparation method of a surface sizing agent with good combination property. The preparation method comprises the steps of: with polymers (dihydric alcohol and diisocyanate) as raw materials, adding a hydroxyl-containing modifying agent, stirring for reaction at a temperature of 80-90 DEG C and under the protection of an inert gas to prepare a waterborne polyurethane oligomer; adding a hydrophilic substance, stirring at a temperature of 80-90 DEG C for reacting for 2.5-3.5h to obtain a waterborne polyurethane prepolymer; cooling to 45-50 DEG C, adding a neutralizing agent and a cosolvent, stirring for reaction to ensure that the waterborne polyurethane prepolymer neutralizes to form a salt; cooling to 5-10 DEG C, sequentially adding water, a part of starch and a chain extender, then raising the temperature to 50-60 DEG C, reacting to prepare hydroxyl silicone oil modified waterborne polyurethane; and performing reduced pressure distillation to remove the cosolvent, adding the rest of starch, raising the temperature to 90 DEG C, and stirring for reaction to obtain the waterborne polyurethane / starch compound surface sizing agent. The preparation method is simple and is low in cost.

Owner:TIANJIN UNIV OF COMMERCE

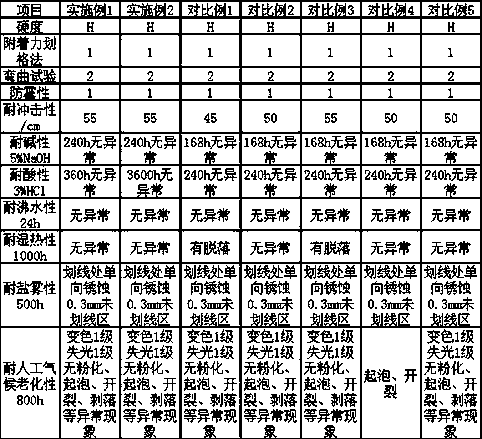

Preparation method of wear-resistant, heat-insulation and corrosion-resistant powder coating

InactiveCN110760234AMeet the needs of efficient operationReduce harmFireproof paintsCarboxyl rubber coatingsNitrile rubberFirming agent

The invention discloses a preparation method of a wear-resistant, heat-insulation and corrosion-resistant powder coating. The powder coating is prepared from the following raw materials: benzoxazine resin, epoxy resin, chlorinated polyether, carboxylated-terminated acrylonitrile-polybutadiene rubber, a curing agent, barite powder and wollastonite powder. The wear-resistant, heat-insulation and corrosion-resistant powder coating can be prepared by processes such as melting, mixing and extruding, cooling for tabletting, crushing and sieving and has excellent wear and corrosion resistance and heat insulation properties, the surface of a processed coating meets the national and industrial standards on the aspects such as adhesive force, flexibility, impact strength, smoothness, hardness and chemical resistance, and the wear-resistant, heat-insulation and corrosion-resistant powder coating is low in curing temperature, convenient to use and capable of reducing the cost.

Owner:孙振龙

Polyurethane degradation method and application of degradation product thereof in plastic track component B

InactiveCN107245162ALow amine valueModerate amine valuePlastic recyclingGround pavingsPolyurethane elastomerOrganic acid

The invention discloses a polyurethane degradation method and application of a degradation product thereof in a plastic track component B. The method is characterized in that a polyurethane elastomer is degraded by using organic acid as a degradation agent in the presence of a catalyst, and the obtained degradation product can be used instead of brand new polyether polyol in the polyurethane plastic track component B. According to the invention, the method does not need the use of a large amount of degradation agent and does not need vacuumizing; fractions in the degradation process are mainly moisture contained in the raw material; after degradation, amine byproducts are greatly reduced, so that no treating agent for the amine byproducts needs to be added, thereby achieving the purposes of reducing three wastes, improving the yield, simplifying the process and saving the cost; and the degradation product can be used completely instead of the brand new polyether polyol in the polyurethane plastic track component B, thereby greatly lowering the cost of a polyurethane plastic track mixed component.

Owner:SUN YAT SEN UNIV +1

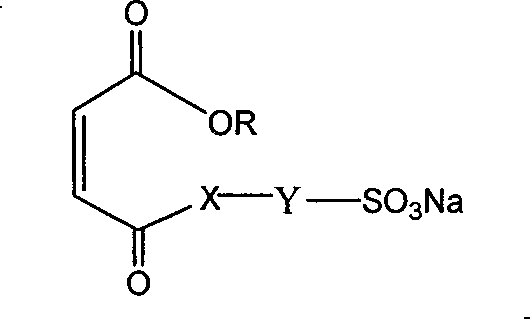

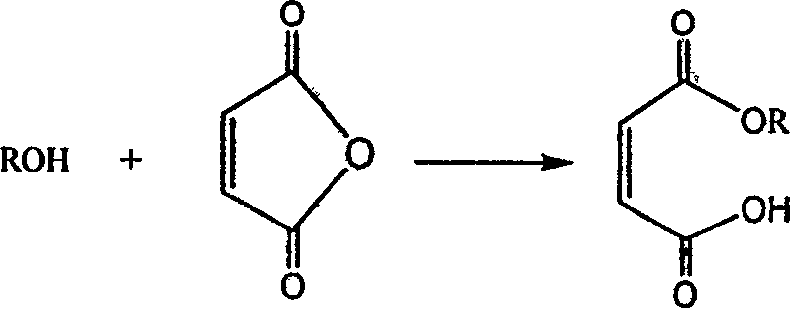

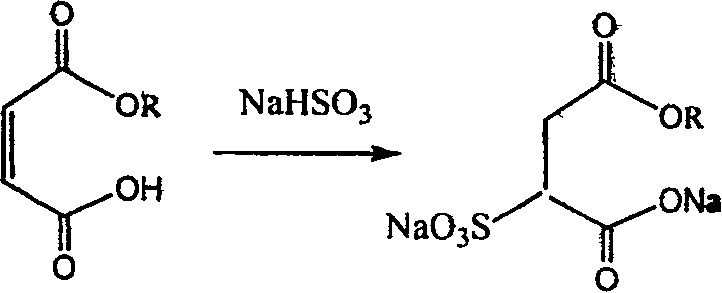

Maleic acid type anion polymerisable emusifier and its preparation method

InactiveCN100409933CAdjust lipophilicityImprove methodTransportation and packagingMixingCritical micelle concentrationPolymer science

The invention relates to a maleic acid anion polymerisable emulsifier and relative preparation, wherein said method comprises that: using maleic acid as material, via esterification chlorination and amination to prepare the emulsifier. The inventive emulsifier has strong property, which can reduce the interfacial tension of water, with simple operation. And it can adjust the length of carbon chain of aliphatic alcohol to control the HLB value of surface activator. The inventive emulsifier can improve the stability of polymer emulsion and improve the water resistance of film water resistance.

Owner:DALIAN UNIV OF TECH

Low-hydroxyl-value hydroxyl-terminated polyester resin for Tetramethoxymethylglycuril curable texture powder coating and preparation method thereof

ActiveCN106832236AImprove textureStrong three-dimensional sensePowdery paintsPolyester coatingsAlcoholSuccinic acid

The invention discloses low-hydroxyl-value hydroxyl-terminated polyester resin for Tetramethoxymethylglycuril curable texture powder coating. The low-hydroxyl-value hydroxyl-terminated polyester resin is obtained by melt polycondensation of the following ingredients (by weight): 0-3% of trimethylol propane, 0-3% of 1,2,6-hexanetriol, 35-40% of dihydric alcohol, 43-52% of terephthalic acid, 5-14% of m-phthalic acid, 0-4% of succinic acid and 0.05-0.12% of a catalyst. The invention also discloses a preparation method of the polyester resin. The texture powder coating prepared by the use of the synthesized polyester resin has fine and strong three-dimensional coating texture and good mechanical property and weatherability.

Owner:GUANGZHOU KINTE IND

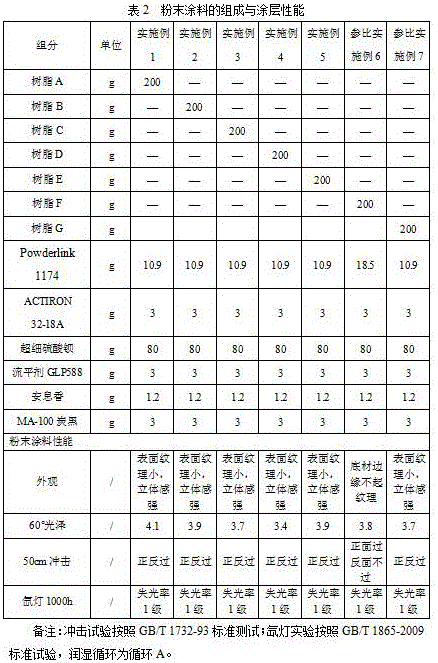

C2 post-hydrogenation acetylene removing method

ActiveCN106928002AModerate reactivityGreat operating flexibilityHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsThermal insulationInorganic oxide

The invention discloses a C2 post-hydrogenation acetylene removing method. A column top effluent from a deethanizer in a C2 post-hydrotreatment device is fed into a thermal insulation reactor for selective hydrogenation, and thus acetylene in the effluent can be removed. A Fe family selective hydrogenation catalyst is adopted as a hydrogenation catalyst, a high temperature resistant inorganic oxide is adopted as a carrier, and hydrogenation raw materials mainly consist of 0.98-2.2% of acetylene, 11.2-30.3% of ethane and 65.0-85.0% of ethylene. The reaction conditions are that the inlet temperature of a thermal insulating bed reactor is 40-100 DEG C, the reaction pressure is 1.5-2.5MPa, and the gas volume airspeed is 2000-10000 h<-1>. The C2 post-hydrogenation acetylene removing method disclosed by the invention is moderate in catalyst reaction activity, good in operation elasticity and good in ethylene selectivity, and the 'green oil' generation amount is far less than that of an acetylene removing method using a noble metal catalyst.

Owner:PETROCHINA CO LTD

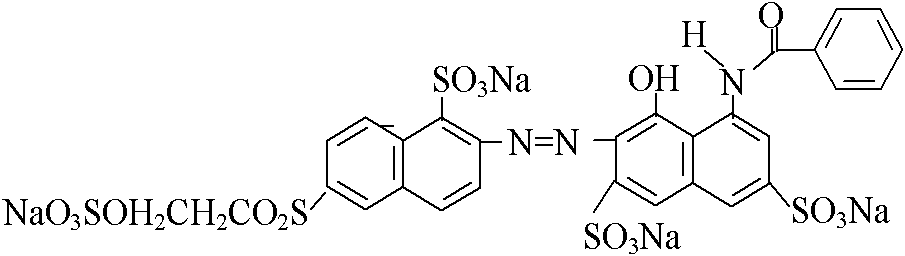

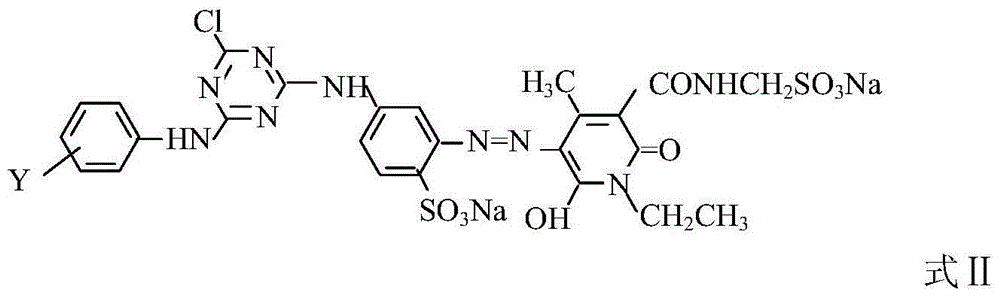

Composite reactive light yellow dye composition

ActiveCN104559317AGood shade controllabilityModerate reactivityOrganic dyesSolubilityInorganic salts

The invention discloses a composite reactive light yellow dye composition which mainly comprises a Formula I compound and a Formula II compound in a mole ratio of 1:(0.1-10), wherein Y is -SO3Na, and the Y group is meta-position or para-position. The dye can be used for a printing technique of an automatic sizing system, and the direct Rf value is 0.9; and the composite-structure bright yellow dye has the advantages of moderate reactivity and favorable color light controllability. The dye has favorable dye lifting power and high product solubility, the 2-DEG C solubility is greater than 200 g / L, and the dyeing deepness is 1 / 1. The fastness to light is Grade 6, the fastness to soaping is Grade 4-5, the fastness to perspiration is Grade 4-5, the fastness to chlorine water soaking is Grade 4, the fastness to dry rubbing is Grade 4-5, the fastness to wet rubbing is Grade 4, the fastness to ironing is Grade 4, and thus, the product has better properties than the traditional reactive light yellow dye. The dye has favorable printing lifting power, the strength is more than 2 times of the reactive light yellow K-6G, the printing color paste sewage is free of inorganic salts, and the content of hydrolytic dyes is low, thereby being beneficial to energy saving and environment friendliness.

Owner:无锡润新染料有限公司

Preparation method of polymetal carbosilane precursor

The invention discloses a preparation method of a polymetal carbosilane precursor, which comprises the following steps: sequentially adding alkali metal and metallocene into an organic solvent in a protective atmosphere, then dropwise adding chlorosilane, carrying out first reaction, solid-liquid separation and solvent removal to obtain a reactant B, and then carrying out second reaction on the reactant B and a reactant A in the protective atmosphere to obtain the polymetal carbosilane precursor. And removing the solvent to obtain polymetal carbosilane, wherein the reactant A is liquid polysilicon carbosilane. According to the preparation method, a large amount of metal is introduced through the reaction of chlorosilane and metallocene, a reactant B which has high reaction activity and contains more Si-Si bonds is obtained at the same time, then the reactant B continues to react with liquid polysilicocarbosilane, and the obtained product has high metal content and good performance stability at the same time. And the distribution of metal elements is uniform, the metal content is adjustable, and the precursor does not contain oxygen.

Owner:CHANGSHA DAFEI NEW MATERIAL TECH CO LTD

Halogen-free resin composition and flexible copper clad laminate prepared thereby

ActiveCN108948665ALower glass transition temperatureGood flexibilityPolyureas/polyurethane adhesivesSynthetic resin layered productsIon contentChemistry

The invention discloses a halogen-free resin composition. The halogen-free resin composition comprises the following components dispersing in an organic solvent, by weight: 5-10 parts of polyurethanemodified epoxy resin, 20-30 parts of multifunctional epoxy resin, 40-60 parts of a polyurethane and polyamide block copolymer, 10-20 parts of MQ resin, 5-10 parts of a curing agent, 0.2-0.5 part of acuring accelerator, and 15-20 parts of a phosphorus-containing flame retardant. The invention also discloses a flexible copper clad laminate prepared by using the halogen-free resin composition. The flexible copper clad laminate has excellent flexibility and folding resistance, low ion content, no dendritic crystallization during an ion migration test and good insulation property. Moreover, sincea toughening agent does not contain a saturated double bond, the flexible copper clad laminate has excellent aging resistance and can be applied in the field of high reliability requirements.

Owner:湖北恒驰电子科技有限公司

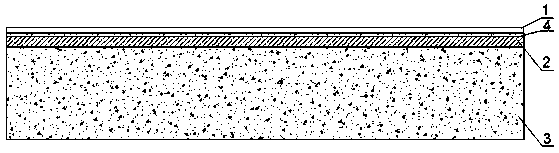

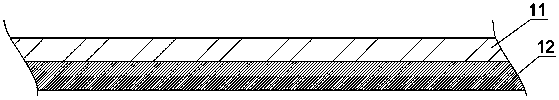

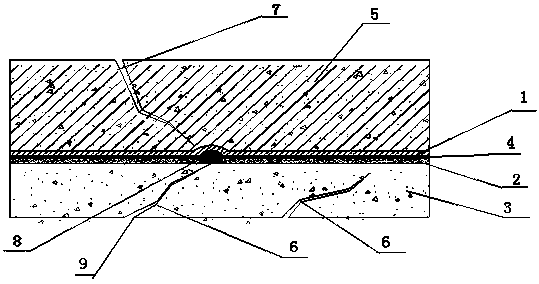

Composite waterproof structure and preparation method thereof

ActiveCN108859344ANo delaminationStrong chemical bondSynthetic resin layered productsLaminationPolymer modifiedSurface layer

The invention discloses a composite waterproof structure and a preparation method thereof, and belongs to the field of building waterproof materials. The composite waterproof structure is prepared from a waterproof coil layer, a reaction type macromolecular elastic coating layer and a waterproof base layer in turn from top to bottom, wherein the waterproof coil layer is prepared from an upper surface layer and a self-sticking material layer in turn from top to bottom; the self-sticking layer is self-sticking polymer modified asphalt. According to the composite waterproof structure and the preparation method thereof disclosed by the invention, separation between the coating and the coil is avoided, and the waterproof effect is perfect.

Owner:四川省威盾新材料有限公司

Terpolymer and thermosetting resin composition thereof

ActiveCN104211846AExcellent dielectric propertiesExcellent process controllabilityMetal layered productsEpoxyDielectric loss

The invention provides a terpolymer containing structural units represented by a general formula (I), a general formula (II) and a general formula (III). The terpolymer has appropriate reaction activity, so as to improve the processing and storage performance of a composition of the terpolymer and epoxy resin, and has excellent dielectric properties. The invention also provides a thermosetting resin composition containing the terpolymer and epoxy resin. The composition has low dielectric constant, low dielectric loss tangent, and excellent heat resistance, processing manufacturability and storage performance. The invention also provides a prepreg and a laminate prepared from the thermosetting resin composition, and the thermosetting resin composition can be used in printed circuit substrate material and printed circuit board.

Owner:SHENGYI TECH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com