Low-hydroxyl-value hydroxyl-terminated polyester resin for Tetramethoxymethylglycuril curable texture powder coating and preparation method thereof

A technology of tetramethoxymethyl glycoluril and hydroxyl-terminated polyester, which is applied in the field of polyester resin, can solve problems such as unfavorable surface texture, unfavorable mechanical properties, viscosity growth, etc., and achieve good mechanical properties and weather resistance, and strong three-dimensional effect , fine texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

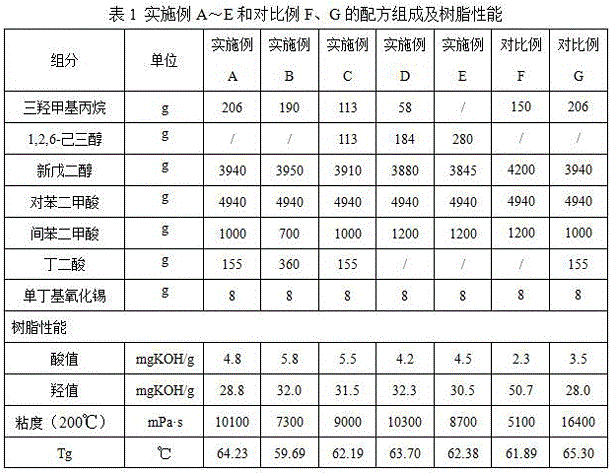

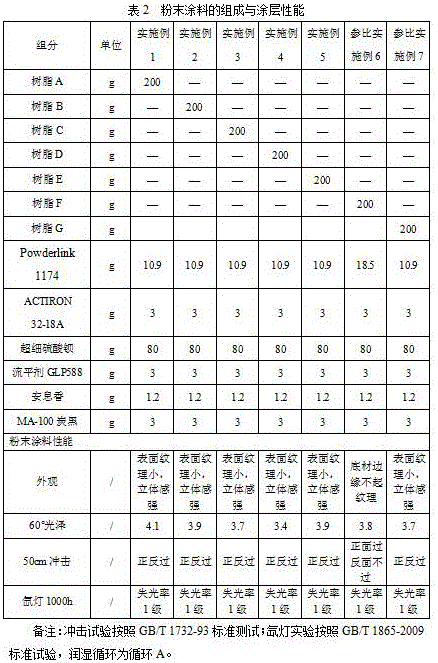

[0022] Some specific examples are enumerated below to illustrate the present invention. Table 1 shows the composition of the formulations of Examples A to E and Comparative Examples F and G and the properties of the synthesized polyester resin.

[0023] The preparation method of embodiment A is as follows: One-time feeding: In a 100L reactor, add a proportioned amount of trimethylolpropane and / or neopentyl glycol, and heat up to 140°C to melt the material; then add proportioned amounts of terephthalic acid and isophthalic acid in sequence , succinic acid and catalyst monobutyltin oxide, and continue to heat up the reaction with nitrogen gas, until 175 ° C esterification water begins to form and distill out; Heating and heat preservation: Then gradually heat up to 240°C at a speed of 1-1.5°C / 10min, and keep warm at 240°C until the column top temperature is lower than 70°C. After the material is clear and transparent, the acid value of the sample is 13.5mgKOH / g, and the melt v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com