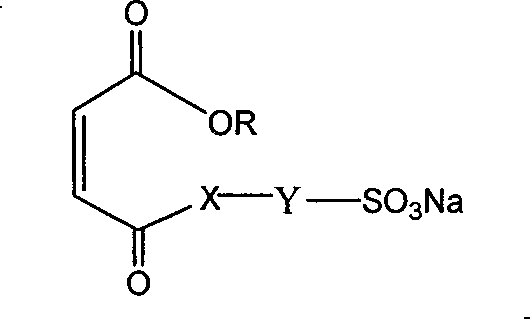

Maleic acid type anion polymerisable emusifier and its preparation method

A technology of polymerizing emulsifier, maleic acid, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., can solve the problem of affecting film gloss and other surface properties, reducing film water resistance, easy to produce gel and other problems, to avoid the reduction of emulsification effect, moderate reactivity, and reduce surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

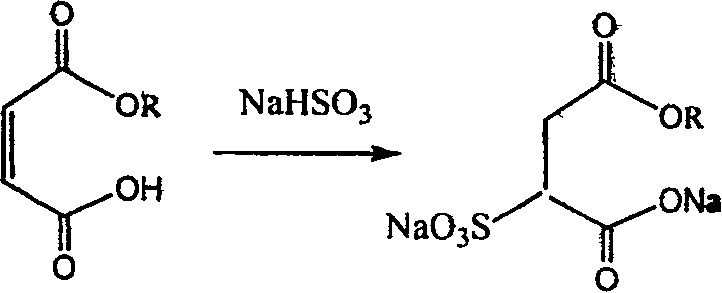

[0040] Preparation of octyl maleate amide type anionic polymerizable emulsifier

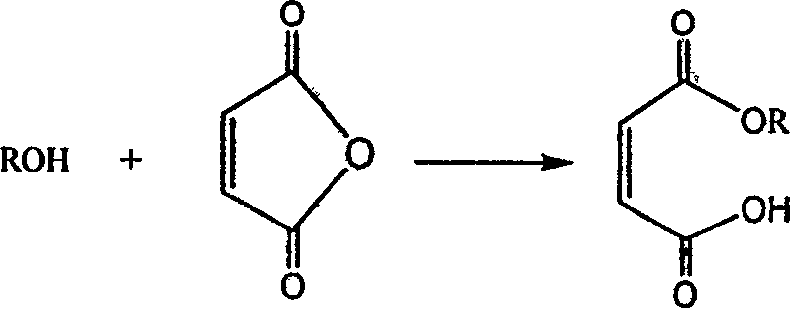

[0041] 1-1 prepares monooctyl maleate by maleic anhydride and octanol

[0042]Synthesis steps: Weigh 0.5 mol of octanol and 0.5 mol of maleic anhydride into a three-necked flask, heat and stir until the maleic anhydride melts, raise the temperature to 80° C., and react for 3 hours. Then slowly add 150ml heptane, continue to stir until a homogeneous liquid is formed, stir at room temperature for 3-5 hours, white crystals are precipitated, filtered with suction, and the filter cake is recrystallized with heptane to obtain monooctyl maleate with a melting point of 32.5- 33.3°C.

[0043] 1-2 prepares monooctyl maleoyl chloride by the reaction of monooctyl maleate and phosphorus trichloride

[0044] Synthesis steps: Weigh 0.05 mol of monooctyl maleate into a three-neck flask, heat up to melt, slowly add 0.025 mol of phosphorus trichloride dropwise, and react at 40-70°C after dropping. After the rea...

Embodiment 2

[0050] Preparation of laurylamide maleate type anionic polymerizable emulsifier

[0051] 2-1 Preparation of dodecyl monoester maleate by maleic anhydride and lauryl alcohol

[0052] Synthesis steps: Weigh 0.5 mol of n-dodecyl alcohol and 0.5 mol of maleic anhydride into a three-necked flask, heat and stir until the maleic anhydride melts, raise the temperature to 80° C., and react for 3 hours. Then slowly add 150ml of heptane, stir at room temperature for 3-5 hours, white crystals are precipitated, filtered with suction, and the filter cake is recrystallized with heptane to obtain dodecyl monoester maleate with a melting point of 57.8-58.3°C.

[0053] 2-2 Preparation of monododecyl maleic acid chloride by reaction of monododecyl maleate and sulfur oxychloride

[0054] Synthesis steps: Weigh 0.05 mol of monododecyl maleate into a three-neck flask, raise the temperature until the monoester melts, slowly add 0.15 mol of thionyl chloride dropwise, and react at 50-80°C after the d...

Embodiment 3

[0062] Preparation of Monostearyl Maleic Anhydride Semiamide Type Anionic Polymerizable Emulsifier

[0063] 3-1 Preparation of monostearyl maleate from maleic anhydride and stearyl alcohol

[0064] Synthesis steps: Weigh 0.5 mol of stearyl alcohol and 0.5 mol of maleic anhydride into a three-necked flask, heat and stir until the maleic anhydride melts, raise the temperature to 80°C, and react for 2-4 hours. Then slowly add n-heptane, stir at room temperature for 3-5 hours, white crystals precipitate out, filter with suction, and recrystallize the filter cake with n-heptane to obtain monostearyl maleate.

[0065] 3-2 Preparation of stearyl alcohol ester maleoyl chloride by the reaction of monostearyl maleate and phosphorus trichloride

[0066] Synthesis steps: Weigh 0.05mol monostearyl oleyl maleate in a three-necked flask, heat up to melt, and slowly add 0.05mol PCl dropwise 3 After dropping, keep warm at 50-80°C for reaction. After the reaction, the upper layer solution is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com