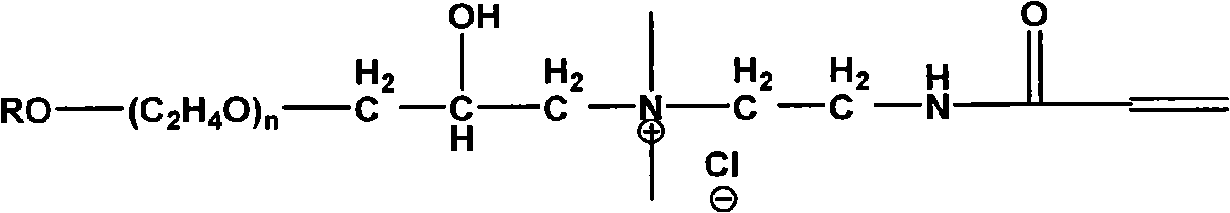

Acrylamide polymerizable emulsifier with cations and non-ions and preparation method thereof

A polymerized emulsifier, acrylamide type technology, applied in the field of acrylamide type polymerizable emulsifier and its preparation, can solve the problems of many side reactions, poor stability of calcium ions in emulsion, poor stability, etc., and achieves simple experimental operation, The effect of excellent emulsifying properties and polymerization stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

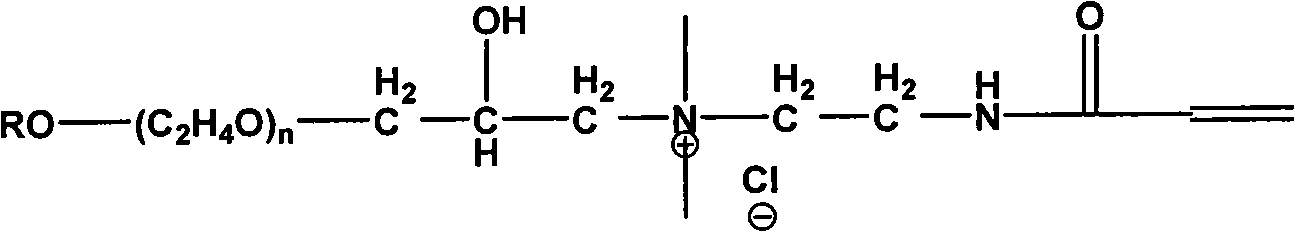

[0029] Preparation of lauryl alcohol polyoxyethylene (3) acrylamide type quaternary ammonium salt polymerizable emulsifier:

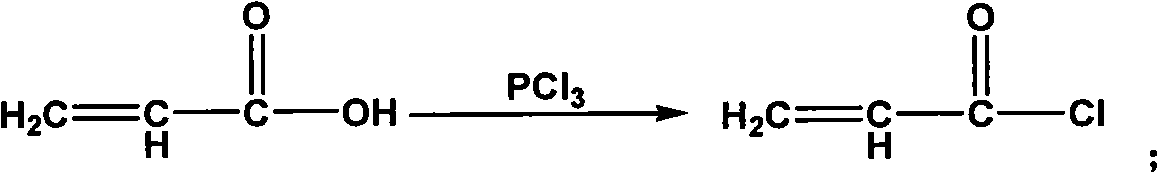

[0030] (a) Preparation of Acryloyl Chloride

[0031] Synthesis steps: Weigh 0.12mol of acrylic acid, stir and heat; when the temperature rises to 40°C, add 0.04mol of phosphorus trichloride dropwise; after the dropwise addition, keep the system at 50°C for 2.5 hours, stop heating; stand at room temperature for 1 Filter through an ordinary funnel for 1 hour to obtain a colorless transparent liquid.

[0032] (b) Dimethylaminoacetamide Acrylate

[0033] Synthesis steps: Weigh 1.30mol of dimethylethylenediamine, place it in a 250mL three-neck flask, stir the reaction system and cool it to 0°C; add 0.12mol of anhydrous sodium carbonate, then slowly drop 0.12mol of acryloyl chloride, 1.5 The drop is completed in about 1 hour; the system is kept at 0°C for 5 hours to obtain acrylic acid dimethylaminoacetamide.

[0034] (c) Preparation of polyoxyethylene lau...

Embodiment 2

[0040] Preparation of tetradecyl alcohol polyoxyethylene (7) acrylamide type quaternary ammonium salt polymerizable emulsifier:

[0041] (a) Preparation of Acryloyl Chloride

[0042] Synthesis steps: Weigh 0.19 mol of acrylic acid, stir and heat; when the temperature rises to 40°C, add 0.07mol of phosphorus trichloride dropwise; after the dropwise addition, keep the system at 40°C for 3 hours, stop heating; stand at room temperature for 1 Hours, filtered to obtain a colorless transparent liquid.

[0043] (b) Dimethylaminoacetamide Acrylate

[0044]Synthesis steps: Weigh 0.80mol dimethylethylenediamine, put it in a 250mL three-neck flask, stir the reaction system and cool it to 3°C under an ice-water bath; add 0.16mol anhydrous sodium carbonate, and then slowly drop 0.14mol Acryloyl chloride, drop it off in about 1.5 hours; keep the system at 3°C for 4.5 hours; obtain dimethylaminoacetamide.

[0045] (c) Preparation of Tetradecyl Polyoxyethylene (7) Glycidyl Ether

[0046...

Embodiment 3

[0051] Preparation of lauryl alcohol polyoxyethylene (25) acrylamide type quaternary ammonium salt polymerizable emulsifier:

[0052] (a) Preparation of Acryloyl Chloride

[0053] Synthesis steps: Weigh 0.17mol of acrylic acid, stir and heat; when the temperature rises to 40°C, add 0.06mol of phosphorus trichloride dropwise; after the dropwise addition, keep the system at 60°C for 2 hours, stop heating; stand at room temperature for 1 Hours, filtered to obtain a colorless transparent liquid.

[0054] (b) Dimethylaminoacetamide Acrylate

[0055] Synthesis steps: Weigh 1.24mol dimethylethylenediamine, put it in a 250mL three-necked flask, stir the reaction system and cool it to 5°C under an ice-water bath; add 0.16mol anhydrous sodium carbonate, and then slowly drop 0.15mol Acryloyl chloride, drop in about 1.5 hours; keep the system at 5°C for 4 hours to obtain dimethylaminoacetamide.

[0056] (c) Preparation of polyoxyethylene lauryl alcohol (25) glycidyl ether

[0057] Syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com