Self-supporting flexible composite electrode film, preparation method and application thereof

A self-supporting electrode and composite electrode technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., achieves the effects of low cost, improved rate performance, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The steps for preparing the flexible self-supporting composite electrode film described in the technical solution of the present invention are as follows:

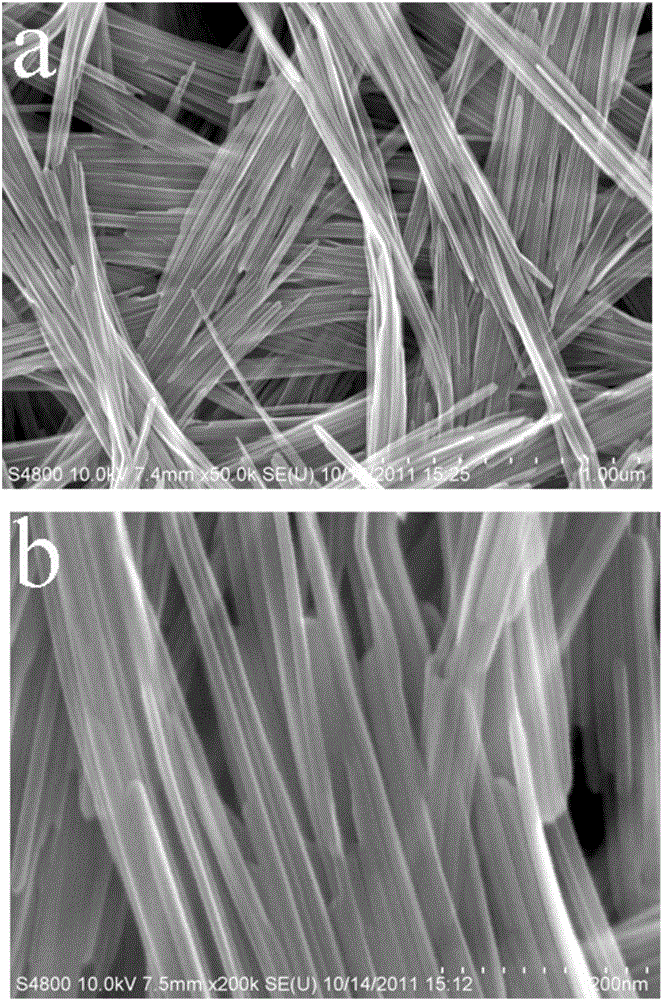

[0039] 1) Vanadium pentoxide nanowires: Add 0.6g of ammonium metavanadate and 1g of P123 into 50mL of water, add hydrochloric acid to adjust its pH value to 2, stir at room temperature for 12 hours to completely dissolve in water, and form an orange-red precursor body solution. Then transfer to a reaction kettle and react at 120° C. for 24 hours. After cooling, an khaki suspension was obtained. Centrifuge and wash three times with deionized water, and then put it into a vacuum drying oven to dry at 80° C. for 24 hours. Obtain dry vanadium pentoxide nanowire solid powder. Its scanning electron microscope pictures are as figure 1 As shown, the diameter distribution range of vanadium pentoxide nanowires is 10-50 nm.

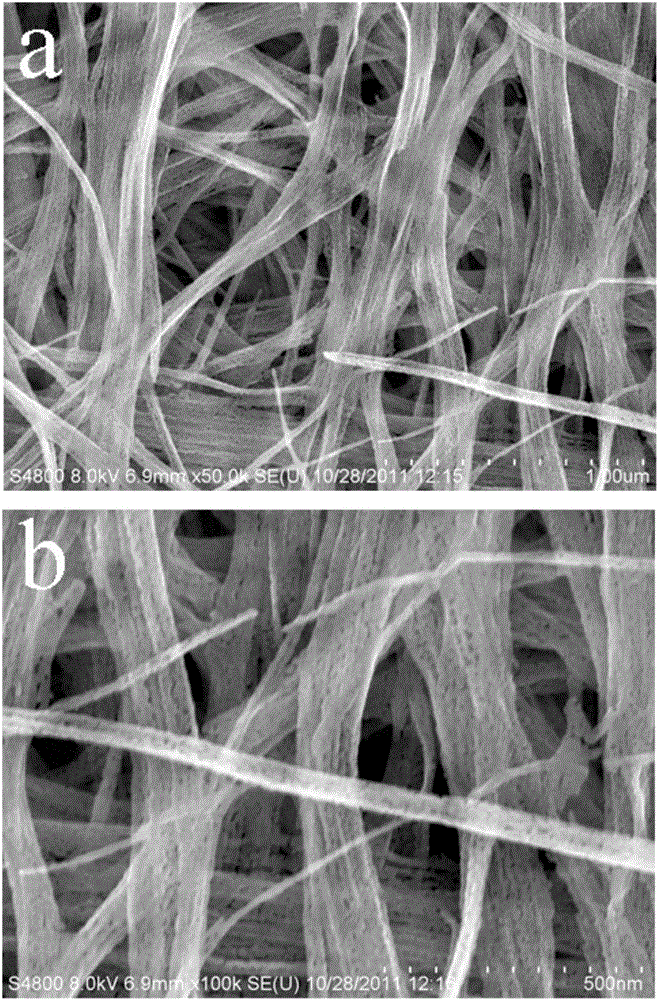

[0040]2) Preparation of porous vanadium nitride nanowires by high-temperature ammonification: 200...

Embodiment 2

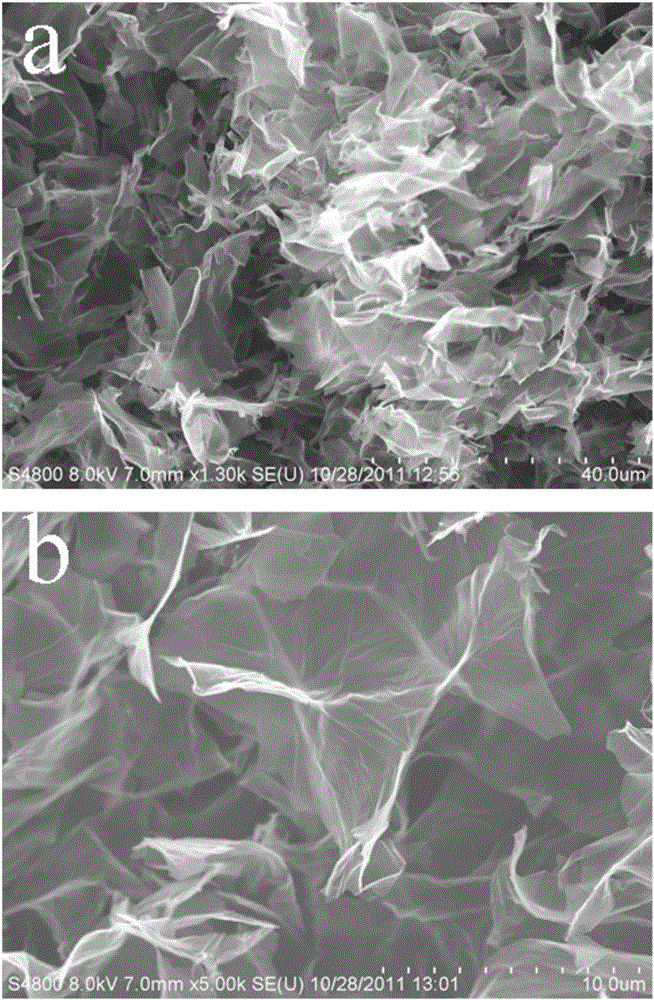

[0045] According to the method of Example 1, a composite electrode based on vanadium nitride porous nanowire-nanographite sheet was prepared. The difference is step 4) the process of mixing and dispersing the solution: adding 100 mg of vanadium nitride porous nanowires to 50 mL of 0.5 mg / mL graphite nanosheet dispersion solution, and adding 75 mg of NaDBS to help it disperse. Sonicate in a water bath for 10 minutes to fully dissolve the surfactant, then place it in a probe sonicator, and sonicate for 60 minutes at a power of 200W to form a black mixed dispersion solution.

[0046] 5) Vanadium nitride porous nanowire-nanographite sheet composite electrode film: select nylon filter membrane (Φ35mm, 0.4 micron pore size), take 25mL mixed dispersion liquid and put it into the solvent filter where the filter membrane is placed for vacuum filtration, and water and ethanol Rinse three times to remove surfactant. After taking it off, dry it in the air to obtain a circular vanadium ni...

Embodiment 3

[0048] According to the method of Example 1, a composite electrode based on vanadium nitride porous nanowire-nanographite sheet was prepared. The difference is step 4) the process of mixing and dispersing the solution: adding 25 mg of vanadium nitride porous nanowires to 50 mL of 0.5 mg / mL graphite nanosheet dispersion solution, and adding 50 mg of NaDBS to help it disperse. Sonicate in a water bath for 10 minutes to fully dissolve the surfactant, then place it in a probe sonicator, and sonicate for 60 minutes at a power of 200W to form a black mixed dispersion solution.

[0049] 5) Vanadium nitride porous nanowire-nanographite sheet composite electrode film: select nylon filter membrane (Φ35mm, 0.4 micron pore size), take 25mL mixed dispersion liquid and put it into the solvent filter where the filter membrane is placed for vacuum filtration, and water and ethanol Rinse three times to remove surfactant. After taking it off, dry it in the air to obtain a circular vanadium nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com