Reactive golden yellow dye and composite reactive brown dye

A technology of reactive bright yellow and brown dyes, applied in the field of dyes, can solve the problems of not being able to meet the high requirements of textiles, obvious heat-sensitive discoloration, poor light fastness of light colors, etc., and achieve moderate reactivity, high solubility, and low directness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

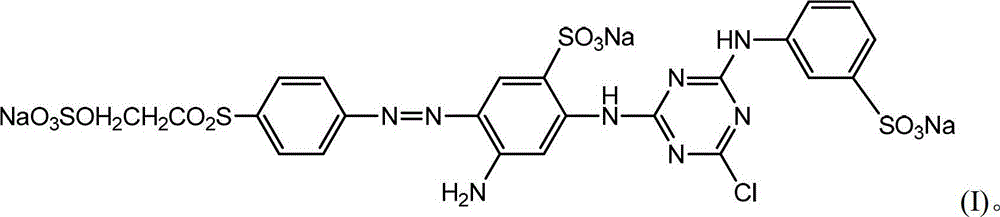

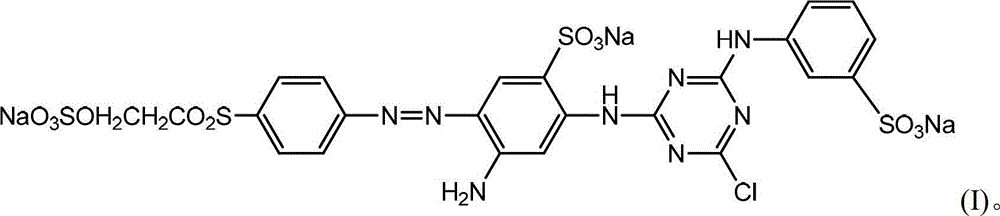

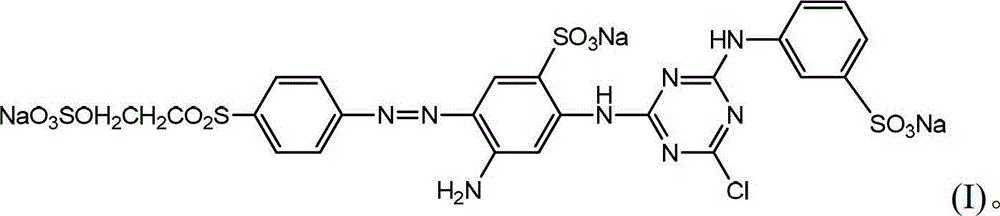

[0018] Preparation Example 1: Synthesis of Reactive Brilliant Yellow

[0019] 1.0 mole of para-ester is diazotized with 1.05 mole of hydrochloric acid (using the remaining acid in the dry powder para-ester) and 1.0 mole of sodium nitrite according to the usual method to obtain a diazonium salt, and 1.0 mole of 10% 2 , in 4-diaminobenzenesulfonate sodium solution, carry out coupling reaction under the conditions of pH 4.5 and temperature 8-15 for 4 hours, and obtain a dye solution of C.I reactive yellow 201 sodium salt structure.

[0020] Beat 1.02 moles of cyanuric chloride with ice and water for 1 hour, add the above dye solution, react for 4 hours at pH 6.0~7.5, temperature 0~10°C, then add 1.1 moles of m-aminobenzenesulfonic acid , reacted at PH6.0~7.0, temperature 40-50℃ for 6 hours to obtain reactive brilliant yellow dye solution, which was purified by membrane treatment (further recrystallization purification, m / z: 829.93).

Embodiment 1

[0022] Divide and dry the mother liquors of the six dyes mentioned above including Brilliant Yellow, C.I Reactive Orange 107, Reactive Dark Blue M-R, Reactive Sea Blue (C.I Reactive Blue 203), Reactive Crimson, and Reactive Red SHE according to 50:10:10:10:12:8 , compounded, and added 10% of the total dye amount of sodium sulfate and 3% of dustproof agent for spray drying, commercialized to obtain commercial dyes.

[0023] Its Rf value is 0.89, moderate reactivity, 20°C solubility greater than 200g / l, 1 / 1 dyeing depth: light fastness level 5, soaping fastness level 4-5, perspiration fastness level 4-5, resistance to chlorine water immersion Fastness to grade 4, dry rubbing fastness to grade 4~5, wet rubbing fastness to grade 4, ironing fastness to grade 4, the performance of the product is better than other compounded reactive brown dyes, especially the reddish metamerism of A lamp And thermal discoloration phenomenon has been significantly improved.

Embodiment 2

[0025] Divide and dry the mother liquors of the above six dyes, including Brilliant Yellow, C.I Reactive Orange 107, Reactive Dark Blue M-R, Reactive Sea Blue (C.I Reactive Blue 203), Reactive Crimson, and Reactive Red SHE, according to 46:12:12:12:12:8 , compounded, and added 10% of the total dye amount of sodium sulfate, 5% of alkali-resistant diffusing agent JS-K and 3% of dustproof agent for spray drying, and commercialized to obtain commercial dyes.

[0026] Its Rf value is 0.89, moderate reactivity, 20°C solubility greater than 200g / l, 1 / 1 dyeing depth: light fastness level 5, soaping fastness level 4-5, perspiration fastness level 4-5, chlorine water immersion resistance Fastness to grade 4, dry rubbing fastness to grade 4~5, wet rubbing fastness to grade 4, ironing fastness to grade 4, the performance of the product is better than other compounded reactive brown dyes, especially the reddish metamerism of A lamp And thermal discoloration phenomenon has been significantl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| soaping fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com