Halogen-free resin composition and coverage film used for flexible printed circuit board and prepared from same

A resin composition, a technology for printed circuit boards, applied in epoxy resin coatings, coatings, fire-retardant coatings, etc., can solve the problem that the cover film cannot meet the technical requirements, and achieve excellent peel strength, excellent toughening effect, ionic low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

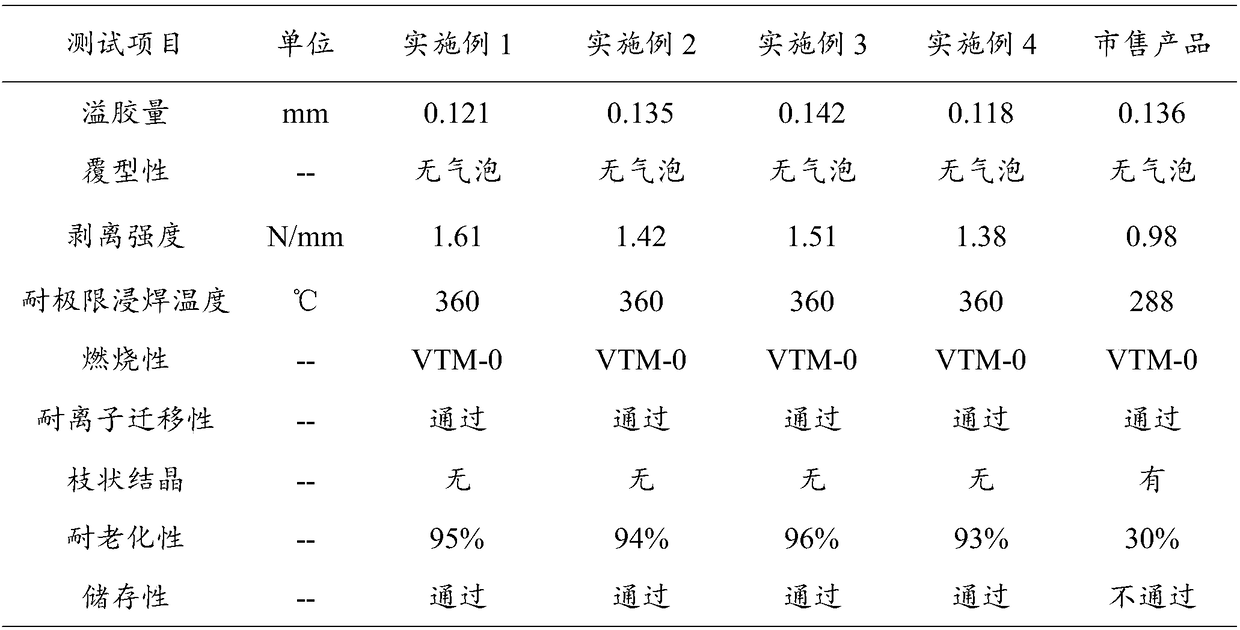

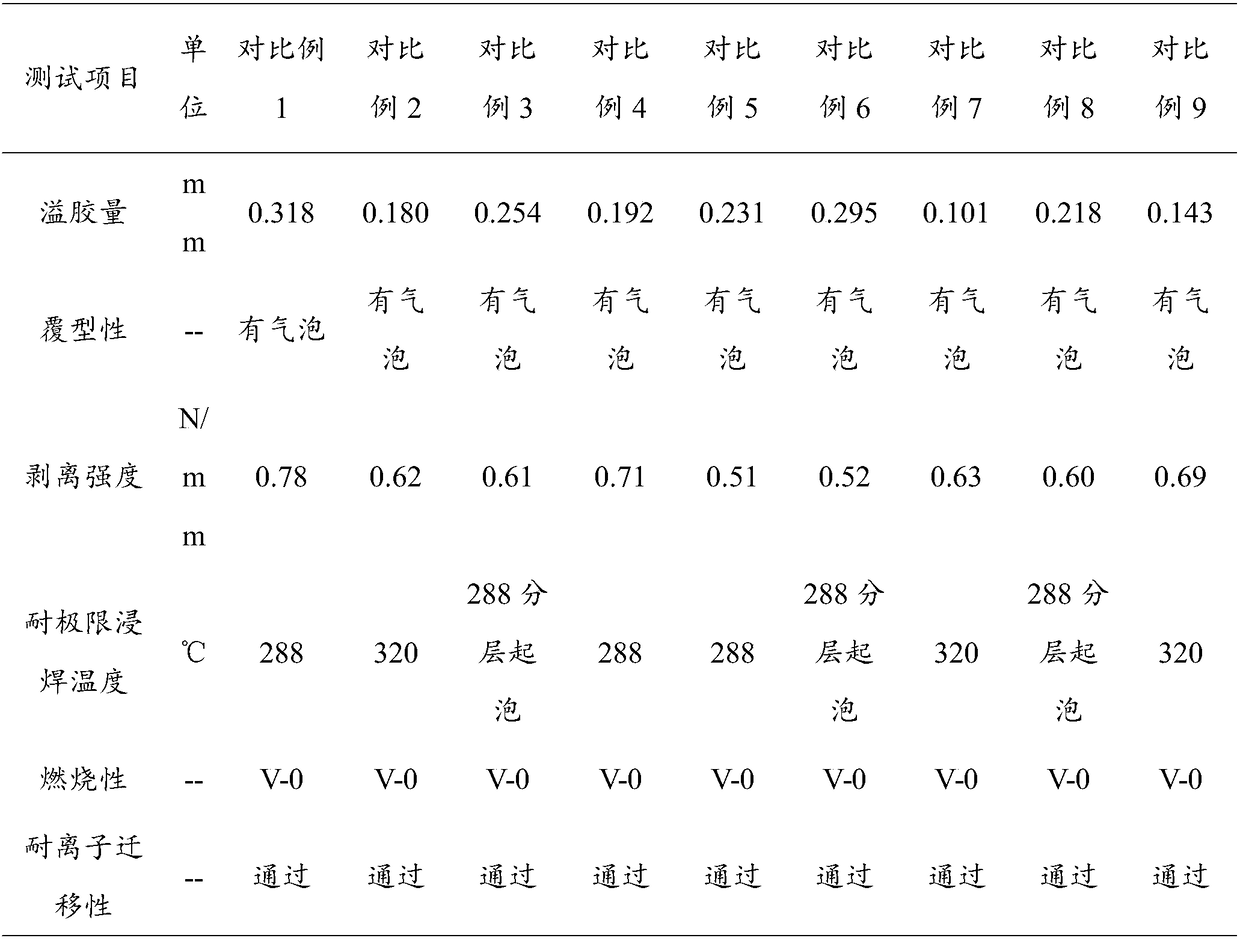

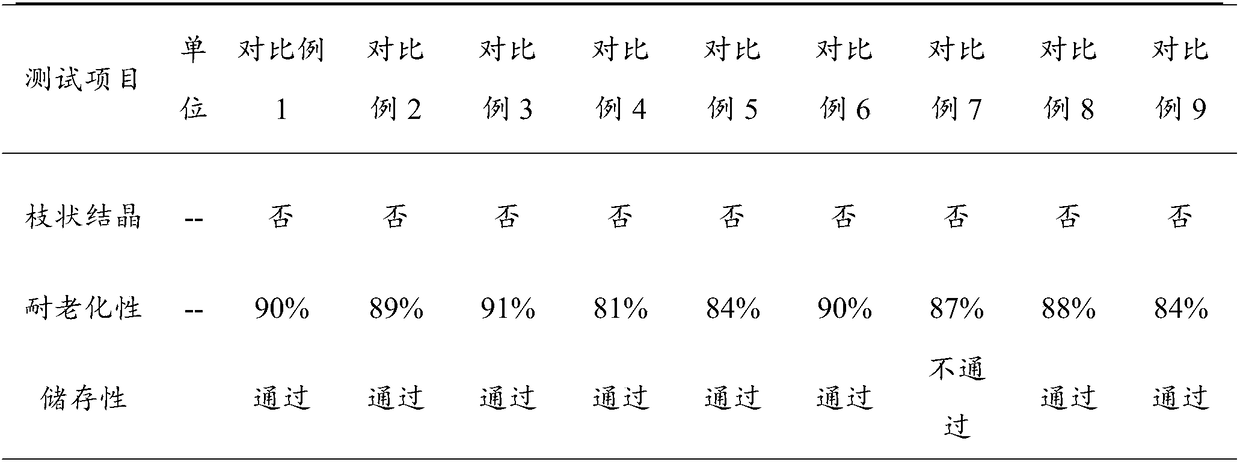

Examples

Embodiment 1

[0036] 1. Halogen-free resin composition

[0037] 1. The halogen-free resin composition includes 10 parts of DOPO-type phosphorus-containing epoxy resin, 10 parts of phenol-type novolac epoxy resin, 35 parts of polyurethane and polyamide block copolymer, 10 parts of MQ resin, and 2 parts of dicyandiamide , m-phenylenediamine 3 parts, phosphorus-containing flame retardant (SPB-100) 5 parts.

[0038] 2. The amine value of the polyurethane and polyamide block copolymer is 12mgKOH / g, wherein the number average molecular weight of the polyurethane segment is 1500, and the glass transition temperature Tg is -40°C; the number average molecular weight of the polyamide segment is 3000, the glass transition temperature Tg is 10°C; polyamide segments account for 60% of the total moles of polyurethane and polyamide segments in the copolymer, and polyurethane segments account for 40% of the total moles of polyurethane and polyamide segments in the copolymer %.

[0039] 3. Dissolving, mix...

Embodiment 2

[0043] 1. Halogen-free resin composition

[0044] 1. The halogen-free resin composition includes 15 parts of DOPO-HQ type phosphorus-containing epoxy resin, 10 parts of bisphenol A novolac epoxy resin, 40 parts of polyurethane and polyamide block copolymer, 15 parts of MQ resin, 4 parts , 5 parts of 4'-diaminodiphenyl sulfone, 2 parts of diethylene triamine, 8 parts of phosphorus-containing flame retardant (OP-935).

[0045] 2. The amine value of the polyurethane and polyamide block copolymer is 15mgKOH / g, wherein the number average molecular weight of the polyurethane segment is 1800, and the glass transition temperature Tg is -35°C; the number average molecular weight of the polyamide segment is 3500, the glass transition temperature Tg is 15°C; polyamide segments account for 70% of the total moles of polyurethane and polyamide segments in the copolymer, and polyurethane segments account for 30% of the total moles of polyurethane and polyamide segments in the copolymer %. ...

Embodiment 3

[0050] 1. Halogen-free resin composition

[0051] 1. The halogen-free resin composition includes 20 parts of phosphate ester modified epoxy resin, 15 parts of o-cresol novolac epoxy resin, 45 parts of polyurethane and polyamide block copolymer, 20 parts of MQ resin, 3,3' - 10 parts of diaminodiphenyl sulfone, 15 parts of phosphorus-containing flame retardant (OP-930).

[0052] 2. The amine value of the polyurethane and polyamide block copolymer is 18mgKOH / g, wherein the number average molecular weight of the polyurethane segment is 2200, and the glass transition temperature Tg is -20°C; the number average molecular weight of the polyamide segment is 4500, the glass transition temperature Tg is 20°C; polyamide segments account for 80% of the total moles of polyurethane and polyamide segments in the copolymer, and polyurethane segments account for 20% of the total moles of polyurethane and polyamide segments in the copolymer %.

[0053] 3. Dissolving, mixing and dispersing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com