Terpolymer and thermosetting resin composition thereof

A technology of terpolymer and resin composition, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., and can solve the problems of harsh reaction conditions, processing technology and storage effects, and dielectric constant and increased dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

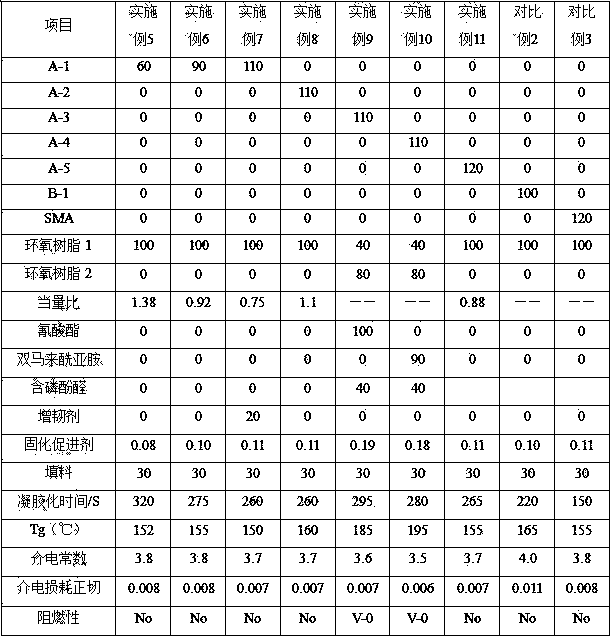

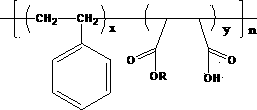

[0051] Fully dissolve 49 g of maleic anhydride, 110 g of dicyclohexylcarbodiimide, and 100 g of phenol in ethyl acetate, and then place them in a three-neck reaction flask for thorough mixing, then add 1.0 g of 4-dimethylaminopyridine under stirring, and After reacting at low temperature for 4 hours, the reaction solution was cooled in a low temperature environment of 0-5° C. for a period of time and then filtered to separate solid impurities, and then the obtained product was distilled and purified to obtain diphenyl maleate. Then, fully dissolve the diphenyl maleate 80g, styrene 830g, and maleic anhydride 175g prepared in front in butanone, add 45g benzoyl peroxide initiator and 100g pentene chain transfer agent, at 70~ The terpolymer (A-1) was prepared by reacting at 90°C for 5 hours. Its number average molecular weight was measured by GPC method to be 7000g / mol, and its structural formula contained the following three structural units:

[0052] (I) , (II) , (Ⅲ) ,

...

Embodiment 2

[0055] Fully dissolve 49g of maleic anhydride, 110g of dicyclohexylcarbodiimide, and 100g of phenol in ethyl acetate and then place them in a three-necked reaction flask and mix them thoroughly, then add 1.5g of 4-dimethylaminopyridine under stirring, and After reacting at low temperature for 4 hours, the reaction solution was cooled in a low temperature environment of 0-5° C. for a period of time and then filtered to separate solid impurities, and then the obtained product was distilled and purified to obtain diphenyl maleate. Then, fully dissolve the diphenyl maleate 400g, styrene 1040g, and maleic anhydride 33g prepared in front in butanone, add 50g benzoyl peroxide initiator and 100g pentene chain transfer agent, at 70~ The terpolymer (A-2) was prepared by reacting at 90°C for 5 hours. The number-average molecular weight was 11,000 g / mol as measured by GPC, and its structural formula contained the following three structural units:

[0056] (I) , (II) , (Ⅲ) ,

[0057...

Embodiment 3

[0059] Fully dissolve 49g of maleic anhydride, 110g of dicyclohexylcarbodiimide, and 170g of 3-hydroxy-1,2,3-benzotriazin-4(3H)-one in ethyl acetate and place in a three-neck reaction flask Mix well, then add 2.0g of 4-dimethylaminopyridine under stirring, react at room temperature for 8 hours, place the reaction solution in a low temperature environment of 0-5°C to cool for a period of time, then filter to separate solid impurities, and then prepare The obtained product is distilled and purified to obtain diphenyl maleate. Then, fully dissolve maleic acid diester 267g, styrene 312g, and maleic anhydride 33g in butanone, add 20g benzoyl peroxide initiator and 50g pentene chain transfer agent, at 70~90 The terpolymer (A-3) was prepared by reacting at ℃ for 5 hours. The number average molecular weight was measured by GPC method to be 14000g / mol, and its structural formula contained the following three structural units:

[0060] (I) , (II) , (Ⅲ) ,

[0061] In the formula,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com