Composite reactive grey for printing and dyeing and clean production process thereof

A production process and active ash technology, applied in the field of dyes, can solve the problems of unsatisfactory printing process, poor lifting force of dark printing, low product solubility, etc., and achieve the effect of bright color, good chlorine resistance and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

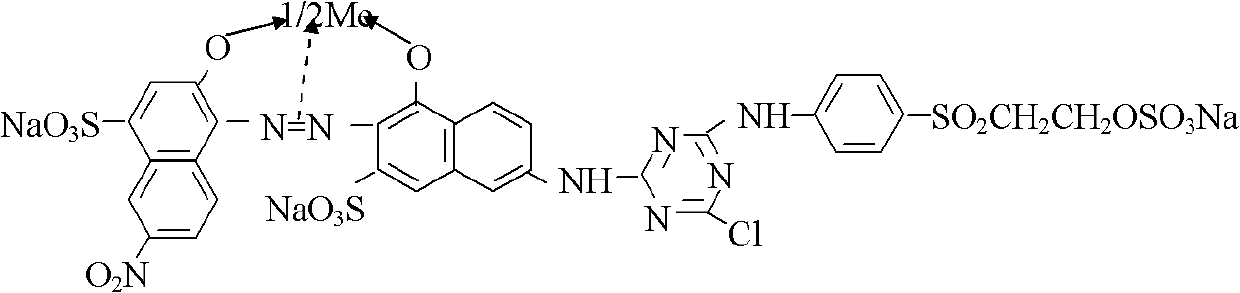

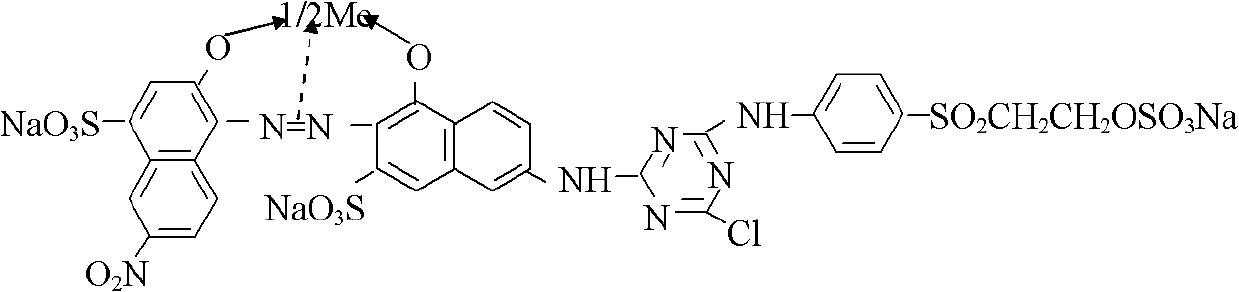

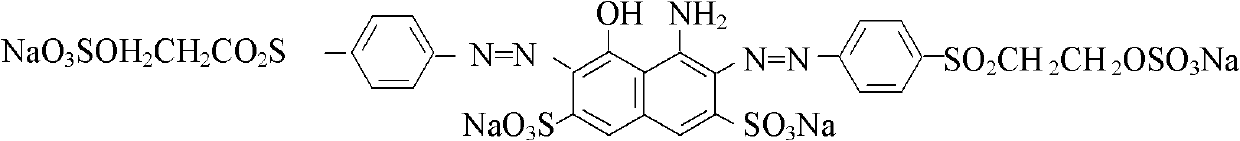

[0026] Reactive gray dyes that can be used for printing and dyeing, dissolved by 1 part (mole parts, the same below) 1-amino-2-naphthol-6-nitro-4-sulfonic acid at pH5.5~7, 15℃ Aqueous solution, add 1 part of sodium nitrite to make a mixed solution, add 3 parts of hydrochloric acid at 0 ~ 10 ° C to carry out diazotization, the prepared diazonium salt and 1.01 parts of J acid solution and liquid caustic soda are at pH 6.5 ~ 7.5, react overnight under the conditions to obtain a coupled chromophore. 0.55 parts of cobalt sulfate and 1.6 parts of liquid caustic soda, or coupling chromophore with 0.55 parts of chromium sulfate and 2.2 parts of sodium acetate for metal complexation reaction at 100-105 ° C, cooling and neutralizing to pH 6.5-7.5 for later use. 1 part of para-ester and 1.01 parts of cyanuric chloride are condensed once at pH 3-6 and temperature 8-15°C, and the obtained primary condensation liquid is condensed with the above-mentioned metal complexing liquid for the seco...

Embodiment 2

[0029] The active ash powder and C.I. active black 5 prepared by the method in Example 1 are mixed according to the mass weight ratio of 15 parts of cobalt, 80 parts of chromium, and 5 parts of C.I. Starch powder and 2% dustproof agent are standardized to obtain commercial products.

Embodiment 3

[0031] Active ash powder and C.I. active black 5 prepared by the method in Example 1 are mixed according to the mass weight ratio of 15 parts of cobalt, 80 parts of chromate, and 5 parts of C.I. Agent NNO and 2% dustproof agent, standardized to obtain commercial products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com