Preparation method of polymetal carbosilane precursor

A carbosilane and metal technology, applied in the field of preparation of polymetallic carbosilane precursors, can solve the problems of β-SiC grain growth, large interface stress, high content, etc., and achieve uniform distribution of metal elements and good viscosity stability. The effect of adjustable sex and metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

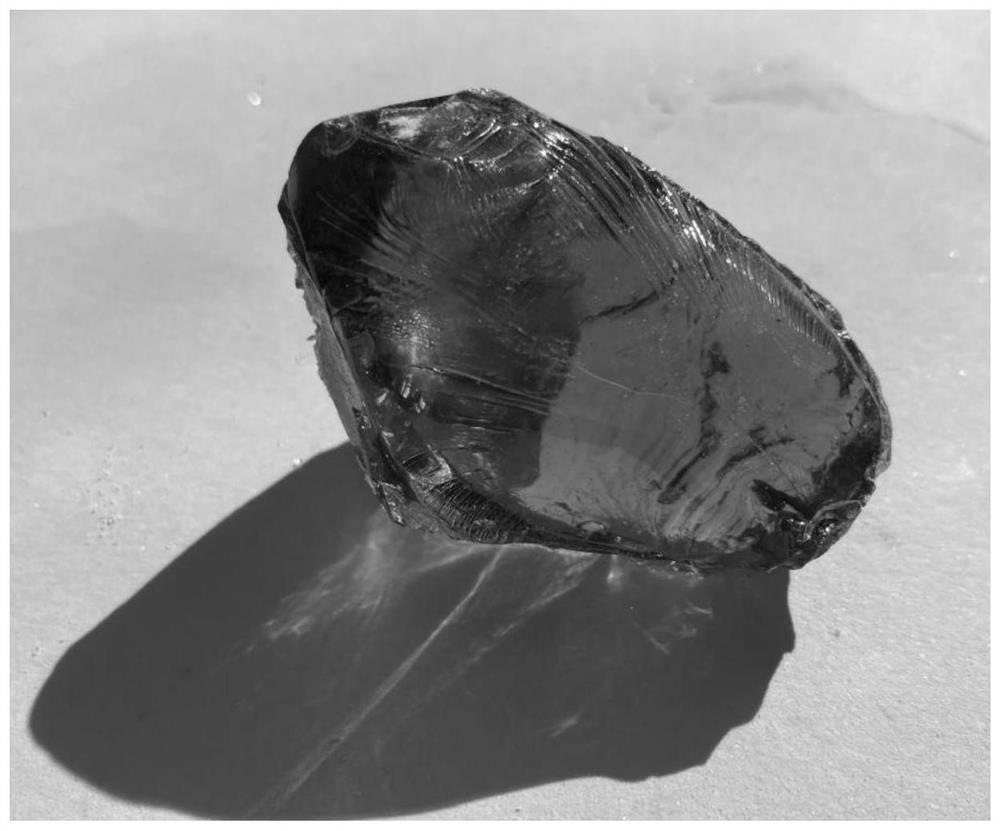

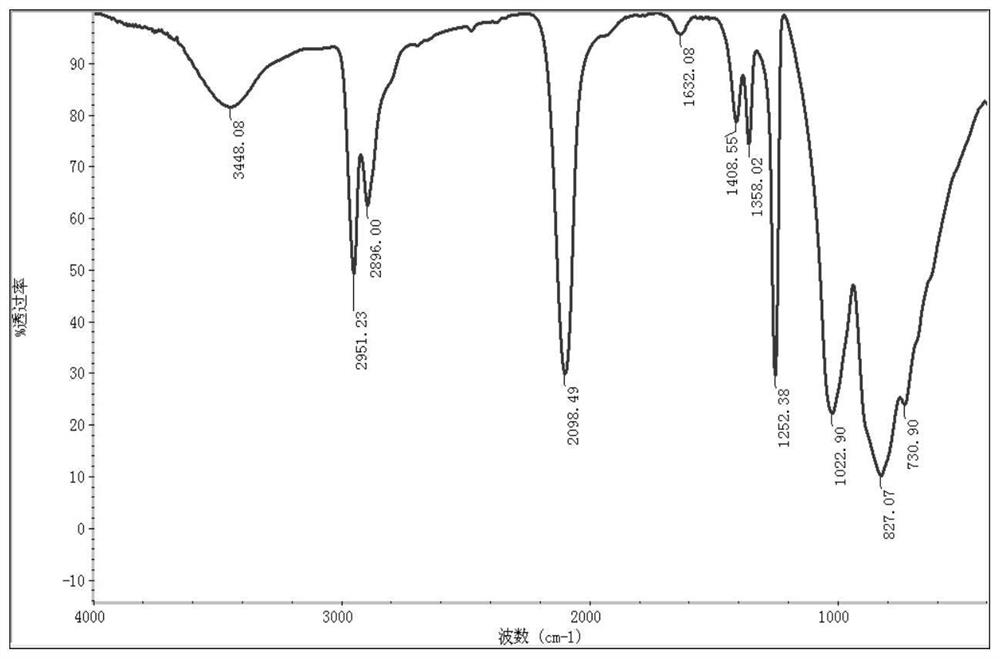

Image

Examples

Embodiment 1

[0042] Add 20kg of polydimethylsilane to the reactor, and heat up and crack under an inert atmosphere to obtain 18.0kg of liquid polysilocarbosilane, which is called reactant A; 12.0kg of sodium metal and 150kg of xylene are added to another reactor, Raise the temperature to 100°C under a nitrogen atmosphere, stir at high speed for 1 hour to break the metal sodium block into sodium sand, add 6.46kg of dichlorozirconocene, and then slowly add 27.10kg of dichlorodimethylsilyl chloride into the reaction system in the form of dropwise addition , after the dropwise addition, heat up to 135°C, continue to stir for 6 hours until the solution is neutral, cool to room temperature, filter the solution to get the clear liquid, remove xylene, and obtain 24.10kg of reactant B; mix A and B In a reaction kettle with a cracking column and a reflux device, the temperature was raised to 380°C under the protection of nitrogen, kept for 4 hours, and cooled to room temperature to obtain 30.50 kg of...

Embodiment 2

[0044] Add 40kg of polydimethylsilane to the reaction kettle, heat up and crack under an inert atmosphere to obtain 34.8kg of liquid polysilocarbosilane, which is called reactant A; add 11.3kg of metal sodium and 80kg of trimethylbenzene solvent into another reaction kettle , heated up to 100°C under a nitrogen atmosphere, stirred at high speed for 1 hour to break the metal sodium block into sodium sand, added 5.0kg dimethyl zirconocene, and then slowly added 27.10kg dichlorodimethylsilyl chloride in dropwise form The reaction system was heated up to 165°C after the dropwise addition, and continued to stir for 5 hours until the solution was neutral, cooled to room temperature, filtered the solution to obtain the clear liquid, and obtained 20.10kg of reactant B after removing trimethylbenzene; Mix in a reaction kettle with a cracking column and a reflux device, heat up to 410°C under nitrogen protection, keep warm for 5 hours, and cool to room temperature to obtain 36.10kg of cr...

Embodiment 3

[0046] Add 30kg of polydimethylsilane to the reactor, and heat up and crack under an inert atmosphere to obtain 26.8kg of liquid polysilocarbosilane, which is called reactant A; 6.9kg of sodium metal and 60kg of xylene are added to another reactor, Raise the temperature to 100°C under a nitrogen atmosphere, stir at high speed for 1 hour to break the metal sodium block into sodium sand, add 2.5kg of dichlorozirconocene, and then slowly add 17.20kg of dichlorodimethylsilyl chloride into the reaction system in the form of dropwise After the dropwise addition, continue to heat up to 138 ° C, stir for 5 hours until the solution is neutral, cool to room temperature, filter the solution to get the clear liquid, and remove xylene to obtain 12.10 kg of reactant B; mix A and B in In a reaction kettle with a cracking column and a reflux device, heat up to 410°C under the protection of nitrogen, keep it warm for 6 hours, and cool to room temperature to obtain 23.10 kg of crude polyzirconiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com