Patents

Literature

53results about How to "Moderate softening point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

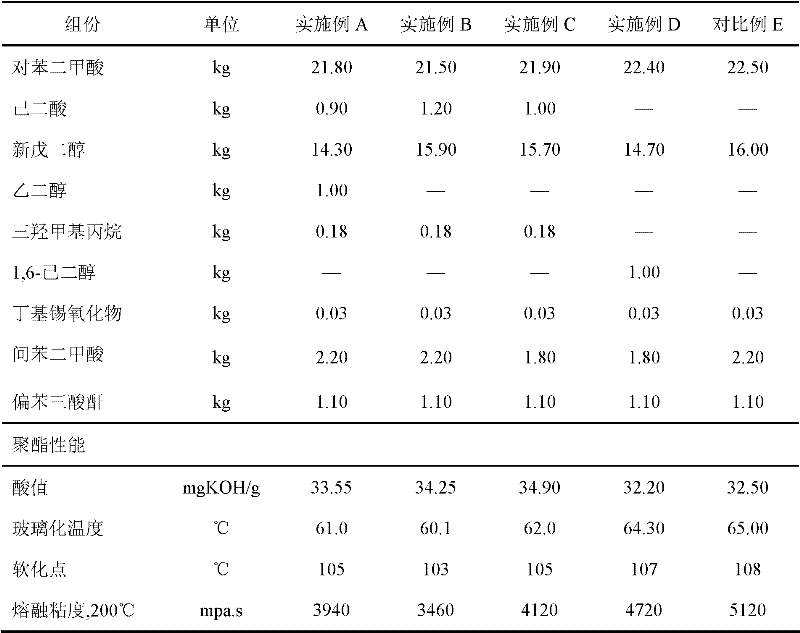

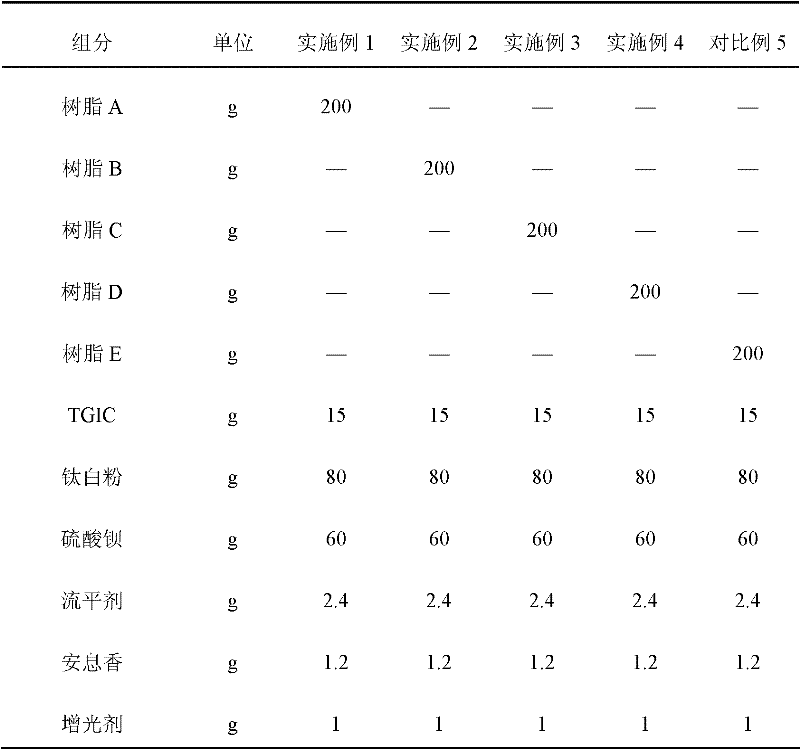

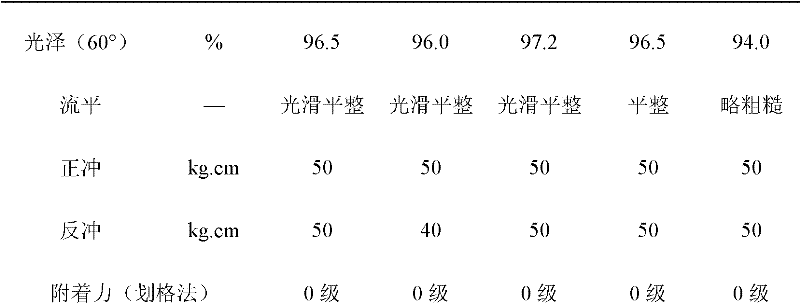

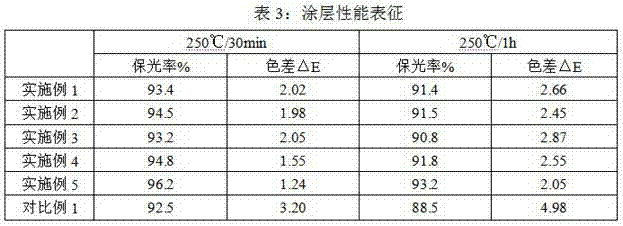

Terminal carboxyl group polyester resin for weather-resistance high-gloss powder coating and preparation method thereof

ActiveCN102127212ASuitable glass transition temperatureGood storage stabilityPowdery paintsPolyester coatingsWeather resistancePolyester resin

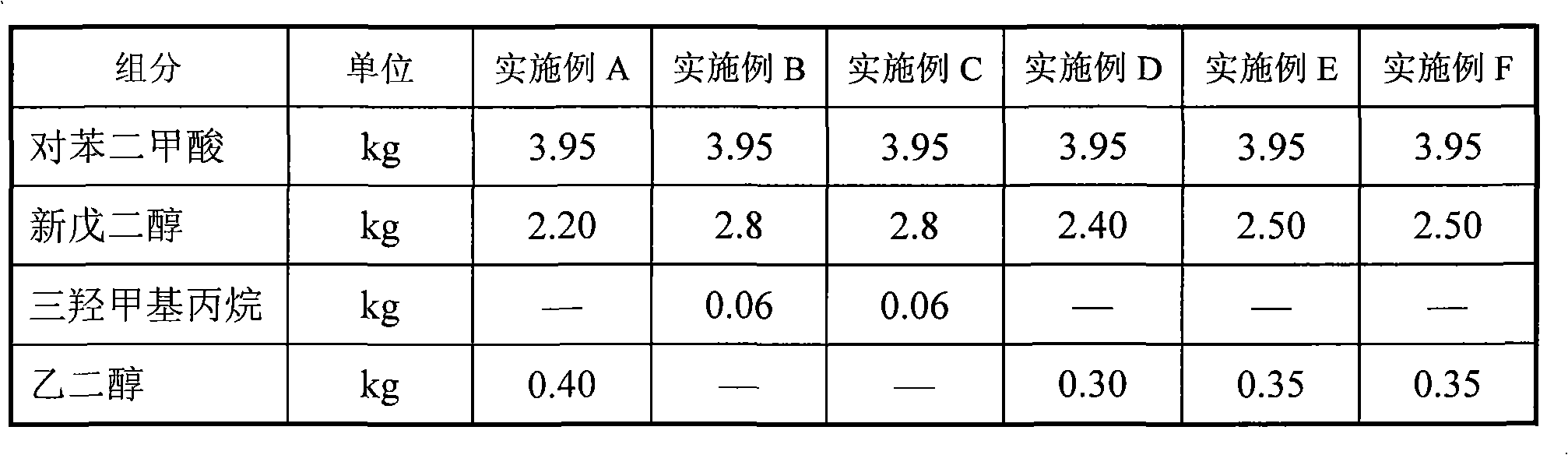

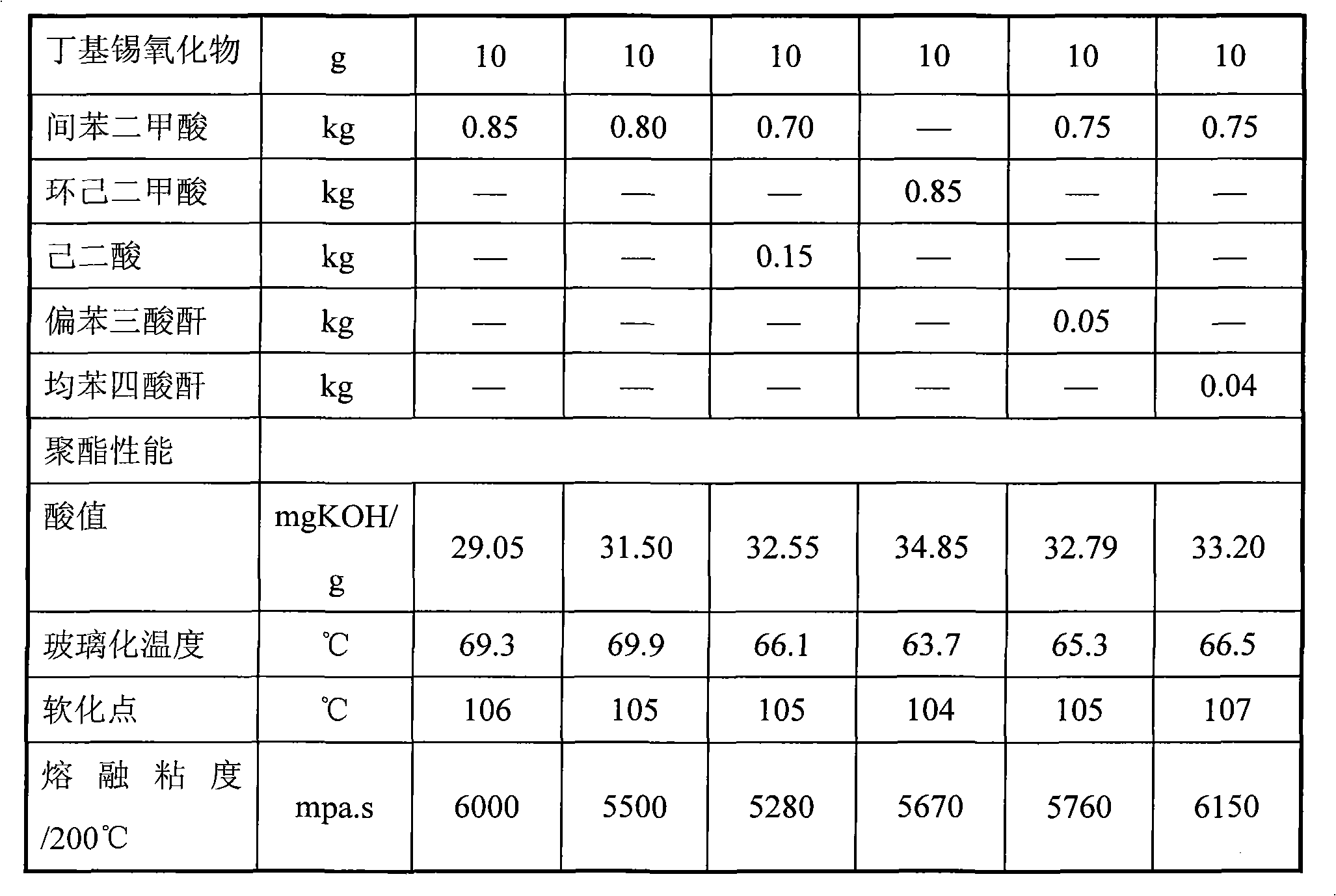

The invention discloses a terminal carboxyl group polyester resin for a weather-resistance high-gloss powder coating. The terminal carboxyl group polyester resin is obtained by carrying out melt polycondensation on the following components in percentage by weight: 25-45 percent of polyalcohol, 35-65 percent of aromatic polyacid, 0-3 percent of fatty polyacid, 0-1 percent of branching agent, 6-20 percent of acid-hydrolyzing agent and 0.01-0.15 percent of esterification catalyst. The invention also discloses a preparation method of the terminal carboxyl group polyester resin for the weather-resistance high-gloss powder coating. The polyester resin has proper glass-transition temperature, softening point, viscosity and storage stability; and the powder coating prepared by adopting the preparation method disclosed by the invention has 60-degree gloss more than 96 percent and favorable leveling performance and weather resistance.

Owner:GUANGZHOU KINTE IND

Weather resistant polyester resin with excellent water-boiling resisting performance and method for preparing same

ActiveCN101735431AImprove boiling resistanceImprove the level ofPowdery paintsPolyester coatingsMelt viscosityChemistry

The invention discloses weather resistant polyester resin with excellent water-boiling resisting performance, which is prepared through the melt polycondensation of the following components: 20-45 percent by weight of polyol, 40-55 percent by weight of aromatic polybasic acid, 0-8 percent by weight of fat polybasic acid, 0-5 percent by weight of branching agent, 5-15 percent by weight of acidolysis agent and 0.01-0.15 percent by weight of esterification catalyst. The invention also discloses a method for preparing the weather resistant polyester resin with excellent water-boiling resisting performance. The polyester resin prepared with the method has high glass transition temperature, high softening point, appropriate melt viscosity and appropriate storage stability. The powder coating produced from the polyester resin has excellent water-boiling resisting performance, good leveling performance and good impact performance, etc.

Owner:GUANGZHOU KINTE IND

Organosilicone modified carboxyl-terminated polyester resin for TGIC heat-resistant powder coating and preparation method thereof

ActiveCN103073711AImprove heat resistanceSuitable glass transition temperaturePowdery paintsPolyester coatingsPolymer sciencePolyol

The invention discloses an organosilicon modified carboxyl-terminated polyester resin for a heat-resistant powder coating. The organosilicon modified carboxyl-terminated polyester resin is formed by melt polycondensation reaction of the following components by weight percent: 5-25 percent of organosilicon, 25-45 percent of polyatomic alcohol, 35-65 percent of aromatic polyhydric acid, 0-5 percent of fat polyhydric acid, 4-15 percent of acidolysis agent and 0.01-0.15 percent of esterification catalyst. The invention further discloses a preparation method of the organosilicon modified carboxyl-terminated polyester resin for the heat-resistant powder coating. The polyester resin prepared by adopting the method has proper glass transition temperature, softening point and storage stability, and the powder coating prepared by the organosilicon modified carboxyl-terminated polyester resin has excellent heat resistance and is particularly suitable for polyester / TGIC curing systems.

Owner:GUANGZHOU KINTE IND

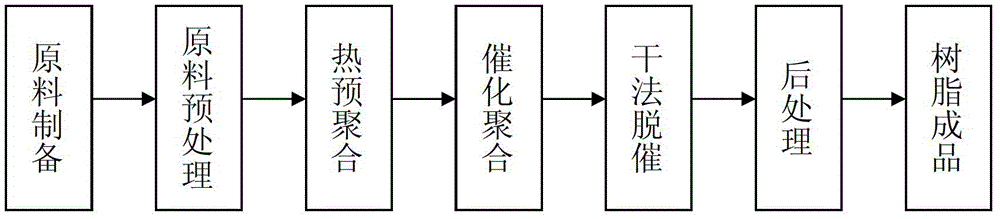

Method for preparing C5/C9 copolymerized petroleum resin

The invention relates to a method for preparing C5 / C9 copolymerized petroleum resin. The method comprises the following steps of: mixing crude m-pentadiene, crude cyclopentadiene and selectively hydrogenated and pretreated C9 material D uniformly, performing pre-polymerization at the temperature of between 180 and 230 DEG C to obtain a dimmer mixture F of C10 and C15, blending hydro-cracking aviation kerosene serving as a solvent, performing catalytic polymerization for 2 to 5 hours at the temperature of between 30 and 65 DEG C by using gaseous boron trifluoride as a catalyst to obtain deep yellow to brown polymerization solution, rectifying under reduced pressure to remove the solvent and oligomers, and thus obtaining the C5 / C9 copolymerized petroleum resin. The prepared C5 / C9 resin is good in compatibility and light in color; the preparation method is reasonable and strong in pertinence; the hue, the compatibility and the thermal stability of the resin are remarkably improved; and the resin can be widely applied in the fields of ink, coating, papermaking, plastics and the like.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

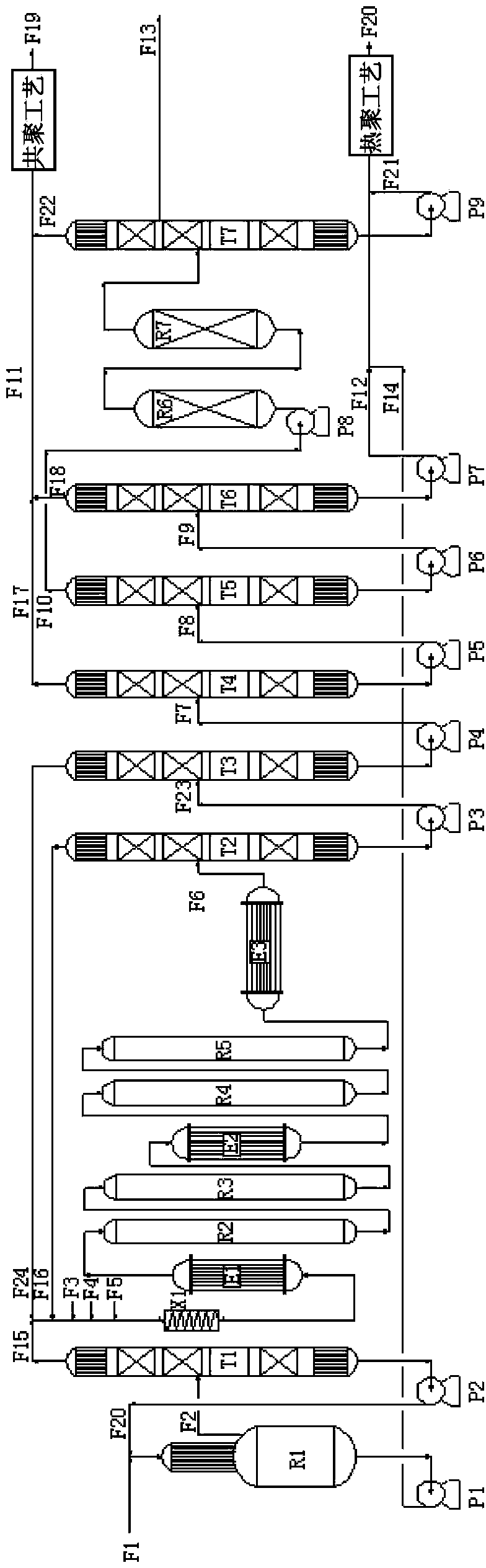

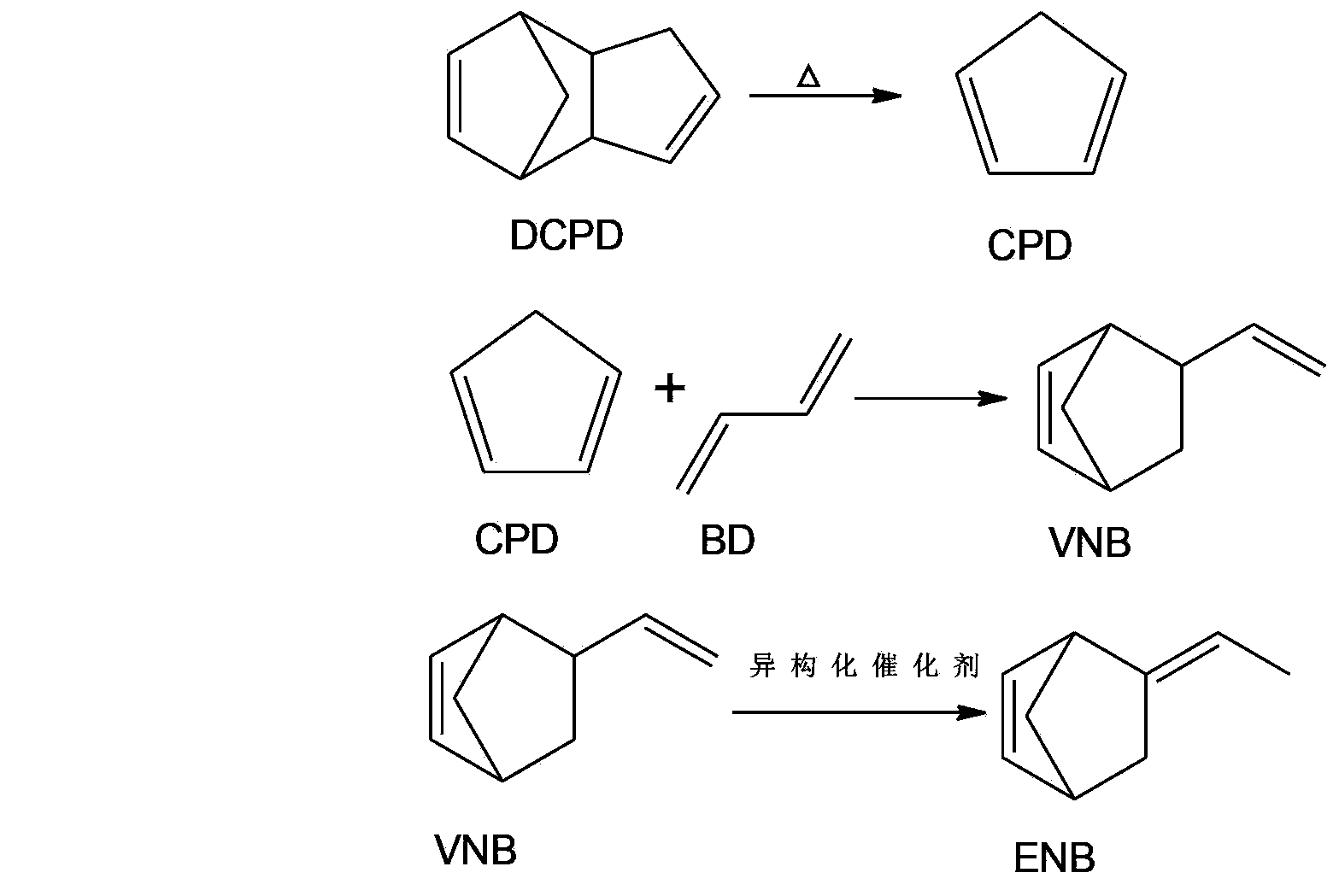

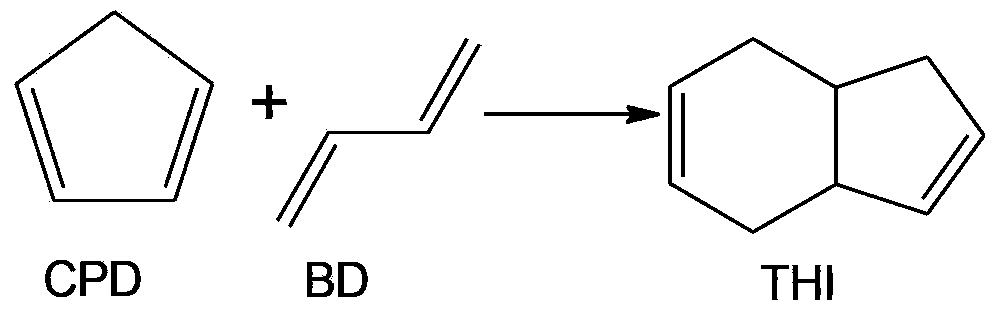

Preparation method of high-purity ethylidene norbornene (ENB)

ActiveCN103483135AHigh yieldAvoid lostHydrocarbon by isomerisationHydrocarbon by depolymerisationIsomerizationDead volume

The invention relates to a preparation method of high-purity ethylidene norbornene (ENB), which comprises the following steps: 1) preparing cyclopentadiene (CPD) from cracked C9 bicyclic section distillate; 2) reacting the CPD and 1,3-butadiene (BD) in a non-dead-volume cascade tubular reactor to generate 5-vinyl-2-norbornene (VNB); 3) separating the crude VNB to obtain refined VNB, collecting the unreacted BD, CPD and circulating solvent, and returning to the front of the tubular reactor, thereby forming a circulating loop; and 4) dehydrating the refined VNB obtained in the step 3), carrying out isomerization reaction to obtain crude ENB, and removing light and heavy components from the crude ENB by a refining tower to obtain the high-purity ENB. The method has the advantages of simple and reliable process route and low facility request, and is suitable for large-scale production.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

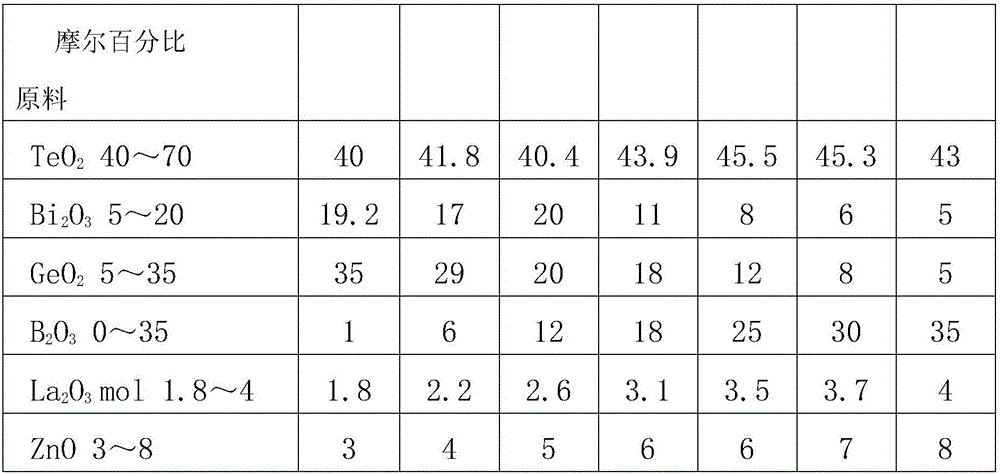

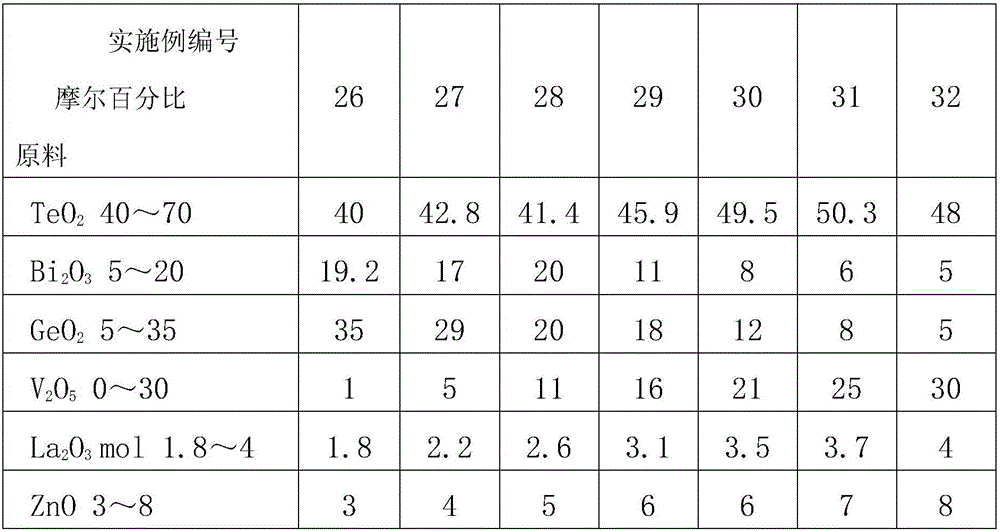

Preparation method of tellurite glass powder for silicon solar battery positive electrode silver paste

InactiveCN105800942ALower melting temperatureLow viscosityPhotovoltaic energy generationCable/conductor manufactureSilver pasteSilicon solar cell

The invention discloses a preparation method of tellurite glass powder for silicon solar battery positive electrode silver paste.The preparation method is characterized in that by molar percentage, 40-70% of TeO2, 5-20% of Bi2O3, 5-35% of GeO2, 0-30% of V2O5, 0-35% of B2O3, 1.8-4% of La2O3 and 3-8% of ZnO are weighed and blended, postprocessing steps including mixed material fine grinding and drying, glass melting, secondary fine grinding and the like are conducted, and the tellurite glass powder for silicon solar battery positive electrode silver paste is obtained.By the adoption of the prepared tellurite glass powder, no lead is contained, and it is beneficial to protect the environment and the human health; the tellurite glass powder is good in adaptation to a silicon substrate and silver, is matched with the silicon substrate and silver in coefficient of thermal expansion and is good in chemical stability, moderate in softening temperature and particularly suitable for a binding phase of the silicon solar battery positive electrode silver paste.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

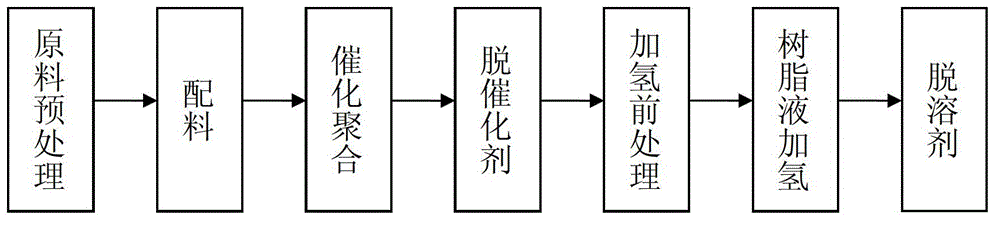

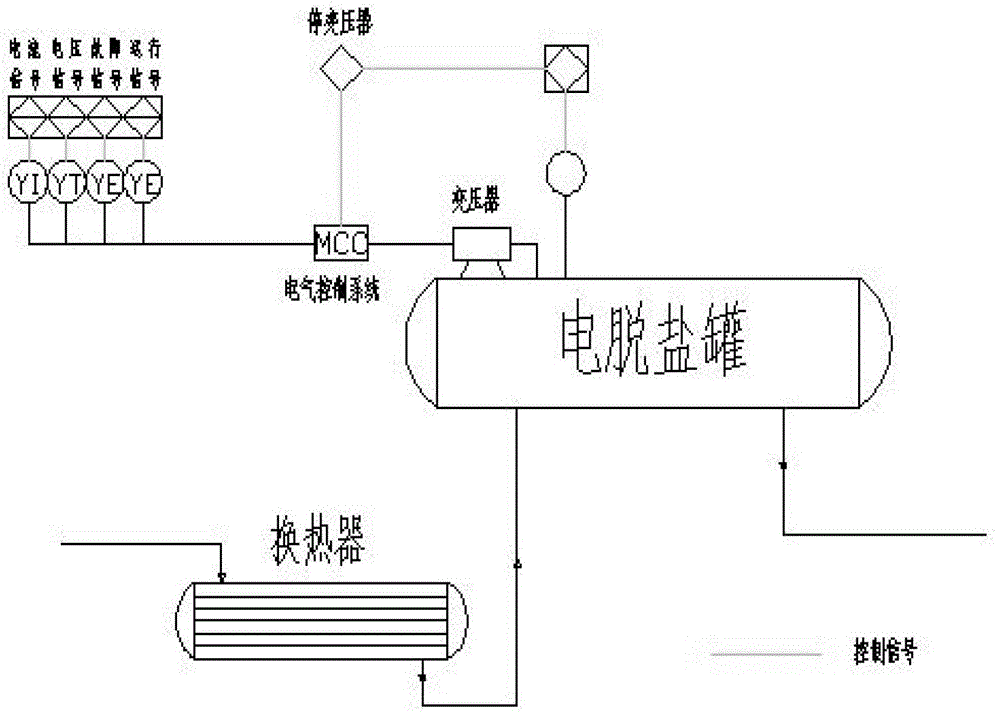

Preparation method of C5/C9 hydrocarbon resin

ActiveCN102718925AReduce reactivityGood compatibilityPhysical/chemical process catalystsOligomerBoron trifluoride

The invention relates to a preparation method of C5 / C9 hydrocarbon resin. The method comprises the following steps of: mixing piperlene fraction, crude isoamylene fraction and C9 fraction, pre-polymerizing the mixture at 180 to 230 DEG C, and finally polymerizing the mixture under the catalyzing of a gaseous boron trifluoride catalyst to obtain C5 / C9 hydrocarbon resin liquid; performing electrolytic desalting and dehydrating on the resin liquid, preprocessing the resin liquid through an active Al2O3 solid bed layer prior to hydrogenising, and then catalyzing and hydrogenising the resin liquid through a Pd / Zns / Al2O3 catalyst with ethyl methyl cyclohexane serving as solvent, and finally performing decompression and rectification on the resin liquid to remove the solvent and oligomer to obtain the C5 / C9 hydrocarbon resin. The C5 / C9 hydrocarbon resin prepared by the method based on hydrogenising has the advantages of light color, moderate softening point and high compatibility with most polarity resin, and can be widely used in the field of adhesives.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

Wafer adhesive wax

ActiveCN102936485AUnderstand clearlyModerate softening pointWax adhesivesRosin adhesivesPolymer scienceMicrocrystalline wax

The invention aims to disclose a wafer adhesive wax, comprising the following components of, by weight, 1-5% of a microcrystalline wax, 5-10 % of a synthetic wax, 5-10% of a amide wax, 65-75% of rosin and 5-10% of a modified rosin. Compared with a conventional wafer adhesive wax, the wafer adhesive wax provided by the invention has a moderate softening point, good viscosity and fluidity and high cohesive force. The softening point is 80-90 DEG C; kinematic viscosity is 100-200 mm<2> / s at a temperature of 110 DEG C; and the tensile shear strength is higher than 30 Kg / cm<2>. The wafer adhesive wax can realize the object of the invention.

Owner:江苏泰尔新材料股份有限公司

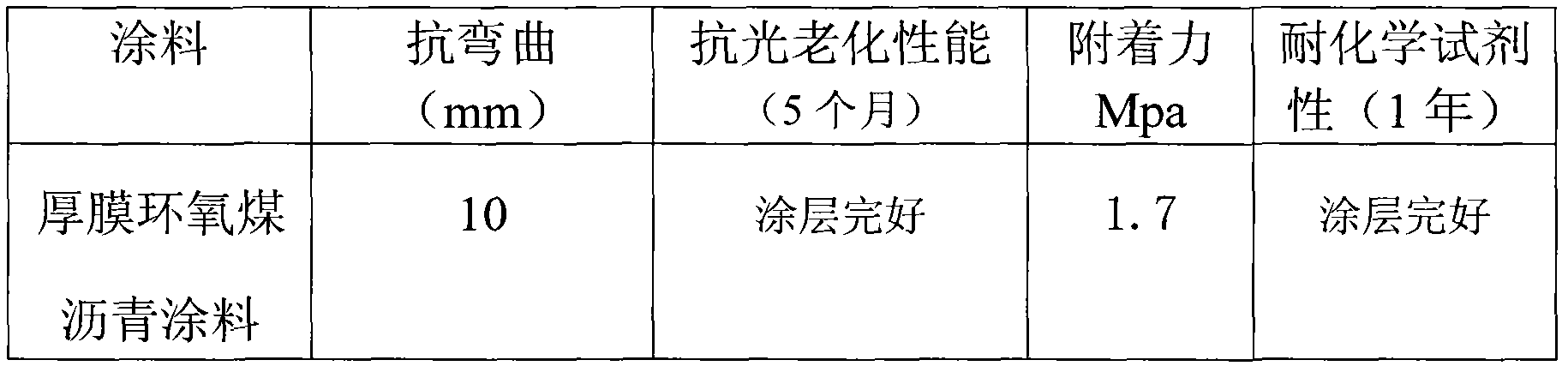

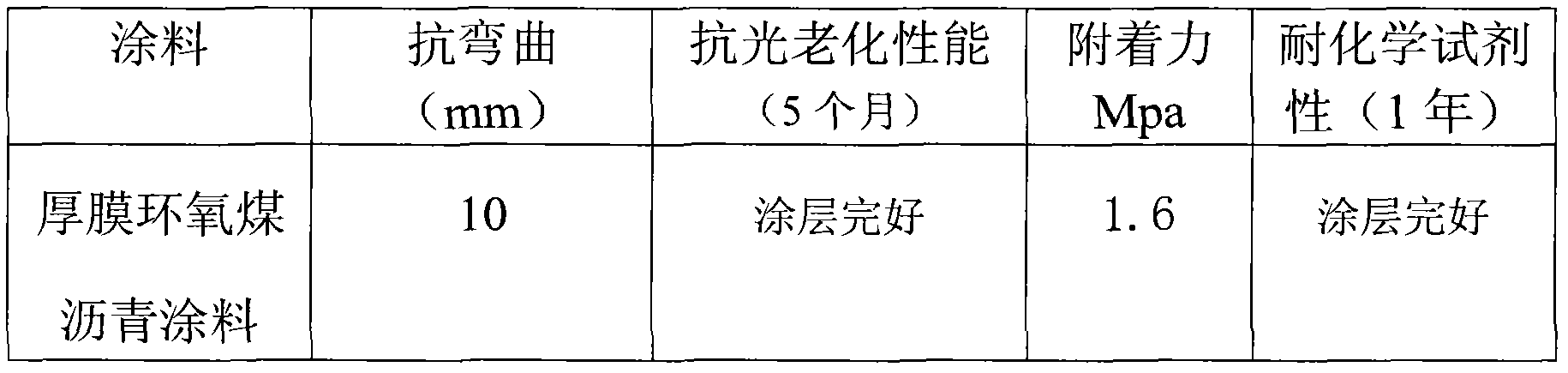

High-build epoxy coal tar pitch anticorrosive coating and preparation method thereof

InactiveCN102040902AGood resistance to microbial damageModerate softening pointCorrosion preventionAnti-corrosive paintsN-Butyl AlcoholTalc

The invention relates to a high-build epoxy coal tar pitch anticorrosive coating and a preparation method thereof. The preparation method comprises the following steps of: adding dimethylbenzene, n-butyl alcohol, butanone, coal tar pitch resin liquid, toughened resin, precipitated barium sulfate, silk mica powder, talc powder, a hoof-joint type rheological control aid, a coupling agent 01, a CibaEFKA3650 aid, an organic defoaming agent and poly organic carboxylate into bisphenol A type epoxy resin with medium molecular weight, stirring, dispersing at a high speed, and grinding into a component A; stirring phenolic ammonia, an accelerator, ethanol and a CibaTINUVIN 460 light stabilizer to form a component B; and uniformly mixing the component A and the component B in a ratio of 10:1. The high-build epoxy coal tar pitch anticorrosive coating has certain toughness, and has excellent adhesion, high microbial corrosion resistance, long construction operating period and certain light ageing resistance when applied to prestressed concrete cylinder pipe (PCCP) exterior walls.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC

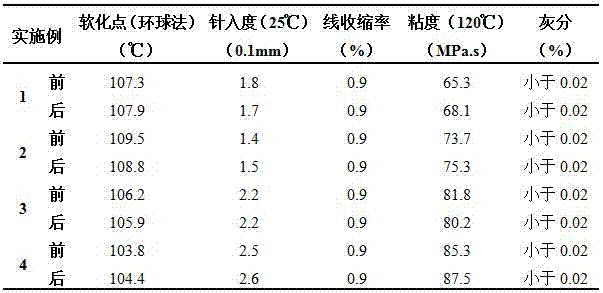

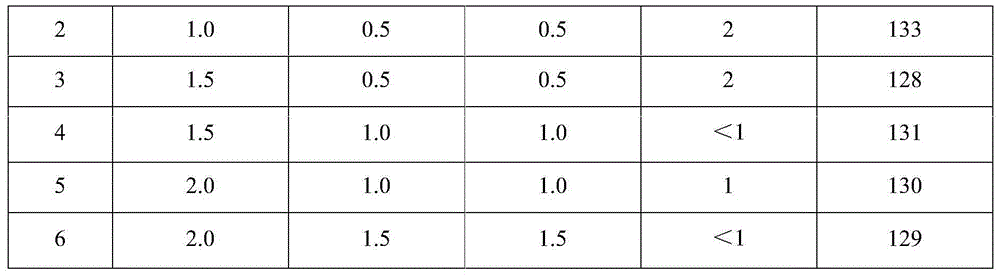

Precision-casting wax pattern material based on Fischer-Tropsch wax and preparation method thereof

The invention discloses a precision-casting wax pattern material based on Fischer-Tropsch wax and a preparation method thereof. The precision-casting wax pattern material comprises a basic component. The basic component comprises the following raw materials in percentage by mass: 10-50% of paraffin, 5-20% of Fischer-Tropsch wax, 10-50% of stearic acid, 5-30% of petroleum resin and 0-10% of lignite wax. The preparation method comprises the following steps: uniformly mixing and stirring all the raw materials under heating conditions to obtain a transparent liquid, performing filtering, and performing molding. The precision-casting wax disclosed by the invention has the advantages of moderate softening point, very low penetration degree, low linear shrinkage ratio, higher bending strength and low ash content, and can be widely used for preparing wax patterns of high-precision aviation casting structural parts and wax patterns for other precision casting purposes.

Owner:DONGGUAN UNIV OF TECH

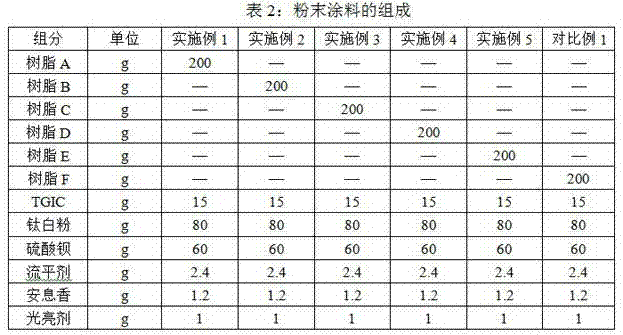

Preparation method for low-temperature curing composite resin powder coating

InactiveCN110041810AGood storage stabilityModerate molecular weightPowdery paintsEpoxy resin coatingsEpoxyHeat resistance

The invention relates to a preparation method for a low-temperature curing composite resin powder coating, and belongs to the technical field of coatings. Terminal carboxyl polyester resin and epoxy resin are taken as raw materials to prepare the low-temperature curing composite resin powder coating. Since the terminal carboxyl polyester resin and the epoxy resin are compounded, the low-temperature curing of the resin powder coating can be effectively realized, power coating application is not limited to the coating of the surface of a thermal-resistance base material, a possibility for applying the power coating to the surface coating film of a thermosensitive base material is greatly increased, the preparation method performs a great function for expanding the application range and the application field of the powder coating, the curing temperature of the low-temperature curing powder coating is low, the cost generated in a baking link in a production process is lowered, the consumption of energy is greatly reduced, resources are saved, the curing time is shortened while the mechanical property of the coating film is guaranteed, a production period is shortened, the production efficiency is improved, and economic benefits are increased.

Owner:江苏海獭新材料科技有限公司

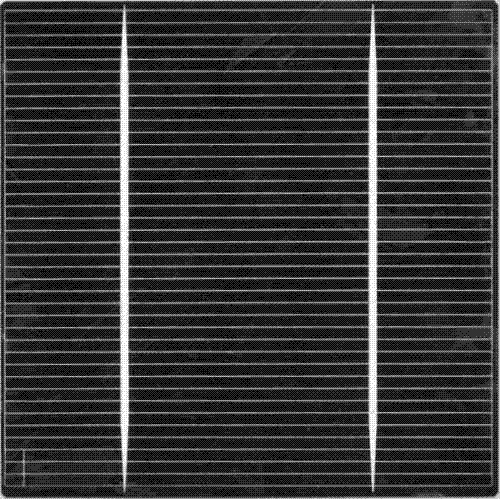

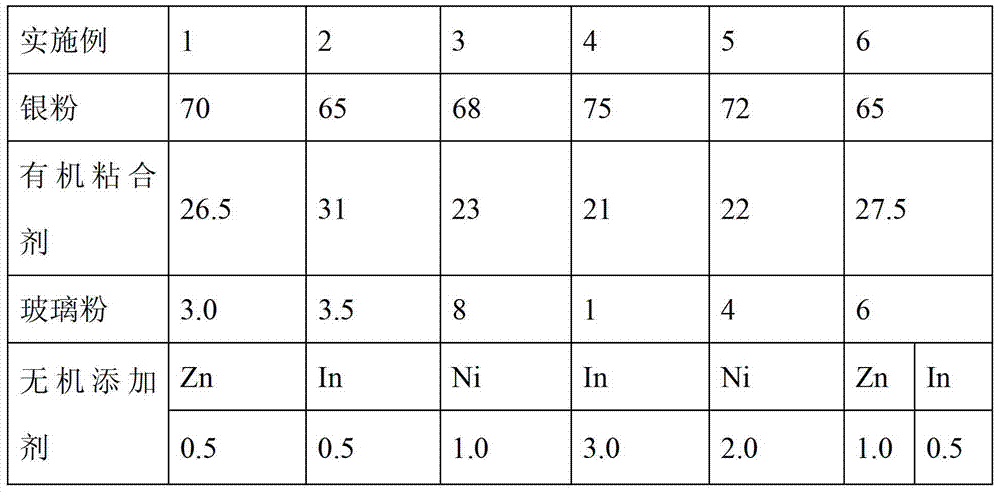

Front-face electrode slurry with low silver content for silica-based solar cell main grid and preparation method of front-face electrode slurry

ActiveCN103578604AStrong compactnessEasy to fillNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodeSilicon solar cell

The invention relates to an electrode material of a crystalline silicon solar cell, in particular to front-face electrode slurry with the low silver content for a silica-based solar cell main grid and a preparation method of the front-face electrode slurry. The front-face electrode slurry with the low silver content for the silica-based solar cell main grid is mainly formed by mixing, by weight, 65-75% of silver powder, 21-31% of organic bond, 1-8% of glass powder and 0.5-3% of inorganic additives. The front-face electrode slurry is used for crystalline silicon solar cell main grid lines, and developed for reducing the production cost and the manufacturing cost of the silica-based solar cell. The front-face electrode slurry is printed on the back face of the crystalline silicon solar cell, and forms a silver electrode with the high adhesive force and the high reliability on the main grid on the front face of the crystalline silicon solar cell through the infrared fast-burning process, wherein the actual peak temperature of the surface of a silicon wafer is 780-810 DEG C, and the peak time is 1-2s.

Owner:HANGZHOU RIGHTSILVER ELECTRONICS MATERIAL

Road building oil and its production method

An oil for building rod is prepared from medium-temp asphalt and anthracene oil. Its advantages are high stability, quality and content of asphalt, and proper softening point of distilled residue.

Owner:WUKUN STEEL

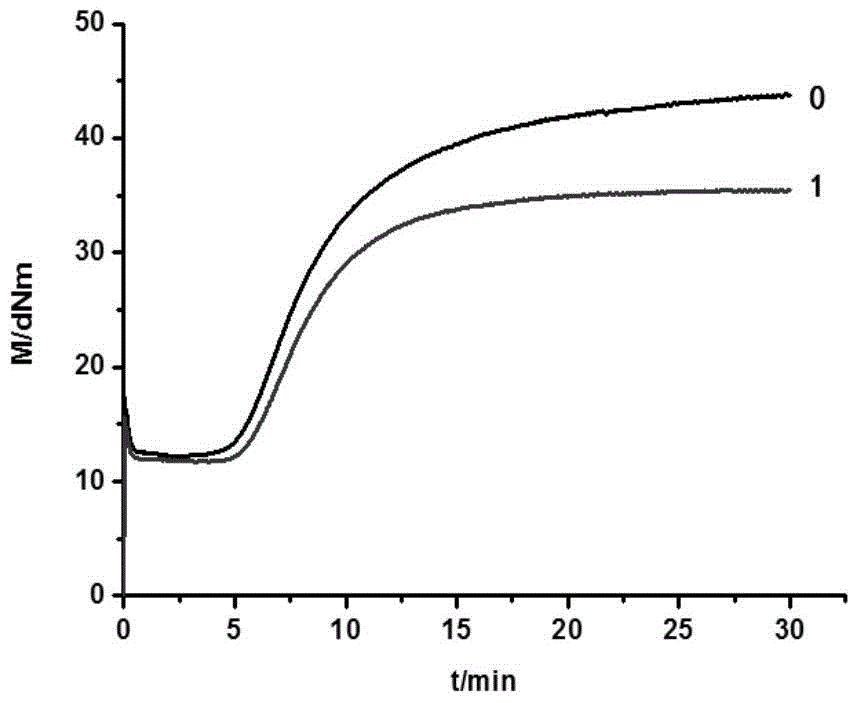

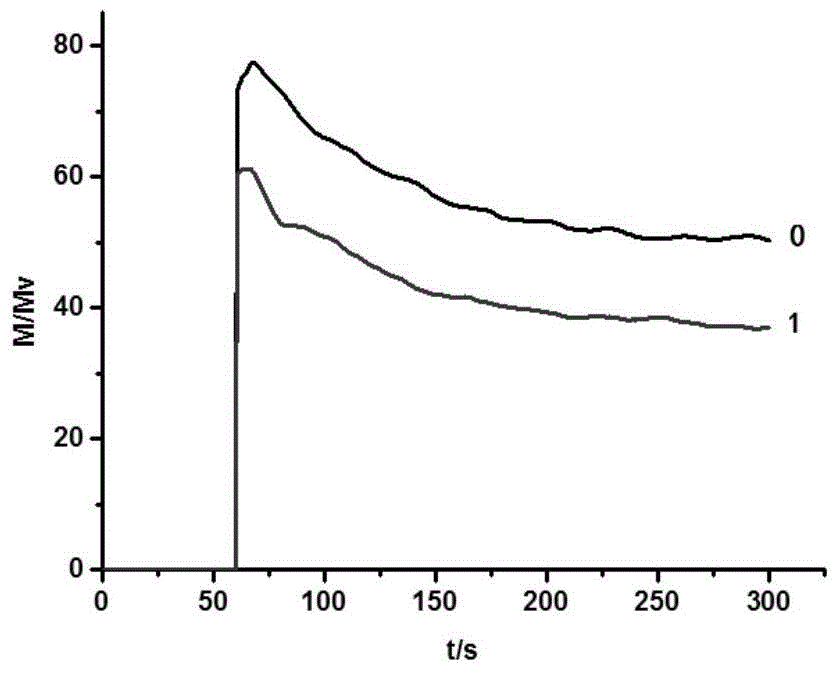

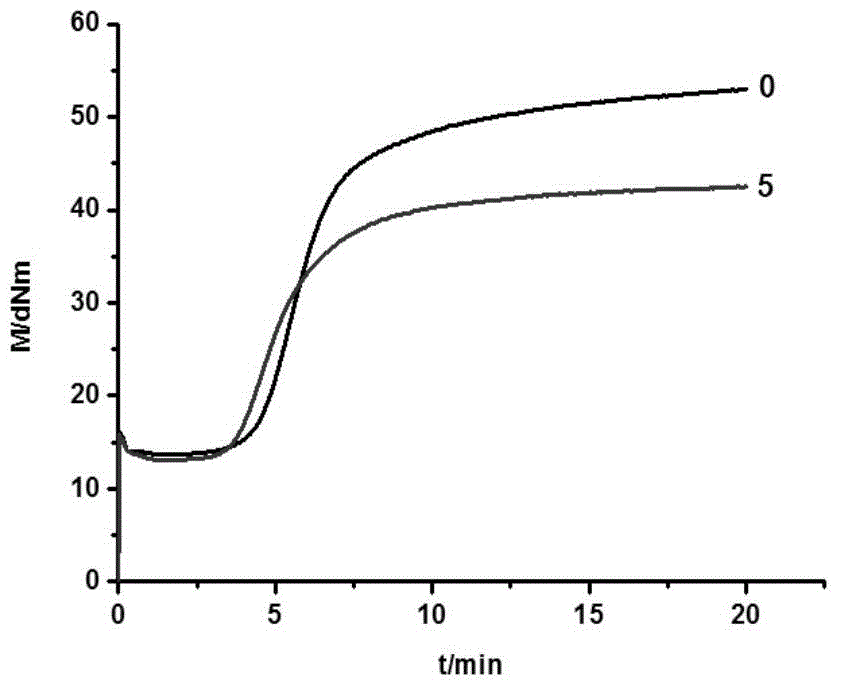

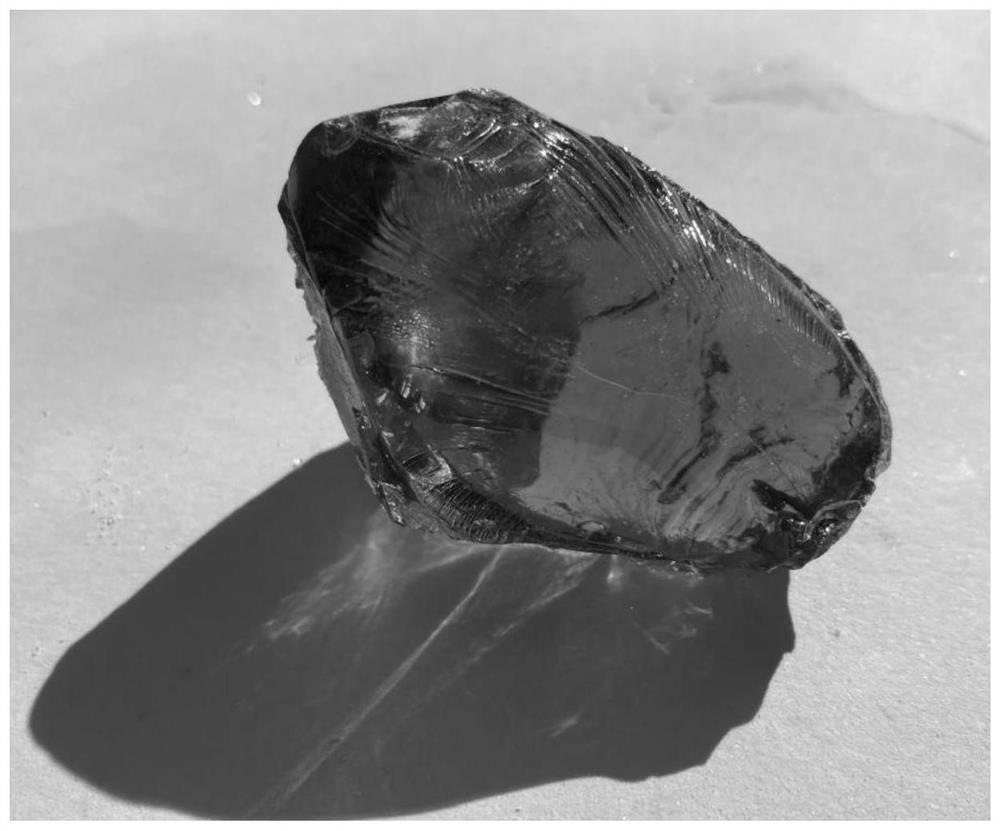

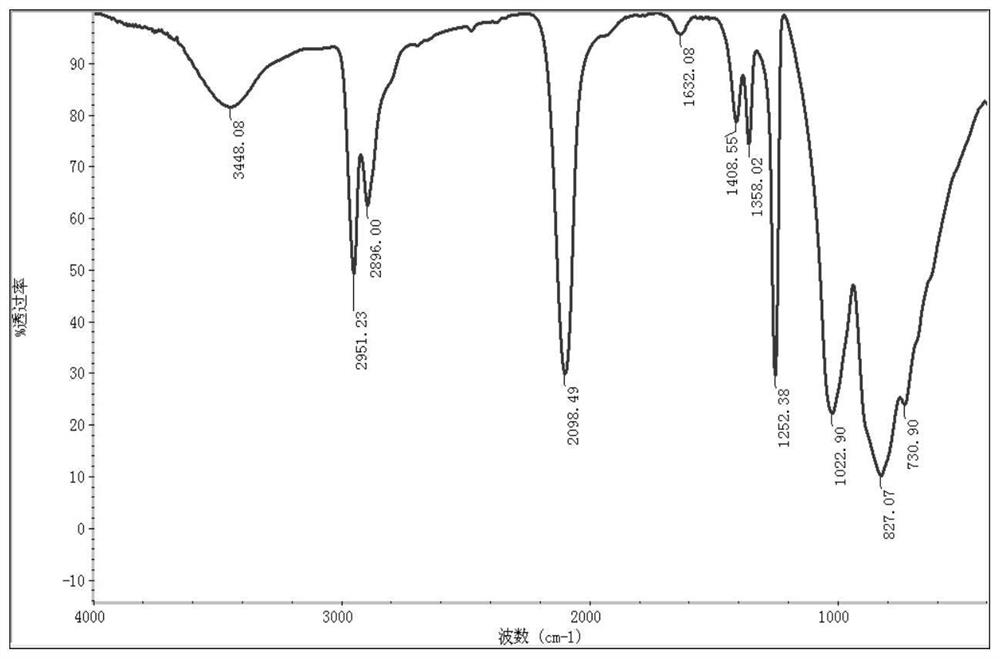

Bio-based reinforced plasticiser-eucommia ulmoides resin and preparation method thereof

The invention discloses a bio-based reinforced plasticiser-eucommia ulmoides resin and a preparation method thereof, and bio-based reinforced plasticiser-eucommia ulmoides resin and the preparation method thereof are applied to the field of rubber industry plasticisers. Traditional rubber plasticisers all come from fossil resources, belong to non-renewable materials and can deteriorate the mechanical property of rubber. The eucommia ulmoides resin can improve the processing property of the rubber and reduce energy consumption, also can improve the mechanical property of the rubber and overcome the defect that the traditional plasticisers achieve plastification and do not achieve reinforcement and is a novel, renewable, green and environment-friendly bio-based reinforced plasticiser. A rubber material modified by the eucommia ulmoides resin has the advantages that the Mooney viscosity is reduced, the vulcanizing time is shortened, the tensile strength and the tear strength are improved, the elongation at break is increased, and the dynamic fatigue property is improved. The eucommia ulmoides resin is an important composing part of comprehensive development of eucommia ulmoides gum, can enable by-products obtained through eucommia ulmoides gum production to be effectively utilized and has the advantages that the raw material utilization efficiency is improved, waste materials are changed into things of value, the environment is protected, the production process is simple and convenient, the production cost of the eucommia ulmoides gum is lowered, and the economic benefit and the social benefit are significant.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing light-color pentadiene petroleum resin

The invention relates to a method for preparing light-color pentadiene petroleum resin. The method comprises the following steps of: adding pentadiene serving as a raw material and trichloro triethyl di-aluminum in an amount which is 0.3 to 3 percent of the mass of the pentadiene into a dried and closed reactor, stirring, heating to the temperature of between 30 and 90 DEG C, and performing polymerization reaction for 3 to 9 hours by taking the trichloro triethyl di-aluminum as a catalyst and methylbenzene, dimethylbenzene or tetrahydrofuran as a solvent to obtain viscous liquid; and washing to remove the catalyst by using 3 to 12 mass percent alkaline liquor, washing by using distilled water until the viscous liquid is neutral, and distilling at the temperature of between 180 and 350 DEG C to remove the solvent to obtain the light-color pentadiene petroleum resin, wherein a mass ratio of the pentadiene to the solvent is 1:(1-3). The prepared pentadiene petroleum resin has the advantages of small color number, moderate softening point, narrow molecular weight distribution and the like, and the preparation process is easy to operate.

Owner:PETROCHINA CO LTD

Preparation method of polymetal carbosilane precursor

The invention discloses a preparation method of a polymetal carbosilane precursor, which comprises the following steps: sequentially adding alkali metal and metallocene into an organic solvent in a protective atmosphere, then dropwise adding chlorosilane, carrying out first reaction, solid-liquid separation and solvent removal to obtain a reactant B, and then carrying out second reaction on the reactant B and a reactant A in the protective atmosphere to obtain the polymetal carbosilane precursor. And removing the solvent to obtain polymetal carbosilane, wherein the reactant A is liquid polysilicon carbosilane. According to the preparation method, a large amount of metal is introduced through the reaction of chlorosilane and metallocene, a reactant B which has high reaction activity and contains more Si-Si bonds is obtained at the same time, then the reactant B continues to react with liquid polysilicocarbosilane, and the obtained product has high metal content and good performance stability at the same time. And the distribution of metal elements is uniform, the metal content is adjustable, and the precursor does not contain oxygen.

Owner:CHANGSHA DAFEI NEW MATERIAL TECH CO LTD

Lead-free glass powder for aluminum back field of silicon solar battery and preparation method thereof

The invention relates to the technical field of solar batteries, and relates to lead-free glass powder for the aluminum back field of a silicon solar battery. The lead-free glass powder comprises the following components in parts by weight: 40-65 parts of Bi2O3, 15-35 parts of B2O3, 10-20 parts of SiO2, 3-10 parts of ZnO, 1-10 parts of P2O5, 0.5-5 parts of BaO, 0.5-5 parts of CaO and 0.5-2 parts of MoO3; the expansion coefficient of the binding phase of the glass powder is (35-50)*10<-7>, the softening point of the glass powder is 520-600 DEG C, the sintering temperature of the glass powder is 750-950 DEG C, and the density of the glass powder is 2-4 g / cm<3>. According to the lead-free glass powder disclosed by the invention, the glass powder for the aluminum back field is matched with the expansion coefficient, softening point and density of a battery silicon slice, and therefore the aluminum slurry has the advantages of small bending deformation obtained after sintering, high adhesive force with the silicon slice and good conductive property.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

Universal coating adhesive and preparation method thereof

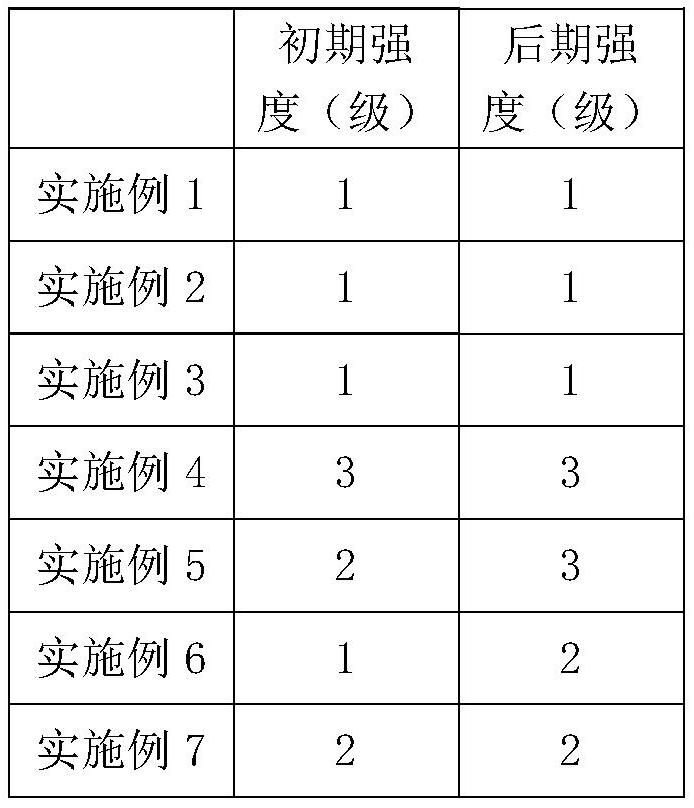

PendingCN112625638AHigh strengthIncrease late strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to the technical field of coating adhesive, in particular to a universal coating adhesive and a preparation method thereof. The coating adhesive comprises the following raw materials in parts by weight: 15-30 parts of polyether polyol, 10-20 parts of acrylic resin, 35-80 parts of polyester polyol, 0.01-0.05 part of a defoaming agent, 5-15 parts of a polyurethane elastomer, 0-5 parts of a filler, 5-10 parts of a chain extender, 10-20 parts of isocyanate and 0.01-0.1 part of a catalyst. The coating adhesive disclosed by the invention can meet the requirements of coating application of various base materials, has good initial strength and later strength, and solves the problem of adhesion to wood materials, wood-plastic materials, aluminum materials and the like and problems in initial adhesion for bonding of thick film materials.

Owner:南通恒华粘合材料科技有限公司

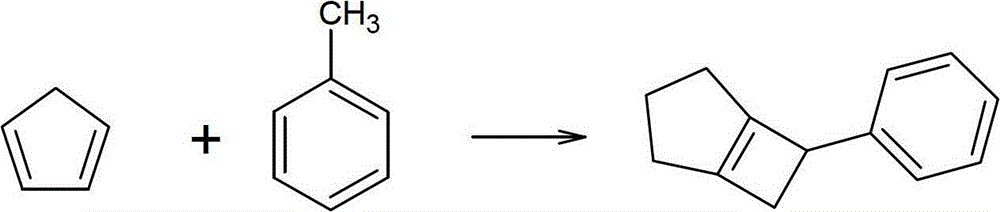

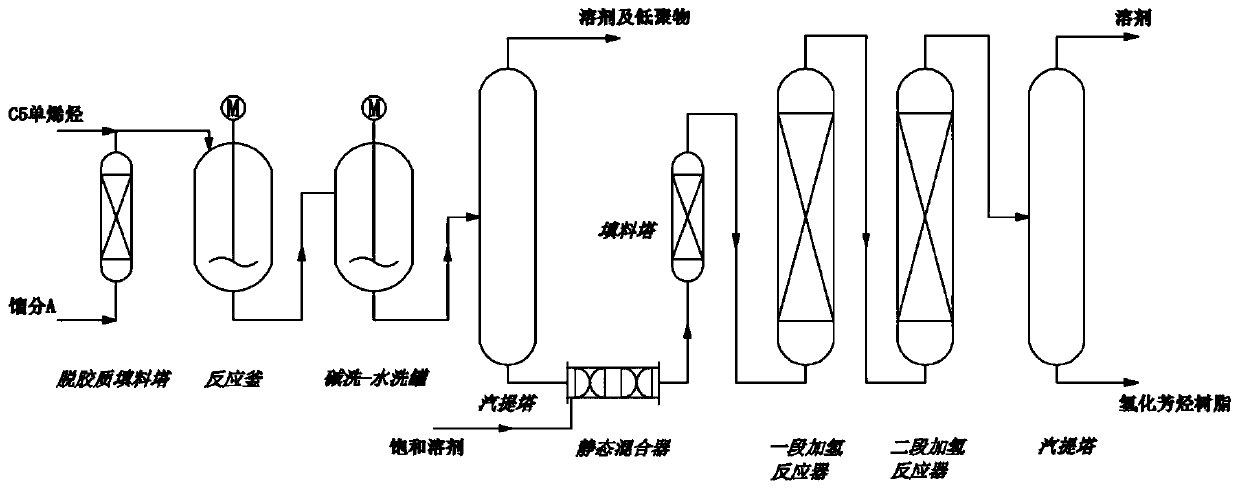

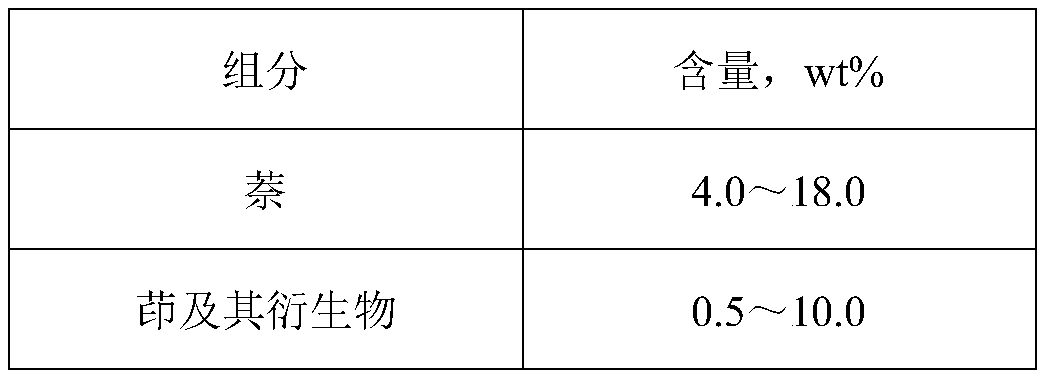

Preparation method of high aromatic hydrocarbon hydrogenated resin

ActiveCN111592617AAdaptableHigh economic valueMetal/metal-oxides/metal-hydroxide catalystsRaney catalystsElastomerPolymer science

The invention relates to a preparation method of high aromatic hydrocarbon hydrogenated resin. The preparation method comprises the processes of fraction cutting, pretreatment, catalytic polymerization, two-stage hydrogenation and the like. The high aromatic hydrocarbon hydrogenated resin has excellent compatibility with SBS, SIS and other elastomers, and is suitable for the fields of hot melt adhesives, coatings, rubber modification and the like.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

Laser alumite hot stamping back gum and preparation method thereof

ActiveCN110804407AImprove adhesionEnhanced resistance to peelingNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceButadiene Dioxide

The invention discloses a laser alumite hot stamping back gum and a preparation method thereof. The laser alumite hot stamping back gum comprises the raw materials: a maleic anhydride-vinyl acetate-methacrylate copolymer, a chloroprene-acrylic acid-acrylate copolymer, fumed silica and a solvent; the maleic anhydride-vinyl acetate-methacrylate copolymer comprises the raw materials by weight: 1 to 2parts of maleic anhydride, 1 to 2 parts of vinyl acetate and 5 to 8 parts of methacrylate monomers; the chloroprene-acrylic acid-acrylate copolymer comprises the raw materials by weight: 2 to 4 partsof chloroprene, 2 to 4 parts of acrylic acid and 4 to 8 parts of acrylate monomers. The laser alumite hot stamping back gum has good adhesive force and stripping resistance, and when the back gum isused, the hot stamping effect is good, and the definition is high; the softening point is proper, and the anti-adhesion phenomenon is avoided.

Owner:WUHAN HUAZHONG KEDA FINE CHEM

Weather resistant polyester resin with excellent water-boiling resisting performance and method for preparing same

ActiveCN101735431BImprove boiling resistanceImprove the level ofPowdery paintsPolyester coatingsPolymer sciencePtru catalyst

The invention discloses weather resistant polyester resin with excellent water-boiling resisting performance, which is prepared through the melt polycondensation of the following components: 20-45 percent by weight of polyol, 40-55 percent by weight of aromatic polybasic acid, 0-8 percent by weight of fat polybasic acid, 0-5 percent by weight of branching agent, 5-15 percent by weight of acidolysis agent and 0.01-0.15 percent by weight of esterification catalyst. The invention also discloses a method for preparing the weather resistant polyester resin with excellent water-boiling resisting performance. The polyester resin prepared with the method has high glass transition temperature, high softening point, appropriate melt viscosity and appropriate storage stability. The powder coating produced from the polyester resin has excellent water-boiling resisting performance, good leveling performance and good impact performance, etc.

Owner:GUANGZHOU KINTE IND

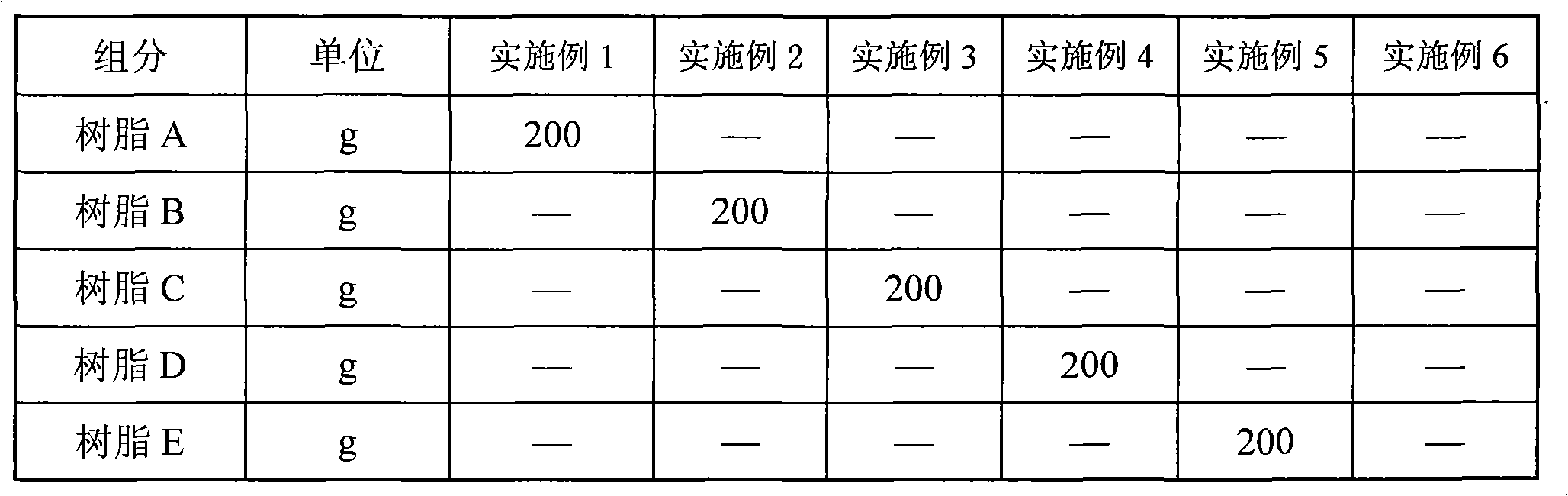

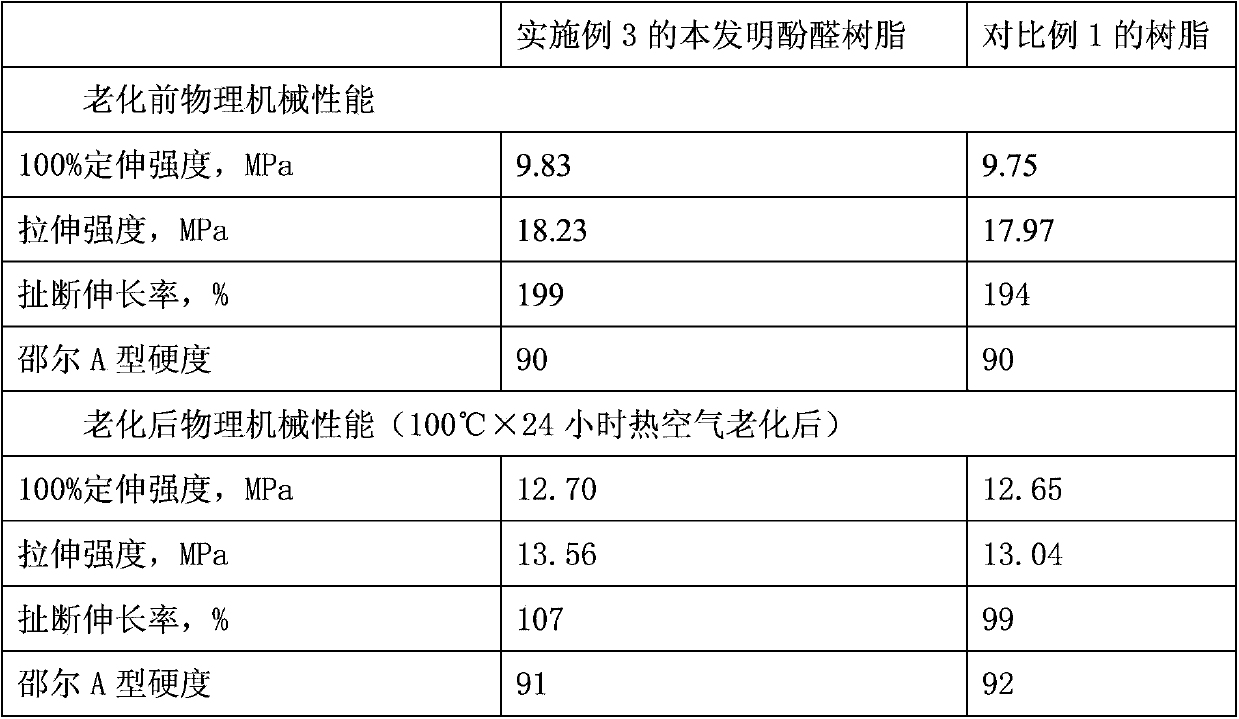

Phenolic resin, its composition, preparation method and application

InactiveCN103992456AModerate softening pointImprove reinforcementFree phenolPhenol formaldehyde resin

The invention relates to a phenolic resin, which has a free phenol content of less than 1% and a softening point of 90-130DEG C. The phenolic resin is prepared by reacting phenol with formaldehyde, and conducting vacuum distillation to reduce free phenol. The invention also discloses a preparation method and application of the phenolic resin. The invention also discloses a rubber composition with the resin as rubber reinforcing resin. The preparation method provided by the invention has the advantages of less wastewater and simple operation.

Owner:SINO LEGEND CHINA CHEM

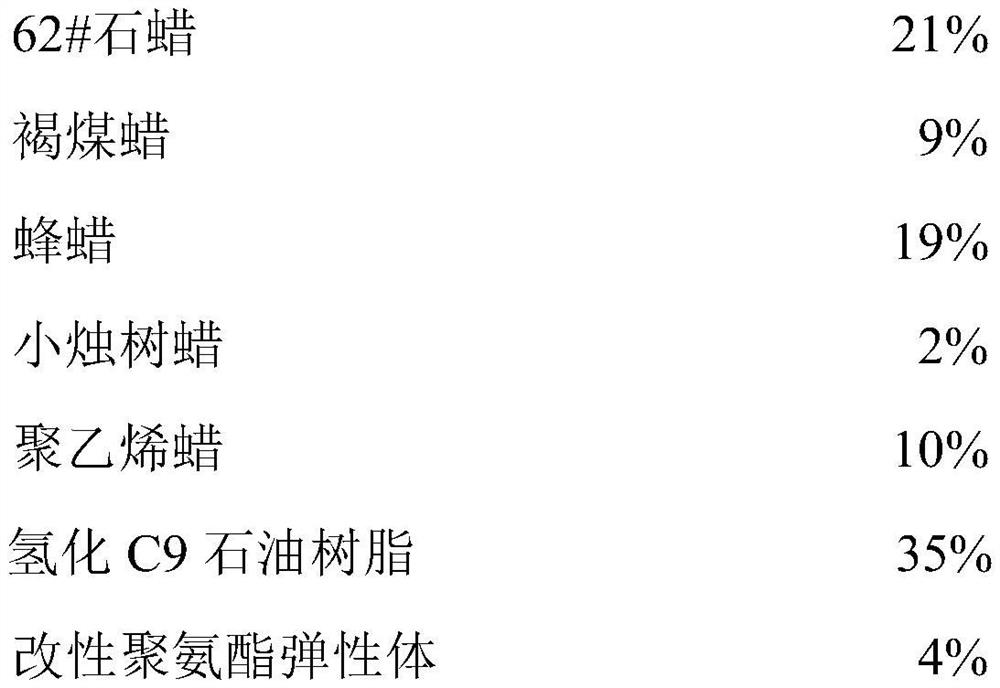

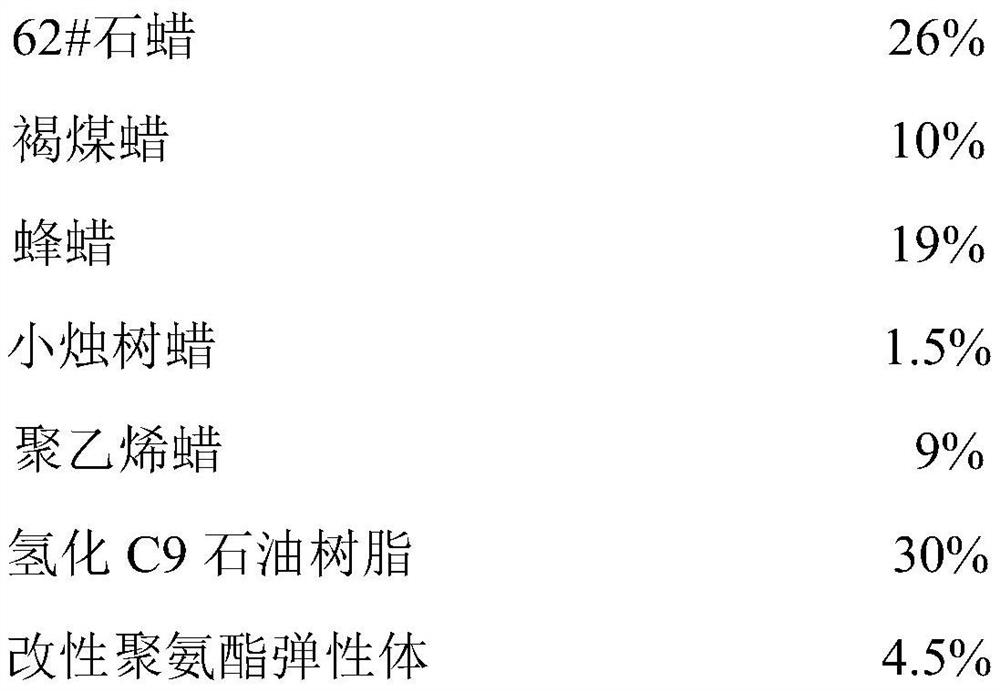

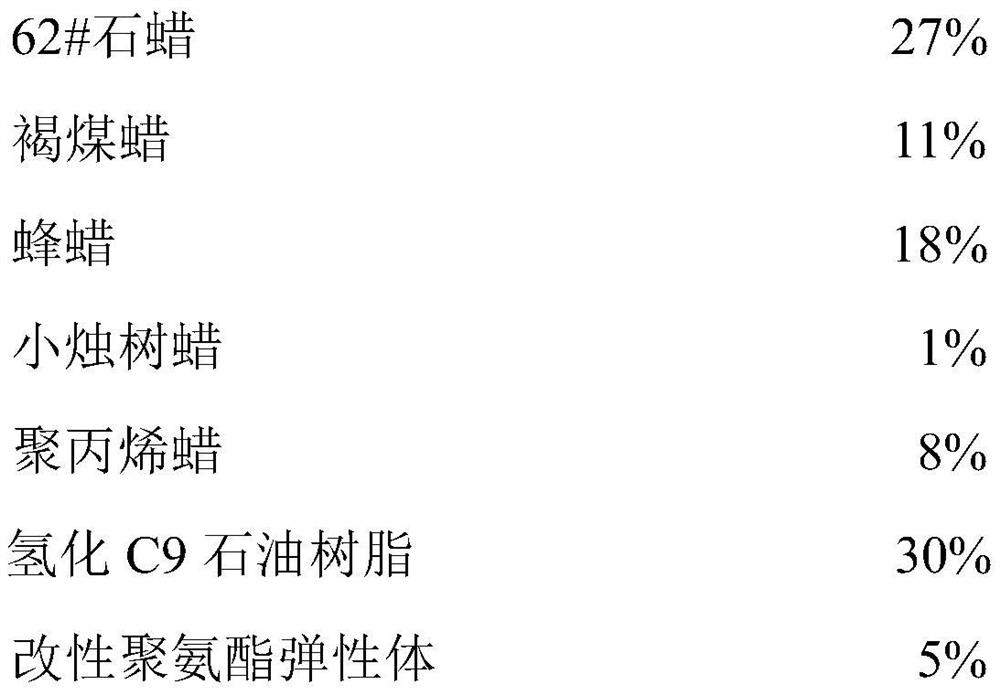

Ornament investment casting pattern material based on modified polyurethane elastomer and preparation method thereof

PendingCN113214659AImprove performanceModerate softening pointFoundry moulding apparatusPolyurethane elastomerMINERAL WAX

The invention relates to the technical field of investment casting, in particular to an ornament investment casting pattern material based on a modified polyurethane elastomer and a preparation method thereof. The ornament investment casting pattern material comprises 30%-55% of mineral wax, 16%-23% of animal and plant wax, 3%-10% of synthetic wax, 15%-35% of tackifying resin and 4%-9% of the modified polyurethane elastomer. The modified polyurethane elastomer is prepared from a polyurethane elastomer and a polyolefin elastomer through silanization grafting modification. The preparation method comprises the following steps: physically blending the polyurethane elastomer and the polyolefin elastomer, and carrying out silanization modification to obtain the modified polyurethane elastomer; and heating and melting the mineral wax, the animal and plant wax and the synthetic wax, and adding the tackifying resin and the modified polyurethane elastomer to obtain the ornament investment casting pattern material. The ornament investment casting pattern material is moderate in softening point and needle penetration, low in viscosity, good in toughness, low in ash content, suitable for ornaments with high toughness requirements and high in market value.

Owner:DONGGUAN UNIV OF TECH +1

A Wafer Bonding Wax

ActiveCN102936485BModerate softening pointIncrease stickinessWax adhesivesRosin adhesivesMicrocrystalline waxAdhesive

The invention aims to disclose a wafer adhesive wax, comprising the following components of, by weight, 1-5% of a microcrystalline wax, 5-10 % of a synthetic wax, 5-10% of a amide wax, 65-75% of rosin and 5-10% of a modified rosin. Compared with a conventional wafer adhesive wax, the wafer adhesive wax provided by the invention has a moderate softening point, good viscosity and fluidity and high cohesive force. The softening point is 80-90 DEG C; kinematic viscosity is 100-200 mm<2> / s at a temperature of 110 DEG C; and the tensile shear strength is higher than 30 Kg / cm<2>. The wafer adhesive wax can realize the object of the invention.

Owner:江苏泰尔新材料股份有限公司

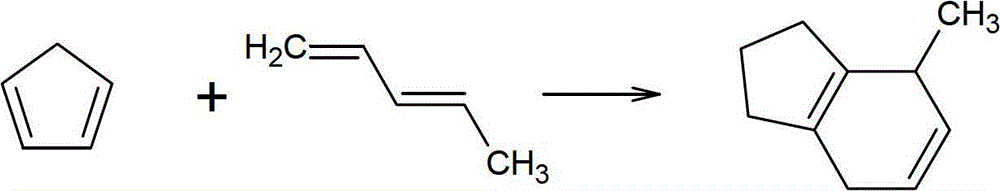

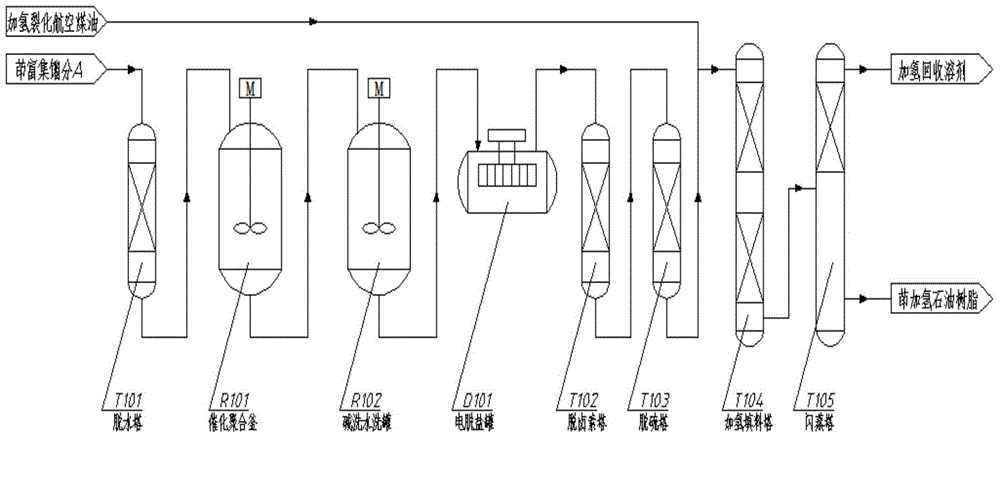

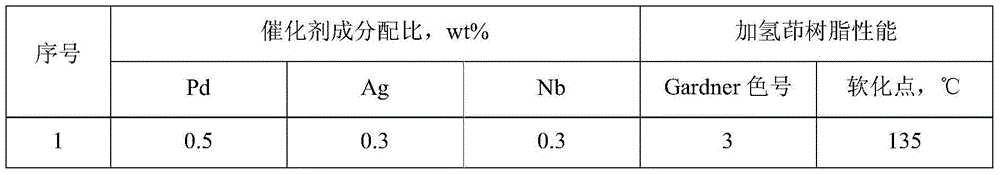

Method for preparing hydrogenated indene resin

The invention relates to a method for preparing hydrogenated indene resin. The method includes the steps: depolymerizing an ethylene cracked C9 fraction to obtain an indene-enriched fraction A with the boiling point of 140-210 DEG C, removing trace water, then carrying out catalytic polymerization with boron trifluoride ether or gas boron trifluoride to obtain an indene resin polymerization liquid, washing, filtering to obtain a resin liquid, pre-treating the resin liquid, then mixing and dissolving with hydrogenated aviation kerosene, to obtain a hydrogenated resin liquid under an action of a hydrogenation catalyst, and removing a solvent to obtain the product. The method has simple process, and the prepared hydrogenated indene resin is light in hue, good in thermal stability and excellent in compatibility, and is mainly applied in printing ink printing, food packaging and other fields.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

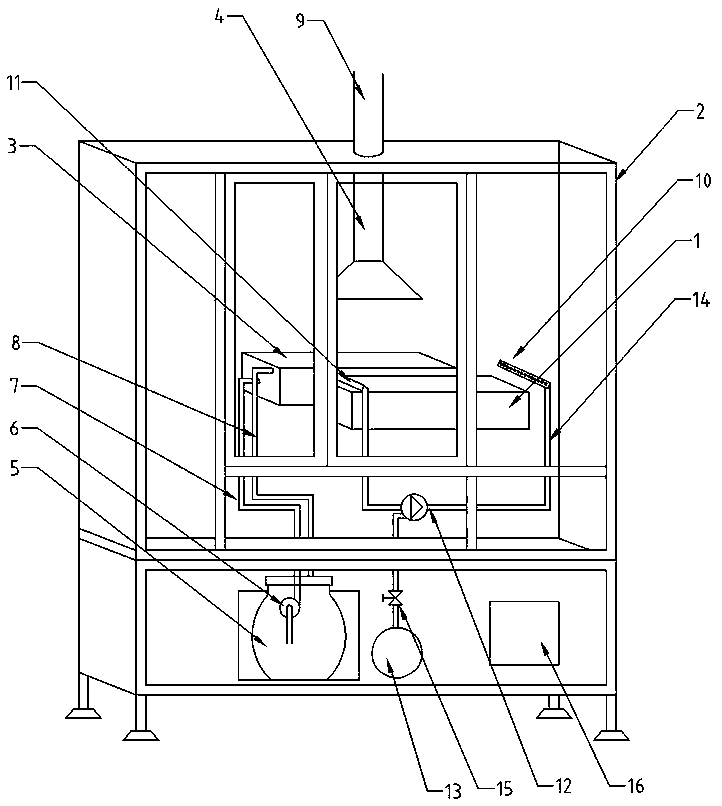

Full-automatic anti-oxidation soldering tin furnace for reducing exhaust emission treatment and special soldering flux

PendingCN109014484AReduce dosageReduce generationHeating appliancesWelding/cutting media/materialsBenzoic acidDimethylcarbinol

The invention relates to a full-automatic anti-oxidation soldering tin furnace for reducing exhaust emission treatment. The full-automatic anti-oxidation soldering tin furnace comprises a soldering tin furnace body (1), a tin furnace gas hood (2), a soldering flux tank (3) and a smoke pumping device (4). A pair of "nitrogen curtain" devices is arranged oppositely in the side direction of the widthdirection of the soldering fluid surface of a liner of the soldering tin furnace body (1). The invention further relates to a special soldering flux for the anti-oxidation soldering tin furnace. Rosin and rosin ester form modified rosin resin, and acrylate-modified butadiene resin, polyethylene, polyurethane and furfural resin form a film-forming enhancer. Octyphenol polyoxyethylene ether, succinic acid, anhydrous citric acid, benzoic acid and xylene are compounded to form an organic acid activator, and dimethylcarbinol, benzotriazole and hexamethylene diamine form a solvent. The full-automatic anti-oxidation soldering tin furnace for reducing exhaust emission treatment and the special soldering flux for the anti-oxidation soldering tin furnace can improve the workshop environment, prevent the oxidation of soldering tin in large quantity, improve the production efficiency, and save labor cost for an enterprise.

Owner:资兴市慧华电子有限公司

Road building oil and its production method

An oil for building rod is prepared from medium-temp asphalt and anthracene oil. Its advantages are high stability, quality and content of asphalt, and proper softening point of distilled residue.

Owner:WUKUN STEEL

Special C5 petroleum resin for adhesive and preparation method of special C5 petroleum resin

ActiveCN112250795ALow purity requirementReduce manufacturing costMineral oil hydrocarbon copolymer adhesivesAlkaneAdhesive cement

The invention relates to special C5 petroleum resin for an adhesive and a preparation method of the special C5 petroleum resin. The special C5 petroleum resin for the adhesive comprises the followingpolymerization raw material components in percentage by weight: 5-70% of a raw material A, 4%-35% of a raw material B, 15%-90% of C5 alkane fraction C and 0.5-2.0 wt% of a composite aluminum trichloride cation catalyst. The preparation process comprises the steps of forming a copolymerization reaction solution from the raw material A and the raw material B, taking the C5 alkane fraction C as a polymerization solvent, catalyzing a polymerization reaction by using the composite aluminum trichloride cation catalyst, performing the polymerization reaction by adopting a closed dynamic stirring pressure reaction kettle, transferring the polymerization solution into a water washing kettle after the polymerization reaction is finished, neutralizing and washing to obtain a resin polymerization solution, and carrying out reduced pressure distillation and steam stripping on the resin liquid to obtain the C5 petroleum resin. The special C5 petroleum resin for the adhesive has the advantages of ideal resin yield, moderate softening point and melt viscosity and low wax fog point, and is suitable for the adhesive production industry.

Owner:DAQING HUAKE

Thermoplastic composition for dental impression as well as preparation method and application of thermoplastic composition

InactiveCN109453038AModerate softening pointModerate modulusImpression capsDental impression compositionsFlexural strengthPolycaprolactone

The invention provides a thermoplastic composition for dental impression. The thermoplastic composition is prepared from a first thermoplastic polymer, a second thermoplastic polymer and a plasticizer, wherein the first thermoplastic polymer is prepared from one or more of polyurethane, polyketone, polycarbonate and polyhydroxybutyrate; the second thermoplastic polymer is prepared from one or moreof polylactic acid, polyglycollide and polycaprolactone. By utilizing a synergistic action of the specific first thermoplastic polymer and the specific second thermoplastic polymer and combining theplasticizer, the thermoplastic composition for dental impression can realize one-time impression, and is moderate in softening point and modulus and simple in mould taking. The experimental results show that the softening point of the composition provided by the invention is 60-80 DEG C, the flexural strength is 80MPa or above, and the modulus is 2GPa or below; the thermoplastic composition facilitates the operation of doctors and patients, and fills the gap in the industry.

Owner:吉林省登泰克牙科材料有限公司

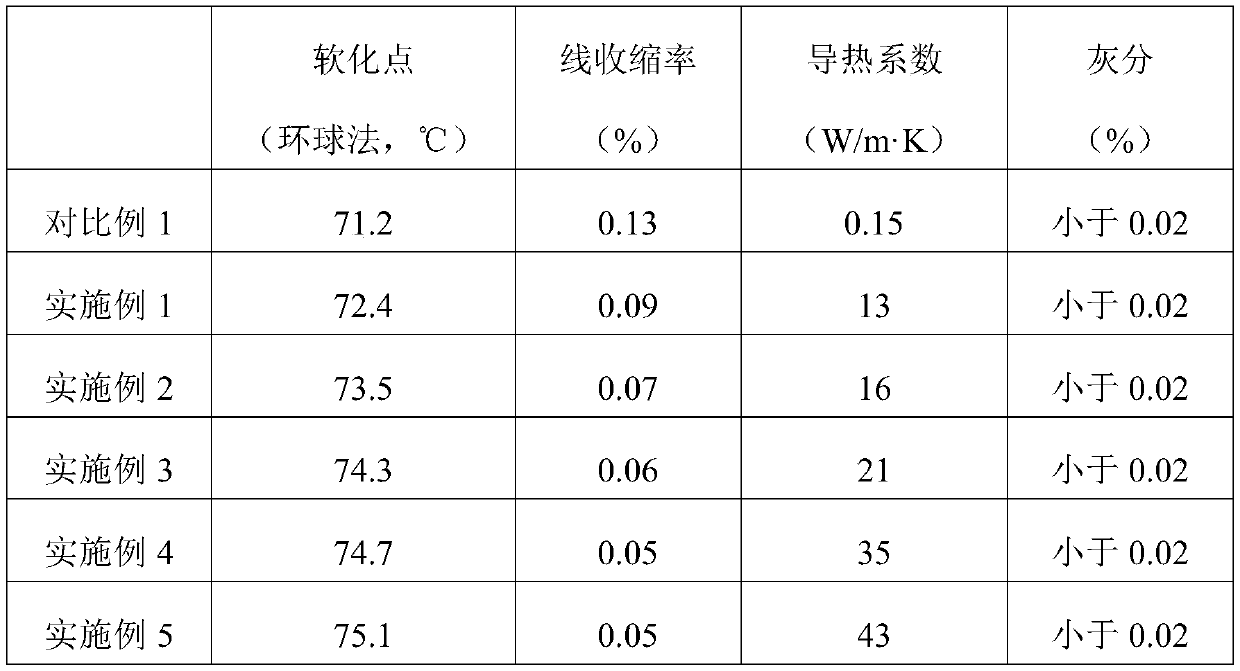

A filler type investment casting wax based on lipophilic micron graphite and preparation method thereof

ActiveCN107913979BModerate softening pointImprove flexural strengthFoundry moulding apparatusParaffin waxPolymer science

The invention discloses a filling type investment casting wax based on lipophilic micron graphite and a preparation method thereof. A filler type investment casting wax based on lipophilic micron graphite comprises basic components, the basic components are composed of the following raw materials in mass percentage: 40-60% of paraffin wax, 6-10% of rosin or rosin resin, 3-10% of PE wax, 25-35% of petroleum resin, 5-15% of lipophilic micron graphite, and 0-0.5 wt% of pigments as basic components. At the same time, the preparation method of the filling type investment casting wax based on lipophilic micron graphite is also disclosed. The filling type investment casting wax of the present invention has moderate softening point, small penetration and linear shrinkage, high bending strength and small ash content, which can well meet the requirements of high dimensional accuracy and high surface quality of precision castings, and meet the requirements of actual production needs.

Owner:DONGGUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com