Preparation method of high-purity ethylidene norbornene (ENB)

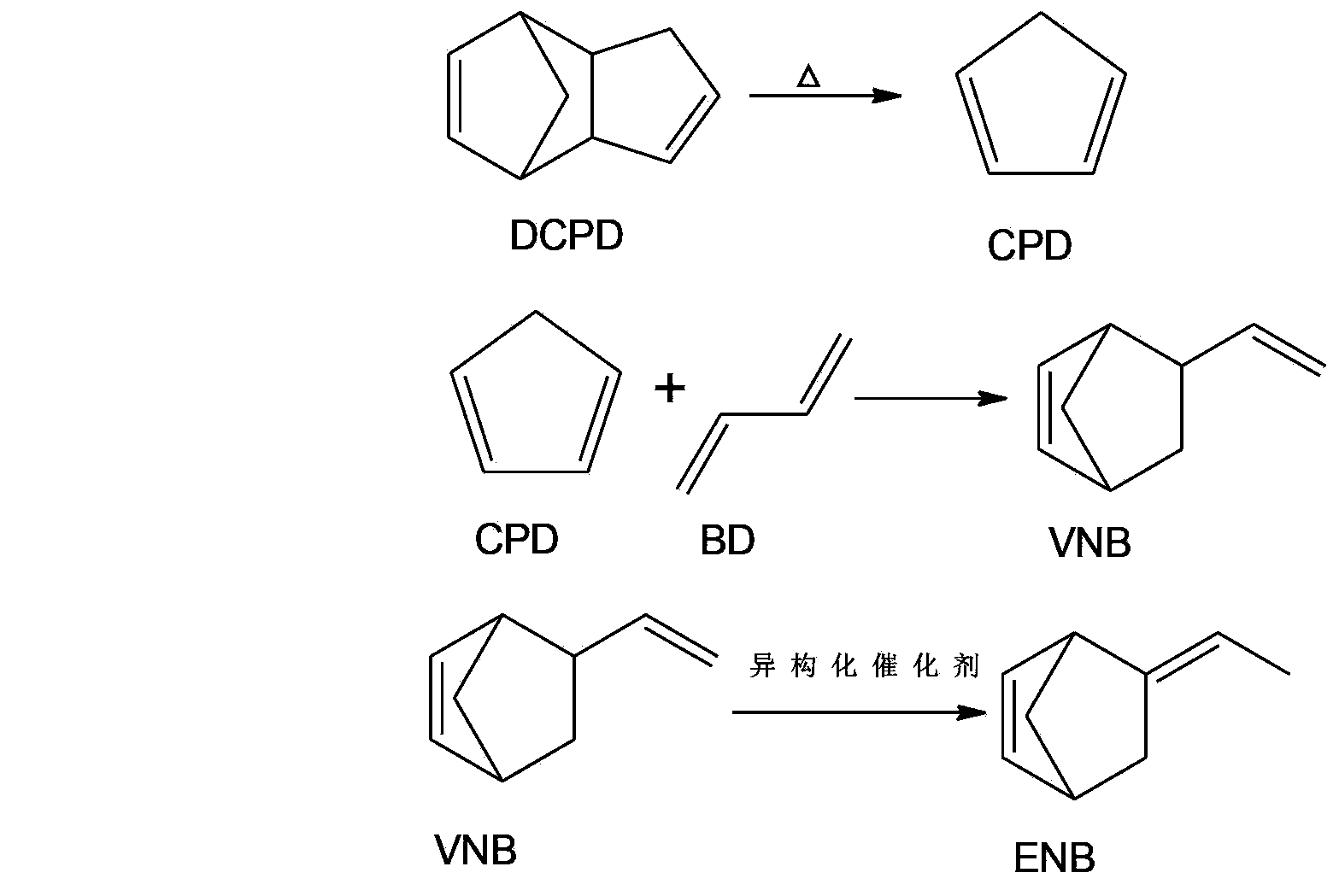

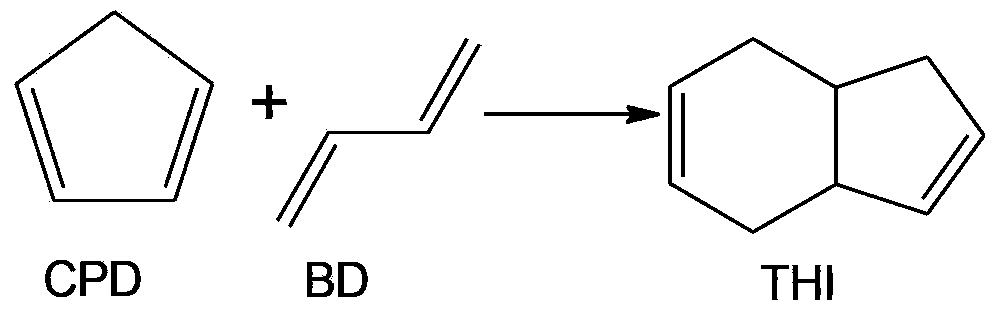

A high-purity ethylidene norbornene technology, which is applied in the direction of depolymerization to hydrocarbons, isomerization to hydrocarbons, and organic chemistry. VNB dimerization mode and process control, and the use of by-products are not mentioned, so as to improve the comprehensive utilization rate, overcome a large number of losses, and reduce the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

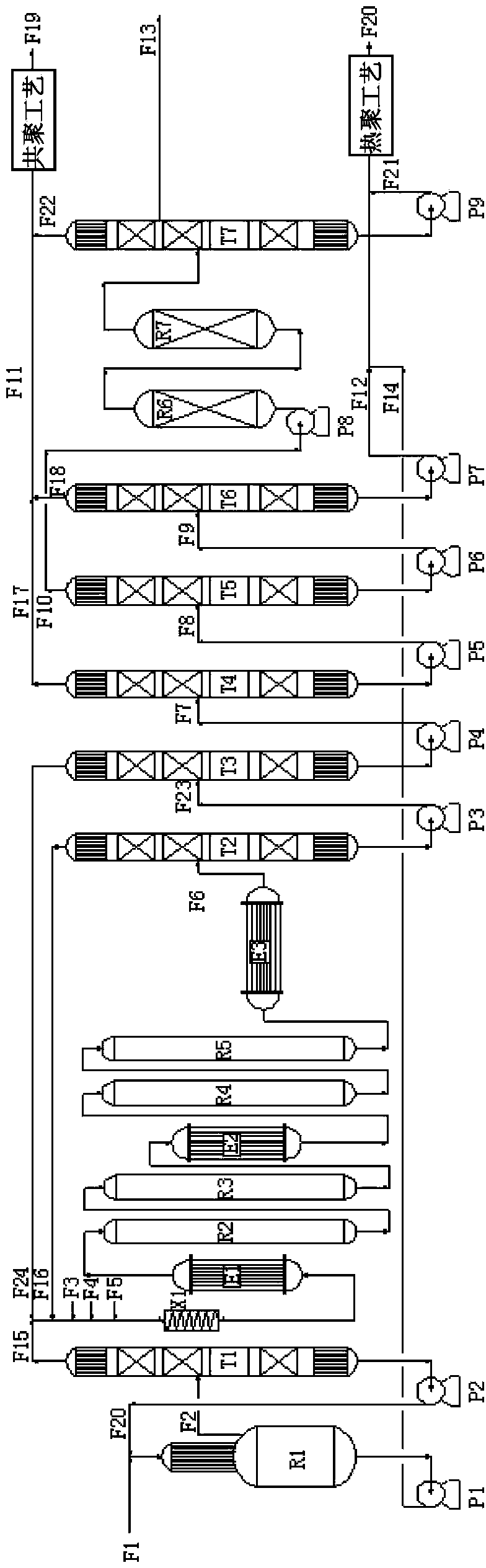

[0058] The distillate of cracked C9 bicyclic section enters the depolymerization kettle R1, the depolymerization temperature is 220°C, the system operating pressure is 0.08MPa (G), and the residence time is 1.5h; the generated F2 material enters the CPD refining tower T1, and the top of the refining tower 40°C, the temperature of the tower kettle is 140°C, the system pressure is 0.05MPa(G), and the reflux ratio is 2. The high-purity CPD obtained at the top of the tower is mixed with isooctane at a mass ratio of 1:1, and the mixed The material and BD are mixed according to the mass ratio of 2:1, and then 1000ppm of polymerization inhibitor is added, and enter the dimerization reactor, and the temperature is controlled by the intercooler E2 at 130°C, and the temperature is kept at 3MPa (G) for 200min to form a reaction mixture from dimerization The bottom discharge of reactor R5. The obtained mixture enters the rectification tower T2 after being cooled by the cooler E3. The oper...

Embodiment 2

[0063] The distillate of cracked C9 bicyclic section enters the depolymerization kettle R1, the depolymerization temperature is 220°C, the system operating pressure is 0.08MPa (G), and the residence time is 1.5h; the generated F2 material enters the CPD refining tower T1, and the top of the refining tower 40°C, the temperature of the tower kettle is 140°C, the system pressure is 0.05MPa(G), and the reflux ratio is 2. The high-purity CPD obtained at the top of the tower is mixed with isooctane at a mass ratio of 2:1, and the mixed The material and BD are mixed according to the mass ratio of 3:2. After adding 1000ppm of polymerization inhibitor, it enters the dimerization reactor, and the temperature is controlled by the intercooler E2 at 130°C, and the temperature is kept at 3MPa (G) for 200min to form a reaction mixture from dimerization The bottom discharge of reactor R5. The obtained mixture enters the rectification tower T2 after being cooled by the cooler E3. The operating...

Embodiment 3

[0066]The distillate of cracked C9 bicyclic section enters the depolymerization kettle R1, the depolymerization temperature is 220°C, the system operating pressure is 0.08MPa (G), and the residence time is 1.5h; the generated F2 material enters the CPD refining tower T1, and the top of the refining tower 40°C, the temperature of the tower kettle is 140°C, the system pressure is 0.05MPa(G), and the reflux ratio is 2. The high-purity CPD obtained at the top of the tower is mixed with isooctane at a mass ratio of 1:1, and the mixed The material is mixed with BD according to the mass ratio of 2:1, after adding 1500ppm of polymerization inhibitor, it enters the dimerization reactor, and the temperature is controlled by the intercooler E2 at 130°C, and the temperature is kept at 3MPa (G) for 200min to form a reaction mixture from dimerization The bottom discharge of reactor R5. The obtained mixture enters the rectification tower T2 after being cooled by the cooler E3. The operating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com