Laser alumite hot stamping back gum and preparation method thereof

A technology of anodized aluminum and hot stamping back, which is applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., and can solve the problems of poor hot stamping effect, poor adhesion, and excessive VOC of volatile organic compounds, etc. problem, to achieve the effect of good hot stamping effect, good water resistance and good anti-peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. This embodiment provides a laser anodized aluminum hot stamping back glue, and its raw materials include the following components in parts by weight:

[0031] 4.5 parts of maleic anhydride-vinyl acetate-methacrylate copolymer;

[0032] 4.5 parts of chloroprene-acrylic acid-acrylate copolymer;

[0033] 1.5 parts of fumed silica;

[0034] 40 parts of solvent.

[0035] This example provides a preparation method of laser anodized aluminum hot stamping adhesive: under the condition of constant stirring, 4.5 parts of maleic anhydride-vinyl acetate-methacrylate copolymer, chloroprene-acrylic acid- Add 4.5 parts of acrylate copolymer and 1.5 parts of fumed silica to 40 parts of solvent (ethanol and ethyl acetate), then stir at room temperature for 30-60 minutes at 300 r / min to obtain the finished product.

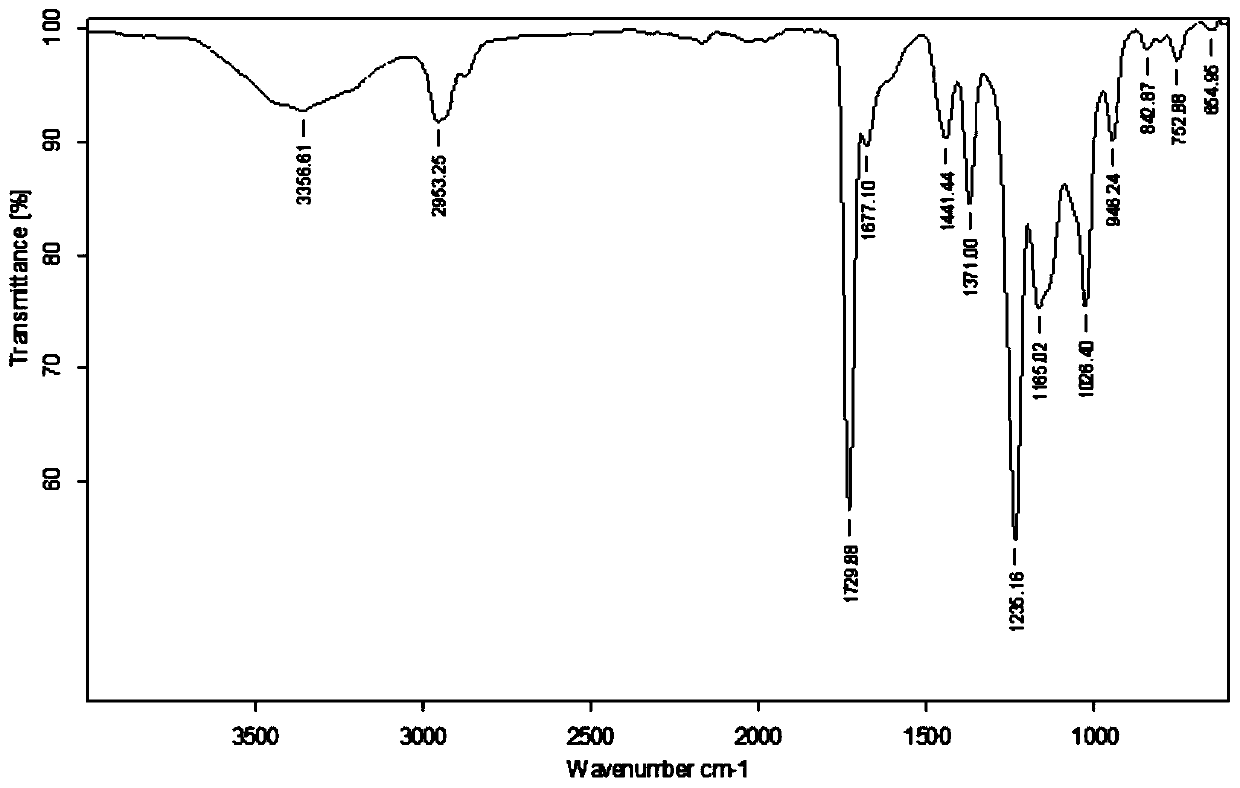

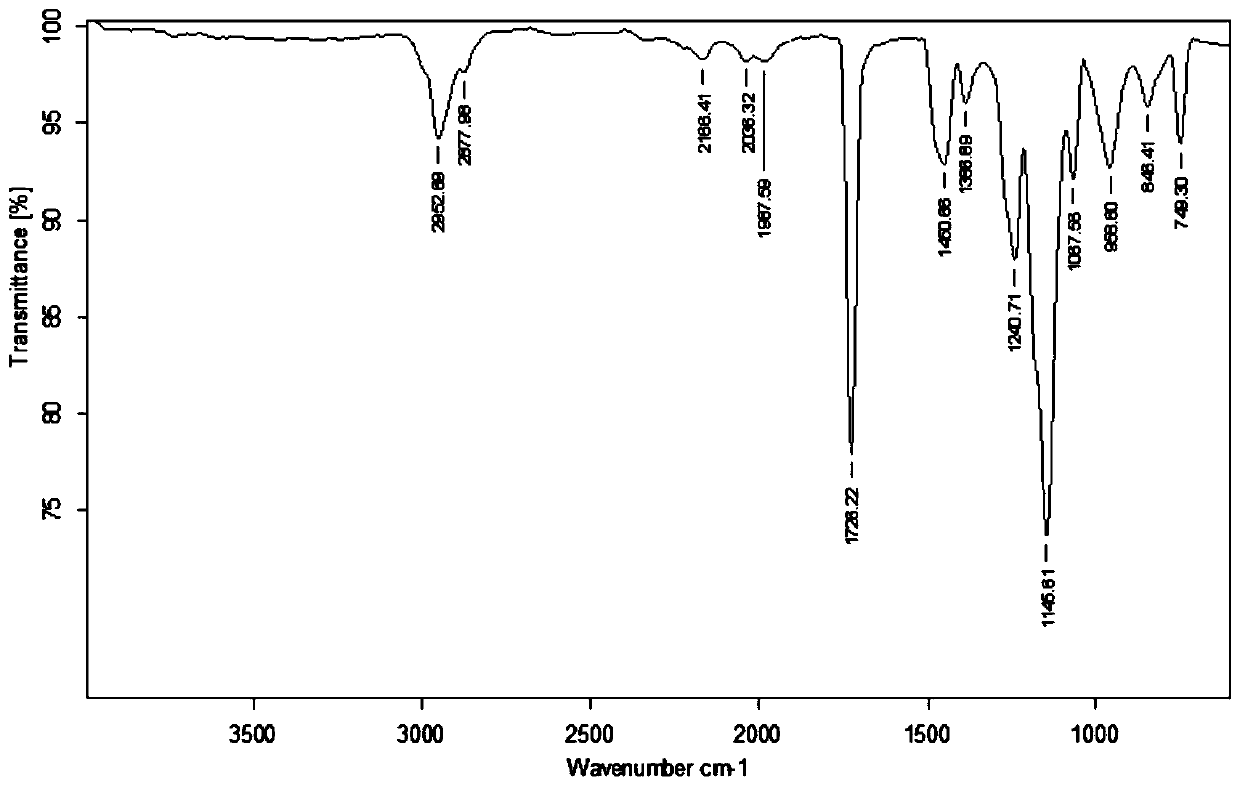

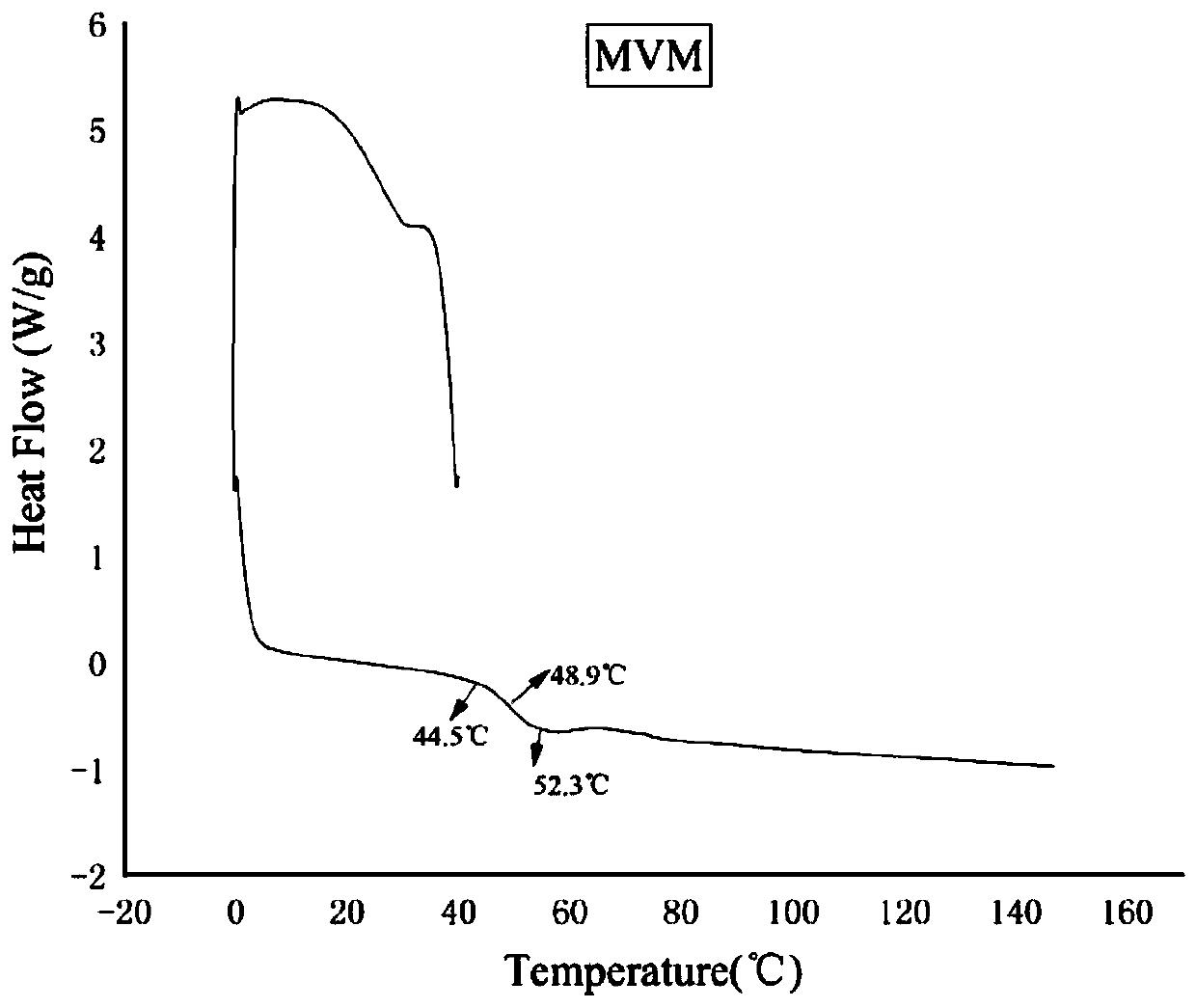

[0036] 2, the preparation method of described maleic anhydride-vinyl acetate-methacrylic acid ester copolymer is: in the four-necked bottle that agitator, condensation...

Embodiment 2

[0039] 1. This embodiment provides a laser anodized aluminum hot stamping back glue, and its raw materials include the following components in parts by weight:

[0040] 4 parts of maleic anhydride-vinyl acetate-methacrylate copolymer;

[0041] 5 parts of chloroprene-acrylic acid-acrylate copolymer;

[0042] 1 part of fumed silica;

[0043] 35 parts of solvent.

[0044] This example provides a preparation method of laser anodized aluminum hot stamping adhesive: under the condition of constant stirring, 4.5 parts of maleic anhydride-vinyl acetate-methacrylate copolymer, chloroprene-acrylic acid- Add 4.5 parts of acrylate copolymer and 1.5 parts of fumed silica to 40 parts of solvent (ethanol and ethyl acetate), then stir at room temperature for 30-60 minutes at 300 r / min to obtain the finished product.

[0045] 2, the preparation method of described maleic anhydride-vinyl acetate-methacrylic acid ester copolymer is: in the four-necked bottle that agitator, condensation tube, ...

Embodiment 3

[0048] 1. This embodiment provides a laser anodized aluminum hot stamping back glue, and its raw materials include the following components in parts by weight:

[0049] 5 parts of maleic anhydride-vinyl acetate-methacrylate copolymer;

[0050] 4 parts of chloroprene-acrylic acid-acrylate copolymer;

[0051] 2 parts of fumed silica;

[0052] 45 parts of solvent.

[0053] This example provides a preparation method of laser anodized aluminum hot stamping adhesive: under the condition of constant stirring, 4.5 parts of maleic anhydride-vinyl acetate-methacrylate copolymer, chloroprene-acrylic acid- Add 4.5 parts of acrylate copolymer and 1.5 parts of fumed silica to 40 parts of solvent (ethanol and ethyl acetate), then stir at room temperature for 30-60 minutes at 300 r / min to obtain the finished product.

[0054] 2, the preparation method of described maleic anhydride-vinyl acetate-methacrylic acid ester copolymer is: in the four-necked bottle that agitator, condensation tube,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com