Special C5 petroleum resin for adhesive and preparation method of special C5 petroleum resin

A C5 petroleum resin and adhesive technology, applied in adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve resin softening point and unstable viscosity value, aluminum trichloride powder strong water absorption, polymerization Problems such as colloids appear in the process, and the softening point and melt viscosity are moderate, the molecular weight distribution range is narrowed, and the effect of facilitating the reaction process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

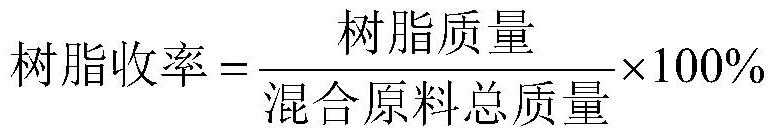

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of described a kind of adhesive special-purpose carbon five petroleum resin operates according to the following steps:

[0031] 1) Raw material preparation:

[0032] Adjust the total content of olefins and the ratio of dimonoene in the polymerization system so that the mass concentration ratio of dimonoene is 0.65:1, the total content of dienes is 21.36%, the total content of monoenes is 33.09%, and the content of alkane is 45.55%. After mixing 178g of raw material A and 80g of raw material B evenly, add it to the dropping funnel for later use.

[0033] 2) Polymerization reaction:

[0034] Turn on the reactor to stir, turn on the reflux water, and weigh 3.24gAlCl successively 3 Add the composite catalyst and 282g of carbon penta-alkane fraction C into a closed pressure dynamic stirring reactor, drop the spare raw materials into the reactor, and continue to react at a constant temperature at a temperature of 40-85°C and a pressure of 0.15-0.45MPa...

Embodiment 2

[0041] The technical means and method steps are the same as in Example 1, except that the mass concentration ratio of dienes and monoenes in the polymerization system is adjusted to 0.96:1, the total content of dienes is 30.25%, the total content of monoenes is 31.55%, and the content of alkane is 38.2%. Mix 265g of raw material A with 64g of raw material B for later use, 3.51g of composite AlCl 3 Catalyst, 211g carbon penta-alkanes cut C adds airtight pressure dynamic reactor.

[0042] The yield of the resin obtained by the polymerization reaction was 39.2%, the softening point was 101.0°C, the hue was 4#, the viscosity was 149.2MPa·s, and the wax fog point was 110°C.

Embodiment 3

[0044] The technical means and method steps are the same as in Example 1 and Example 2, the difference is that the mass concentration ratio of diene and monoene in the polymerization system is adjusted to 0.85:1, the total content of diene is 27.9%, the total content of monoene is 32.92%, and the alkane Content 39.18%. Mix 243g of raw material A with 85g of raw material B for later use, 4.32g of composite AlCl 3 Catalyst, 212g carbon penta-alkanes cut C adds airtight pressure dynamic reactor.

[0045] The yield of the resin obtained by the polymerization reaction was 37.3%, the softening point was 96.0°C, the hue was 4#, the viscosity was 129.6MPa·s, and the wax fog point was 95.0°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com