Patents

Literature

40results about How to "Avoid solid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

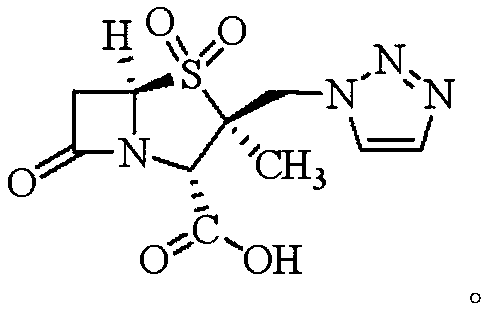

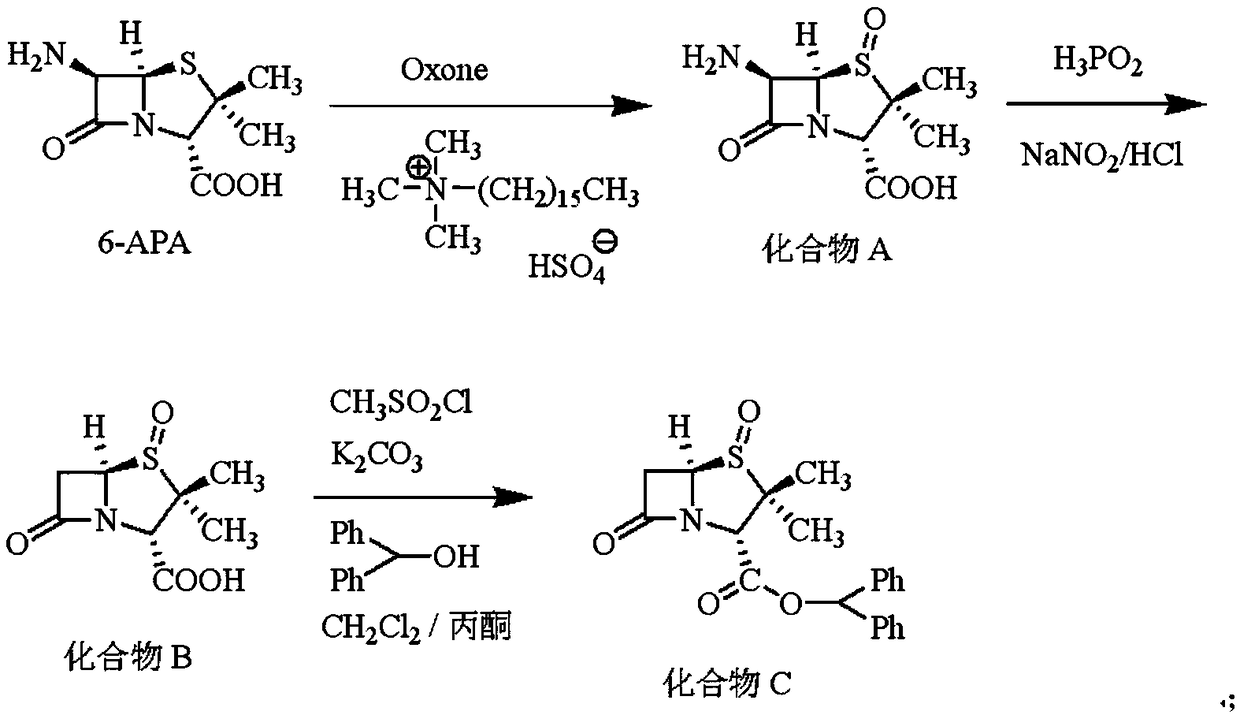

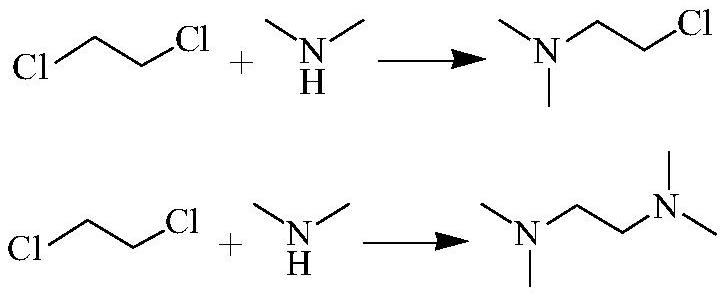

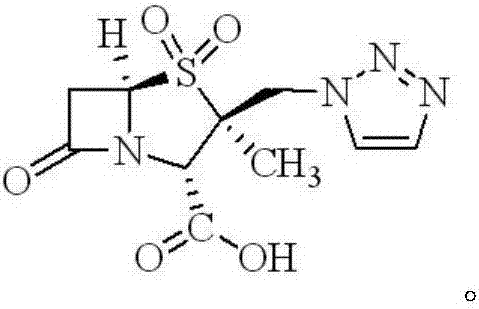

Synthetic method of tazobactam acid

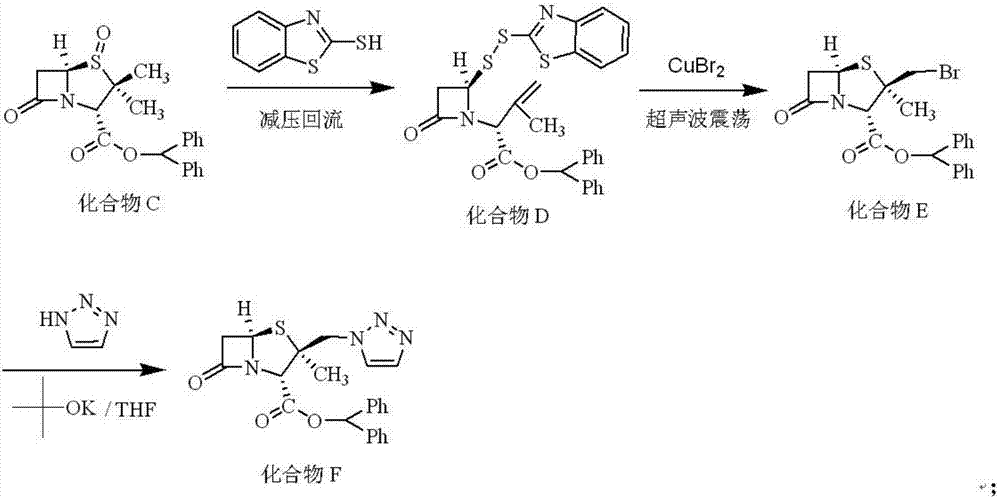

The invention provides a synthetic method of tazobactam acid, comprising the steps of (a) using 6-APA (6-aminopenicillanic acid) as a starting material and cetyltrimethylammonium hydrogensulfate as a catalyst to oxidize with oxone to obtain compound A; subjecting the compound A to deamination reaction to obtain compound B; esterifying the compound B to obtain compound C; (b) subjecting the compound C and 2-mercaptobenzothiazole to reduced pressure backflow to obtain compound D; ultrasonically vibrating the compound D and copper bromide to obtain compound E; reacting the compound E and 1H-1,2,3-triazole to obtain compound F; (c) allowing hydrogen peroxide and acetic anhydride to act on the compound F to obtain compound G; reacting the compound G with anisole to obtain tazobactam acid. Amino groups in 6-APA are diazotized directly, diazo groups are then removed, reduced pressure backflow and ultrasonic vibration are performed, hydrogen peroxide and acetic anhydride are used as oxidants, less byproducts are generated, and the yield and quality of tazobactam acid are effectively increased.

Owner:SHIJIAZHUANG WANYE CHEM IND CO LTD

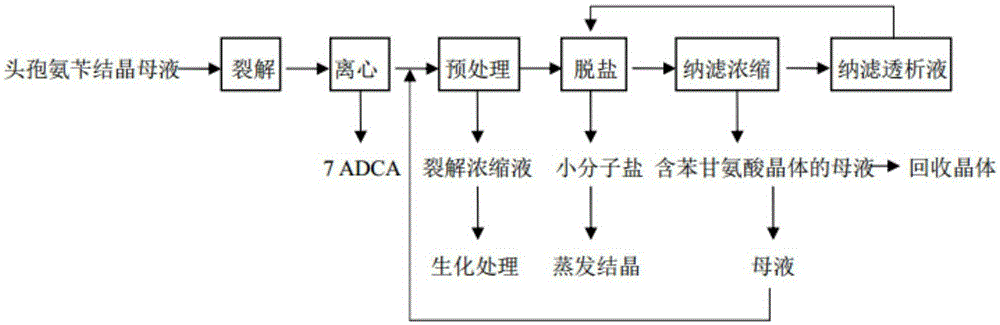

Method for recycling phenylglycine in cefalexin crystallization mother liquid

ActiveCN105349608AConducive to maximizing the use ofImprove protectionOrganic compound preparationAmino-carboxyl compound preparationRecovery methodOrganic solvent

The invention relates to a method for recycling phenylglycine in cefalexin crystallization mother liquid. The method comprises the steps of pyrolysis, centrifugation, pretreatment, desalination and nano-filtration concentration. The method provided by the invention solves the difficulty that wastewater containing cefalexin cannot be directly treated biochemically, and phenylglycine recovered by the method can be directly applied to subsequent production. According to the method disclosed by the invention, an organic solvent is not used, and the production cost is reduced, so that the method is beneficial for environmental protection and is a green and efficient recovery method.

Owner:XIAMEN TQX MEMBRANE TECH

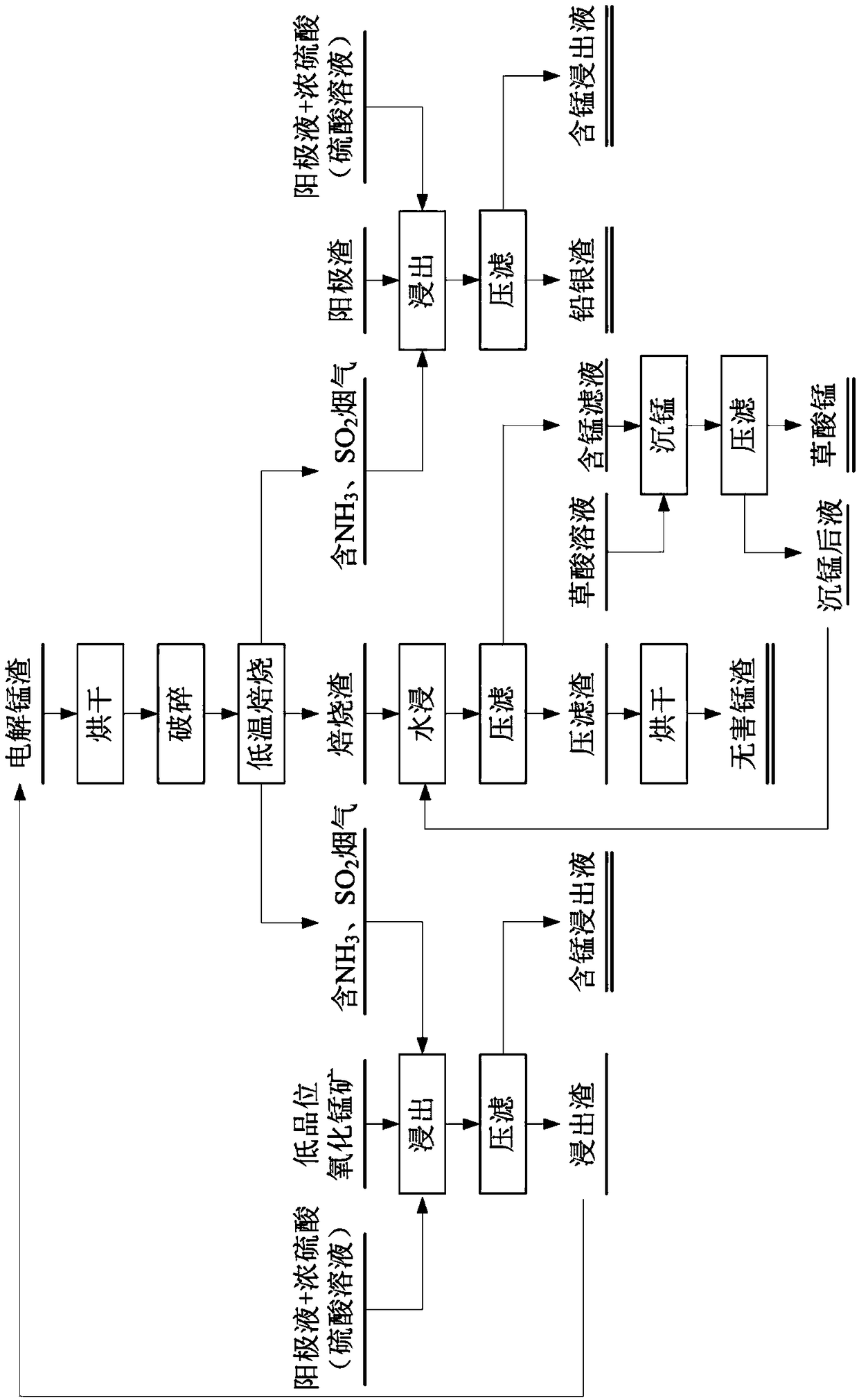

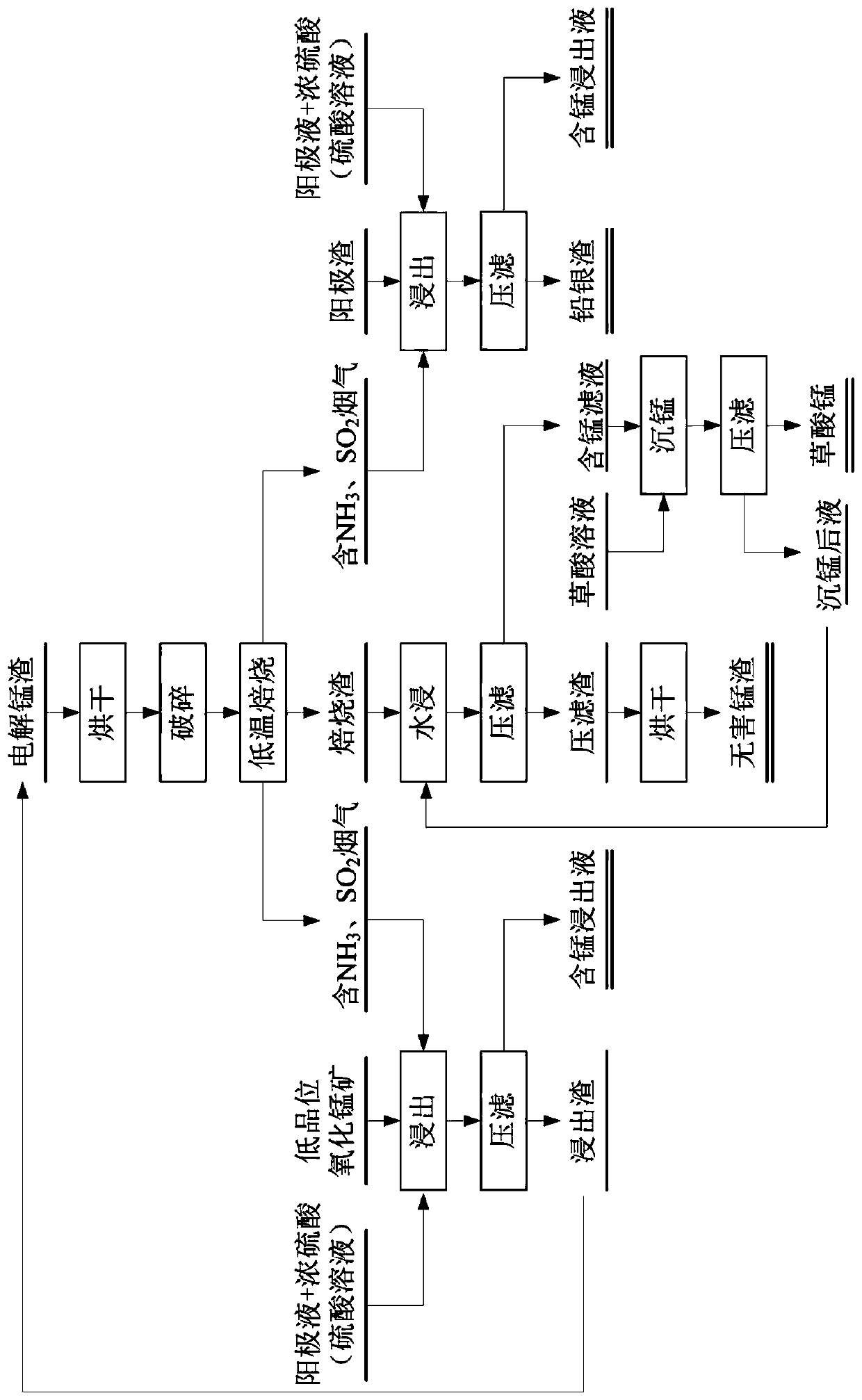

Harmless treatment method of electrolytic manganese residue

ActiveCN108728634AShort processing timeLow costOrganic compound preparationCarboxylic acid salt preparationElectrolysisSlag

The invention discloses a harmless treatment method of an electrolytic manganese residue. The harmless treatment method comprises the following steps that (1) the electrolytic manganese slag is driedand crushed and then subjected to low-temperature roasting to obtain a calcined material, and flue gas containing NH3 and SO2 is generated; (2) the obtained calcined material is subjected to water immersion and then subjected to solid-liquid separation to obtain a filter residue and manganese-containing filtrate; (3) the filter residue obtained from the separation is dried to obtain a harmless manganese residue, a precipitant is added to the manganese-containing filtrate to precipitate manganese, and after the completion of manganese precipitation, the solid-liquid separation is performed to obtain manganese-precipitated post-liquid and a manganese-containing product. The harmless treatment method of the electrolytic manganese residue is simple in process, mild in process conditions, shortin time required for the flow path and low in cost, and can effectively realize the harmless resource treatment of the electrolytic manganese residue, environmental protection is achieved, and the environmental protection pressure and production cost of related enterprises are reduced.

Owner:CENT SOUTH UNIV

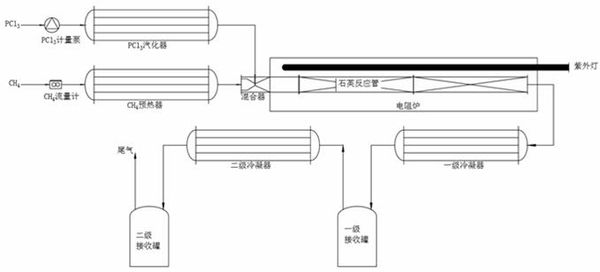

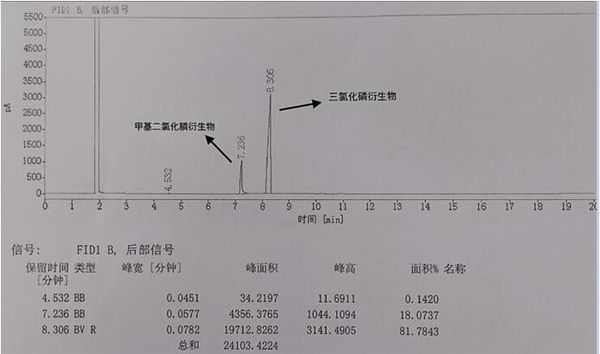

Method for synthesizing methyl phosphine dichloride

ActiveCN111909201ALow costOperational securityGroup 5/15 element organic compoundsPtru catalystPhysical chemistry

The invention mainly aims at the problems of high reaction temperature, certain reaction pressure, easy generation of solid impurities, low continuous production capacity, high cost, high environmental pressure and the like in the existing process of synthesizing methyl phosphine dichloride by a high-temperature method, and provides a method for synthesizing methyl phosphine dichloride by using methane and phosphorus trichloride as raw materials. According to the synthetic method, the reaction selectivity and yield are maintained. Meanwhile, no toxic initiator is added, the pressure, temperature and other conditions required by the reaction are reduced, the problem that the reaction conversion rate is reduced due to the fact that the surface of the solid catalyst is covered and inactivatedis solved, the continuous degree is higher, and the yield is higher. According to the method, a product with the content of methyl phosphine dichloride being greater than 17wt% can be synthesized, and after the product is rectified, a methyl phosphine dichloride product with the content being greater than 99wt% and phosphorus trichloride with the content being greater than 98.5 wt% can be obtained.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

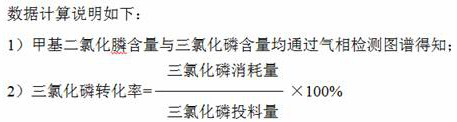

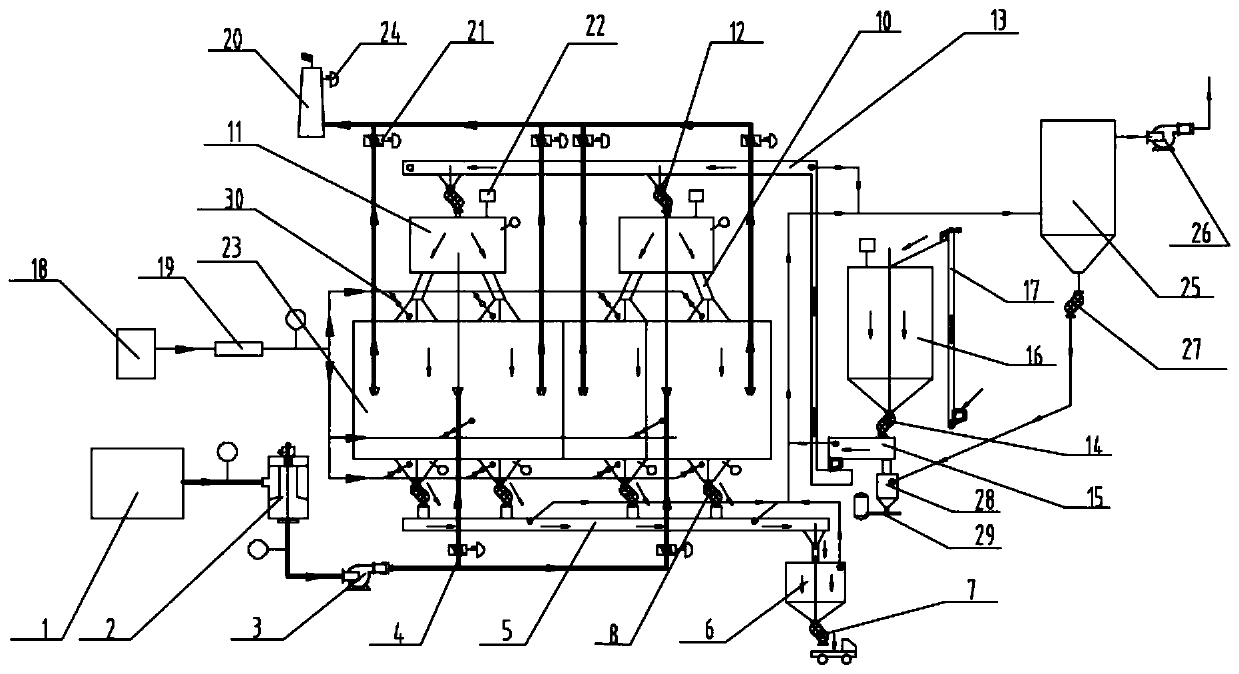

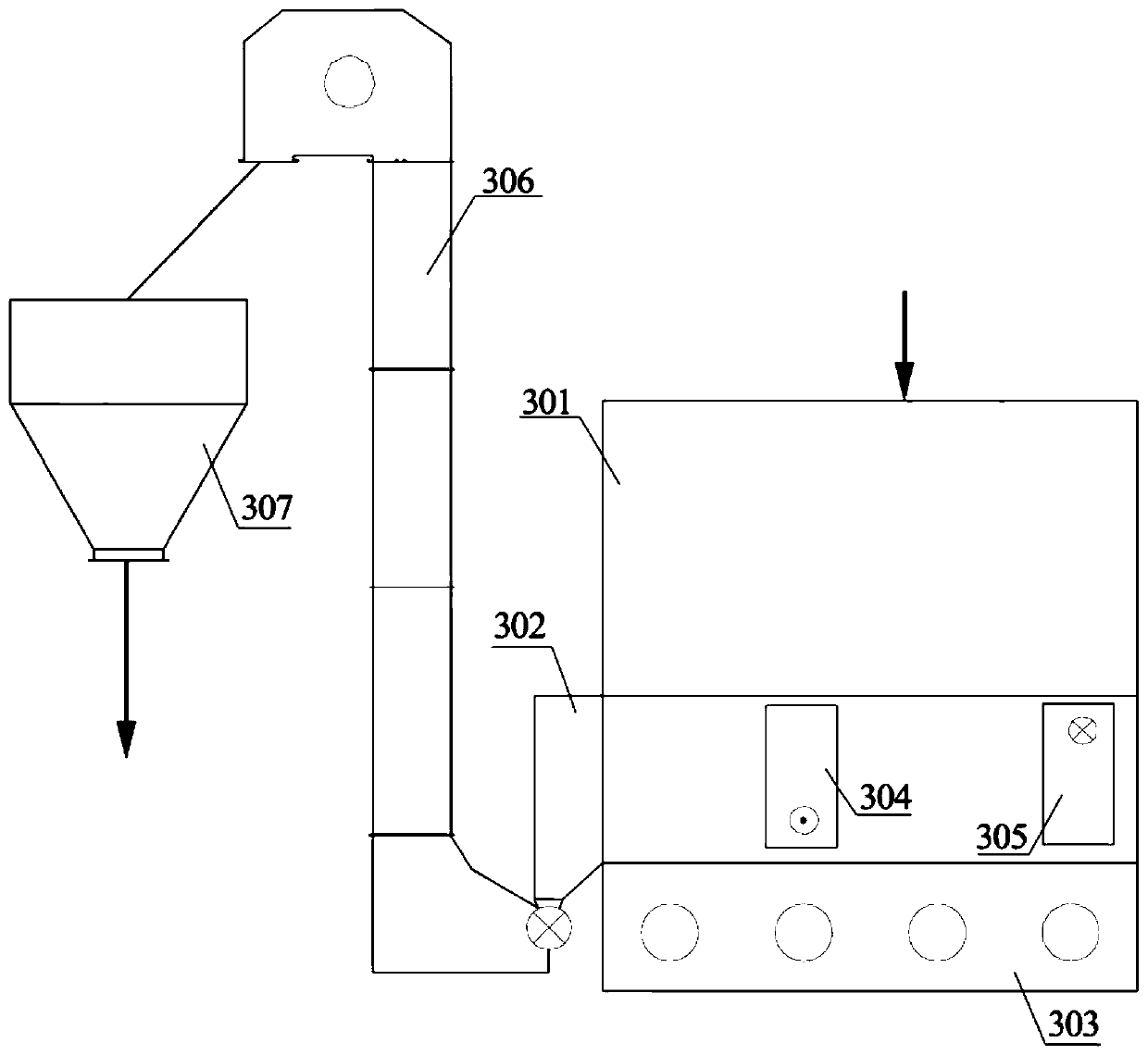

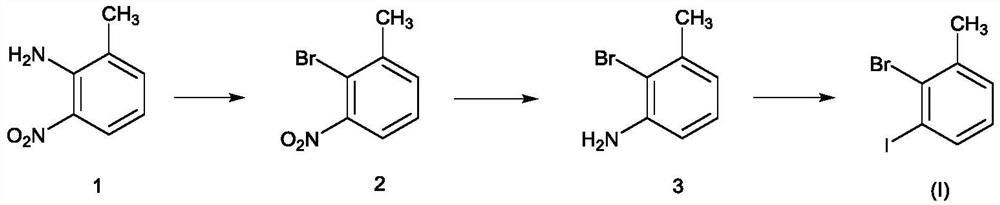

Dry activated coke desulfurization system and method for purifying tail gas of steel rolling heating furnace

InactiveCN111249892AEasy to operateGuaranteed uptimeGas treatmentDispersed particle separationActivated carbonHot air oven

The invention provides a dry activated coke desulfurization system for purifying tail gas of a steel rolling heating furnace. The system comprises a flue gas system, an adsorption system, a nitrogen protection system and a material transportation system; the flue gas system comprises a steel rolling furnace tail gas connector, a hot-blast stove and a fan; the steel rolling furnace tail gas connector is connected with a hot-blast stove gas inlet through a pipeline, and a hot-blast stove gas outlet is connected with a fan gas inlet through a pipeline; the adsorption system comprises an air inletchamber, an adsorption tower, a top stock bin and a chimney; an air outlet of the fan is communicated with the middle part of the air inlet chamber by virtue of a pipeline with a flue gas inlet regulating valve. The system is simple in process operation and stable in equipment operation, the activated carbon can be recycled, and the operation cost is reduced. Old activated carbon can be ground into powder and then conveyed to coal injection, and solid waste such as Na2SO4 and CaSO4 generated in the desulfurization process is avoided. The activated carbon can adsorb and degrade pollutants in the flue gas, and the separated SO2 is sent to an acid making system for resource recycling.

Owner:XINXING HEBEI ENG & RES INC

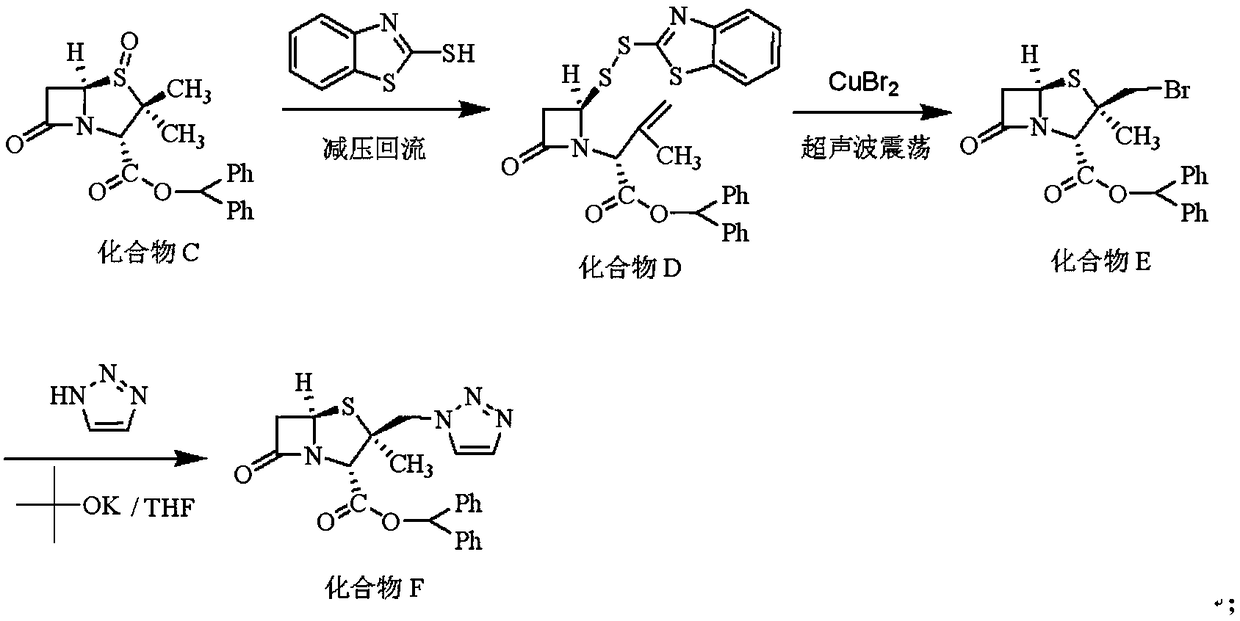

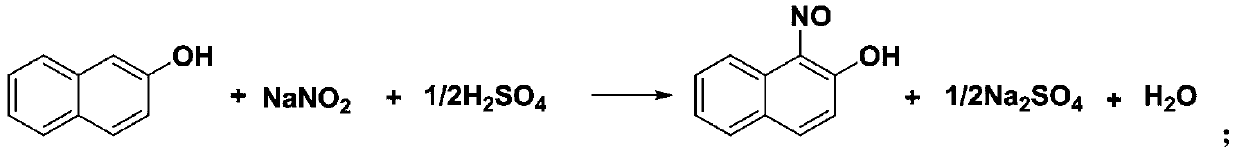

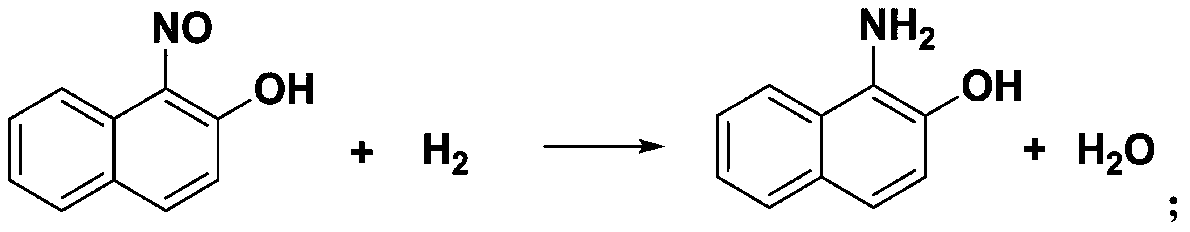

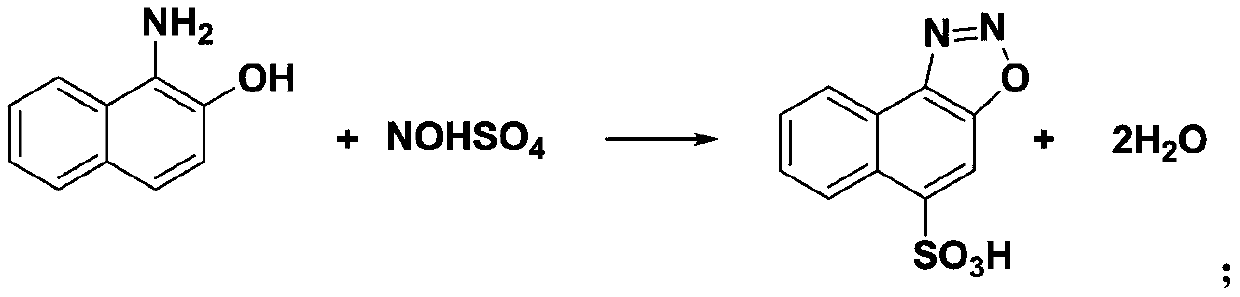

Method for preparing 6-nitro-2-diazo-1-naphthol-4-sulfonic acid hydrate

ActiveCN111217764ASolve the need to consume a lot of acidSolve with alcohol as solventOrganic chemistryNitrosoFixed bed

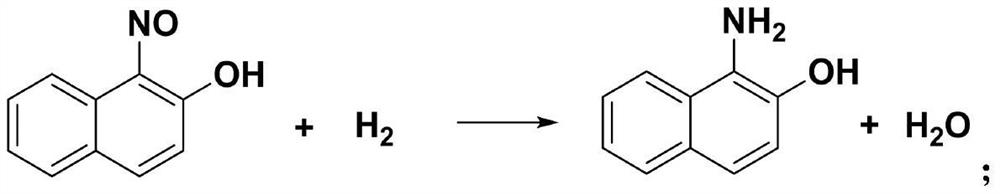

The invention discloses a method for preparing 6-nitro-2-diazo-1-naphthol-4-sulfonic acid hydrate. The method comprises the following steps: carrying out a nitrosation reaction on 2-naphthol serving as a raw material, sodium nitrite and dilute sulfuric acid in a tubular reactor to generate 1-nitroso-2-naphthol, carrying out catalytic hydrogenation on the 1-nitroso-2-naphthol and hydrogen in a Raney nickel immobilized fixed bed reactor to generate 1-amino-2-naphthol, carrying out sulfonation diazotization cyclization on 1-amino-2-naphthol and nitrosyl sulfuric acid in the tubular reactor, and nitrifying with nitric acid to obtain the final product 6-nitro-2-diazo-1-naphthol-4-sulfonic acid hydrate. According to the novel synthesis method of the 6-nitro-2-diazo-1-naphthol-4-sulfonic acid hydrate, hydrogen is used for reduction in the route, nitrosyl sulfuric acid is used for sulfonation diazotization cyclization, so the problem that a large amount of solid waste is generated in a traditional route is avoided, the atom utilization rate is high, the yield is increased, the safety coefficient is increased by using a tubular process, and the method is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

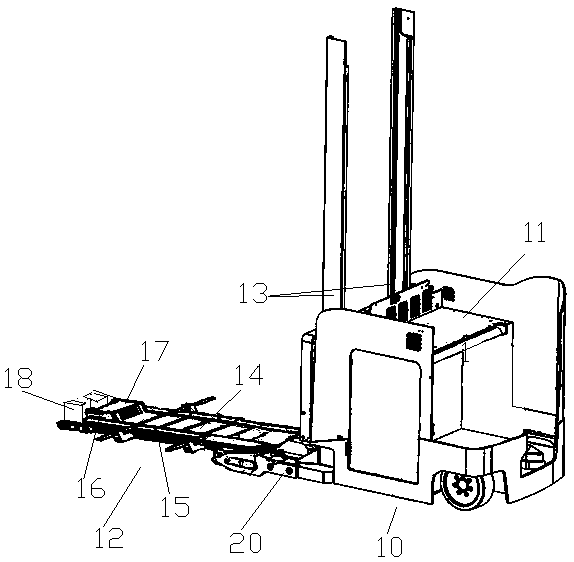

Process for removing defective green bodies from autoclaved aerated concrete bricks and recycling defective green bodies

InactiveCN110524710AEfficient removalImprove pass rateAuxillary shaping apparatusBrickAutoclaved aerated concrete

The invention relates to a process for removing defective green bodies from autoclaved aerated concrete bricks and recycling the defective green bodies. The process for removing defective green bodiesfrom autoclaved aerated concrete bricks and recycling the defective green bodies comprises the following process steps: 1, moving the green bodies which are not cut and machined to a support plate after cutting, and waiting for defect inspection; step 2, judging defective green bodies in the green bodies accumulation body; 3, arranging an electronic eye system on a ground circulating fetching rail, and carrying out electronic eye analysis on the green bodies accumulation body; analyzing data obtained after scanning according to national or enterprise standards, determining position coordinate data of the defective green bodies, and importing the position coordinate data into a related computer and an operation table of a defective green body replacement device; a, positioning: positioning the defective green body by the defective green body replacement device according to the data; b, inserting and clamping: allowing a telescopic rail to operate to continue to extend forwards, andusing a forklift rod to synchronously insert an isolation box and a material pumping box into the defective green body; and c, drawing out the defective brick green body.

Owner:ZHEJIANG NORMAL UNIVERSITY

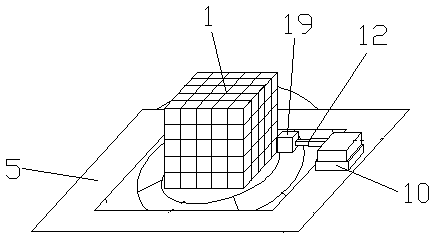

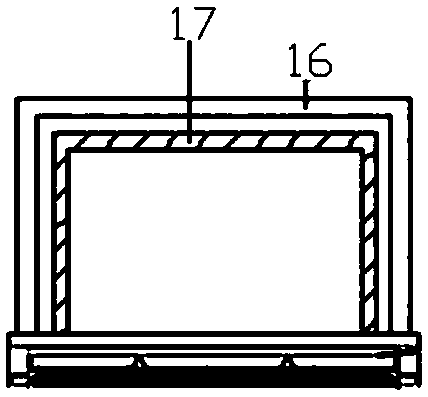

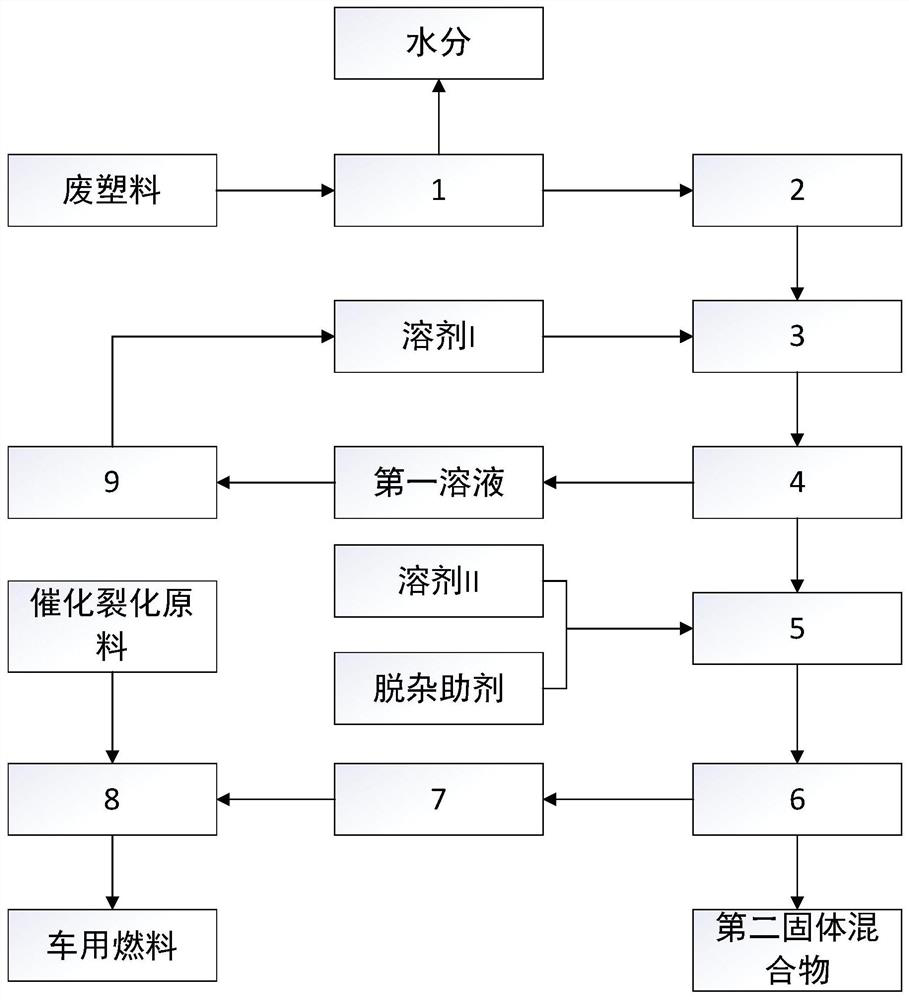

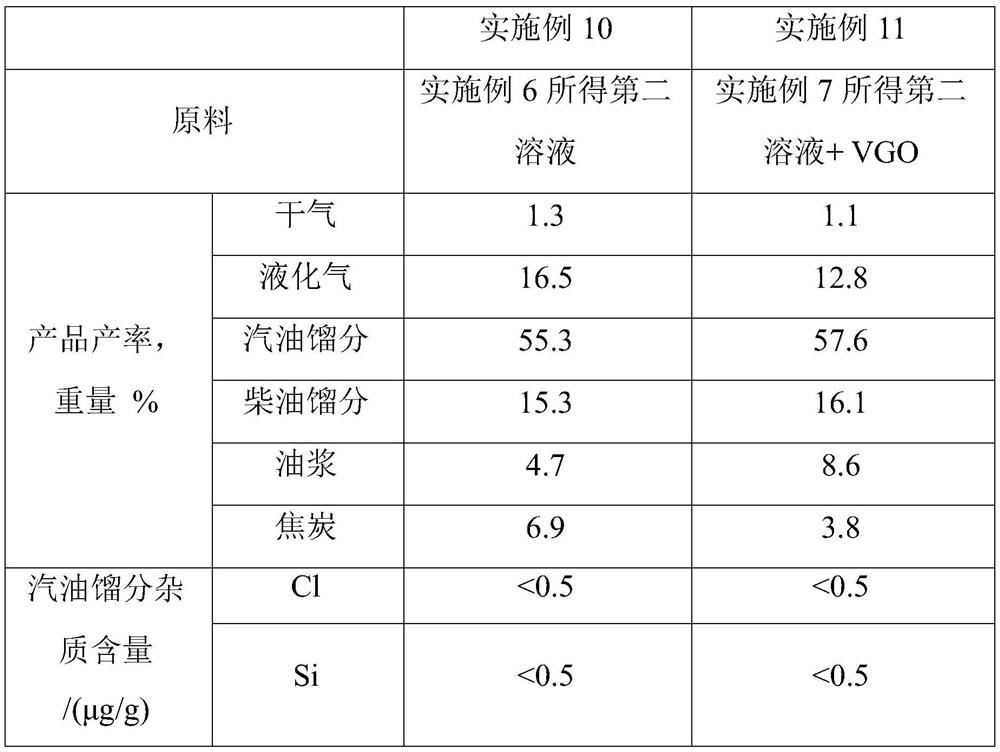

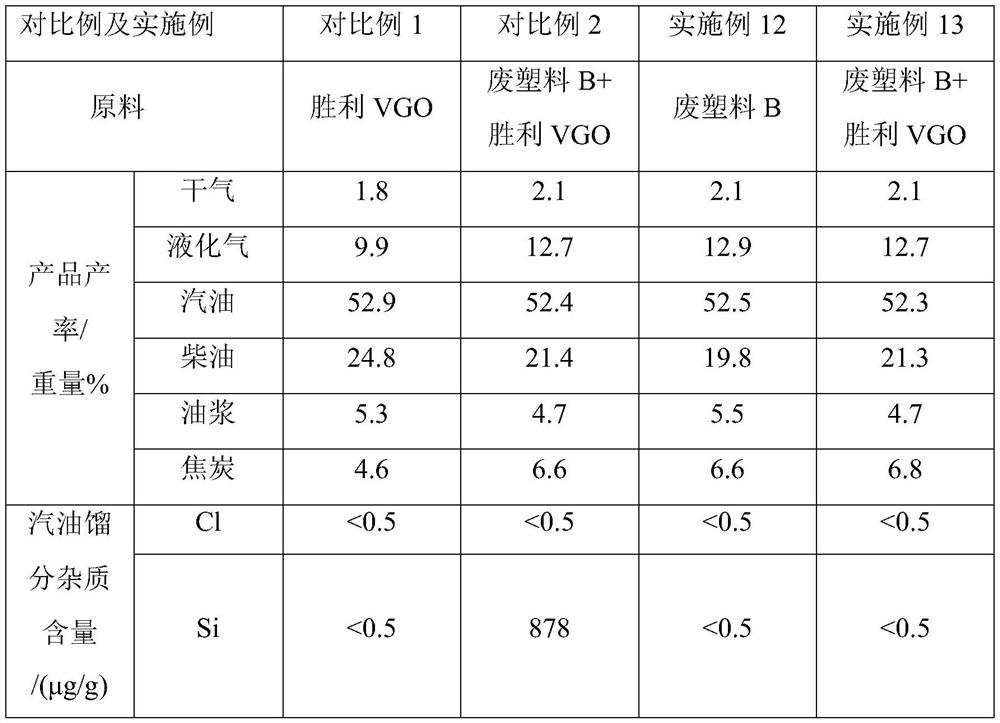

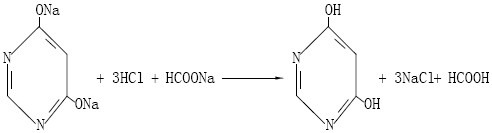

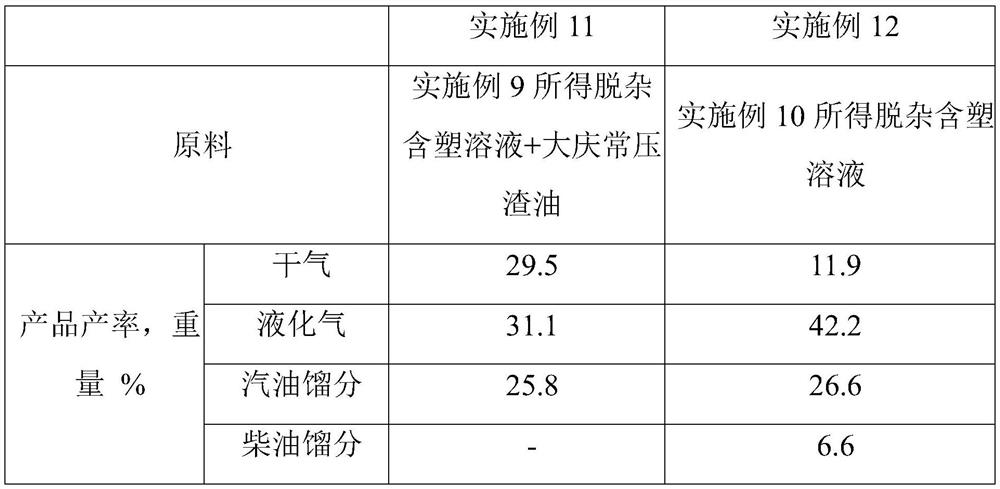

Method and system for producing vehicle fuel from waste plastic

ActiveCN113862018AImprove recycling ratesIncrease valueLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsSocial benefitsProcess engineering

The invention relates to a method and system for producing vehicle fuel from waste plastic. The method comprises the steps that waste plastic sequentially passes through a first waste plastic impurity removal unit and a second waste plastic impurity removal unit for impurity removal reaction to obtain a second solution low in chlorine content and silicon content; and the second solution with low impurity content is fed into a catalytic cracking unit for catalytic cracking reaction to obtain vehicle fuel. The method is beneficial to solving the problem of white pollution, and the prepared vehicle fuel has good environmental benefits, social benefits and economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

Harmless treatment method of electrolytic manganese slag

ActiveCN108728634BShort processing timeLow costOrganic compound preparationCarboxylic acid salt preparationFlue gasPhysical chemistry

The invention discloses a harmless treatment method of an electrolytic manganese residue. The harmless treatment method comprises the following steps that (1) the electrolytic manganese slag is driedand crushed and then subjected to low-temperature roasting to obtain a calcined material, and flue gas containing NH3 and SO2 is generated; (2) the obtained calcined material is subjected to water immersion and then subjected to solid-liquid separation to obtain a filter residue and manganese-containing filtrate; (3) the filter residue obtained from the separation is dried to obtain a harmless manganese residue, a precipitant is added to the manganese-containing filtrate to precipitate manganese, and after the completion of manganese precipitation, the solid-liquid separation is performed to obtain manganese-precipitated post-liquid and a manganese-containing product. The harmless treatment method of the electrolytic manganese residue is simple in process, mild in process conditions, shortin time required for the flow path and low in cost, and can effectively realize the harmless resource treatment of the electrolytic manganese residue, environmental protection is achieved, and the environmental protection pressure and production cost of related enterprises are reduced.

Owner:CENT SOUTH UNIV

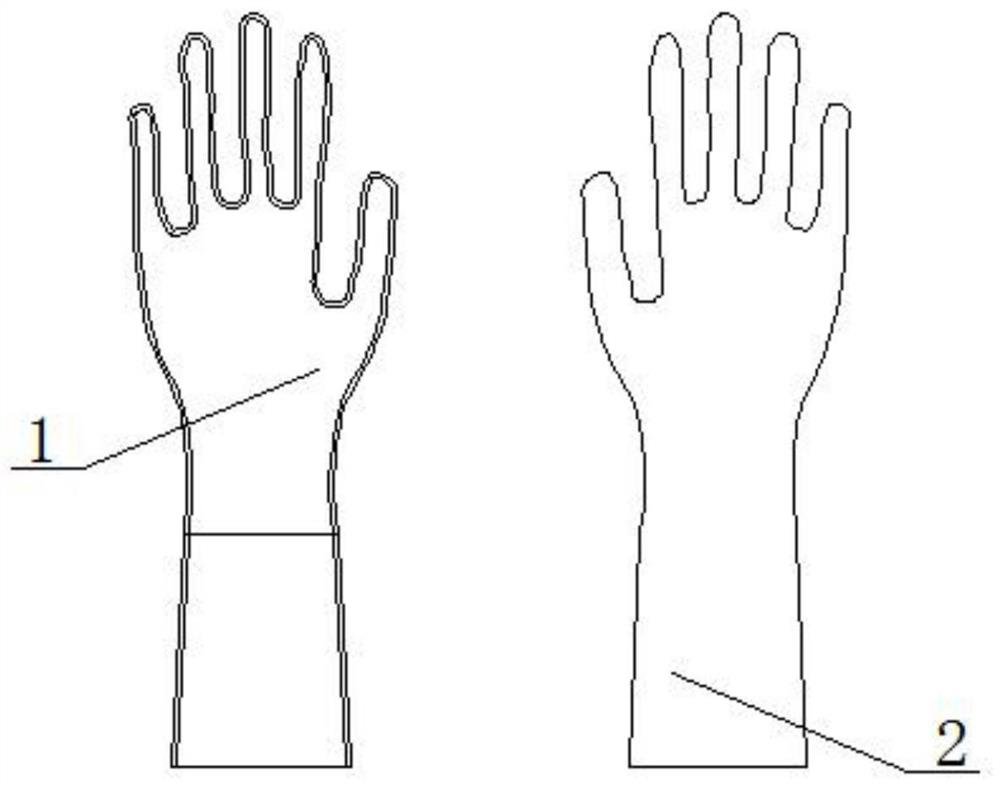

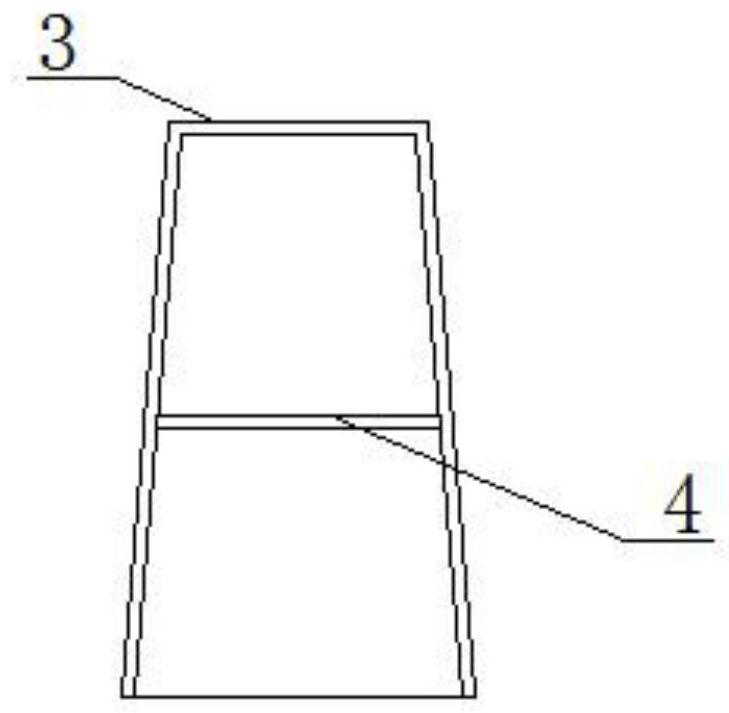

Metal hand mold applied to butyronitrile glove production line and production method thereof

InactiveCN112453839ANo solid wasteTo achieve the effect of repeated useAnodisationProduction lineProcess engineering

The invention discloses a metal hand mold applied to a butyronitrile glove production line. The metal hand mold comprises a first palm, a second palm is fixed to one side of the first palm, an arm module is arranged between the first palm and the second palm in a sleeving mode, and the upper end of the arm module extends to the position between the first palm and the second palm; and partition plates are jointly fixed to the peripheral side walls in the arm module. The invention further provides a production method of the metal hand mold applied to the butyronitrile glove production line, andthe production method comprises the following steps: S1, manufacturing a hand mold machine body: designing and manufacturing the butyronitrile metal hand mold, and according to design requirements, dividing the mold processes into two types, namely a stamping mold or a hydraulic mold. According to the metal hand mold and the production method, metal materials such as high-purity aluminum alloy / magnesium alloy can be used as material, the energy-saving effect can be effectively achieved, the material is not easy to break and wear, the service cycle is long, meanwhile, the material can be repeatedly used, solid wastes are avoided, the raw materials can be recycled, and the cost is reduced.

Owner:李国铭

Device and process for treating silica-containing high-salt wastewater in silica acid precipitation process

ActiveCN109836005AAchieving zero emissionsLow costMultistage water/sewage treatmentEvaporationChemical products

The invention provides a device and process for treating silica-containing high-salt wastewater in a silica acid precipitation process. The device comprises a pretreatment unit, a pre-concentration unit, a two-effect evaporation unit, an MVR evaporation crystallization unit and a drying unit, wherein the units are sequentially connected; the pretreatment unit comprises a sedimentation tank; the pre-concentration unit comprises evaporative cooling; the two-effect evaporation unit comprises a first-effect separator, a first-effect heater, a second-effect separator, a two-effect heater and a filter press; the MVR evaporation crystallization unit comprises an MVR heater, an MVR separator, an MVR compressor, an MVR thickener and an MVR centrifuge; and the drying unit comprises a dryer. Condensed water generated by the process is recycled as production water, a generated silica precipitate is sold as a hydrated silica product, generated anhydrous sodium sulfate can be sold as a chemical product, waste water, solid waste and the like in the process are avoided, zero emission of the wastewater is realized, and a traditional acid precipitation process is changed into a cleaning process.

Owner:JINNENG SCI & TECH

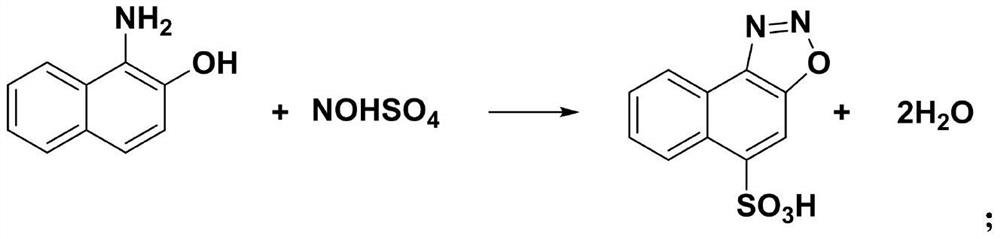

Refining method of isophthalonitrile serving as chlorothalonil raw material

ActiveCN109593051AMild process conditionsReduce energy consumptionPreparation by carboxylic acid amide dehydrationCarboxylic acid nitrile purification/separationSolventAzeotropic distillation

The invention relates to a refining method of isophthalonitrile serving as a chlorothalonil raw material. The refining method is performed according to the following steps: adding isophthalonitrile and a solvent into a refining kettle provided with a reflux condenser and a tail gas absorber; adding a dehydrant for a dehydration reaction; and carrying out cooling, dropwise adding water for a quenching reaction, then, adding washing water into an organic phase, carrying out stirring and skimming, adding water into the organic phase, carrying out heating for azeotropic distillation, carrying outsolid-liquid separation on a suspension of isophthalonitrile and water, and drying isophthalonitrile. The refining method provided by the invention has the following advantages: 1) the process condition is mild, high temperature and high vacuum degree are not needed, equipment is not blocked and the energy consumption is low; and 2) impurities are directly converted into a product, so that not only are solid wastes generated after refining, but also the amount of the product is increased, and the economic benefit is high.

Owner:JIANGYIN SULI CHEM

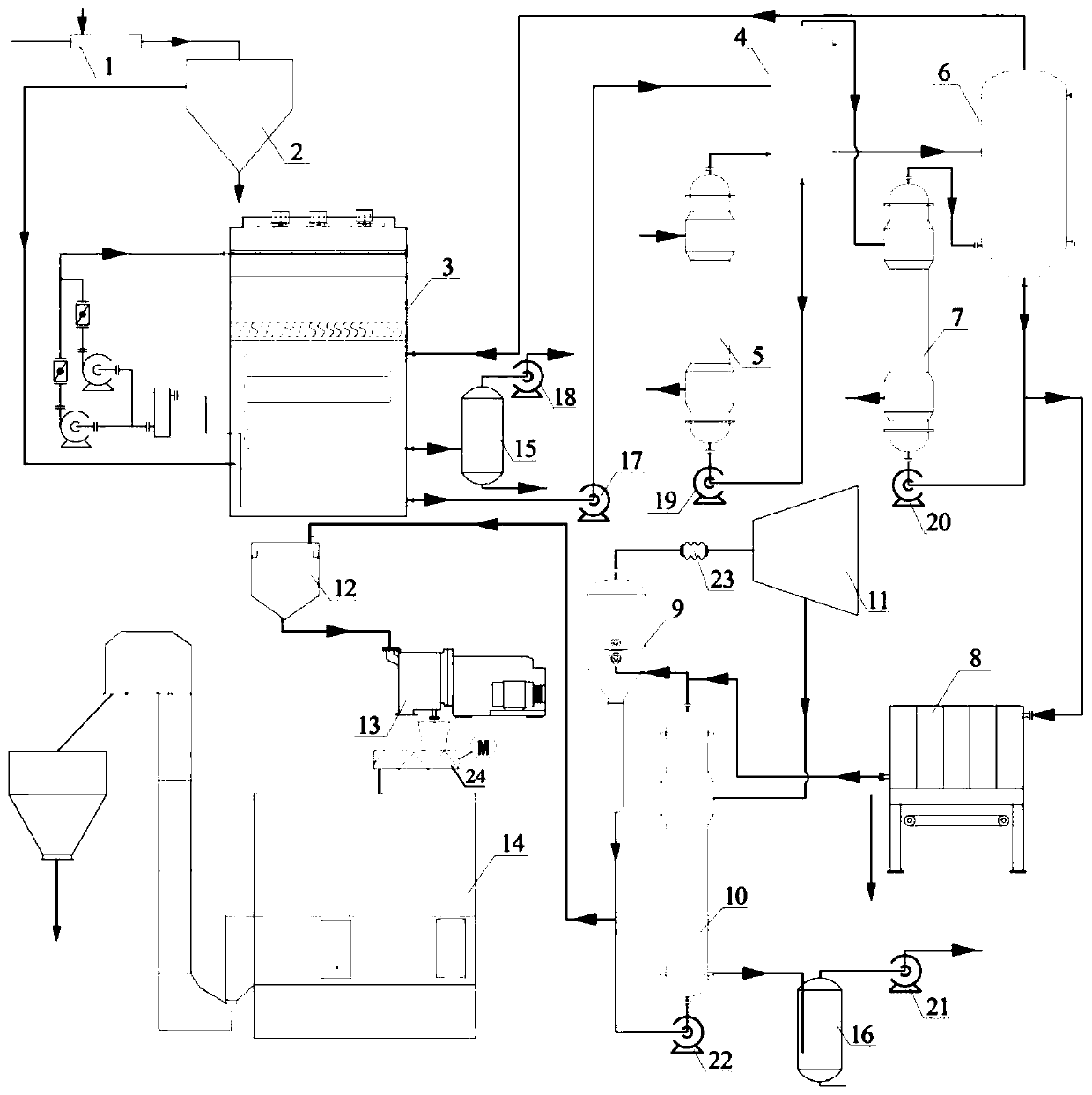

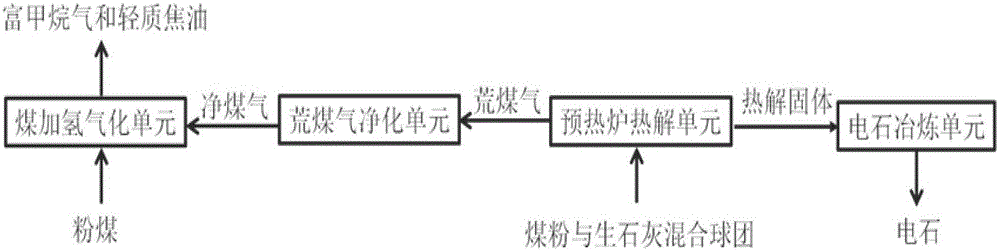

System and method for treating pulverized coal and calcium-based raw material

InactiveCN106635096ALow costHigh quality pyrolysis gasCoal charges mechanical treatmentCombustible gas catalytic treatmentSpray nozzleHydrogen content

The invention relates to a system and a method for treating pulverized coal and a calcium-based raw material. The system comprises a pyrolysis unit, a gas purification unit, a hydrogasification unit and a calcium carbide smelting unit, wherein the pyrolysis unit comprises a pulverized coal and calcium-based raw material mixed pellet inlet, a raw coke oven gas outlet and a pyrolysis solid pellet outlet; the gas purification unit comprises a raw coke oven gas inlet and a purified coke oven gas outlet; the raw coke oven gas inlet is connected with the raw coke oven gas outlet; the hydrogasification unit comprises a pulverized coal spray nozzle, a purified coke oven gas spray nozzle, a coke residue outlet and an oil gas outlet; the purified coke oven gas spray nozzle is connected with the purified coke oven gas outlet; the calcium carbide smelting unit comprises a high-temperature solid pellet inlet, a calcium carbide furnace gas outlet and a calcium carbide outlet; the high-temperature solid pellet inlet is connected with the pyrolysis solid pellet outlet. According to the system and the method disclosed by the invention, by using the advantage of high quality and high hydrogen content of pyrolysis gas obtained by copyrolysis of coal and quick lime in a preheating furnace, the pyrolysis gas can be used as a hydrogen source of coal hydrogasification when calcium carbide is produced, so that the cost of the hydrogen source is reduced, and the thermal efficiency of the system is improved.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

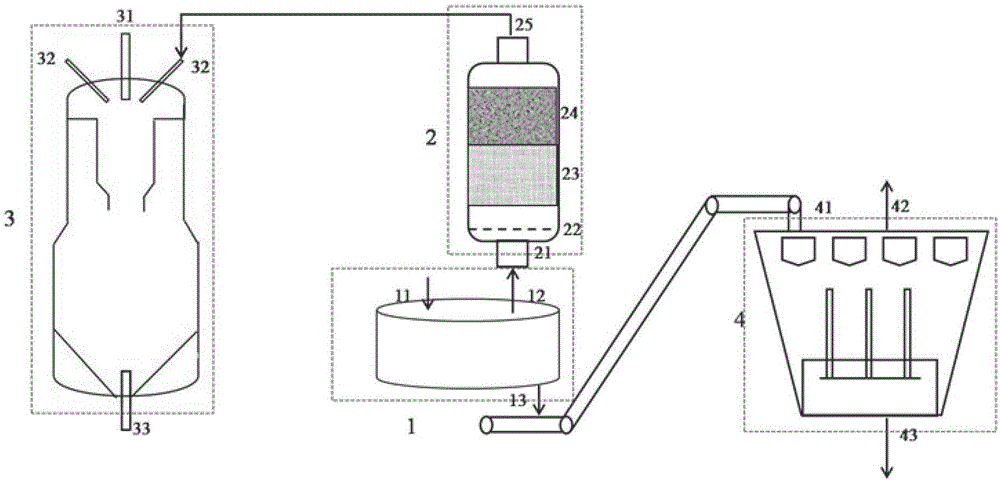

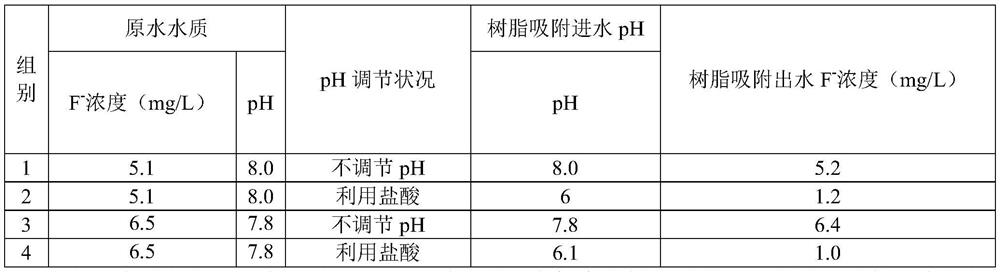

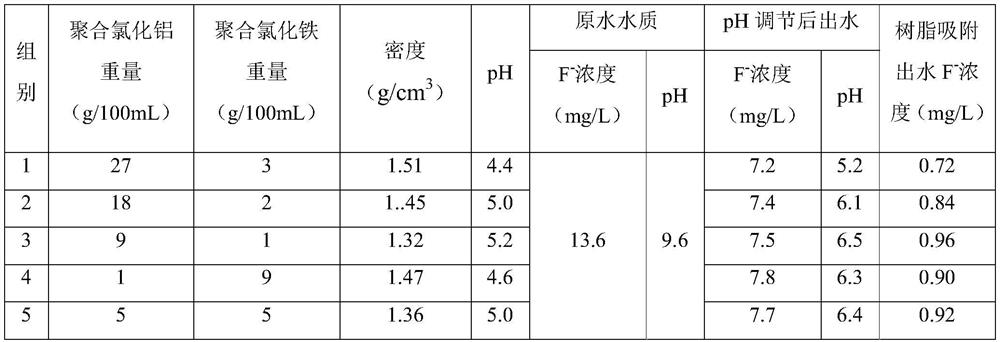

A process for deep defluoridation of fluorine-containing water by precipitation and adsorption

ActiveCN112591840BPromote protonationInhibition of adsorptionWater contaminantsMultistage water/sewage treatmentEconomic benefitsPre treatment

The invention discloses a fluorine-containing water body precipitation adsorption depth defluorination process, which belongs to the technical field of fluorine-containing wastewater treatment. The present invention adopts resin to carry out adsorption treatment on the fluorine-containing water body that has been pretreated to a certain extent, which can effectively avoid major problems caused by precipitation method or chemical method for fluorine removal, and has the characteristics of safety, high efficiency, easy operation, and convenient planning and application. The technological process is simple, the processing cost is low, and the method has good economic benefits.

Owner:NANJING UNIV +1

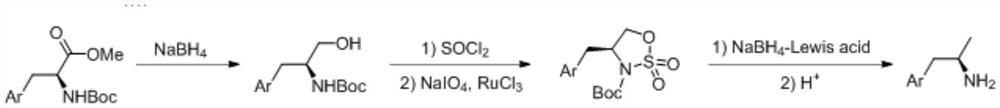

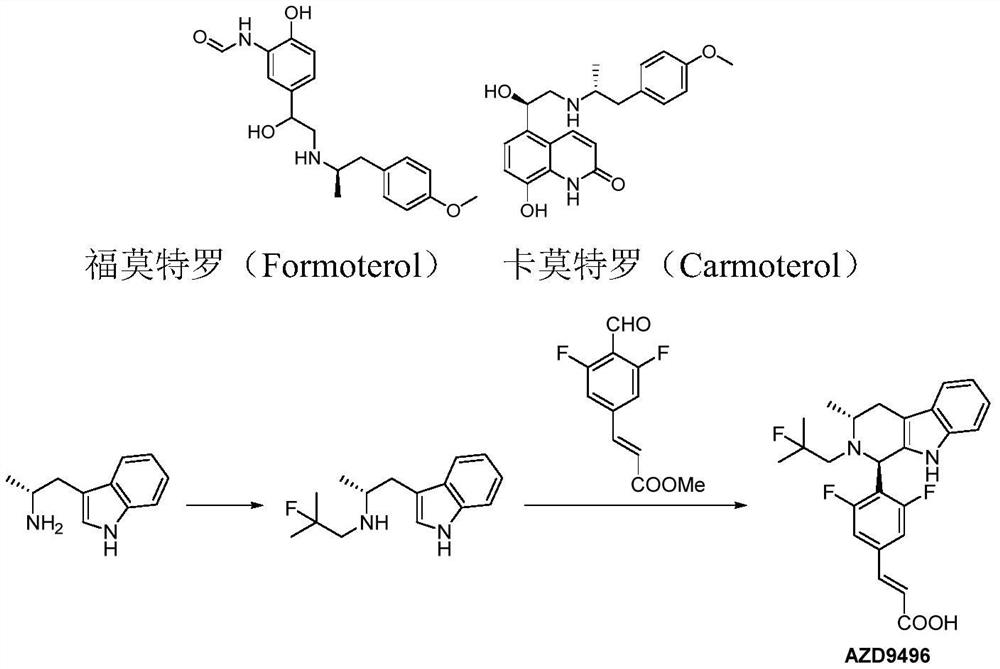

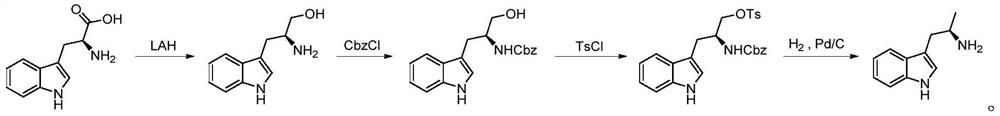

Preparation method of chiral alpha-methyl arylethylamine

ActiveCN112920053AOvercome the split problemAvoid it happening againCarbamic acid derivatives preparationOrganic compound preparationOrganic synthesisMethyl palmoxirate

The invention provides a preparation method of chiral alpha-methyl arylethylamine, and relates to the technical field of organic synthesis medicines. Boc-amino acid methyl ester is used as an initial raw material, Boc-amino alcohol is obtained through reduction, Boc-amino alcohol reacts with thionyl chloride and is oxidized through sodium periodate to obtain a sulfonamide compound, and then the sulfonamide compound is reduced through sodium borohydride promoted by lewis acid and a protecting group is removed under the acidic condition to obtain a target compound. According to the method, raw materials are cheap and easy to obtain, a single optical isomer product is obtained by using chiral raw materials, the problem of column chromatography resolution is solved, generation of a large amount of solid wastes and isomers is avoided, atom economy is improved, the product purity is high, the yield is high, and the production cost is effectively reduced. In addition, the mild reduction system is used for replacing the original high-pressure hydrogenation reaction, the process operation is relatively simple, and the method is more suitable for large-scale industrial production.

Owner:暨明医药科技(苏州)有限公司

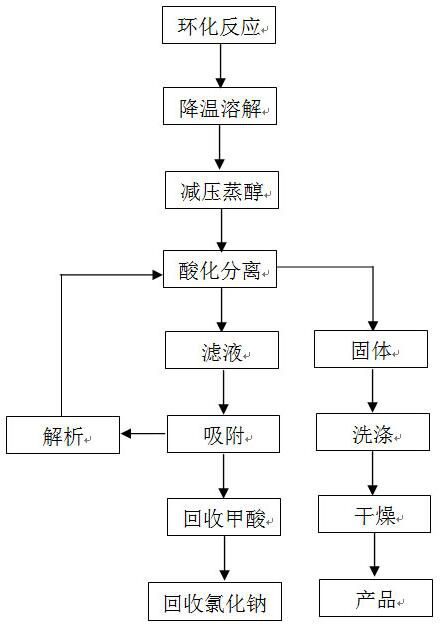

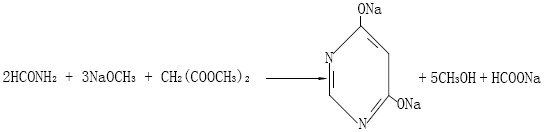

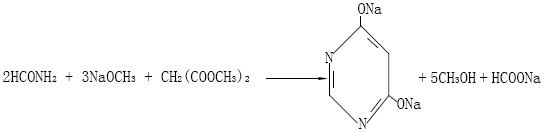

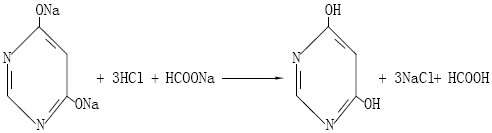

Method for preparing 4,6-dihydroxypyrimidine

The invention belongs to the technical field of synthesis of 4, 6-dihydroxypyrimidine, and particularly relates to a method for preparing 4,6-dihydroxypyrimidine. The method comprises the following steps: (1) cyclization reaction; (2) cooling and dissolving; (3) alcohol distilling under reduced pressure; (4) acidification and separation; (5) washing; (6) adsorption; (7) formic acid recycling; (8) sodium chloride recycling; and (9) analyzing. According to the method provided by the invention, the 4,6-dihydroxypyrimidine in the acidified wastewater is adsorbed by the adsorbent resin, so that the product yield is improved, the content of organic matters in the wastewater is reduced, the defect that the wastewater is difficult to treat is overcome, the quality of a byproduct sodium chloride is improved, the content of organic matters in a byproduct salt is reduced, and good economic benefits and social benefits are achieved.

Owner:潍坊滨海石油化工有限公司

Preparation method of environment-friendly printing and writing paper

ActiveCN106958160AAvoid solid wasteReduce consumptionWater-repelling agents additionPaper recyclingCarboxymethyl cellulosePulp and paper industry

The invention relates to a preparation method of environment-friendly printing and writing paper. Bleached chemical pulp and office waste paper are taken as raw materials, the office waste paper is used for replacing part of traditional bleached chemical pulp, so that large amount of solid office waste paper is treated while production cost is reduced, and the printing and writing paper is environment-friendly. Surface sizing is performed on paper with a surface sizing agent prepared from carboxymethyl cellulose, sodium silicate, a phryma leptostachya extract, gelatin and water, so that the environment-friendly printing and writing paper is not prone to worm damage, bacteria breeding or mildew and can be stored for a long time, and product quality and grade are improved substantially.

Owner:SHANYING INT HLDG CO LTD

Method and system for preparing low-carbon olefin from waste plastics

ActiveCN114507539AImprove recycling ratesImprove dechlorination effectLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPtru catalystEnvironmental engineering

The invention relates to a method and a system for preparing low-carbon olefin from waste plastics. The waste plastics are sequentially treated by a waste plastic dissolving and dechlorinating unit and a waste plastic thermal dissolving and impurity removing unit to obtain an impurity-removed plastic-containing solution; and feeding the impurity-removed plastic-containing solution into a catalytic cracking unit, enabling the impurity-removed plastic-containing solution and an optional catalytic cracking raw material to be in contact with a catalytic cracking catalyst for reaction, and separating a reaction effluent to obtain a catalytic cracking product containing low-carbon olefin. The olefin monomer is prepared from the waste plastics, so that the waste plastics are subjected to closed circulation, and the cyclic utilization of the plastics is really realized. The method not only helps to solve the problem of white pollution, but also is low in pollution discharge and good in environmental protection in the production process, reduces carbon emission, and has good environmental benefits, social benefits and economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

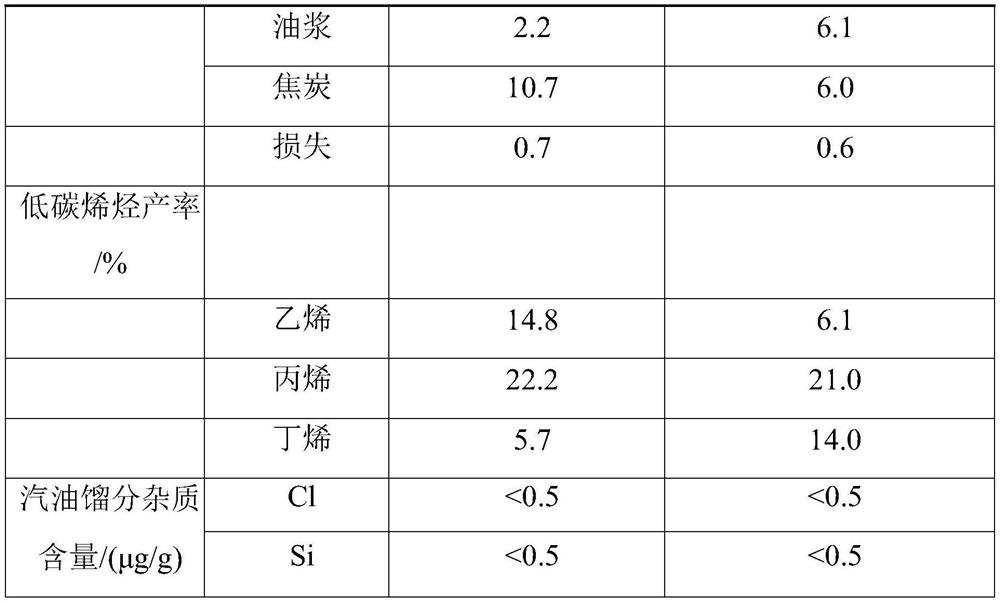

Novel method for preparing 3-iodo-2-bromotoluene

PendingCN113214041AHigh puritySimple and fast operationOrganic compound preparationAmino compound preparationChemical synthesisPtru catalyst

The invention discloses a novel method for preparing 2-bromo-3-iodotoluene, and belongs to the field of chemical synthesis. The method specifically comprises the following steps: a, reacting 2-amino-3-nitrotoluene serving as a raw material with a hydrobromic acid reagent under the action of nitrite and alkali metal bromide to prepare 2-bromo-3-nitrotoluene; b, taking 2-bromo-3-nitrotoluene as a raw material, and preparing 2-bromo-3-aminotoluene through a hydrogenation reduction reaction under the condition of a palladium catalyst; and c, taking 2-bromo-3-aminotoluene as a raw material, and reacting under the action of nitrite, concentrated acid and alkali metal iodide to prepare the 3-iodo-2-bromotoluene.

Owner:河北唯达生物医药产业技术研究有限公司

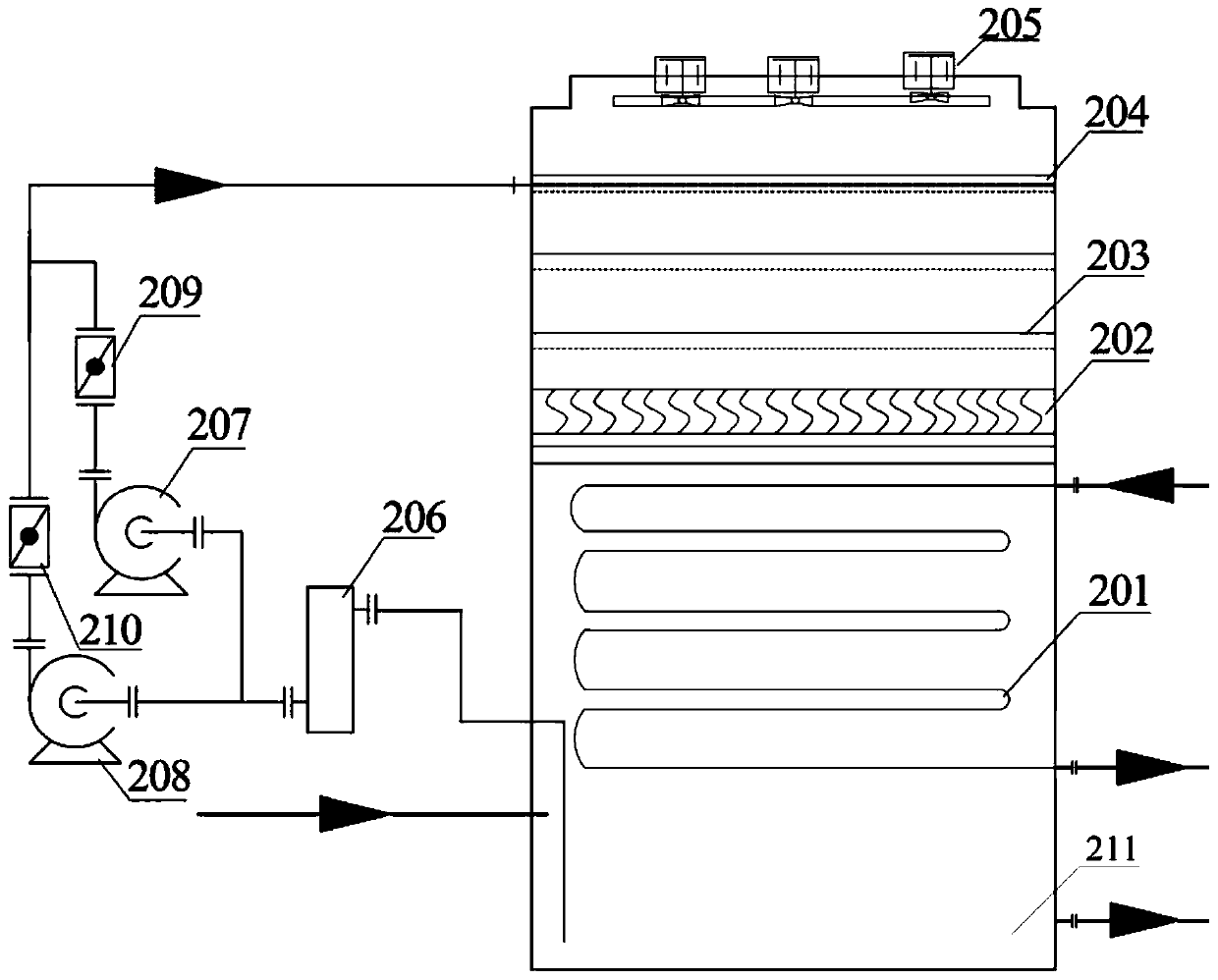

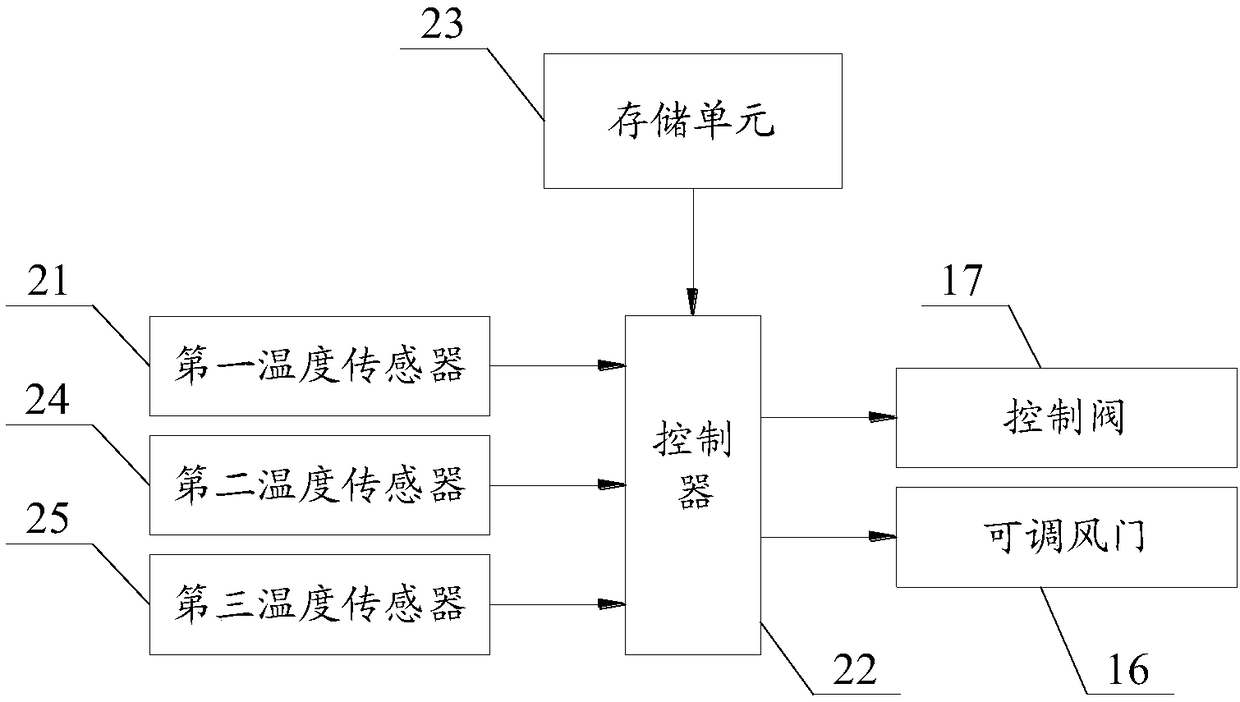

Wastewater treatment process system and method for wet desulfurization

ActiveCN108059294ABalance efficiency impactBalance effectSpecific water treatment objectivesWaste water treatment from gaseous effluentsControl signalEvaporation

The invention discloses a wastewater treatment process system and method for wet desulfurization. A main flue of the system is internally provided with a first group of nozzles; a bypass flue which isarranged in parallel to an air pre-heater is internally provided with a second group of nozzles; an adjustable air door is arranged at an inlet of the bypass flue; a control valve is arranged betweena feeding pump and the first and second groups of nozzles to control pressure to output wastewater to the first group of nozzles and / or the second group of nozzles; a first temperature sensor is arranged at the head end of an evaporation region of the main flue; and a controller outputs a control signal to the control valve and the control end of the adjustable air door according to a temperatureacquired by the first temperature sensor and a preset main flue beginning injection temperature threshold value to adjust starting and stopping control matched with the first group of nozzles and thesecond group of nozzles. The wastewater treatment process system and method provided by the invention can fully utilize smoke waste heat and reasonably deploy two evaporation regions, can greatly lower the system investment and running costs and does not produce new solid wastes.

Owner:FUJIAN LONGKING

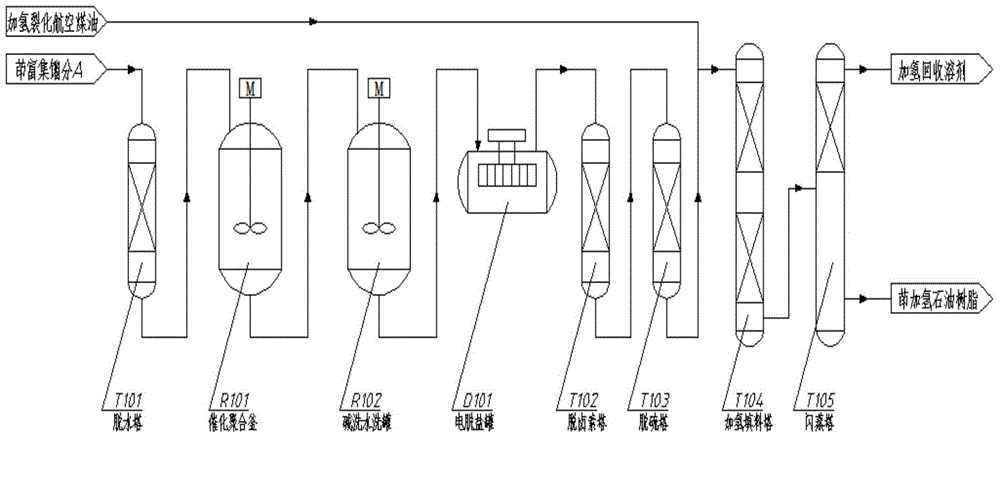

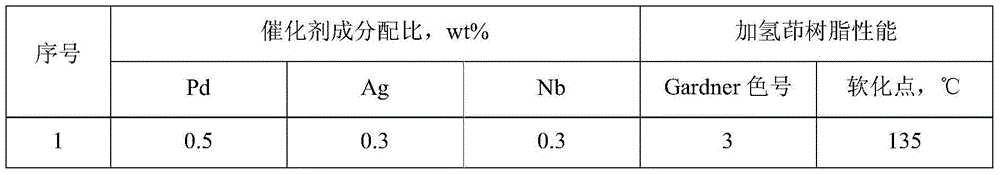

Method for preparing hydrogenated indene resin

The invention relates to a method for preparing hydrogenated indene resin. The method includes the steps: depolymerizing an ethylene cracked C9 fraction to obtain an indene-enriched fraction A with the boiling point of 140-210 DEG C, removing trace water, then carrying out catalytic polymerization with boron trifluoride ether or gas boron trifluoride to obtain an indene resin polymerization liquid, washing, filtering to obtain a resin liquid, pre-treating the resin liquid, then mixing and dissolving with hydrogenated aviation kerosene, to obtain a hydrogenated resin liquid under an action of a hydrogenation catalyst, and removing a solvent to obtain the product. The method has simple process, and the prepared hydrogenated indene resin is light in hue, good in thermal stability and excellent in compatibility, and is mainly applied in printing ink printing, food packaging and other fields.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

A method for preparing 4,6-dihydroxypyrimidine

The invention belongs to the technical field of 4,6-dihydroxypyrimidine synthesis, and specifically relates to a method for preparing 4,6-dihydroxypyrimidine, comprising the following steps: (1) cyclization reaction; (2) cooling and dissolution; (3) ) Alcohol distillation under reduced pressure; (4) Acidification and separation; (5) Washing; (6) Adsorption; (7) Recovery of formic acid; (8) Recovery of sodium chloride; (9) Analysis. The method provided by the invention absorbs 4,6-dihydroxypyrimidine in the acidified wastewater through the adsorption resin, which not only improves the product yield, reduces the content of organic matter in the wastewater, solves the disadvantage of difficult wastewater treatment, but also improves the by-product The quality of sodium chloride reduces the content of organic matter in the by-product salt, which has good economic and social benefits.

Owner:潍坊滨海石油化工有限公司

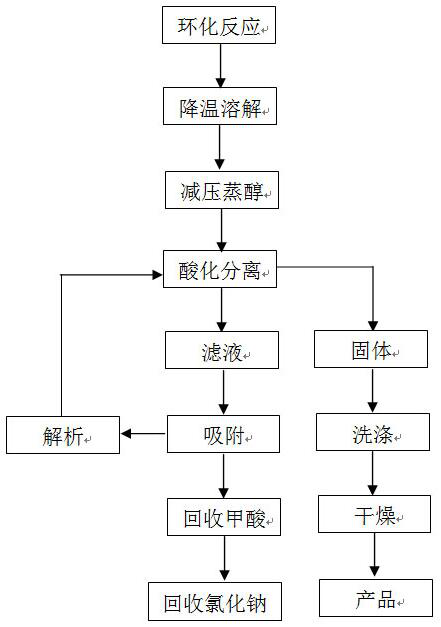

Production process of high-fructose corn syrup

ActiveCN112375850AIncrease productivityReduce water usageBioreactor/fermenter combinationsBiological substance pretreatmentsCorn syrupChemistry

The invention discloses a production process of high-fructose corn syrup. The process comprises astorage tank and comprises the following steps: replacing the original corn starch size mixing, liquefaction and saccharification with glucose separation liquid high-temperature sterilization, deodorization and impurity removal, nanofiltration purification and evaporation concentration treatment; isomerizing the treated material through an isomerization system, wherein isomerized fructose molecules reach 42%-45%; refining again after material isomerization is completed, and purifying through ionicmembrane filtration; conveying the refined material to an evaporation system for concentration; and after the concentration process is finished, adding the finished product into the storage tank for warehousing after passing inspection, thereby finishing the production of the product. The method has the advantages that the production process is improved, the cost performance and the production efficiency are improved, the production cost is reduced, and the enterprise benefit is improved.

Owner:QINGZHOU HUAKANG BIOTECH CO LTD

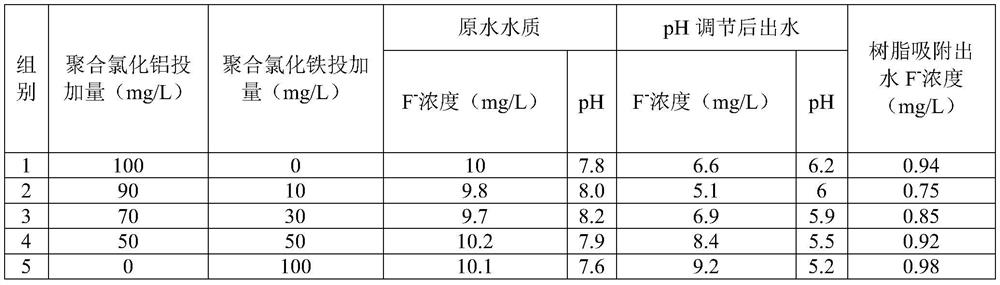

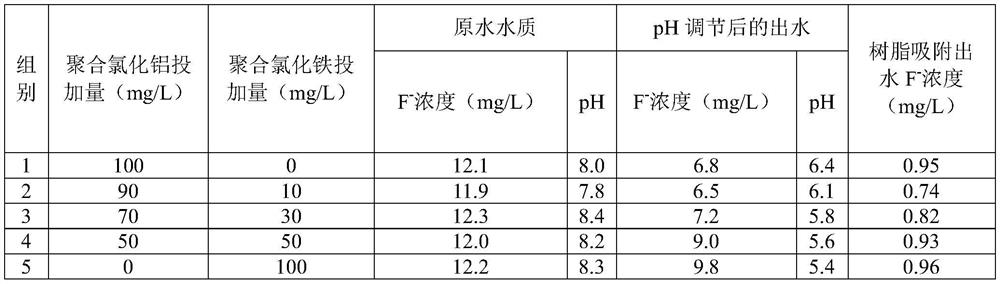

PH adjusting mixed preparation and application thereof in fluorine-containing water body precipitation adsorption treatment

ActiveCN112591868AEasy to achieve precisionAvoid uncontrollableWater contaminantsMultistage water/sewage treatmentAluminium chlorideAluminium chlorohydrate

The invention discloses a pH adjusting mixed preparation and application thereof in fluorine-containing water body precipitation and adsorption treatment. The mixed preparation comprises the followingcomponents in percentage by weight: 40-60% of polyaluminum chloride and 10-15% of polyferric chloride. The medicines are prepared into a liquid medicament, the liquid medicament is added into fluorine-containing wastewater according to a certain ratio, through mechanical stirring, the pH value of the water body is microscopically regulated to be slightly acidic by using a fluorine removal agent,and a supernatant is introduced into a fluorine removal resin adsorption tower for treatment. The mixed preparation has the advantages of simple steps for preparing and adding the agent, low treatmentcost, high fluorine removal rate and the like.

Owner:NANJING UNIV +1

Preparation method of environment-friendly cultural writing paper

ActiveCN106958160BAvoid solid wasteReduce consumptionWater-repelling agents additionPaper recyclingCelluloseSizing

The invention relates to a preparation method of environment-friendly printing and writing paper. Bleached chemical pulp and office waste paper are taken as raw materials, the office waste paper is used for replacing part of traditional bleached chemical pulp, so that large amount of solid office waste paper is treated while production cost is reduced, and the printing and writing paper is environment-friendly. Surface sizing is performed on paper with a surface sizing agent prepared from carboxymethyl cellulose, sodium silicate, a phryma leptostachya extract, gelatin and water, so that the environment-friendly printing and writing paper is not prone to worm damage, bacteria breeding or mildew and can be stored for a long time, and product quality and grade are improved substantially.

Owner:SHANYING INT HLDG CO LTD

A kind of synthetic method of thermosensitive chromogenic agent 4,4'-sulfonylbis[2-(2-propenyl)]phenol

ActiveCN111253290BAvoid high temperature and high pressure reaction above 200 degreesAvoid high temperature and high pressure reactionsOrganic chemistryOrganic compound preparationAluminium chlorideTitanium chloride

The invention provides a synthetic method of 4,4'-sulfonyl bis[2-(2-propenyl)]phenol, a thermal display agent, 4,4'-diallyl diphenyl sulfone is directly in the 4,4'-sulfonylbis[2-(2-propenyl)]phenol is prepared by heating rearrangement in an organic solvent. In the process of preparing 4,4'-sulfonylbis[2-(2-propenyl)]phenol in the present invention, by using a Lewis acid catalyst, high-temperature reactions above 200 degrees can be avoided, safety accidents can be greatly reduced, energy can be saved, consumption can be reduced, and Reduce equipment investment. The catalyst zinc chloride, aluminum trichloride, iron trichloride and titanium tetrachloride used in the process of preparing 4,4'-sulfonyl bis[2-(2-propenyl)]phenol in the present invention have low cost and can be post-treated convenient. In the process of preparing 4,4'-sulfonyl bis[2-(2-propenyl)]phenol, the present invention can avoid the use of high-boiling point solvents and heat-conducting oil, and greatly reduce production costs.

Owner:WEIFANG DAYOU BIOLOGICAL CHEM CO LTD

A kind of synthetic method of tazobactamic acid

The invention provides a synthetic method of tazobactam acid, comprising the steps of (a) using 6-APA (6-aminopenicillanic acid) as a starting material and cetyltrimethylammonium hydrogensulfate as a catalyst to oxidize with oxone to obtain compound A; subjecting the compound A to deamination reaction to obtain compound B; esterifying the compound B to obtain compound C; (b) subjecting the compound C and 2-mercaptobenzothiazole to reduced pressure backflow to obtain compound D; ultrasonically vibrating the compound D and copper bromide to obtain compound E; reacting the compound E and 1H-1,2,3-triazole to obtain compound F; (c) allowing hydrogen peroxide and acetic anhydride to act on the compound F to obtain compound G; reacting the compound G with anisole to obtain tazobactam acid. Amino groups in 6-APA are diazotized directly, diazo groups are then removed, reduced pressure backflow and ultrasonic vibration are performed, hydrogen peroxide and acetic anhydride are used as oxidants, less byproducts are generated, and the yield and quality of tazobactam acid are effectively increased.

Owner:SHIJIAZHUANG WANYE CHEM IND CO LTD

A method for preparing 6-nitro-1,2,4-acid oxygen body

Owner:ZHEJIANG UNIV OF TECH

A kind of refining method of chlorothalonil raw material isophthalonitrile

ActiveCN109593051BMild process conditionsReduce energy consumptionPreparation by carboxylic acid amide dehydrationCarboxylic acid nitrile purification/separationPurification methodsEconomic benefits

The present invention relates to a kind of refining method of chlorothalonil raw material isophthalonitrile, described refining method is carried out according to the following steps: add isophthalonitrile and solvent in the refining kettle with reflux condenser and tail gas absorption tower; add Dehydration reaction of dehydrating agent; cool down, add water dropwise to quench the reaction, add washing water to the organic phase to stir and separate liquid, add water to the organic phase, heat up azeotropic distillation, separate the suspension of isophthalonitrile and water through solid-liquid separation, Phthalonitrile drying. The refining method proposed by the present invention has the following advantages: 1) Mild process conditions, no need for high temperature and high vacuum, no blockage of equipment, and less energy consumption 2) Directly transform impurities into products, which not only avoids solid hazardous waste after refining, but also The quantity of products is increased, and the economic benefit is high.

Owner:JIANGYIN SULI CHEM

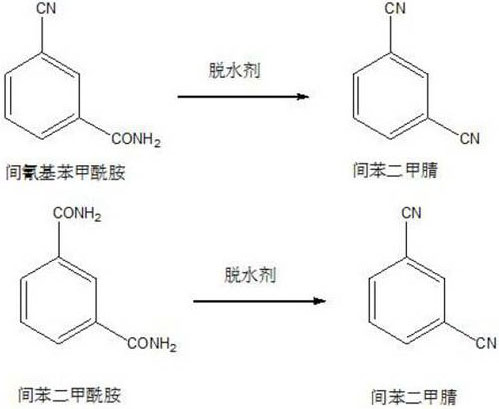

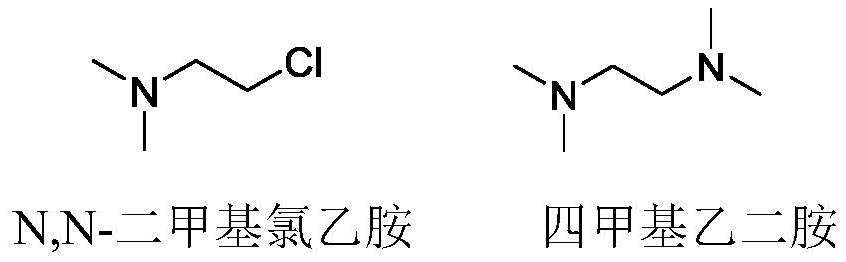

Self-binding acid integrated production method of n,n-dimethylchloroethylamine and tetramethylethylenediamine

ActiveCN108997143BSimple and clean processAtom economy is highAmino compound purification/separationAmino preparation by functional substitutionPolymer scienceDistillation

The invention discloses a self-binding acid integrated production method of N,N-dimethylchloroethylamine and tetramethylethylenediamine, which comprises the following steps: 1) reacting with dimethylamine aqueous solution and dichloroethane Raw materials, adding an acid-binding agent with an equimolar amount of dimethylamine to the reaction raw materials for heating reaction, the heating reaction temperature is 30-90°C, the reaction pressure is 1-3MPa, and the reaction time is 3-8h; 2), the step 1) The resulting reaction product is post-treated to obtain an aqueous solution of N,N-dimethylchloroethylamine and tetramethylethylenediamine and dichloroethane; N,N-dimethylchloroethylamine and tetramethyl The aqueous solution of ethylenediamine is subjected to vacuum rectification, thereby respectively obtaining N,N-dimethylchloroethylamine as a light component and tetramethylethylenediamine as a heavy component. The method of the present invention is adopted to co-produce tetramethylethylenediamine while producing N,N-dimethylchloroethylamine.

Owner:恒光新材料(江苏)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![A kind of synthetic method of thermosensitive chromogenic agent 4,4'-sulfonylbis[2-(2-propenyl)]phenol A kind of synthetic method of thermosensitive chromogenic agent 4,4'-sulfonylbis[2-(2-propenyl)]phenol](https://images-eureka.patsnap.com/patent_img/4c820e4d-f4ad-4db3-832d-4985cca5848c/28942DEST_PATH_IMAGE001.png)