Method for preparing hydrogenated indene resin

A technology of resin and hydrogen indene is applied in the field of preparation of hydrogenated indene resin, which can solve the problems that catalysts and hydrogenation methods are in the laboratory stage and have not yet formed an industrial scale, and can reduce the amount of oil-containing solid waste and improve the hydrogenation selectivity. , the effect of reducing the amount of lye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

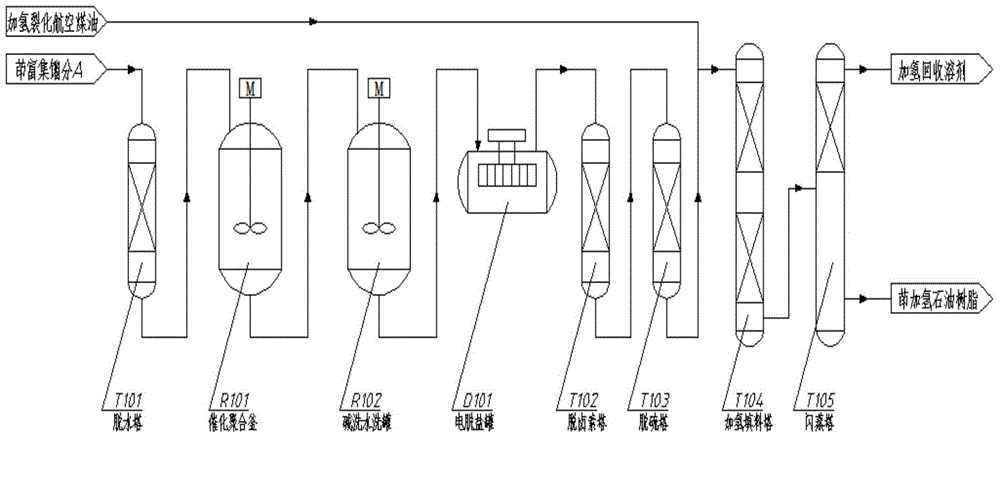

Image

Examples

Embodiment 1

[0041] The following table 1 is the approximate composition of the by-product C9 fraction of the ethylene plant:

[0042] Table 1 Composition of main compounds in ethylene by-product C9 fraction

[0043] serial number

Content, %

serial number

Content, %

1

0.98

9

Trimethylbenzene

2.22

2

1.02

10

o-, m-, p-vinyltoluene

14.41

3

m-, p-xylene

3.38

11

n-decane

1.33

4

8.79

12

β-DCPD

1.96

5

O-xylene

4.01

13

α-DCPD

19.72

6

0.60

14

7.93

7

m-, p-ethyltoluene

3.14

15

2-methylindene

2.67

8

3.35

16

heavy component

24.49

[0044] The indene enrichment fraction A used in the present invention, its typical composition sees the following table 2:

[0045] T...

Embodiment 2~13

[0050] The composition of indene-enriched fraction A is as follows: cyclopentadiene 1.0wt%, methylcyclopentadiene 1.0wt%, styrene 4.0wt%, methylstyrene 8.0wt%, dicyclopentadiene (DCPD) 4.0wt% , indene (Indene) 45wt%, CPD-MCPD dimer, methylcyclopentadiene dimer (DMCPD) 8.0wt%, naphthalene 1.0wt%, and the rest are C8-C12 hydrocarbons.

[0051] Put the above-mentioned fraction A after dehydration into the reactor, and add boron trifluoride diethyl ether BF accounting for 0.4-1.5wt% of the total material mass under the condition of -10°C to 25°C (reaction initiation temperature) 3 ·Et 2 O or gaseous boron trifluoride accounting for 0.1-0.8wt% of the total material mass, polymerized at 10-45°C (reaction temperature) for 0.5-3h to obtain an indene resin polymer solution, which was washed with 5% sodium hydroxide solution The catalyst was removed, and then washed with water until neutral to obtain a light yellow resin solution.

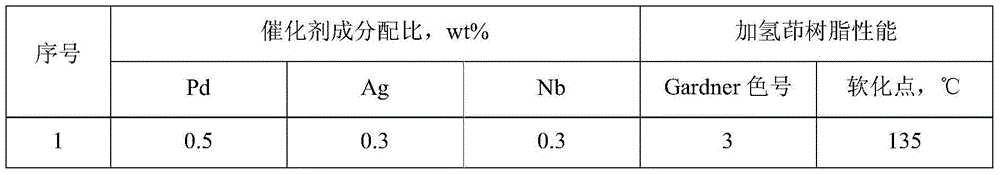

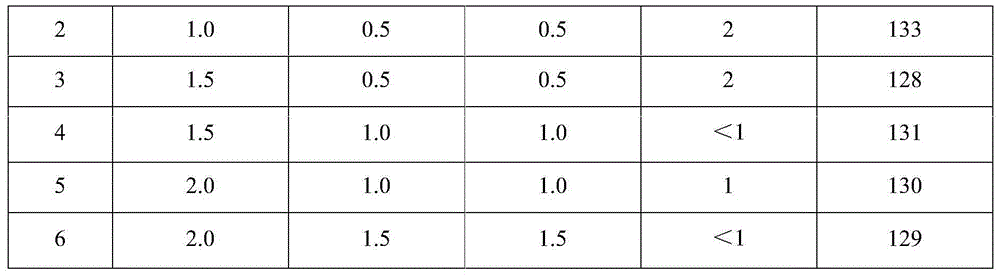

[0052] According to the above reaction steps, exampl...

Embodiment 14~19

[0058] Firstly, the solvent is removed by vacuum distillation at -0.085MPa to 110°C, and then free fluoride ions and trace water are removed through an electric desalination device, and then the high-efficiency dehalogenation agent spherical Al 2 o 3 (Particle size 0.3cm, pore volume 0.5ml / g, bulk density 900kg / m 3 ) to remove trace fluorine at high temperature, and finally modify zinc oxide (ZnO content 95wt%, MgO content 3wt%, SiO 2 Content 2wt%, specification is Φ4×4-15, bulk density 1.25kg / L) the petroleum resin liquid to be hydrogenated is obtained after removing trace sulfur in packed bed;

[0059] The above-mentioned petroleum resin liquid is dissolved in hydrocracked aviation kerosene with a boiling range of 200-240° C. at a mass ratio of 1:3, and a hydrogenation reaction experiment is carried out under the action of a hydrogenation catalyst with a limited composition. Mass percentage of each component in hydrogenation catalyst: carrier γ-Al 2 o 3 96.5%, main catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com