Method for recycling phenylglycine in cefalexin crystallization mother liquid

A technology of phenylglycine and crystallization mother liquor, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve problems such as non-recovery, large consumption of organic solvents, waste of resources, etc., and is conducive to environmental protection and COD emission. Low, lower processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

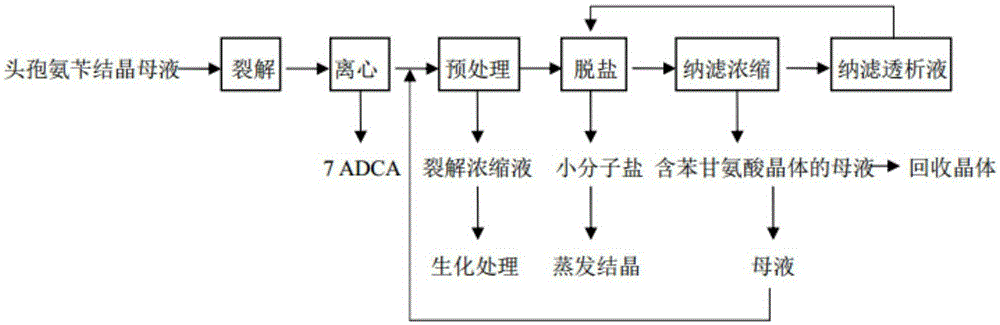

Image

Examples

Embodiment 1

[0031] Take 100L of enzymatic cephalexin crystallization mother liquor, wherein the cephalexin content is 15-18g / L, add 10kg of penicillin G acylase to it, adjust pH=7, and react for 2h at a temperature of 40°C to crack it to obtain Lysis solution of 7-aminodesacetoxycephalosporanic acid and phenylglycine, wherein phenylglycine is 15-18g / L, cephalexin content is less than 1g / L, ammonium sulfate is about 100g / L, conductivity is about 10ms / cm, Biochemical oxygen consumption (COD) is about 200000mg / L, ammonia nitrogen (NH 3 -N) is about 30000mg / L, pH=6-7. Use dilute sulfuric acid to adjust the pH of the lysate to pH=4, and keep the temperature at 30° C. for later use.

[0032] Take 100L of the lysate and carry out centrifugation at a speed of 4000r / min to obtain 1.02kg of 7-aminodesacetoxycephalosporanic acid crystals and about 100L of the centrifuged liquid, which is filtered through a 2KDa-20KDa roll-type ultrafiltration membrane. The operating pressure is 3bar and the temper...

Embodiment 2

[0036]Take 100 L of enzymatic cephalexin crystallization mother liquor, wherein the cephalexin content is 15-18 g / L, add 10 kg of penicillin G acylase to it, adjust pH=5 with dilute sulfuric acid, and react for 5 hours at a temperature of 25° C. to make it Cleavage to obtain a lysate containing 7-aminodesacetoxycephalosporanic acid and phenylglycine, wherein the phenylglycine is 15-18g / L, the cephalexin content is less than 1g / L, the ammonium sulfate is about 100g / L, and the conductivity is about 10ms / cm, biochemical oxygen consumption (COD) is about 200000mg / L, ammonia nitrogen (NH 3 -N) is about 30000mg / L, pH=6-7. Use dilute sulfuric acid to adjust the pH of the lysate to pH=3, and keep the temperature at 25° C. for later use.

[0037] Take 100L of the lysate and carry out centrifugation at a speed of 8000r / min to obtain 1.35kg of 7-aminodesacetoxycephalosporanic acid crystals and about 100L of the centrifuged liquid. The centrifuged liquid is filtered through a roll-type ...

Embodiment 3

[0041] Take 100L of enzymatic cephalexin crystallization mother liquor, wherein the cephalexin content is 15-18g / L, add 10kg of penicillin G acylase to it, adjust the pH=9 with diluted ammonia water, and react for 1h at a temperature of 50°C. Make it crack to obtain the lysate containing 7-aminodesacetoxy cephalosporanic acid and phenylglycine, wherein phenylglycine 15-18g / L, cephalexin content is less than 1g / L, ammonium sulfate is about 100g / L, conductivity is about 10ms / cm, biochemical oxygen consumption (COD) is about 200000mg / L, ammonia nitrogen (NH 3 -N) is about 30000mg / L, pH=6-7. Use dilute sulfuric acid to adjust the pH of the lysate to pH=4, and keep the temperature at 30° C. for later use.

[0042] Get 100L of lysate and carry out centrifugation, rotating speed is 5000r / min, obtain 7-aminodesacetoxy cephalosporanic acid crystal 1.02kg and centrifuged liquid about 100L, centrifuged liquid is through membrane filtration (membrane core is roll type ultrafiltration mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com