Method for synthesizing methyl phosphine dichloride

A technology for synthesizing methylphosphine dichloride and methylphosphine dichloride, which is applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., and can solve the problem of high environmental pressure and high cost , Low continuous production capacity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

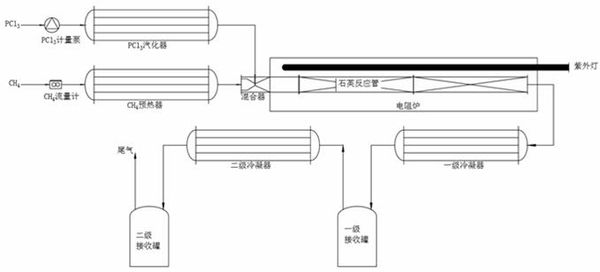

[0033] like figure 1 Shown, a kind of method for synthesizing methyl phosphine dichloride comprises the following steps:

[0034] A. Replace the quartz glass reactor (volume 2.45L, length 40cm) with nitrogen to fill the whole reactor with nitrogen, then turn on the ultraviolet lamp, the wavelength of ultraviolet light is 100nm, turn on the quartz reactor and heat it with a resistance furnace;

[0035] B. After the temperature of the quartz reactor rises to 110°C, then respectively feed methane and phosphorus trichloride (methane flow rate: 610L / h, phosphorus trichloride flow rate: 0.3L / h; the molar ratio of methane to phosphorus trichloride is 8:1), methane undergoes CH 4 The preheater is preheated to 90°C, and phosphorus trichloride is passed through PCl 3 The vaporizer is heated to gasification, mixed by the mixer, and then enters the quartz reactor to stay and react for 10s;

[0036] C. Condensate the mixed material obtained through the reaction in step B through the pri...

Embodiment 2

[0040] like figure 1 Shown, a kind of method for synthesizing methyl phosphine dichloride comprises the following steps:

[0041] A. Replace the quartz glass reactor (volume 2.45L, length 40cm) with nitrogen to fill the whole reactor with nitrogen, then turn on the ultraviolet lamp, the wavelength of ultraviolet light is 280nm, turn on the quartz reactor and heat it with a resistance furnace;

[0042] B. After the temperature of the quartz reactor rises to 90°C, then respectively feed methane and phosphorus trichloride (methane flow rate: 318L / h, phosphorus trichloride flow rate: 0.311L / h; the molar ratio of methane to phosphorus trichloride is 4:1), methane undergoes CH 4 The preheater is preheated to 80°C, and phosphorus trichloride is passed through PCl 3 The vaporizer is heated to gasification, mixed by a mixer, and then enters a quartz reactor to stay and react for 16s;

[0043] C. Condensate the mixed material obtained through the reaction in step B through the primar...

Embodiment 3

[0047] likefigure 1 Shown, a kind of method for synthesizing methyl phosphine dichloride comprises the following steps:

[0048] A. Replace the quartz reactor (volume 2.45L, length 80cm) with nitrogen to fill the whole reactor with nitrogen, then turn on the ultraviolet lamp, the wavelength of ultraviolet light is 185nm, turn on the quartz reactor and heat it with a resistance furnace;

[0049] B. When the temperature of the quartz reactor rises to 300°C, then respectively feed methane and phosphorus trichloride (methane flow rate: 1042L / h, phosphorus trichloride flow rate: 0.41L / h; the molar ratio of methane to phosphorus trichloride is 10:1), methane undergoes CH 4 The preheater is preheated to 150°C, and phosphorus trichloride is passed through PCl 3 The vaporizer is heated to gasification, mixed by the mixer, and then enters the quartz reactor to stay and react for 4s;

[0050] C. Condensate the mixed material obtained through the reaction in step B through the primary c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com