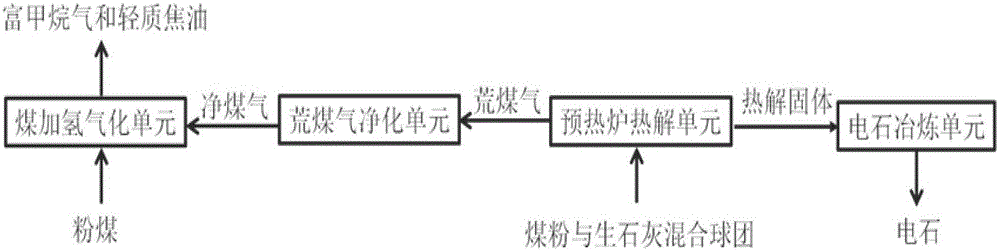

System and method for treating pulverized coal and calcium-based raw material

A pulverized coal, calcium-based technology, used in catalytic treatment of combustible gas, mechanical treatment of coal loaded into the furnace, calcium carbide, etc. The effect of high hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

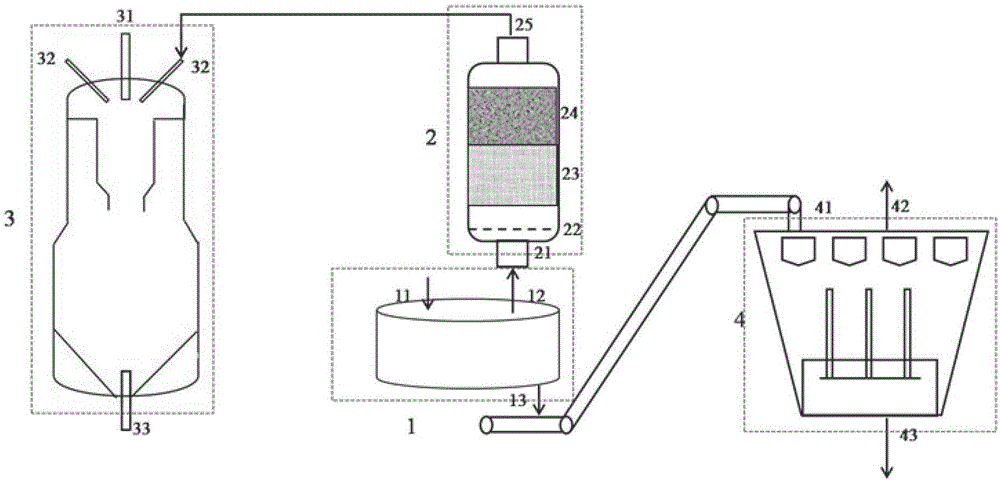

preparation example Construction

[0044] The preparation method of the mixed coal powder and calcium-based raw material ball is as follows: firstly, the medium and low-rank coal and the calcium-based raw material are crushed and screened, and the middle and low-rank coal is crushed to <1 mm; the calcium-based raw material is crushed to <3 mm; then Mix coal powder, calcium-based raw material and binder, and press to form; the amount of binder added is 1.0wt%-10.0wt% of the mixed material; the mass ratio of calcium-based raw material to coal powder is 0.8-1.2:1 ;

[0045] The second step: raw gas purification: the raw gas produced by pyrolysis enters the gas purification unit, and is filtered through a solid bed and tar catalytic cracking to obtain clean gas; the tar catalytic cracking catalyst bed is CaO; the temperature of tar catalytic cracking is 700 -900°C;

[0046] The third step: coal hydrogenation gasification: the clean coal gas sent by the purification unit is used as the hydrogen source, and the hydr...

Embodiment 1

[0056] Using the system of the present invention, first crush and sieve the middle and low rank coal and limestone, crush the middle and low rank coal to <1mm; crush the limestone to <2mm; then mix the coal powder, limestone and binder, and press into shape , to obtain a mixed ball of coal powder and limestone; wherein, the amount of binder added is 1.0wt% of the mixed material, and the mass ratio of limestone to coal powder is 0.8:1.

[0057] Then the pulverized coal and limestone mixed balls are sent to the pyrolysis unit of the preheating furnace by a belt conveyor. The mixed pellets are pyrolyzed at 900°C for 20 minutes in the preheating furnace to obtain raw coal gas and high-temperature solid pellets; the raw coal gas is directly transported to the purification reactor at high temperature, and the temperature in the reactor is kept at 750°C. The raw coal gas first passes through the gas Distributor to ensure that the gas is evenly distributed in the reactor, and then thr...

Embodiment 2

[0059] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. Crushing and screening the middle and low rank coal and quicklime, crushing the middle and low rank coal to <1mm; crushing carbide slag to <3mm; then mixing coal powder, quicklime and binder, and pressing to form coal powder and quicklime Mixed ball; wherein, the amount of binder added is 10.0wt% of the mixed material, and the mass ratio of quicklime to coal powder is 1.2:1.

[0060] Then the pulverized coal and quicklime mixed balls are sent to the pyrolysis unit of the preheating furnace by a belt conveyor. The mixed pellets are pyrolyzed at 800°C for 15 minutes in the preheating furnace to obtain raw coal gas and high-temperature solid pellets; the raw coal gas is directly transported to the purification reactor at high temperature, and the temperature in the reactor is kept at 850°C. The raw coal gas first passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com