Production process of high-fructose corn syrup

A production process, high fructose syrup technology, applied in the field of high fructose syrup production technology, can solve the problems of high production cost, reduced benefit, low cost performance, etc., and achieve the goal of reducing storage cost, reducing energy consumption, and reducing water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

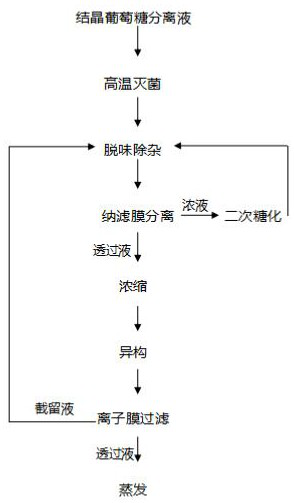

[0030] see figure 1 , an embodiment provided by the present invention: a kind of fructose syrup production process, fructose syrup preparation process:

[0031] S1, high temperature sterilization

[0032] The crystallized glucose separation liquid is heated up to 85° C. with a continuous sterilizer, and then sterilized; wherein; the glucose separation liquid is purchased from the market or made by the factory.

[0033] S2. Deodorization and impurity removal

[0034] The high-temperature sterilized material is mixed with the nanofiltration concentrated liquid of the secondary saccharification according to the dry matter ratio of 1:0.2-0.3. After mixing, the temperature is lowered to 55 ° C, the pH value is adjusted to 3.5, and 6 kg / ton of dry matter is added. The high-speed stirring is uniform and then adsorbed 12 hours, remove impurities with a filter;

[0035] S3, continuous nanofiltration membrane

[0036] Cool down the sugar solution after impurity removal to 44°C, adju...

Embodiment 2

[0048] see figure 1 , an embodiment provided by the present invention: a kind of fructose syrup production process, fructose syrup preparation process:

[0049] S1, high temperature sterilization

[0050] The crystalline glucose separation solution is heated to 85°C with a continuous sterilizer for disinfection and sterilization; the glucose separation solution is purchased from the market or made by the factory.

[0051] S2. Deodorization and impurity removal

[0052] The high-temperature sterilized material is mixed with the nanofiltration concentrated liquid of the secondary saccharification according to the dry matter amount 1:0.3-0.4, and the temperature is lowered to 55-60°C after mixing, the pH value is adjusted to 4.5, and 7kg / ton of activated carbon is added to the dry matter, and the high-speed stirring is uniform After adsorption for 15 hours, remove impurities with a filter;

[0053] S3, continuous nanofiltration membrane

[0054] Cool down the sugar liquid aft...

Embodiment 3

[0066] see figure 1 , an embodiment provided by the present invention: a kind of fructose syrup production process, fructose syrup preparation process:

[0067] S1, high temperature sterilization

[0068] The crystalline glucose separation solution is heated to 85°C with a continuous sterilizer for disinfection and sterilization; the glucose separation solution is purchased from the market or made by the factory.

[0069] S2. Deodorization and impurity removal

[0070] The high-temperature sterilized material is mixed with the nanofiltration concentrated liquid of the secondary saccharification according to the dry matter mass 1:0.4-0.5. After mixing, the temperature is lowered to 60°C, the pH value is adjusted to 4.5, and 8kg / ton of activated carbon is added to the dry matter. 18 hours, remove impurities with a filter;

[0071] S3, continuous nanofiltration membrane

[0072] Cool down the sugar solution after impurity removal to 49°C, adjust the concentration to 35%, sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com