Dry activated coke desulfurization system and method for purifying tail gas of steel rolling heating furnace

A technology of activated coke and desulfurization system, which is applied in the direction of chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as excessive content, and achieve the effects of reduced operating costs, low operating costs, and simple process operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

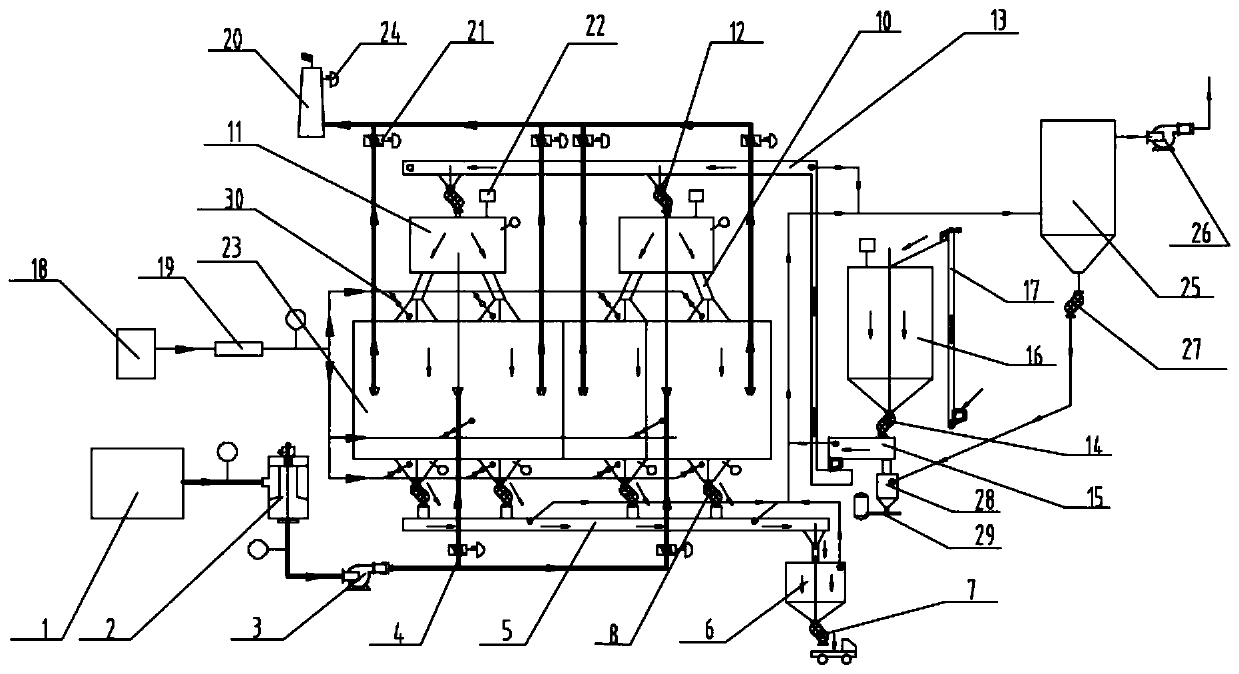

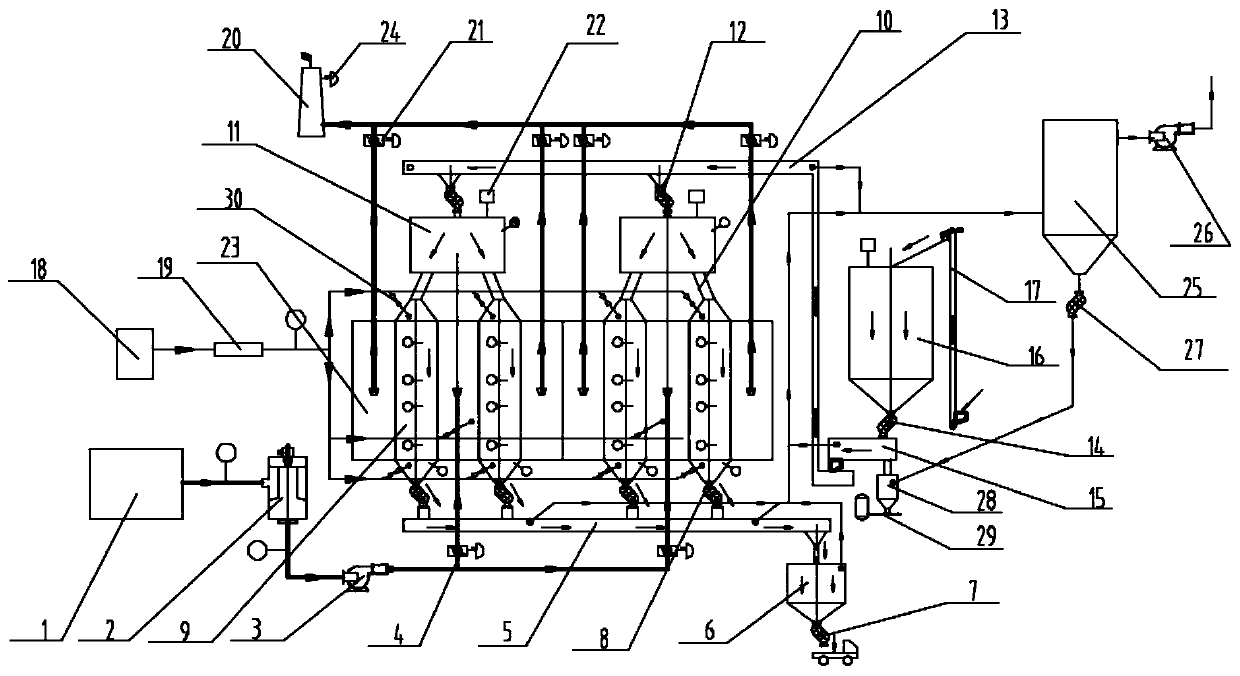

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0029] Such as Figure 1-2As shown, a dry-process activated coke desulfurization system for purifying the tail gas of a steel rolling heating furnace includes a flue gas system, an adsorption system, a nitrogen protection system and a material transportation system. The flue gas system includes a steel rolling furnace tail gas interface 1, a hot blast stove 2 and Fan 3, the exhaust gas interface 1 of the rolling furnace is connected to the air inlet of the hot blast stove 2 by means of a pipeline, and the air outlet of the hot blast stove 2 is connected to the air inlet of the fan 3 by means of a pipeline; the adsorption system includes an air inlet chamber 23, an ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com