Harmless treatment method of electrolytic manganese residue

A technology of harmless treatment and electrolysis of manganese slag, which is applied in chemical instruments and methods, inorganic chemistry, manganese compounds, etc., can solve the problems of surrounding residents' health threats, surrounding environmental pollution, and a large amount of waste gas, and achieve diversified recycling , The time required for the process is short, and the effect of reducing the pressure on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

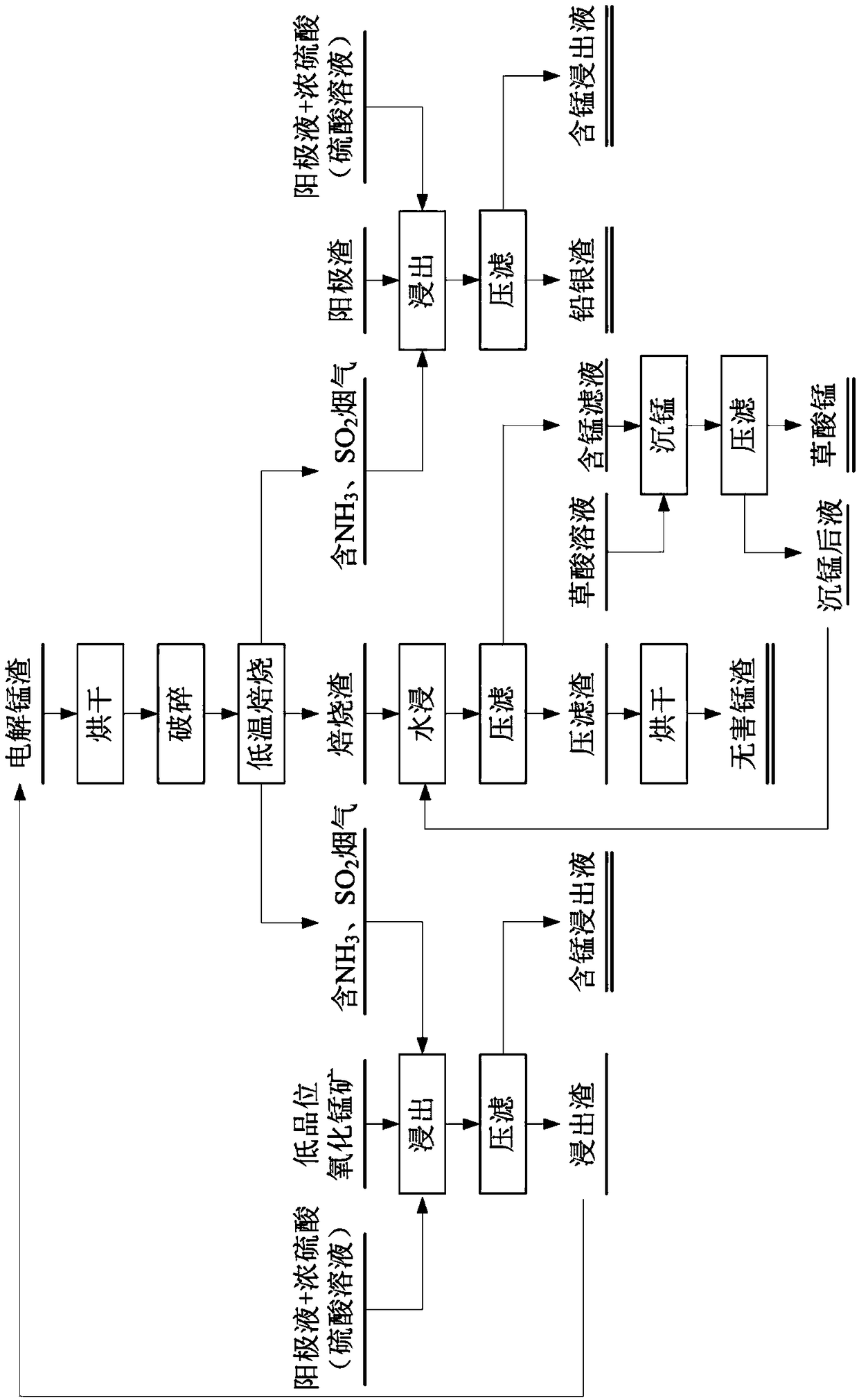

[0048] A harmless treatment method of electrolytic manganese slag of the present invention, the process flow chart is as follows figure 1 shown, including the following steps:

[0049] (1) Dry the electrolytic manganese slag taken from the slag factory, crush the dried electrolytic manganese slag with a powder machine or a crusher to less than 100 mesh, and use a rotary kiln to cool the electrolytic manganese slag at a low temperature of 550°C Roasting for 90min to obtain the calcined material and produce NH-containing 3 and SO 2 smoke.

[0050] (2) Slurry the calcined material obtained in step (1) with water according to the liquid-solid ratio of 3: 1mL / g, then place the obtained slurry in a water bath at 40°C, stir and immerse in water, react for 30 minutes, and then press filter A press filter residue and a manganese-containing filtrate are obtained.

[0051] (3) Dry the press filter residue obtained in step (2) to obtain harmless manganese slag, add the oxalic acid sol...

Embodiment 2

[0057] A harmless treatment method of electrolytic manganese slag of the present invention, the process flow chart is as follows figure 1 shown, including the following steps:

[0058] (1) Dry the electrolytic manganese slag taken from the slag factory, crush the dried electrolytic manganese slag with a powder machine to below 100 mesh, and roast the crushed electrolytic manganese slag at 600°C for 60 minutes in a rotary kiln to obtain Roasted material, and produces NH-containing 3 and SO 2 smoke.

[0059] (2) Slurry the calcined material and water obtained in step (1) according to the liquid-solid ratio of 8: 3mL / g, then place the obtained slurry in a water bath at 50°C with stirring and water immersion, react for 30 minutes, and then press filter to obtain Press filter residue and filtrate containing manganese.

[0060] (3) Dry the press filter residue obtained in step (2) to obtain harmless manganese slag, add the oxalic acid solution to the manganese-containing filtrat...

Embodiment 3

[0066] A harmless treatment method of electrolytic manganese slag of the present invention, the process flow chart is as follows figure 1 shown, including the following steps:

[0067] (1) Dry the electrolytic manganese slag taken from the slag factory, crush the dried electrolytic manganese slag with a powder machine to below 100 mesh, and roast the crushed electrolytic manganese slag at 600°C for 60 minutes in a rotary kiln to obtain Roasted material, and produces NH-containing 3 and SO 2 smoke.

[0068] (2) Slurry the calcined material and water obtained in step (1) according to the liquid-solid ratio of 8: 3mL / g, then place the obtained slurry in a water bath at 50°C with stirring and water immersion, react for 30 minutes, and then press filter to obtain Press filter residue and filtrate containing manganese.

[0069] (3) Dry the press filter residue obtained in step (2) to obtain harmless manganese slag, add the oxalic acid solution to the manganese-containing filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com