Process for removing defective green bodies from autoclaved aerated concrete bricks and recycling defective green bodies

A technology of autoclaved gas filling and concrete, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., which can solve problems such as damage, waste of raw materials, and increased product scrap rate, so as to avoid solid waste and improve the pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below by embodiment the present invention is further described;

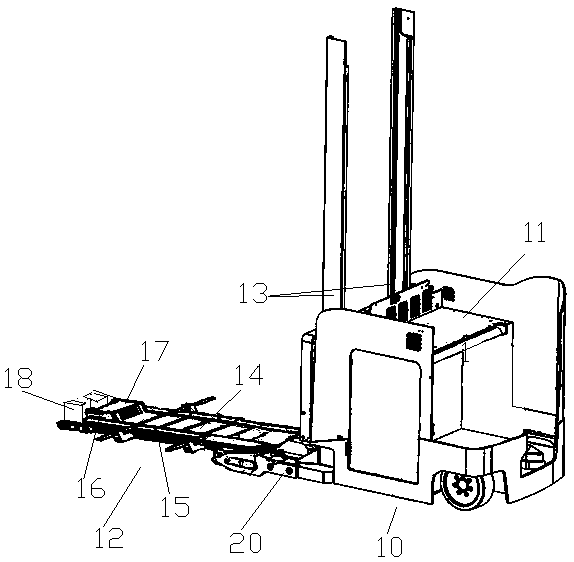

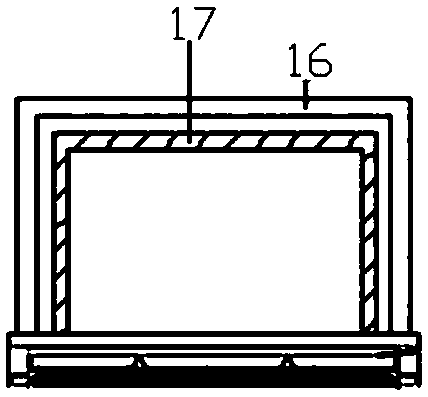

[0034] A process for removing defective embryo bodies and reusing autoclaved aerated concrete bricks. The process steps are as follows. The preparation of aerated concrete bricks is carried out. In the prior art, the preparation of autoclaved aerated concrete bricks is generally The process includes raw material processing and slurry preparation, batching, stirring and pouring molding, static stop, mold removal, cutting, autoclaving and other processes. The process involved in the present invention is specifically:

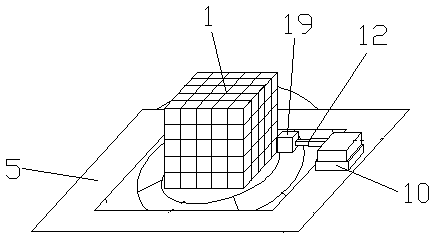

[0035] Step 1. The uncut embryo bodies are moved to the support plate after cutting, and wait for defect inspection. These processed embryo bodies are hereinafter referred to as embryo body accumulation bodies (1);

[0036] Step 2. Judgment of defective embryo bodies in the embryo body accumulation body (1): the entire embryo body accumulation body is transported by the track to the preset posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com