Full-automatic anti-oxidation soldering tin furnace for reducing exhaust emission treatment and special soldering flux

A technology for exhaust gas emission and soldering furnace, applied in auxiliary devices, welding media, welding equipment, etc., can solve the problems of not ensuring uniform heating of solder, affecting workers' health, and pungent smell of solder smoke, and reducing the number of times of scraping the tin surface. , save labor costs, avoid the effect of physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

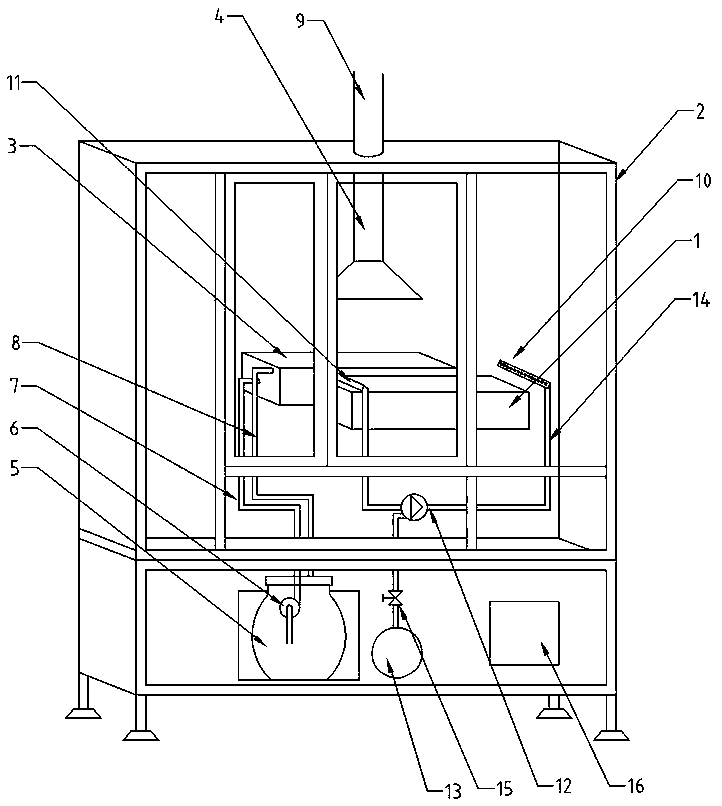

[0012] In this regard, a fully automatic anti-oxidation soldering furnace for reducing waste gas emission treatment in this embodiment includes: a soldering furnace body 1, a tin furnace hood 2, a flux tank 3 and a smoking device 4; the above-mentioned flux tank 3 is set in On the side of the solder furnace body 1, the flux in the flux barrel 5 is sent into the flux tank 3 through the pump 6 and the delivery pipeline 7, and the waste flux produced is returned to the flux barrel 5 through the recovery pipeline 8 for regeneration treatment; The device is installed on the top of the tin furnace hood 2 above the solder furnace body 1, and the flue gas generated during the welding process of the solder furnace body 1 is sent to the outside through the exhaust pipe 9; A pair of "nitrogen curtain" devices are arranged opposite to each ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com