Ornament investment casting pattern material based on modified polyurethane elastomer and preparation method thereof

A polyurethane elastomer and investment casting technology, which is applied in the field of investment precision casting, can solve the problems of performance gap and other problems, and achieve the effects of moderate softening point and penetration, large market value and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In order to obtain the above-mentioned jewelry investment casting molding material, the present invention also provides a related preparation method, which comprises the following steps:

[0039] Preparation of modified polyurethane elastomer: physically blending polyurethane elastomer and polyolefin elastomer, and silylation modification to obtain modified polyurethane elastomer;

[0040] Preparation of jewelry investment casting mold materials: add mineral wax, animal and vegetable wax and synthetic wax to the reaction kettle, heat and melt, and the heating reaction temperature is 120°C-130°C; then add tackifying resin and modified polyurethane elastomer to make it Uniformly dispersed in the base wax matrix, you can get jewelry investment casting mold material.

[0041] In one or more embodiments, the step of preparing a modified polyurethane elastomer includes:

[0042] Physical blending of polyurethane elastomer and polyolefin elastomer: Prepare polyurethane elasto...

Embodiment 1

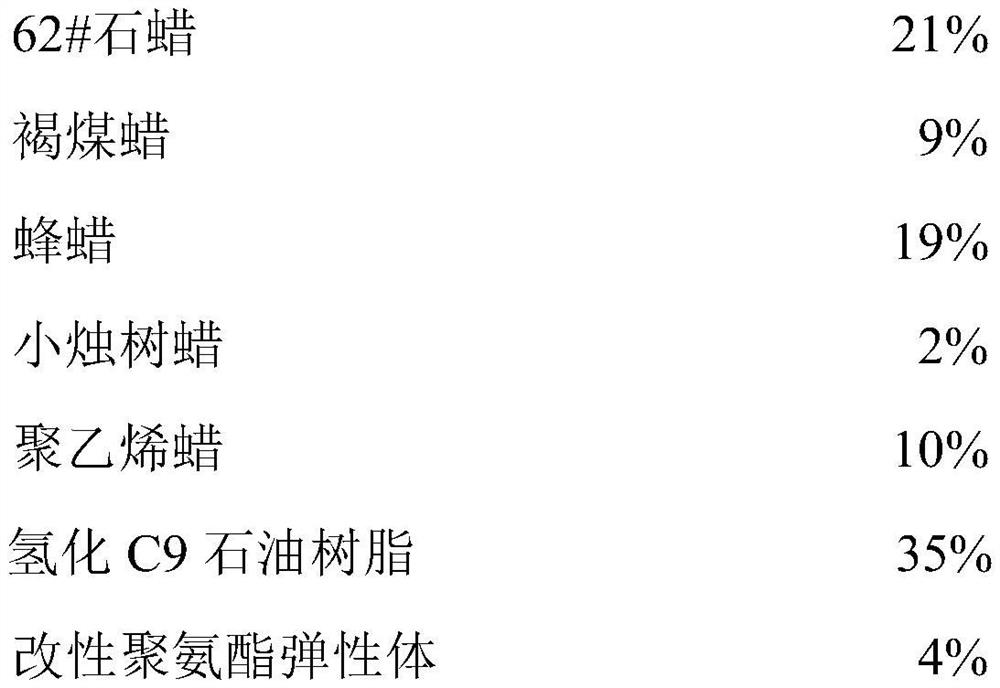

[0048] The ornamental investment casting molding material based on modified polyurethane elastomer of the present embodiment, in terms of mass percentage, includes the following components:

[0049]

[0050] The method for preparing the jewelry investment casting mold material of the present embodiment comprises the following steps:

[0051] (1) Add polyurethane elastomer and polyolefin elastomer raw materials in a high-speed mixer at a ratio of 7:3, heat up to 170°C, and stir at a speed of 500rpm for 15min until the materials are evenly mixed to obtain a blended composite material;

[0052] (2) Then add vinyltrimethoxysilane, dicumyl peroxide, dibutyltin dilaurate, antioxidant 1098 and the blended composite material to melt and mix uniformly under the high-speed mixer. Extrude into granules in the machine;

[0053] (3) Boil the granulated blended material in a constant temperature water bath at 90°C for at least 48 hours to boil and cross-link, and place the cross-linked ...

Embodiment 2

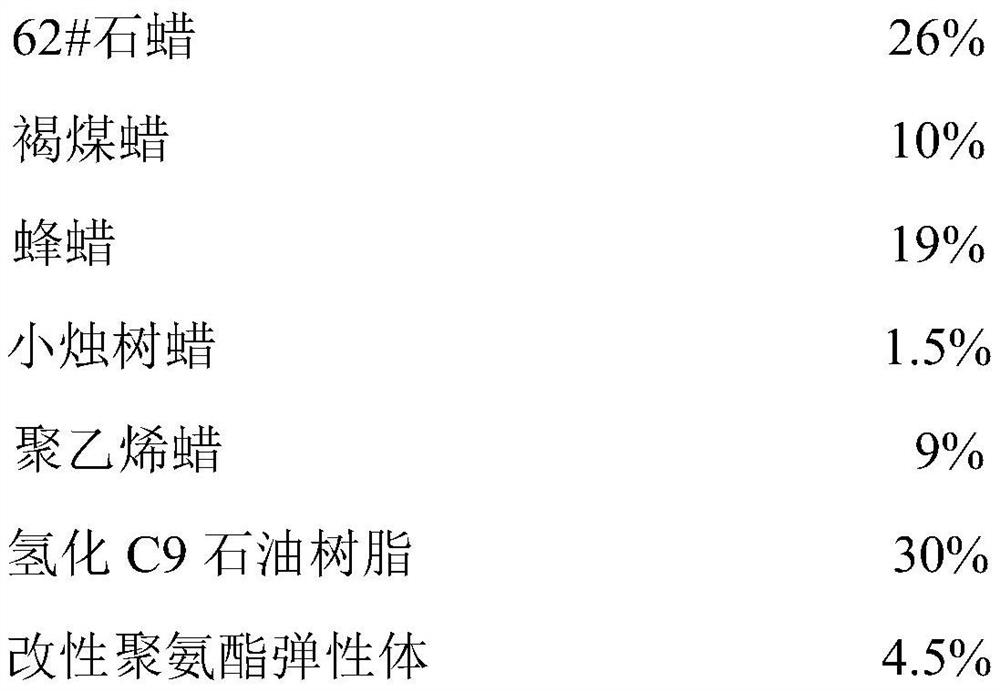

[0057] The ornamental investment casting molding material based on modified polyurethane elastomer of the present embodiment, in terms of mass percentage, includes the following components:

[0058]

[0059] The method for preparing the jewelry investment casting mold material of the present embodiment comprises the following steps:

[0060] (1) Add polyurethane elastomer and polyolefin elastomer raw materials in a high-speed mixer at a ratio of 7:3, heat up to 170°C, and stir at a speed of 500rpm for 15min until the materials are evenly mixed to obtain a blended composite material;

[0061] (2) Then add vinyltrimethoxysilane, dicumyl peroxide, dibutyltin dilaurate, antioxidant 1098 and the blended composite material to melt and mix uniformly under the high-speed mixer. Extrude into granules in the machine;

[0062] (3) Boil the granulated blended material in a constant temperature water bath at 90°C for at least 48 hours to boil and cross-link, and place the cross-linked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com