Precision-casting wax pattern material based on Fischer-Tropsch wax and preparation method thereof

A technology of precision casting and Fischer-Tropsch wax, which is applied in the field of precision casting wax mold material and its preparation, which can solve the problems of potholed surface, inability to obtain models, large shrinkage rate, etc., and achieve high bending strength, moderate softening point, and linear shrinkage small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

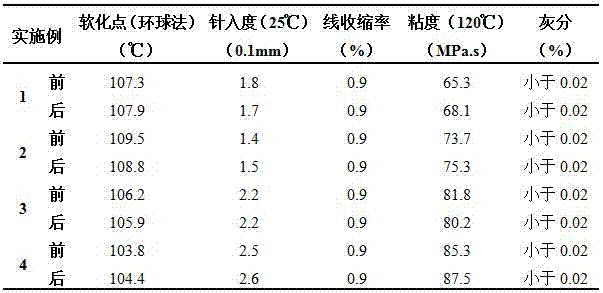

Embodiment 1

[0036] A precision casting wax pattern material based on Fischer-Tropsch wax, which is composed of the following raw materials in mass percentage: paraffin wax: 40%; Fischer-Tropsch wax: 12%; stearic acid: 33%; petroleum resin: 15%.

Embodiment 2

[0038] A precision casting wax pattern material based on Fischer-Tropsch wax, which is composed of the following raw materials in mass percentage: paraffin wax: 43%; Fischer-Tropsch wax: 15%; stearic acid: 27%; petroleum resin: 15%.

Embodiment 3

[0040] A precision casting wax pattern material based on Fischer-Tropsch wax, which is composed of the following raw materials in mass percentage: paraffin wax: 43%; Fischer-Tropsch wax: 10%; stearic acid: 25%; petroleum resin: 20%; montan wax :2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com