Bio-based reinforced plasticiser-eucommia ulmoides resin and preparation method thereof

A kind of eucommia resin, bio-based technology, applied in the field of plasticizers in the rubber industry, can solve the problems of high cost of eucommia gum, obstacles to plasticizers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

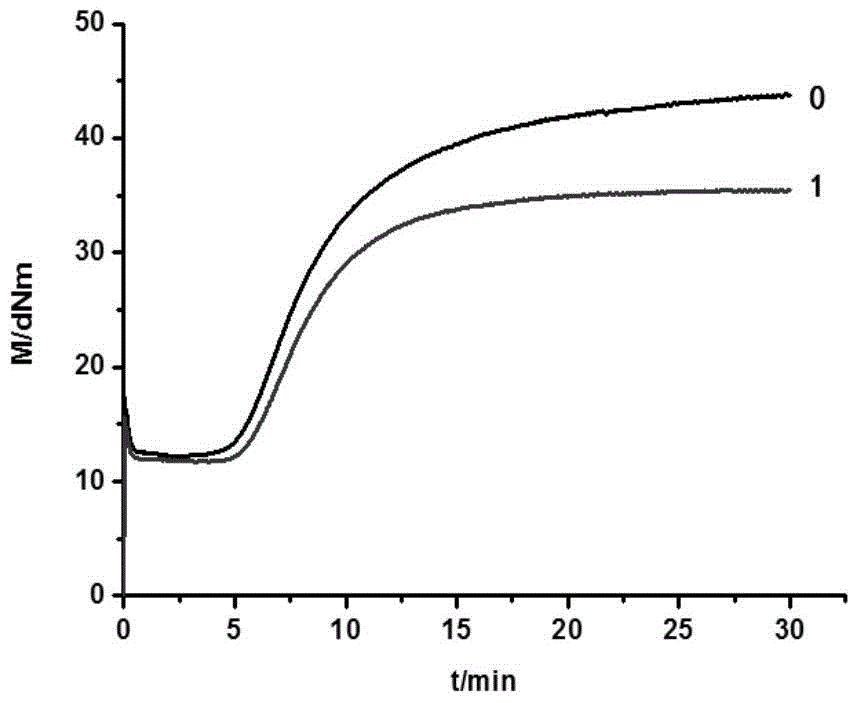

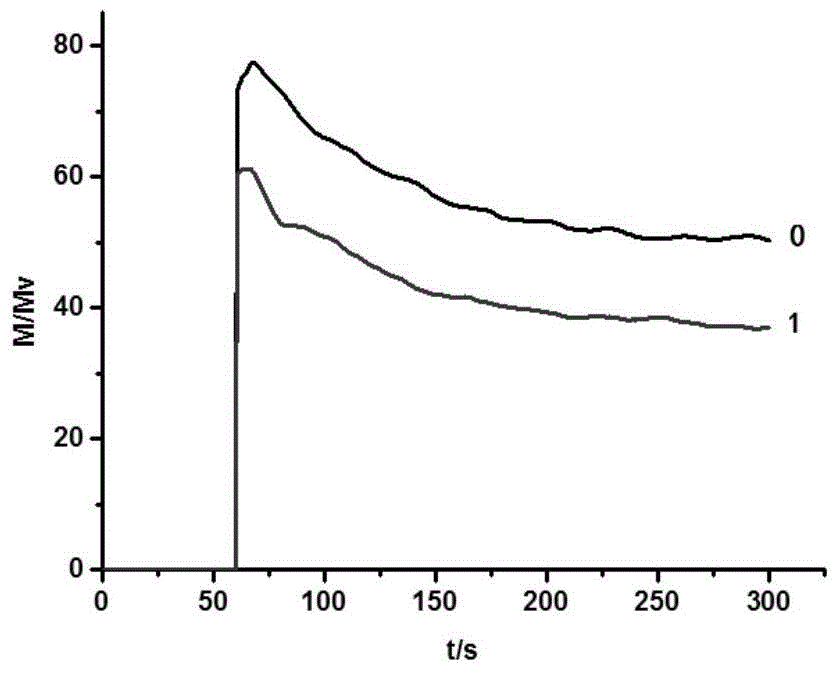

Embodiment 1

[0040]After the harvested eucommia seeds are washed and dried, the seed skins and kernels are separated, the eucommia seed skins are taken, crushed, and passed through a 20-mesh sieve to obtain eucommia seed powder. Take 100g of Eucommia ulmoides seed powder and extract with ethanol to obtain 1.8g of Eucommia ulmoides resin by alcohol method. The verification by the Soxhlet extraction method shows that the extraction rate of Eucommia resin is 90%. According to the formula in Table 2, take 0 part and 1 part of alcohol-processed eucommia resin and styrene-butadiene rubber (SBR-1500) to mix, add zinc oxide, stearic acid, anti-aging agent and other additives and mix well, add carbon black, and finally Add accelerator and sulfur, mix until the upper and lower surfaces are smooth and uniform, take the glue, and vulcanize, control the vulcanization temperature at 130°C, and the vulcanization time is 20 minutes and 17 minutes respectively. After vulcanization is completed, take the gl...

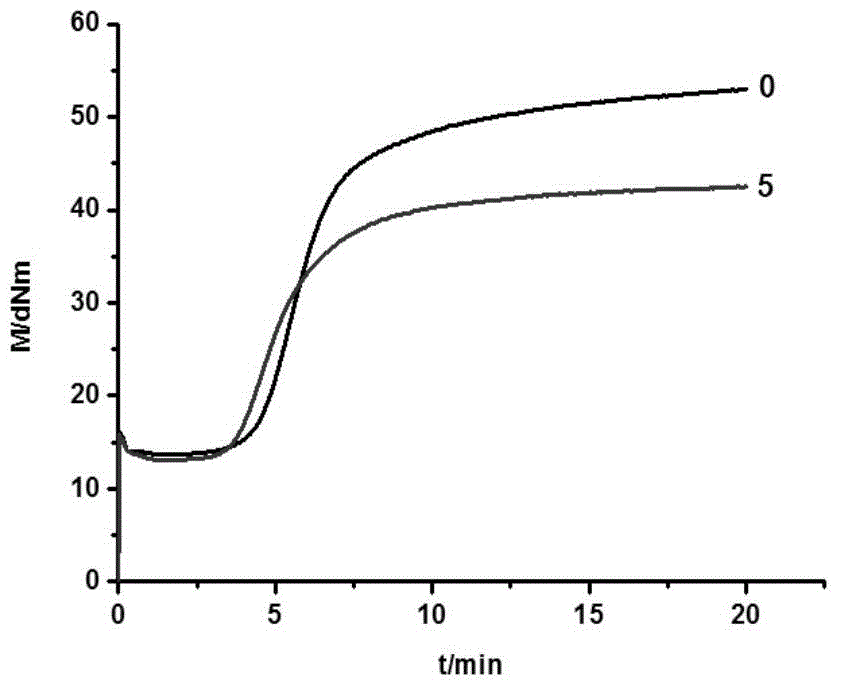

Embodiment 2

[0047] The harvested bark of Eucommia is washed, dried, crushed and passed through a 50-mesh sieve to obtain bark of Eucommia powder. Take 250g of eucommia bark powder and extract with acetone to obtain 10g of eucommia ulmoides resin by ketone method. The verification by the Soxhlet extraction method shows that the extraction rate of Eucommia resin is 95%. According to the formula in Table 4, take 0 parts and 5 parts of resin and butadiene rubber (BR-9000) to mix, add zinc oxide, stearic acid, anti-aging agent and other additives, mix well, add carbon black, and finally add accelerator After mixing with sulfur until the upper and lower surfaces are smooth and uniform, take the rubber and vulcanize. Control the vulcanization temperature at 145°C, and the vulcanization time is 13 minutes and 11 minutes respectively. After the vulcanization is completed, take the glue, cut samples, and conduct performance tests.

[0048] Table 4 ketone method Eucommia resin modified butadiene ru...

Embodiment 3

[0054] The harvested eucommia leaves are washed, dried, crushed and passed through a 70-mesh sieve to obtain eucommia leaf powder. Take 250g of eucommia leaf powder and extract with ethyl acetate to obtain 15g of eucommia resin by ester method. The verification by Soxhlet extraction method shows that the extraction rate of Eucommia resin is 80% (the content of Eucommia gum accounts for 8%). According to the formula in Table 6, take 0 parts and 10 parts of resin and mix with neoprene (CR-322), add zinc oxide, stearic acid, anti-aging agent and other additives, mix well, add carbon black, and finally add accelerator After mixing with sulfur until the upper and lower surfaces are smooth and uniform, take the rubber and vulcanize it. The vulcanization temperature is controlled at 160°C, and the vulcanization time is 19 minutes and 15 minutes respectively.

[0055] Table 6 Ester method Eucommia resin modified neoprene formula

[0056]

[0057] Table 7 Determination of properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com